- 2 -

1) Introduction

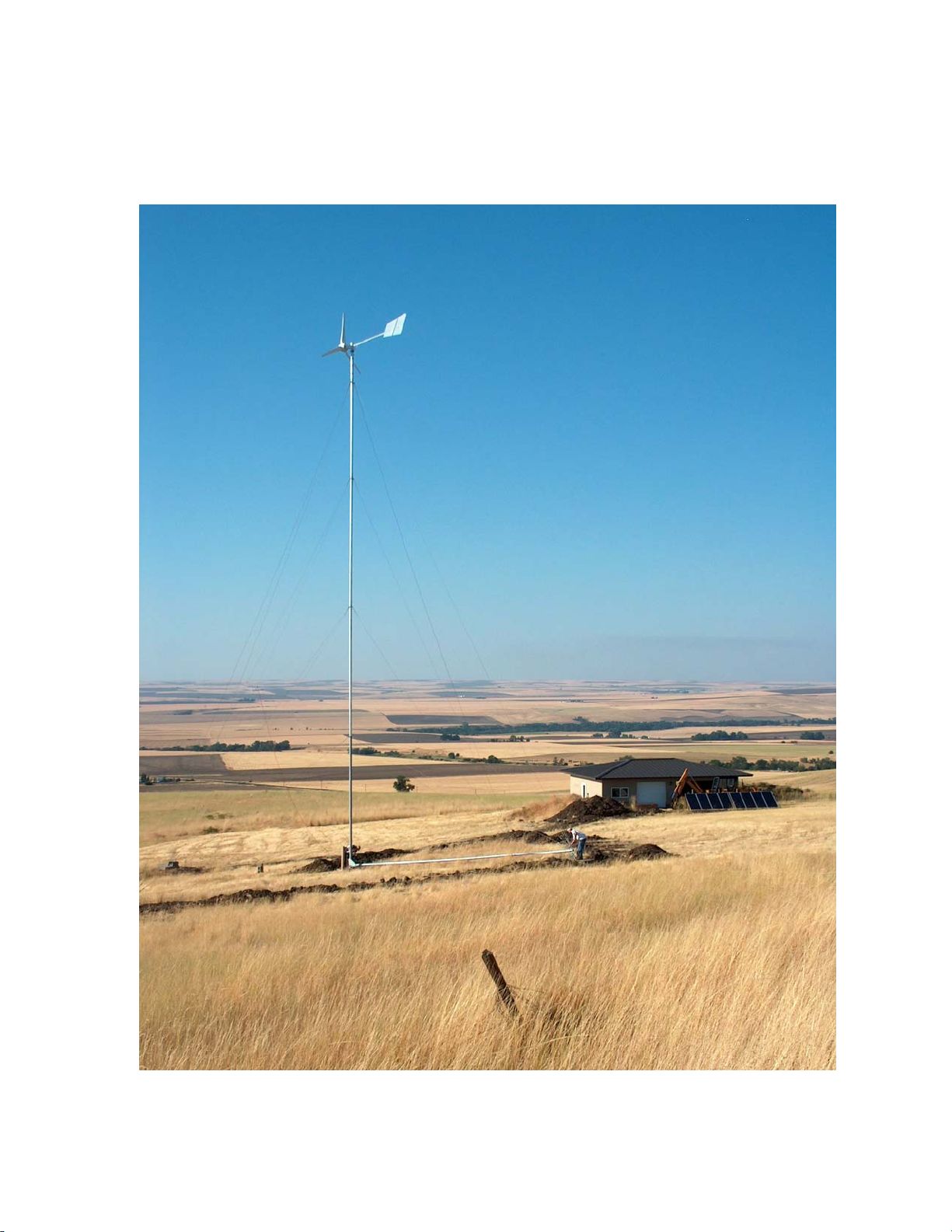

This is an installation manual for a set of towers designed and manufactured by

Abundant Renewable Energy (ARE) for the AWP3.6 wind generator. These

towers are tilt up, guyed, pipe towers, from 43 to 127 feet tall. This manual will

only cover towers which are 43, 64 and 85 feet tall. The 106 and 127 foot towers

are covered in the “Tall Towers” Manual. All of the towers are based on 4-inch,

schedule-10 pipe. The tower consists of a series of 21-foot sections, joined

together by couplers. These couplers are the attachment points for the guy

wires, except for the top guy attachment, which is made at a point below the wind

generator to allow for blade clearance. These towers work in conjunction with a

gin pole, which acts as a lever arm to raise and lower the tower. The gin pole is

21 feet long. The tower is secured by the guy wires connected to anchors at

three points and to the gin pole for the fourth point. For these towers, there are

five concrete foundations that must be created, one for the tower and four for the

guy wire anchors.

Tilt-up towers are NOT designed to be climbed at any time.

