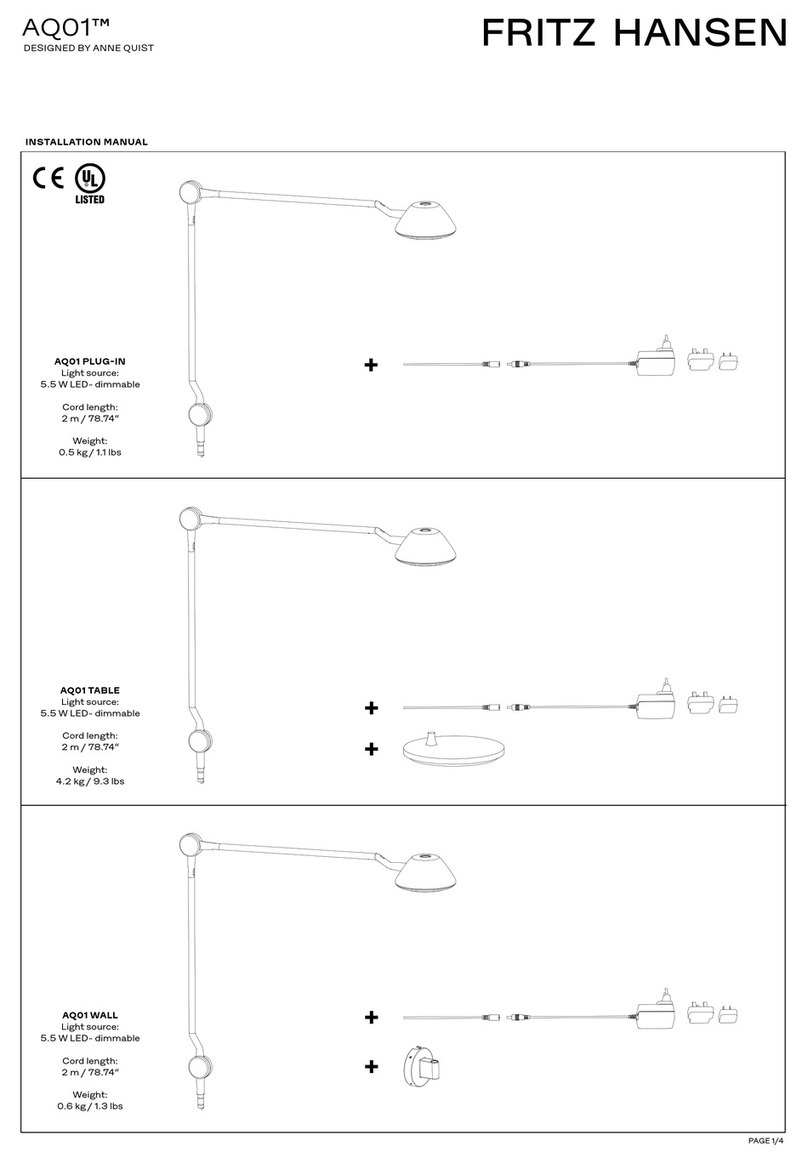

Cutting, connecting and wiring

Warning:

Do not connect LED tape to household 120V AC power.

Only connect to low voltage 12V DC power.

Always maintain polarity when connecting LED tape lighting and low voltage

power wires.

Positive

Negative

Be sure to connect positive wires to positive (+ to +), and negative wires to

negative (– to –). Polarity is easily identified with + and – markings on LED

tape as shown.

Cut with scissors

This tape light model can be cut every 3 LEDs, or about every 2".

■ To use solderless LED Snap Connectors, cut the LED tape with

scissors directly in the center of the copper pad as shown in position

“A” below.

■ You can also cut the tape at position “B,” however, do not use Snap

Connectors on these soldered tape light joints..

■ You can also solder 12V power lead wires at these joints.

Cut tape at center

of copper pads

B

Okay to cut at solder

joints, but do not

use connector

A

Wire Lead Snap Connectors

Wire Lead Snap Connectors are used for going around corners or, when cut in

half, to create two power leads (“jumper” cables) for linking and extending

power wires to LED tape lighting in other areas.

IMPORTANT: Always use the + / – indicators printed on the tape light to

maintain polarity.

To make longer

“jumper” cables

Cut in half to

create two wire

lead connectors

that can be

spliced to longer

wires in order to

get power to LED

tape strips in

other areas.

