The device complies with CE requirements

Read the safety instructions and operating instructions prior to

commissioning!

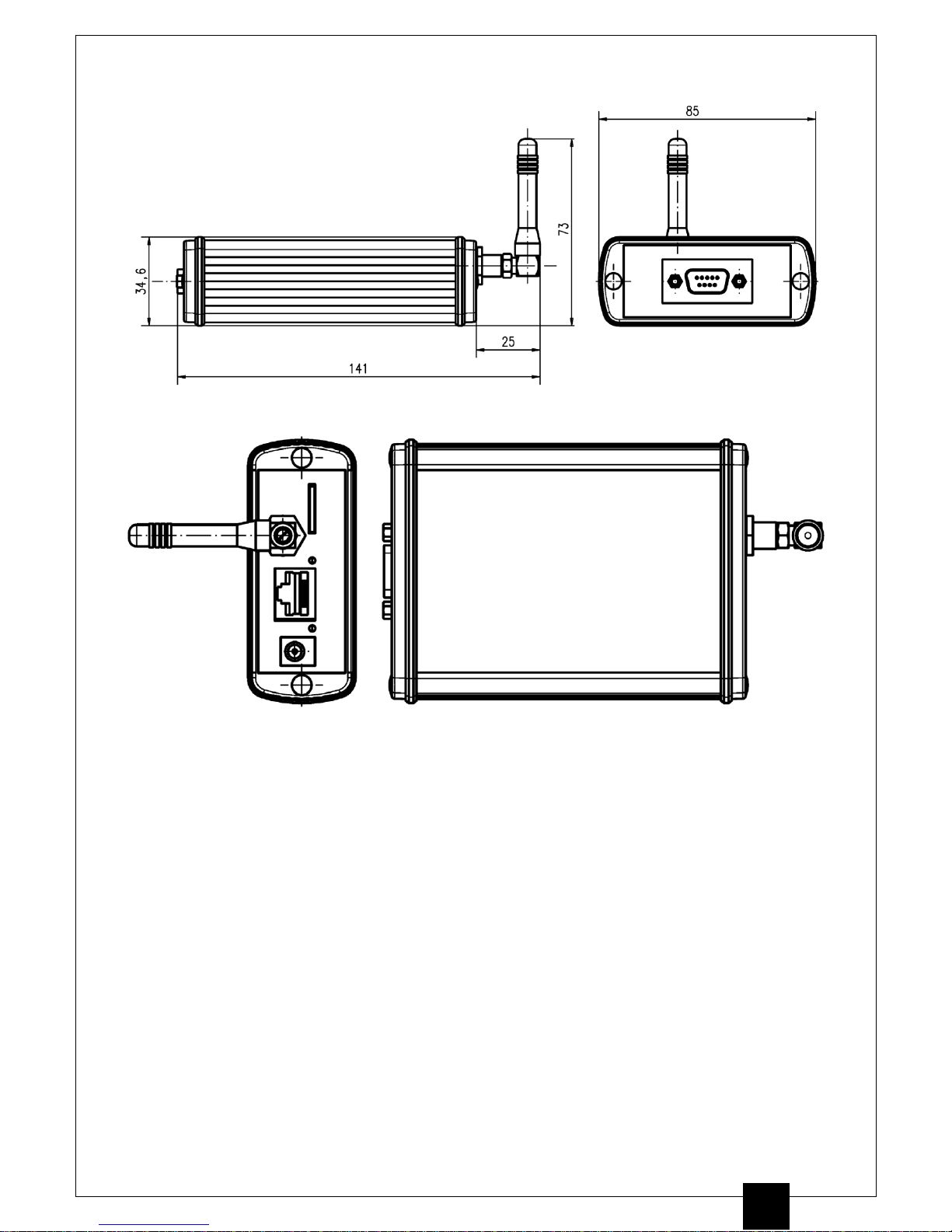

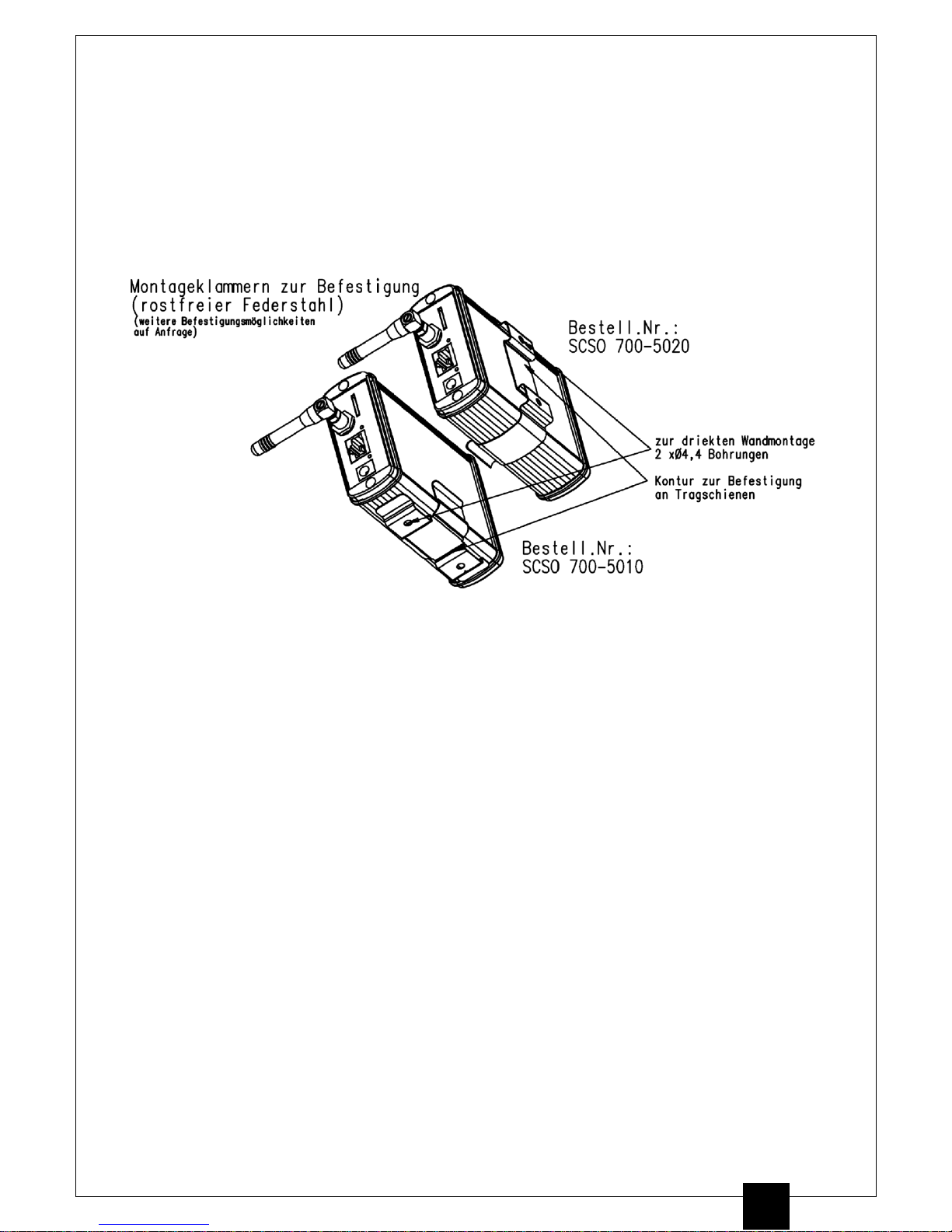

Note: Illustrations do not always precisely correspond to the original. No legal claim can be derived

due to incorrect information. Product design is subject to change without notice.

1.Quick Start

The steps that must be executed for commissioning the LubMon Connect gateway are described

below. The following components are necessary for this:

1. Gateway LubMon Connect

2. Connection of compatible sensors:

LubCos H2Oplus II,

LubCos Level,

LubCos Vis+

OPCom II

Analogue sensors using analogue/CAN nodes μCAN.6.ai-SNAP

3. Sensor cable (order number: SCSO 100-5020)

4. Power supply including rubber connector (order number: SCSO 100-5080)

5. Configuration software for LubMon Connect (www.argo-hytos.com)

6. Additionally for longer cabling: CAN standard cable (5-pole, M12), CAN-T pieces (5-pole,

M12), CAN terminating resistors (5-pole, M12)

The configuration software for LubMon Connect can be downloaded from the website www.argo-

hytos.com.

The components must be prepared as follows:

A) Software installation

1. Installation is not required. The individual components of the software package are

executable immediately after the .zip file is unpacked.