MANUALE D’USO ROUTE - rev. 2 - 10/01 pag. 1/15

USE MANUAL

Via Labirinto, 159

25125 BRESCIA - ITALY

CE

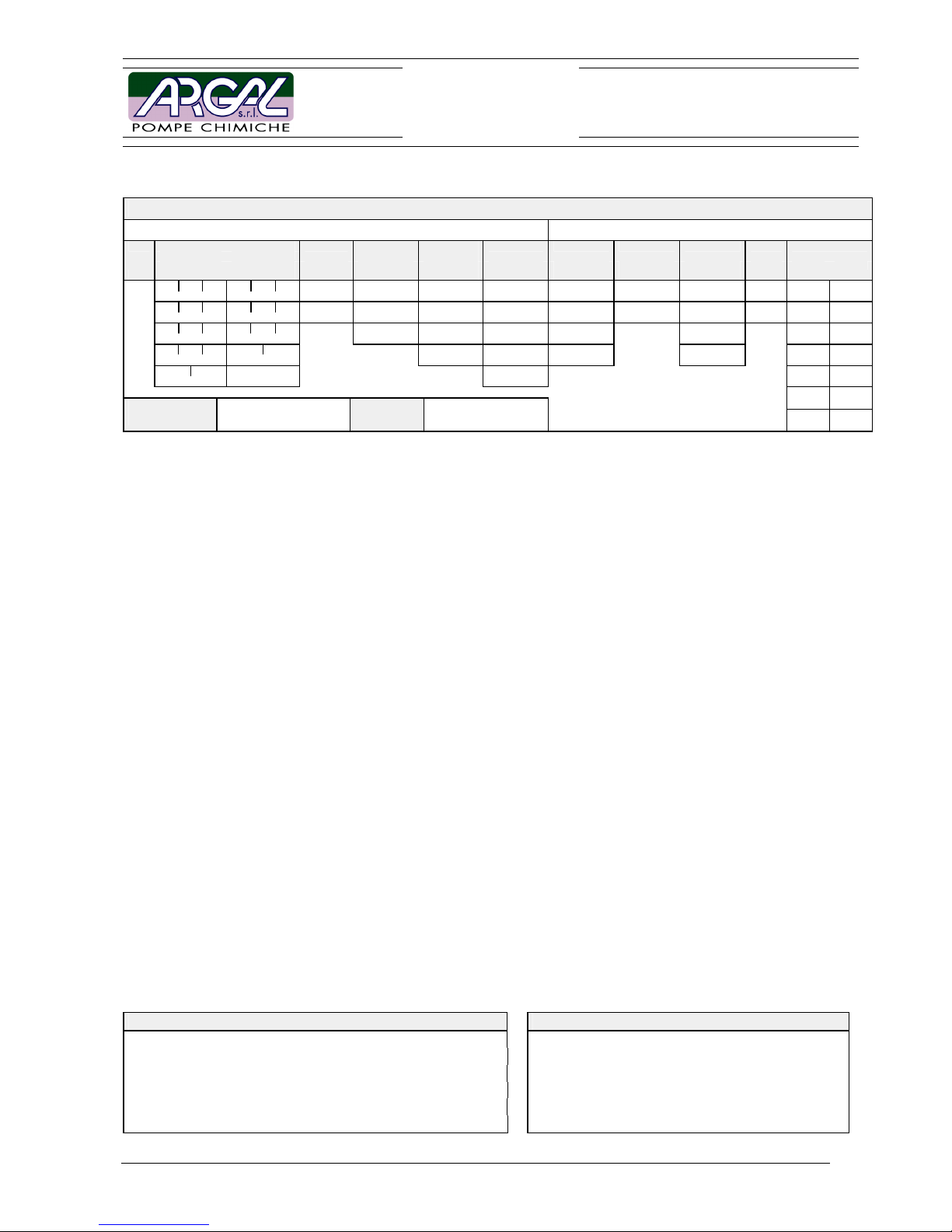

TMR SERIES

IDENTIFICATION CODE

PUMP DATA MOTOR DATA

model

execution material

O-ring

inside

structure

connections rpm motor voltage/EEx phases powersrange

50Hz 60Hz kW HP

NPSNPSWRV R1 B E 0

06.10 07.11

GFR-PP FPM C/Al2O3 filettate BSP 1450 IEC senza motore 3 fasi 0.55 ¾

NPSNPSGF E X1 N U N

10.10 07.14

CFF-E-CTFE EPDM SiC/Al2O3 filettate NPT

2900 NEMA V std 1 fase 0.75 1

NPSNPSK R2 I S