Bridging gaps and extending wires

To increase the length of wire between two LED strips, simply splice in the

extra length of wire required, 18 AWG is generally recommended. Be sure

to match polarity, + to +, - to -. Do not coil wire; shorter lengths and thicker

wire will mean less voltage drop and higher brightness. For an online voltage

drop calculator, visit armacostlighting.com/installation.

(+)

(–)

length to

fit needs

(–)

(+)

(–)

(+) (+)

(–)

Be sure all 12V connections are secure and sealed. Options include soldering

and heat-shrink tubing, crimp connectors, terminal blocks, wire nuts, etc.

Splice Snap Connectors

Splice Snap Connectors are for joining two strips to create a continuous

run of LED lighting.

Splice Snap Connector

(+) (+)

(–) (–)

If the + / – marks do not line up,

flip the tape and use the opposite

end for proper alignment.

How to use Snap Connectors

■ Pry open lid on the snap connector

(splice connector has two lids).

■ Using a side-to-side motion, carefully

slide tape strip into connector channel

as shown below so the copper pads on

the tape are positioned underneath the

connector contacts.

■ Close and snap down lid connector.

■ Perform a power test to be sure connection is secure and LEDs light

before final installation.

■ If LEDs do not light, or LEDs flicker, repeat the steps outlined above.

