Burn-out furnace APE800 and APE800a 2008-06-18

2

Table of contents:

1. Industrial safety instructions ..................................................................................................3

1.1. Responsibilities of the company using the machine .......................................................3

1.2. Responsibilities of the staff.............................................................................................3

1.3. Dangers while operating the furnace...............................................................................3

1.4. Organizational measures .................................................................................................3

1.5. Industrial safety devices..................................................................................................3

1.6. Removal of safety devices...............................................................................................4

1.7. Security measures............................................................................................................4

1.8. Operating the machine.....................................................................................................4

1.9. Security measures while normal machine operation.......................................................4

1.10. Dangers connected with the presence of electric energy ..............................................4

1.11. Structural changes in the machine.................................................................................4

1.12. Activities of special attention........................................................................................4

1.14. Guarantee ......................................................................................................................5

1.15. Responsibilities .............................................................................................................5

2. Intended use of the furnace ....................................................................................................6

3. Furnace design – general comments ......................................................................................6

4. Basic technical parameters of the furnace..............................................................................7

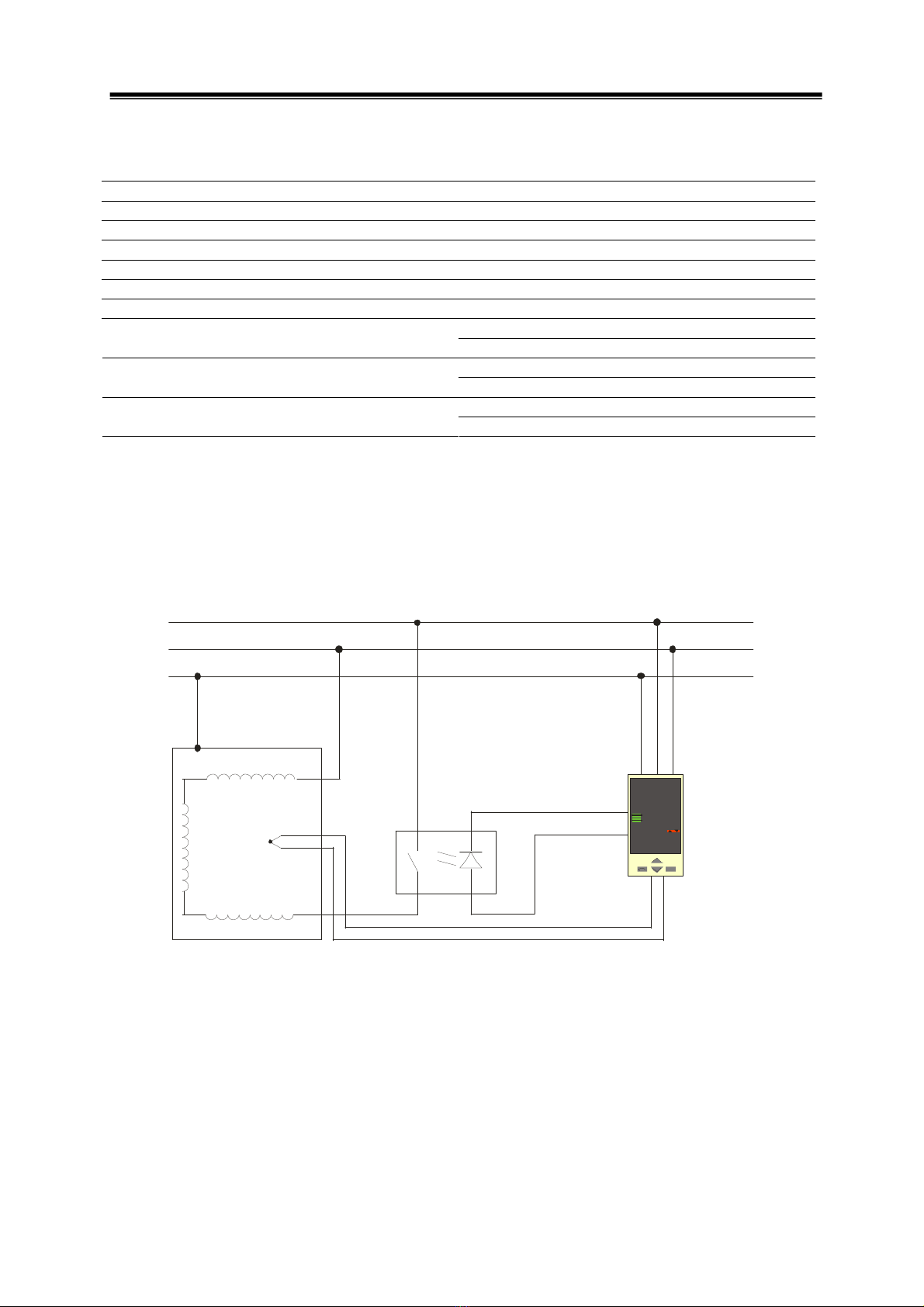

5. Electric connection of the furnace..........................................................................................7