TMR 10.15 11.15 FFKM C/SiC flangiate ISO

1740

V speciale 1.1 1½

NPSNPX2 A E

16.15 11.23 SiC/SiC flangiate ANSI

3500 EEx 1.5 2

NPNJ

16.20 17.25 flangiate JIS

2.2 3

3 5

Year of

manufacture

Part

number

4 5

1 TABLE OF CONTENTS

1 TABLE OF CONTENTS ....................................................................................................................................... 1

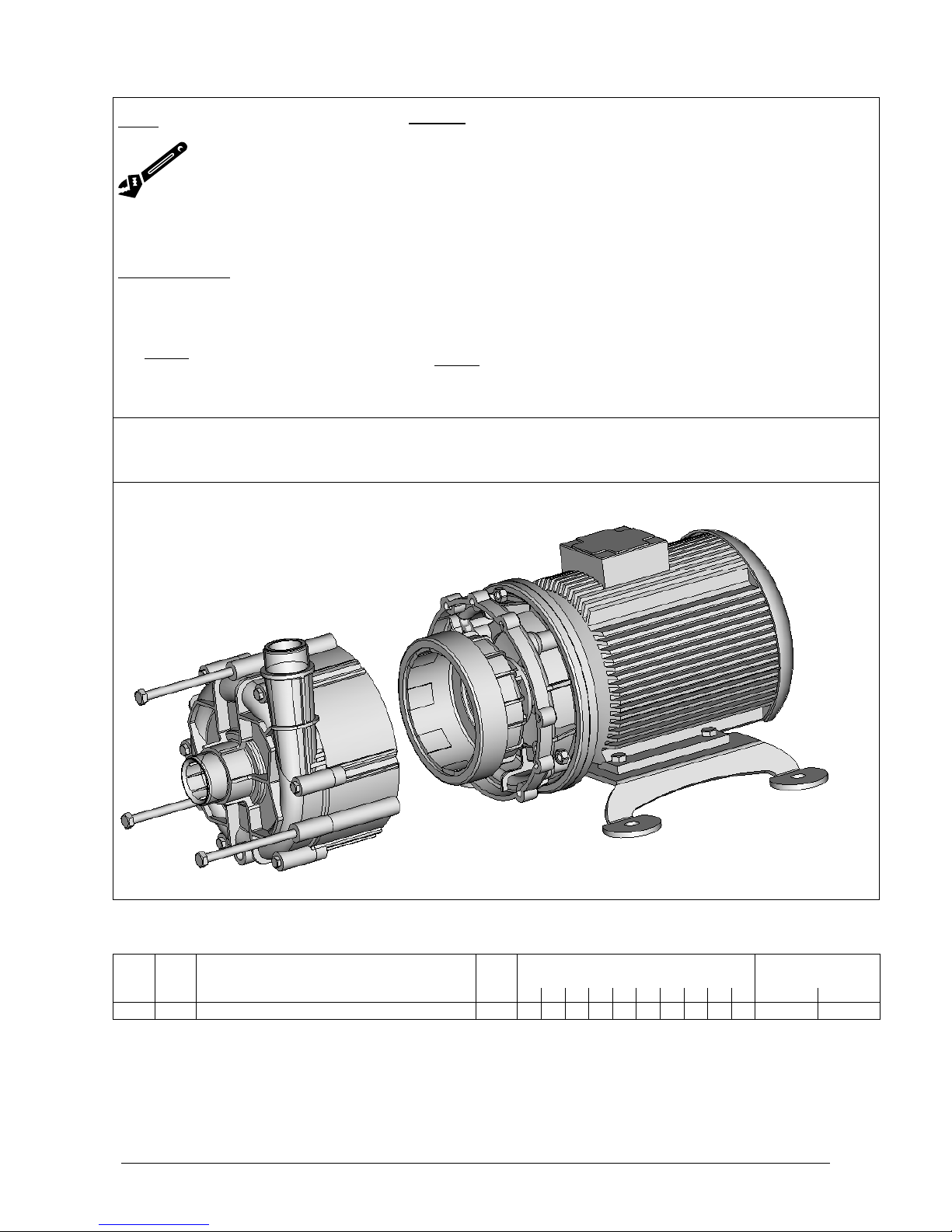

2 DISASSEMBLING SEQUENCE........................................................................................................................... 2

