Operations & maintenance manual – ASTRA evo (DDE)

0.4.1 ENVIRONMENTS IN DANGER OF EXPLOSION - ATEX DIRECTIVE

ASTRA evo pumps (ATEX version) fulfill the requirements of ATEX Directive 2014/34/EU with the following

rating:

II 2/2 GD IIB cT4

Equipment group II: machines intended for use on the surface (not in mines).

Category group 2: equipment that guarantee a high level of protection.

II 2/2 GD The first number indicates that the internal space of the equipment is intended to be used to transfer potentially

explosive fluids (see characteristics zone 1 / zone 21). The second number indicates that the external surface of the

equipment is suitable for use in areas where during normal activities the formation of an explosive atmosphere

consisting in a mixture of air and flammable substances in the form of gas, vapor or mist is likely (ZONE 1). The explosive

atmosphere may also be in the form of cloud of combustible dust in the air (ZONE 21: area in which the formation of

an explosive atmosphere is likely to occur occasionally during normal activities).

IIB Group related to fluids classified with IIB excluding the following products (Hydrogen, Acetylene, Carbon Disulfide).

c Non-electrical equipment intended for use in explosive atmospheres, designed according to the criterion of

constructional safety c:

UNI CEI EN ISO 80079-37:2016: Explosive atmospheres - Part 37: Non-electrical equipment for

explosive atmospheres - Non-electrical type of protection constructional safety “c”.

T4 Class of assigned temperature (maximum surface temperature 135°C). The processed fluid temperature must fall

within such class range and the user must comply with the instructions containing in the manual and with the current

laws. Furthermore, the user must take into account the ignition point of the gases, vapors and mists in addition to

clouds of combustible powder in the air existing in the area of use.

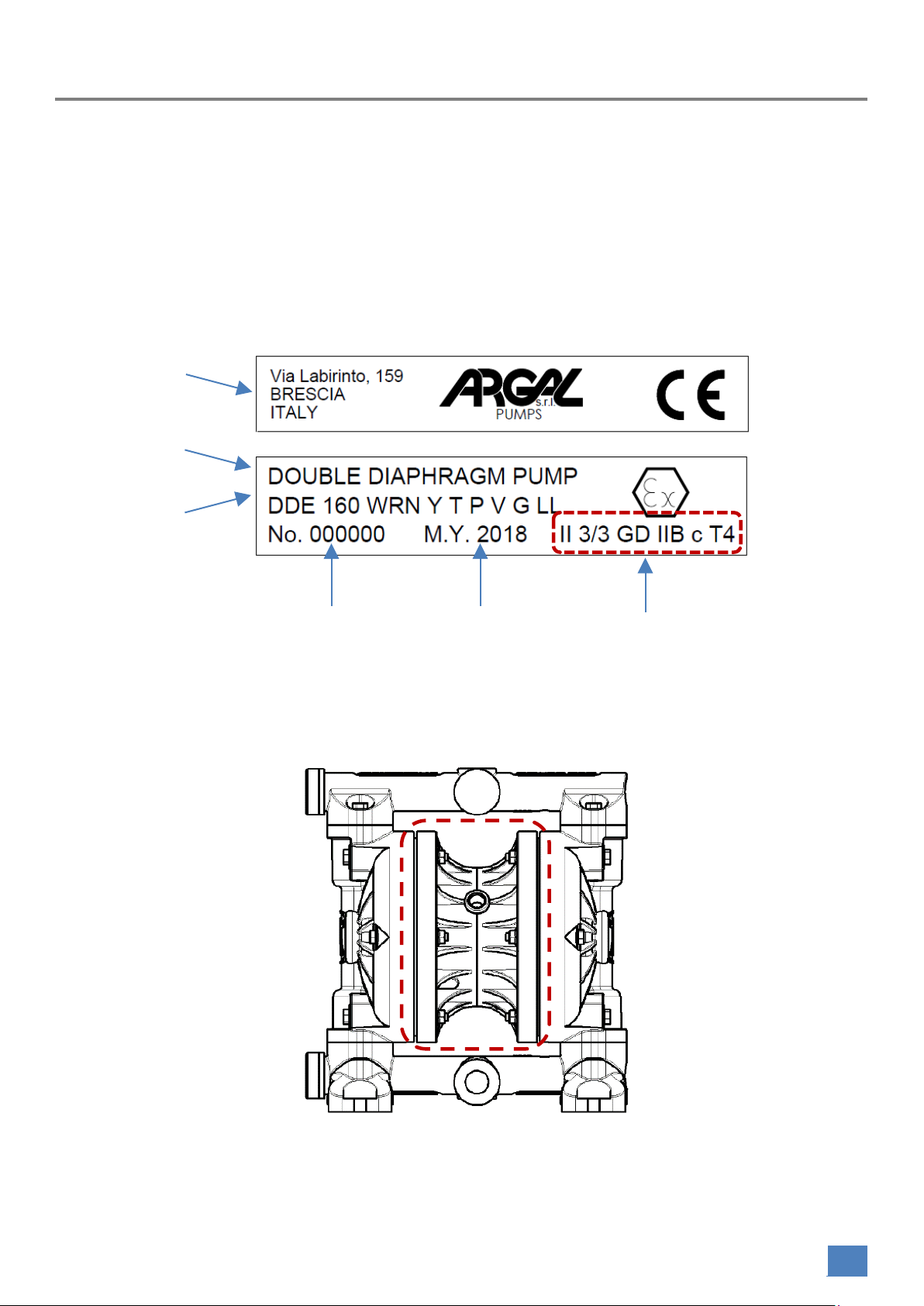

ASTRA evo pumps (STANDARD version) fulfill the requirements of ATEX Directive 2014/34/EU with the following

rating:

II 3/3 GD IIB cT4

Equipment group II: machines intended for use on the surface (not in mines).

Category group 3:equipment that guarantee a normal level of protection.

II 3/3 GD The first number indicates that the internal space of the equipment is intended to be used to transfer potentially

explosive fluids (see characteristics zone 2 / zone 22). The second number indicates that the external surface of the

equipment is suitable for use in areas where during normal activities the formation of an explosive atmosphere

consisting in a mixture of air and flammable substances in the form of gas, vapor or mist is unlikely (ZONE 2) and - if it

occurs - is only of short duration. The explosive atmosphere may also be in the form of cloud of combustible dust in the

air (ZONE 22: area in which the formation of an explosive atmosphere is unlikely to occur during normal activities).

IIB Group related to fluids classified with IIB excluding the following products (Hydrogen, Acetylene, Carbon Disulfide).

c Non-electrical equipment intended for use in explosive atmospheres, designed according to the criterion of

constructional safety c:

UNI CEI EN ISO 80079-37:2016: Explosive atmospheres - Part 37: Non-electrical equipment for

explosive atmospheres - Non-electrical type of protection constructional safety “c”.

T4 Class of assigned temperature (maximum surface temperature 135°C). The processed fluid temperature must fall

within such class range and the user must comply with the instructions containing in the manual and with the current

laws. Furthermore, the user must take into account the ignition point of the gases, vapors and mists in addition to

clouds of combustible powder in the air existing in the area of use.

So it’s specified that the WRN - FCN - ALN - SSN - SPN pumps, according to the ATEX Directive, belong to

category 3, for which they are intended to operate in potentially explosive environments classified as

zone 2. Also available are WRX - FCX - ALX - SSX - SPX pumps, suitable to operate in potentially explosive

environments classified as zone 1.