Subject to change · Dewatering Unit OPS / 438846600 · 0517 · EN

Page 2 www.argo-hytos.com

Contents

Dewatering Unit OPS 010

Contents........................................................................................................................................................................ 2

1. About this documentation........................................................................................................................................... 4

1.1 Applicability of this documentation.................................................................................................................................. 4

1.2 Required and supplementary documentation................................................................................................................... 4

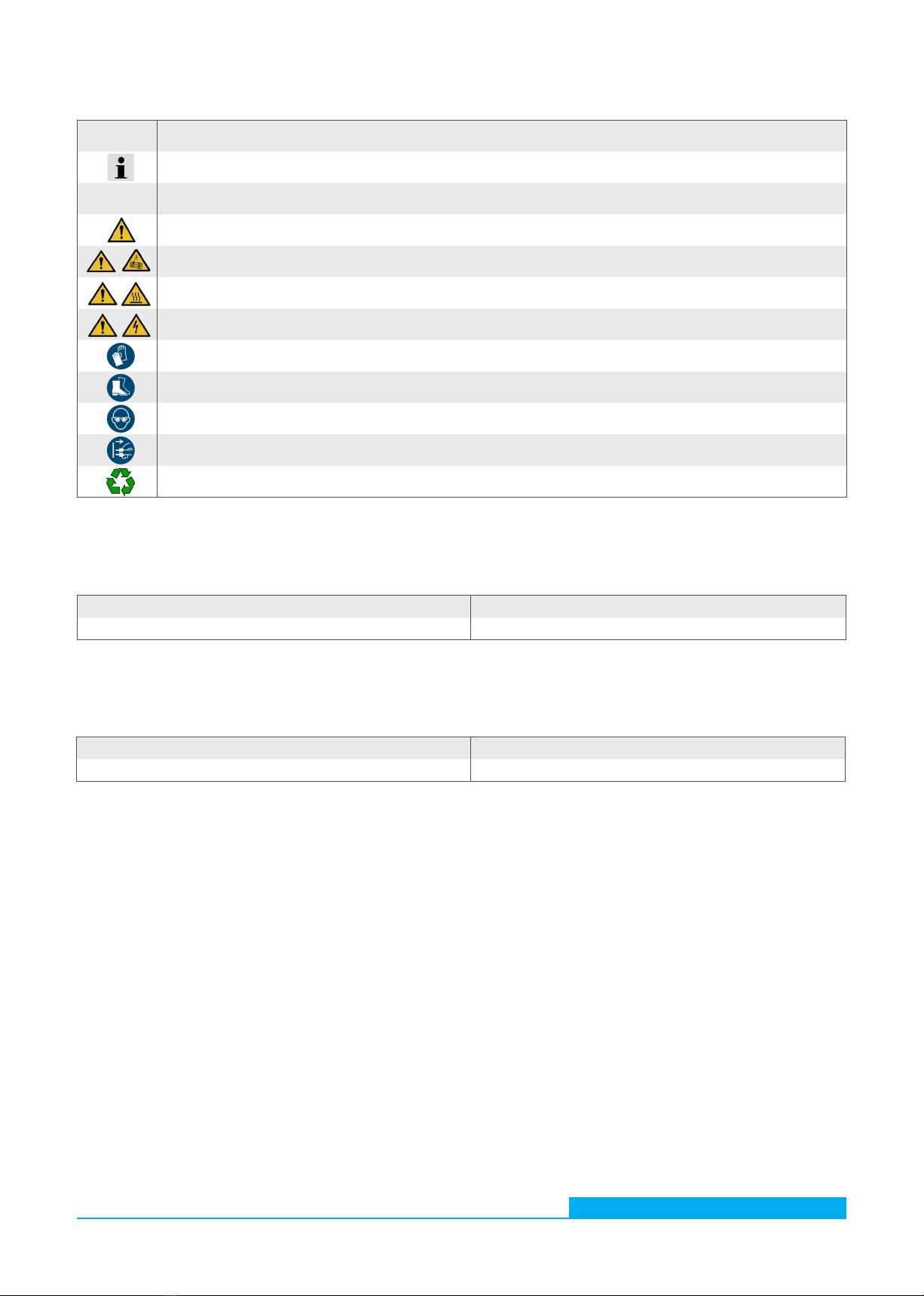

1.3 Presentation of information............................................................................................................................................. 4

1.3.1 Safety instructions ........................................................................................................................................................... 4

1.3.2 Symbols........................................................................................................................................................................... 5

1.3.3 Terms .............................................................................................................................................................................. 5

1.3.4 Abbreviations .................................................................................................................................................................. 5

2. Safety instructions........................................................................................................................................................ 6

2.1 About this chapter........................................................................................................................................................... 6

2.2 Intended use ................................................................................................................................................................... 6

2.3 Improper use................................................................................................................................................................... 6

2.4 Reasonably foreseeable misuse........................................................................................................................................ 6

2.5 Qualification of personnel................................................................................................................................................ 6

2.6 General safety instructions............................................................................................................................................... 7

2.7 Product and technology related safety instructions .......................................................................................................... 7

3. General instructions ..................................................................................................................................................... 8

4. Scope of delivery.......................................................................................................................................................... 9

5. Technical data ............................................................................................................................................................. 10

5.1 Approved oils ................................................................................................................................................................ 10

5.2 Temperature ranges....................................................................................................................................................... 10

5.3 Dimensions and weight ................................................................................................................................................. 10

5.4 Connection, electrical.................................................................................................................................................... 10

5.5 Connection, hydraulic.................................................................................................................................................... 10

5.6 Sound pressure level...................................................................................................................................................... 10

6. About this product ..................................................................................................................................................... 11

6.1 Performance specification.............................................................................................................................................. 11

6.2 Type plate...................................................................................................................................................................... 11

6.3 Component overview .................................................................................................................................................... 12

7. Accessories.................................................................................................................................................................. 13

7.1 Hitch ............................................................................................................................................................................. 13

7.2 Hose package................................................................................................................................................................ 13

7.3 Power supply cable........................................................................................................................................................ 13

8. Transport, storage, installation, disposal ................................................................................................................. 14

8.1 Safety instructions ......................................................................................................................................................... 14

8.2 Transporting the device ................................................................................................................................................. 14

8.2.1 Preparation for transport ............................................................................................................................................... 14

8.2.2 Transportation ............................................................................................................................................................... 15

8.3 Storing the device.......................................................................................................................................................... 15

8.3.1 Preparation for storage.................................................................................................................................................. 15

8.3.2 Storage ......................................................................................................................................................................... 15

9. Setting up the device ................................................................................................................................................. 16

9.1 Requirements to the installation site .............................................................................................................................. 16

9.1.1 Delivery status of a new device...................................................................................................................................... 16

9.1.2 Setting up ..................................................................................................................................................................... 16

9.2 Disposal......................................................................................................................................................................... 16