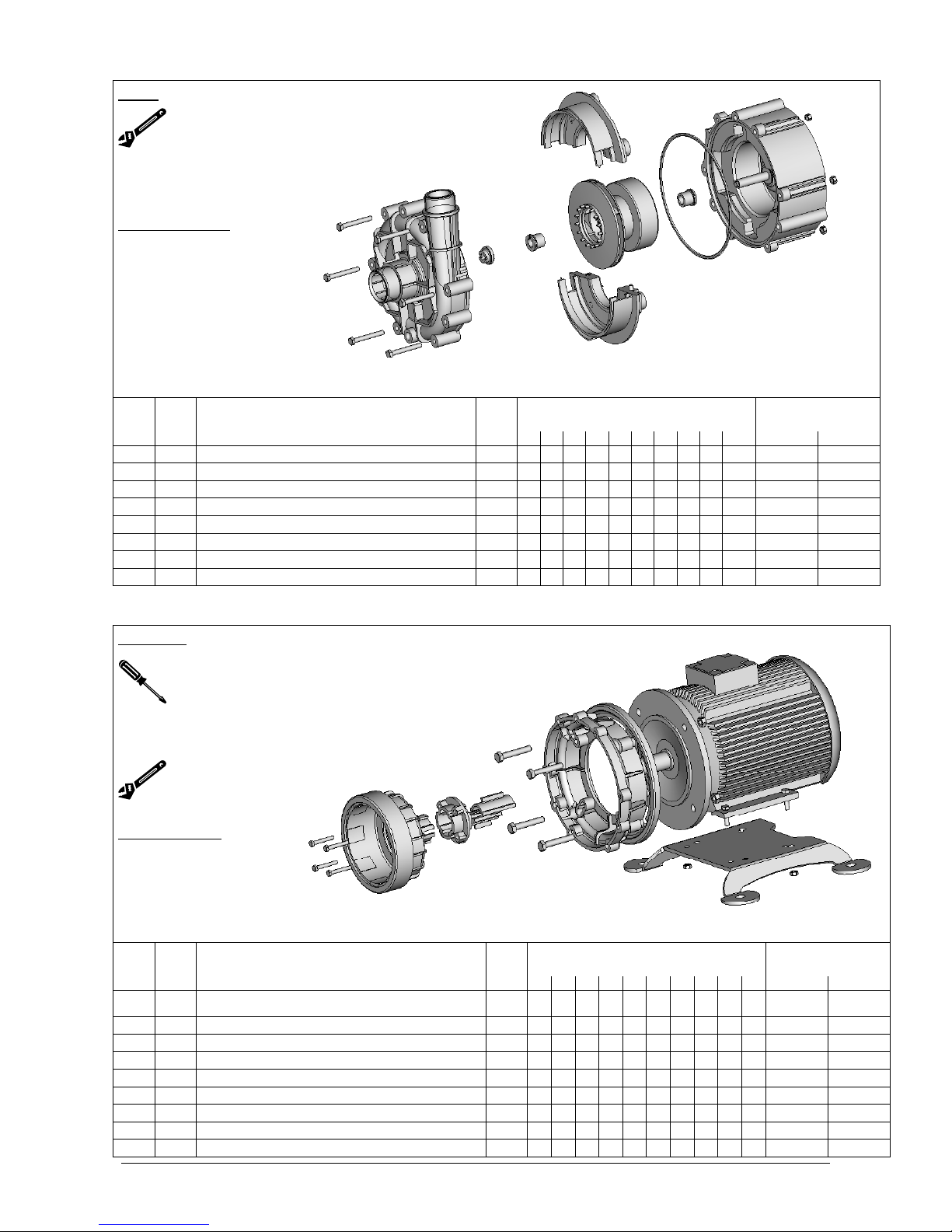

2.1 HYDRAULIC PARTS LEGEND .......................................................................................................................3