6. First launching........................................................................................................................7

7. Temperature program selector ...............................................................................................8

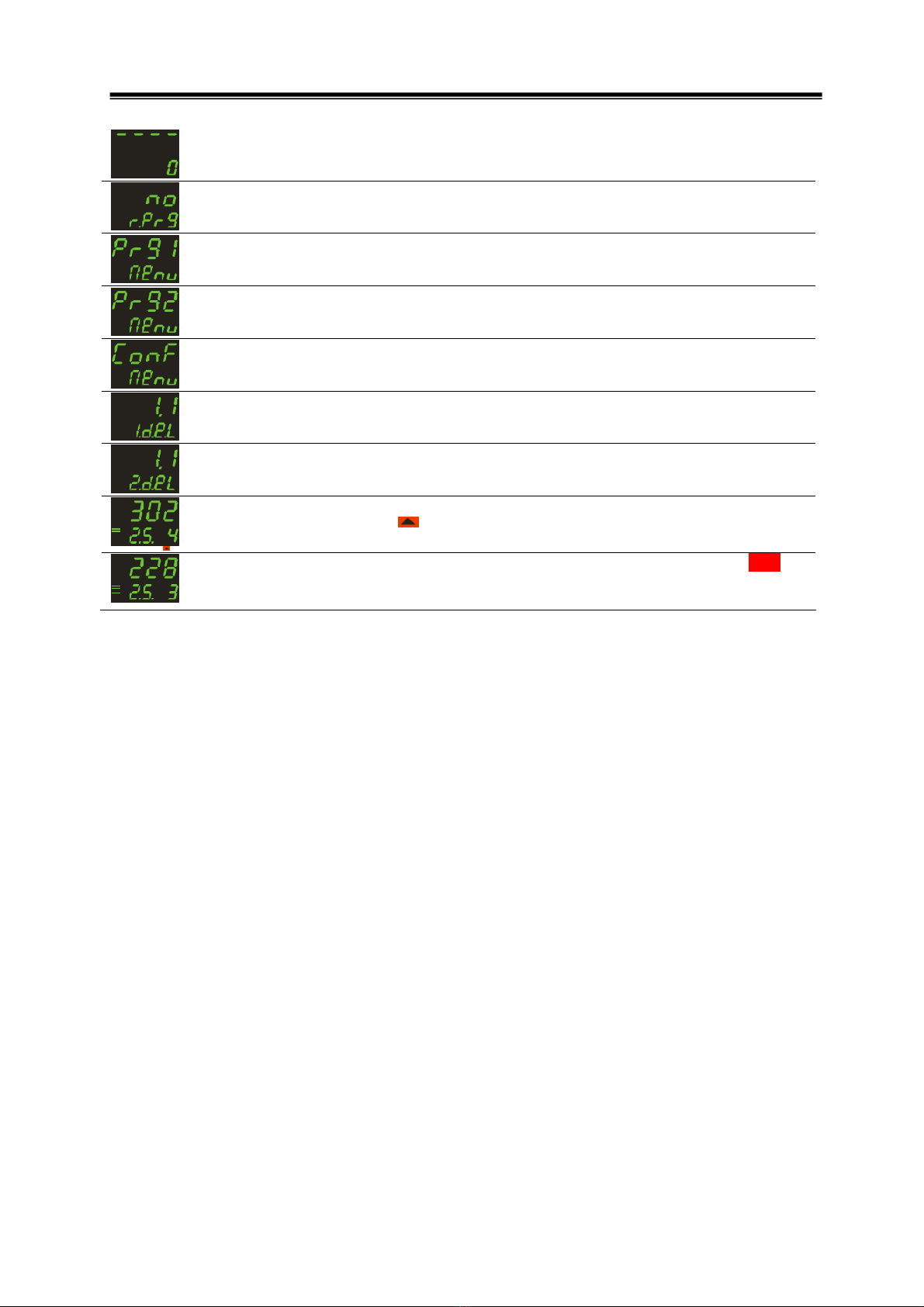

8.1. Program selector operation..............................................................................................9

8.2. Entering the programme................................................................................................11

8.3. Launching the programme without a delay...................................................................12

8.4. Launching the programme with a delay........................................................................13

8.5. Stopping the current programme...................................................................................13

9. Demonstration annealing programme..................................................................................14

10. Warehousing and transport.................................................................................................16

11. Warranty sheet................................................................Błąd! Nie zdefiniowano zakładki.

COMPLIANCE DECLARATION ......................................Błąd! Nie zdefiniowano zakładki.