Insert tape into channel

under contact tabs

Be sure tape slides

into channel groove

Press down lid

until it snaps closed

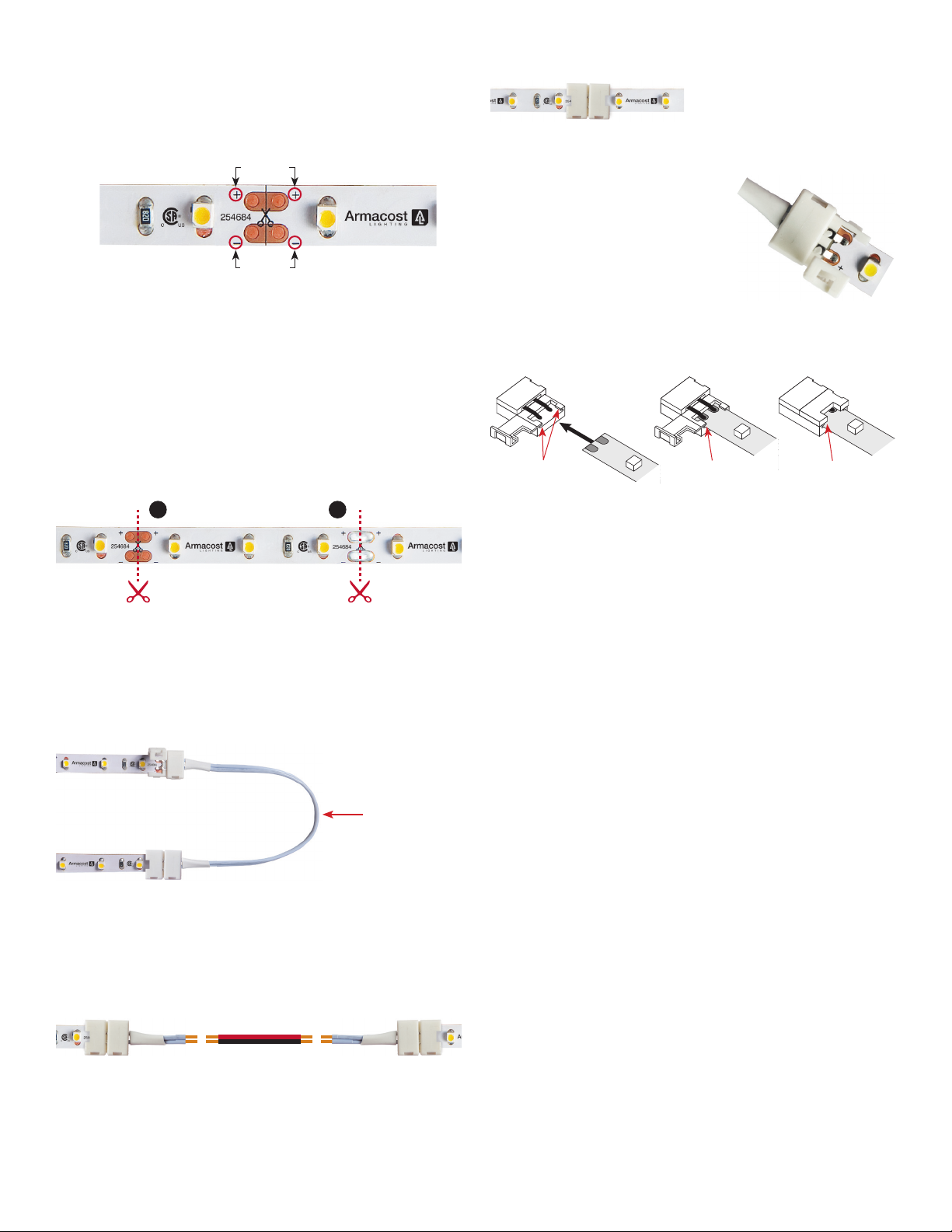

Surface preparation and installing

peel-and-stick LED tape lighting

Before removing the 3M tan colored paper backing, it is important to test the

LED strip in the space you intend to light. Once the paper backing is removed

and the lighting is fully installed, you cannot reposition or move the LED tape

light to another location. The tape may not stick securely.

1. Power the LED tape lighting and temporarily hold or tape into position with

painter’s tape or masking tape – do not remove the 3M paper backing.

2. Adjust the lighting to various angles and positions to get the desired

level of illumination and lighting appearance. If the LEDs create

undesirable bright spots on walls, or reflections, reposition the tape

light strip farther away from surfaces or try a different mounting angle.

3. Once you have determined your final mounting position, clean and prep

the surface to ensure the 3M self-adhesive backing will adhere properly.

IMPORTANT

■ Mounting surfaces should be smooth, clean, completely dry, dust free

and above 60ºF (15 ºC) before installing/sticking the LED tape lighting.

■ Thoroughly clean all mounting surfaces with a 50:50 mixture of

isopropyl alcohol and water. For extra dirty surfaces, first use 100%

alcohol or acetone. Avoid the use of household cleaners and polishes

that may leave behind residues. Also avoid common rubbing alcohol

because it frequently contains oils that can interfere with the

performance of the 3M adhesive tape.

■ For best adhesion – especially when sticking to the underside of

cabinets – lightly sand the surface where you will mount the tape

lighting. This includes unfinished woods, plastics/laminates and all

painted surfaces. Use a very fine grit sandpaper (150-300 grit) and sand

in a circular motion rather than straight-line motion for best results.

■ When installing on painted surfaces, paint should be fully cured based

on manufacturer's cure time.

■ Be careful not to peel off the 3M adhesive from LED strip, just remove

the tan paper backing. If using LED Snap Connectors, carefully cut the

tan backing when it enters the connector. It is beneficial to leave the

3M backing paper inside the connector.

■ 3M sticky back tape requires pressure to activate the adhesive. Using a

clean dry cloth over your fingers and working from one end to the other,

firmly press the tape down the entire length of the strip.

2 3

Power supply location and voltage drop

The power supply that provides 12V DC power to your LED tape lighting

operates on 120V AC household current. The shorter the wire lead

between the power supply and the LED tape lighting, the brighter the

lights will be. If the lights farthest from the power supply appear dim,

it is due to voltage drop.

Voltage drop only becomes undesirable if you notice the brightness in one

area of your lighting is objectionably different than in another area. As a

practical approach, test your lighting prior to final installation. Refer to the

chart below for recommended lengths of power feed wires using 22 and

18 AWG wires.

Excessive voltage drop = reduced brightness and color accuracy

Shorter and/or thicker wires = higher brightness and color consistency

Longer LED tape = an increase in voltage drop

Recommended maximum length of 12V power wires

from power supply to LED lighting

22 AWG WIRE 18 AWG WIRE

If your LED tape

light length is:

Max wire length

to tape light

If your LED tape

light length is:

Max wire length

to tape light

12 Feet 10 Feet 12 Feet 20 Feet

24 Feet 8 Feet 24 Feet 16 Feet

36 Feet 6 Feet 36 Feet 12 Feet

48 Feet 4 Feet 48 Feet 8 Feet

For an online voltage drop calculator, visit armacostlighting.com/

installation.

Switching and dimming options

If you do not have a switched 120V AC outlet for your LED power supply,

consider an optional Armacost Lighting wireless wall switch or an Armacost

12V LED dimmer switch with optional RF wireless designer-style touchpad.

Important: Do not use a standard AC wall dimmer with your power supply unless

the power supply clearly states that it is dimmable with 120V AC dimmers.

For power supply options visit armacostlighting.com/power-supply.