2.2 MOTOR PARTS LEGEND ................................................................................................................................3

3 IDENTIFICATION CODES ................................................................................................................................... 4

4 GENERAL NOTES ............................................................................................................................................... 4

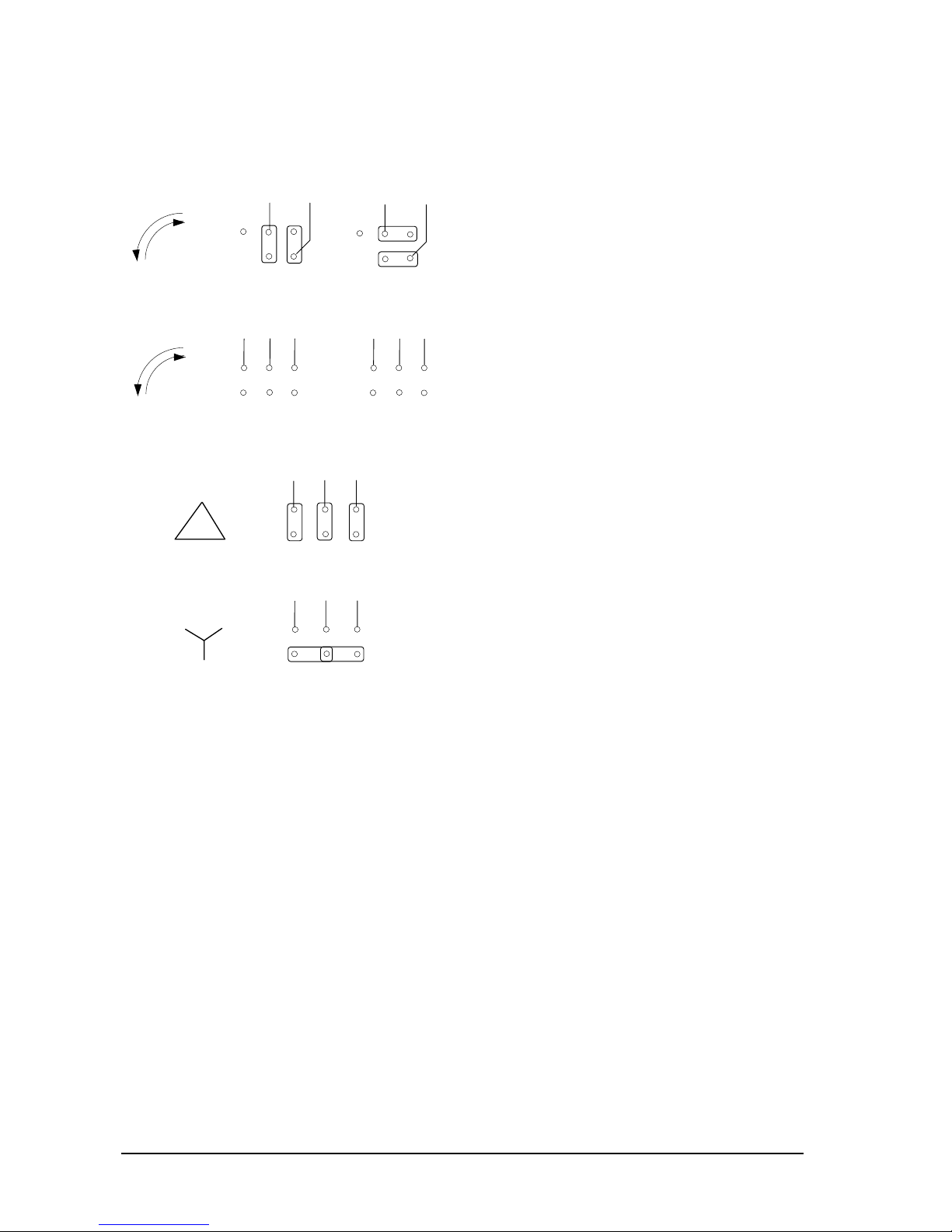

5 OPERATING PRINCIPLE .................................................................................................................................... 5

6 MOTOR ................................................................................................................................................................ 6

7 DRY RUNNING SURVEY .................................................................................................................................... 6