2) Site Selection and Preparation

The ideal site for a tower is a flat, level field. However, any area in which there is

sufficient space for the foundations, and which is reasonably level, will work. A

hillside can also be made to work if there is a line available that allows the side

guy anchors and the base to be level with each other.

For these towers, the anchors are about 22 feet 6 inches from the base. The site

should be free from obstructions and the tower height should extend at least 35

feet above any obstacles in 500-foot radius from the tower (remember that trees

grow). See the wind generator installation manual for more information on siting.

The site for the tower will need to be cleared of all trees and brush to allow for

the assembly and raising of the tower. The foundation radius from the center

foundation is about 27 feet. Additional area will need to be cleared for the tower

when it is in the down position. This will be in the down side direction opposite

the hoist side. The distance needed to be cleared is 51 feet, 72 feet and 93 feet

from the center foundation for the 43, 64, and 85 foot towers respectively.

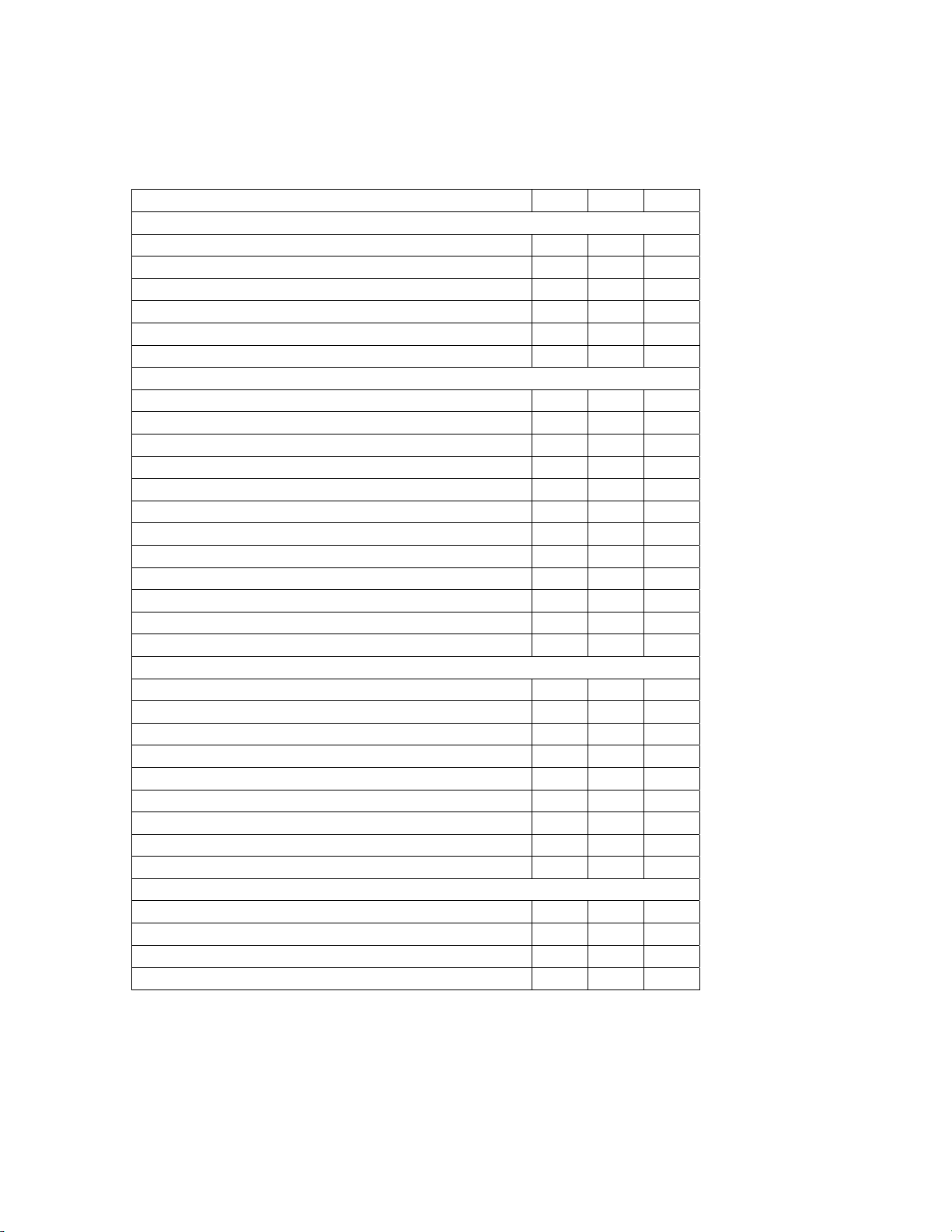

Drawings D2, D7, D8 D9 and D12 in the appendix can be used to help determine

how to select and lay out your site.