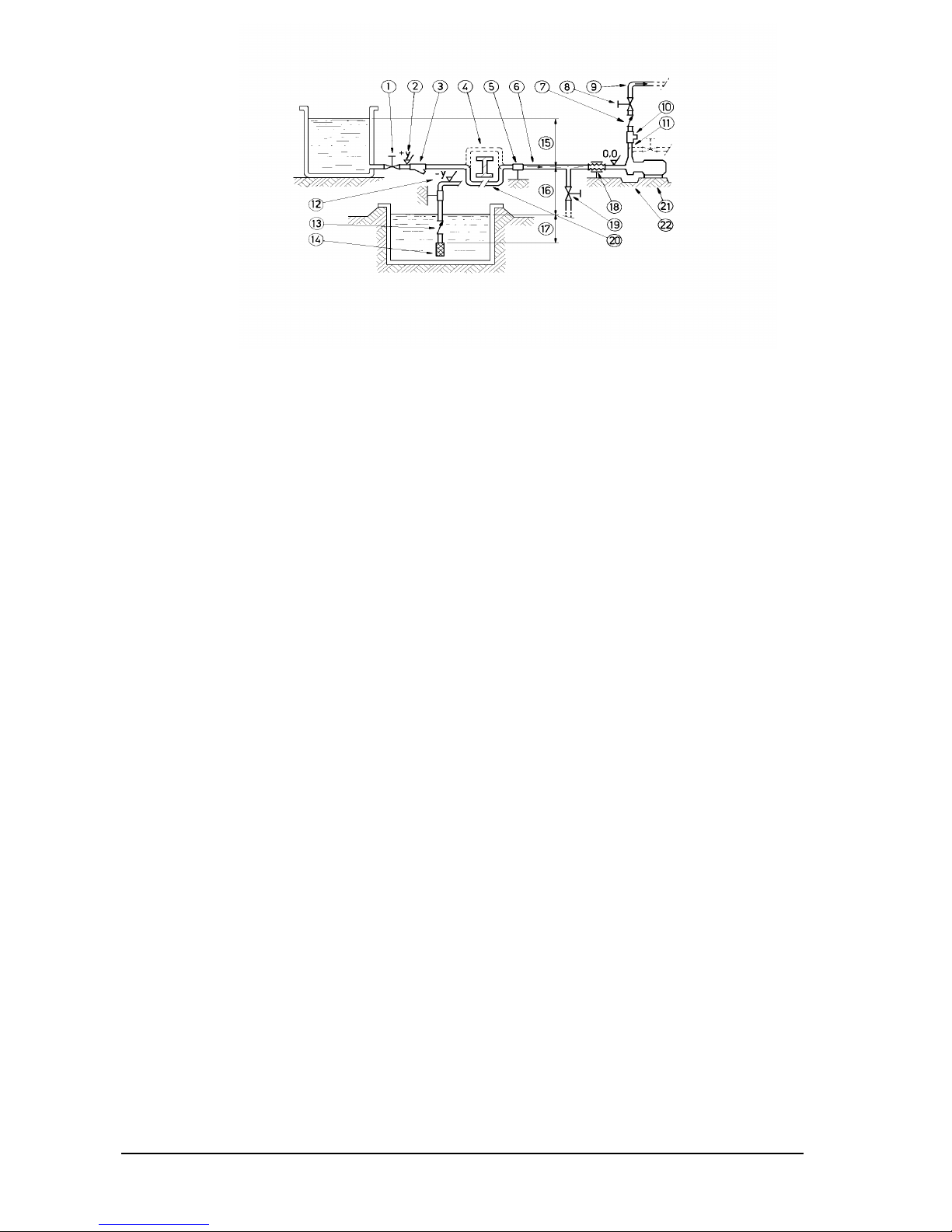

8 INSTRUCTIONS ON INSTALLATION AND USE ................................................................................................ 7

8.1 TRANSPORT .....................................................................................................................................................7

8.2 INSTALLATION................................................................................................................................................7

8.3 START-UP..........................................................................................................................................................8

8.4 USE .....................................................................................................................................................................9

8.5 SHUTDOWN......................................................................................................................................................9

9 MAINTENANCE ................................................................................................................................................... 9

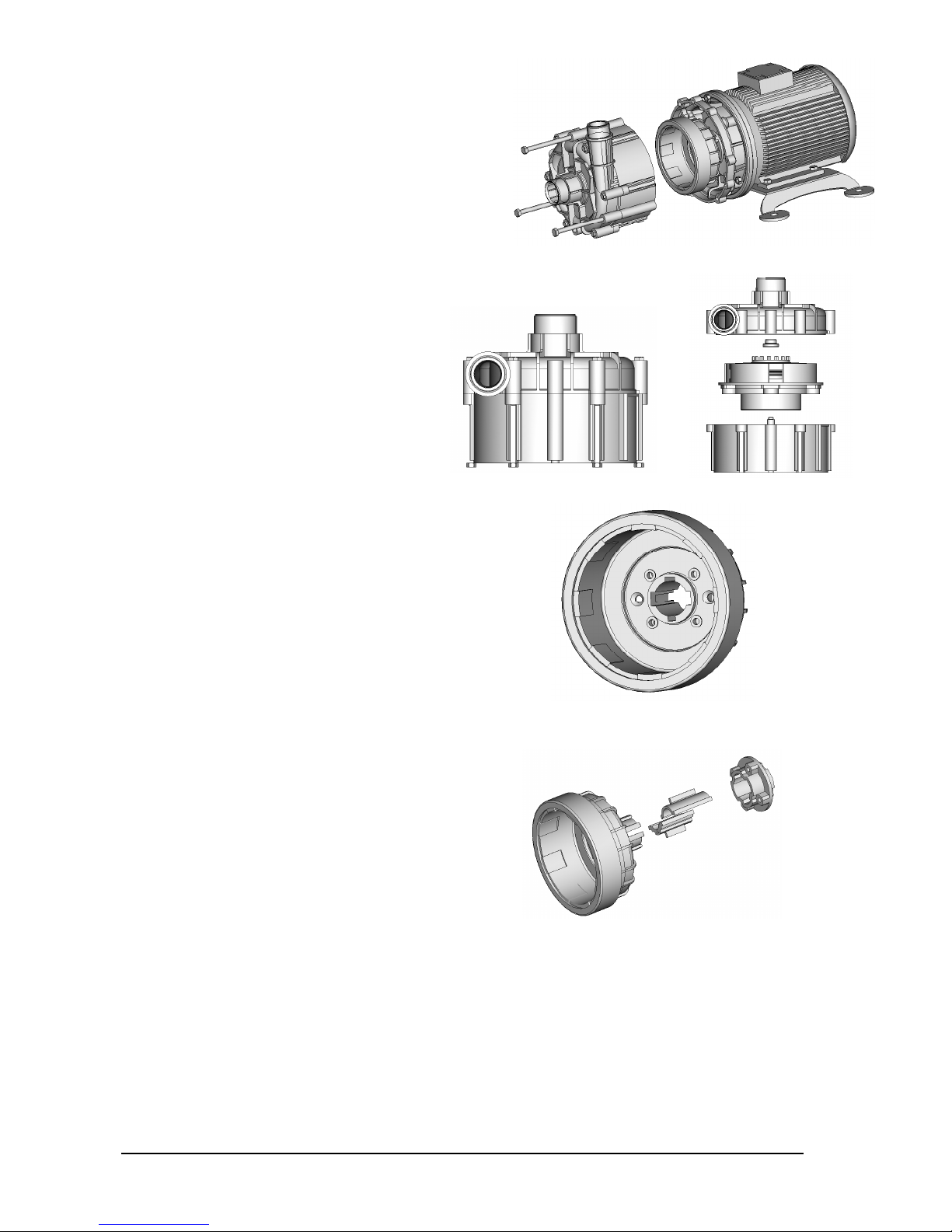

9.1 DISMANTLING .................................................................................................................................................9

9.2 INSPECTION ...................................................................................................................................................10

9.3 ASSEMBLY .....................................................................................................................................................11

10 SAFETY RISKS ............................................................................................................................................. 12

10.1 INSTALLATION AND COMMISSIONING PERSONNEL...........................................................................13

10.2 OPERATORS AND MAINTENANCE PERSONNEL....................................................................................13

10.3 REPAIR PERSONNEL.....................................................................................................................................13

10.4 WASTE DISPOSAL .........................................................................................................................................14

11 IMPROPER USE ........................................................................................................................................... 14

12 OPERATING FAULTS AND POSSIBLE CAUSES ....................................................................................... 14

13 TECHNICAL DATA........................................................................................................................................ 15

14 GENERAL CONDITIONS OF SALE.............................................................................................................. 18

15 MANUFACTURER DATA .............................................................................................................................. 19

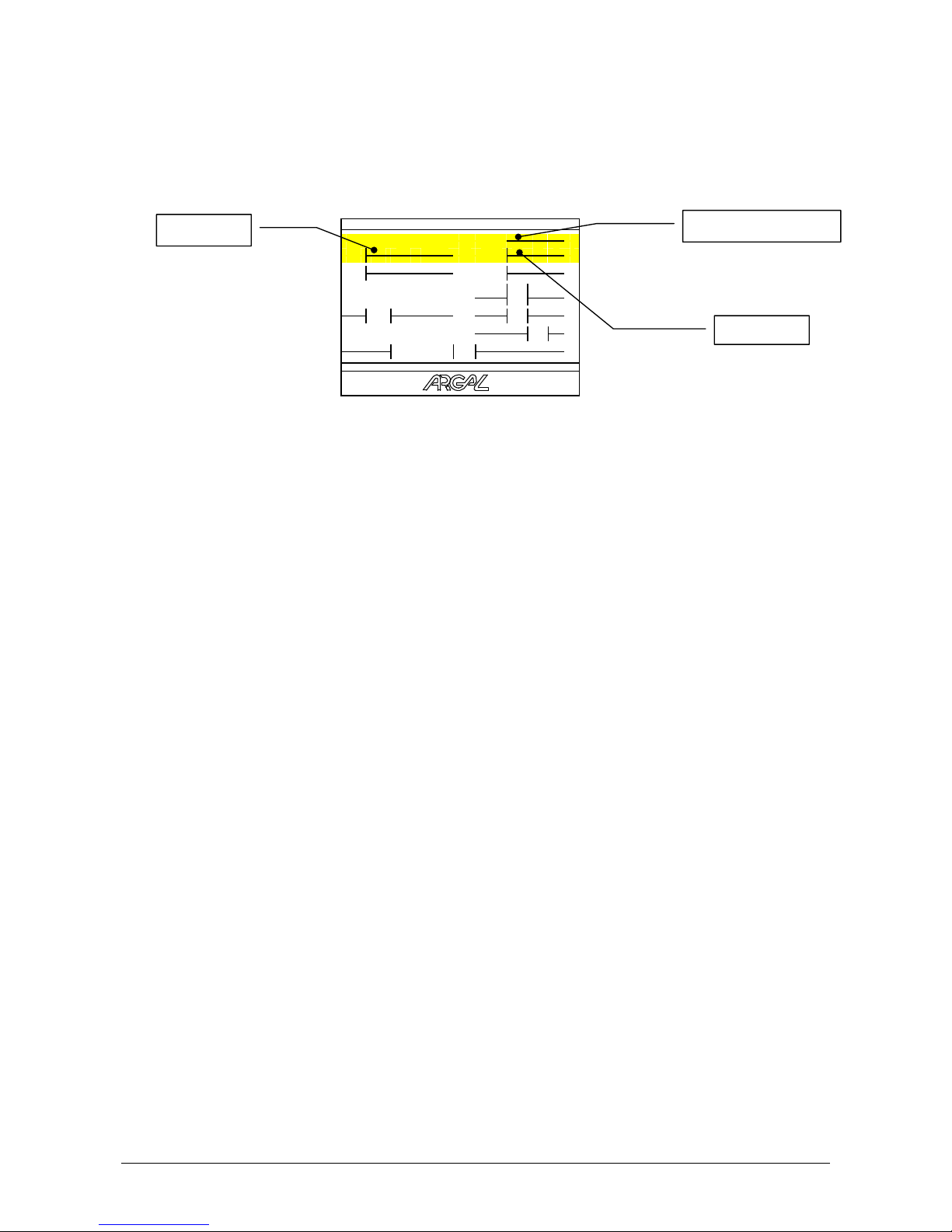

for MAINTENANCE DEALER

date of commissioning

position / system reference

service