TYPICAL CONNECTING AND SWITCHING OPTIONS

120V

AC OUTLET

12V DC

POWER SUPPLY

Armacost

WIRELESS

WALL SWITCH

WIRELESS

SWITCH

RECEIVER

120V

AC OUTLET

12V DC

POWER SUPPLY

Armacost

WIRELESS

LED DIMMER

Armacost

LED DIMMER

AC OUTLET

POWER SUPPLY

SWITCH

Armacost

LED DIMMER

12V BATTERY FUSE

PROTECTION 12V SWITCH

120V

AC OUTLET

12V DC

POWER SUPPLY

Armacost

WIRELESS

WALL SWITCH

WIRELESS

SWITCH

RECEIVER

120V

AC OUTLET

12V DC

POWER SUPPLY

Armacost

WIRELESS

LED DIMMER

Armacost

LED DIMMER

Armacost

LED DIMMER

12V BATTERY FUSE

PROTECTION 12V SWITCH

Interior RV and boat applications can be powered directly by 12V battery

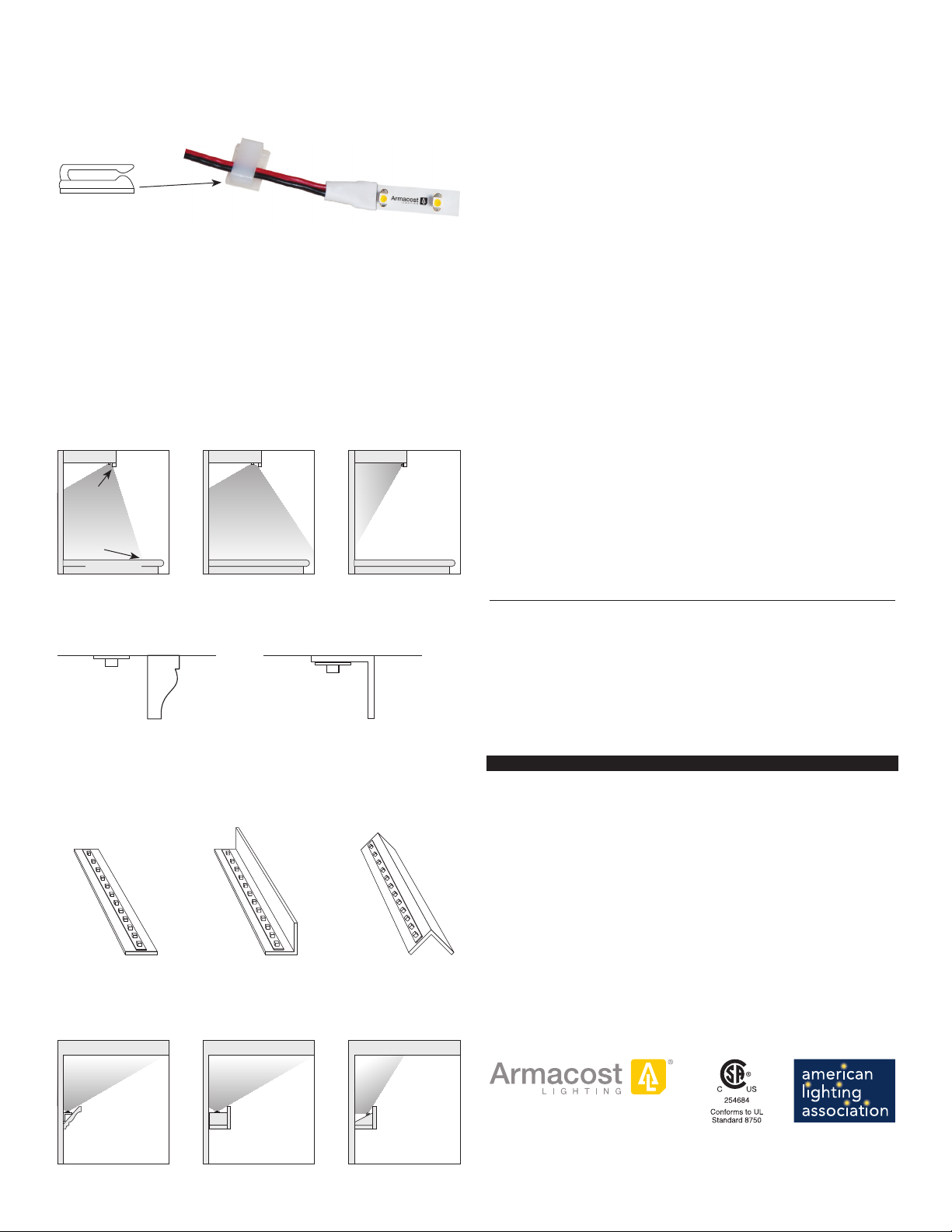

Configuration options

RibbonFlex Pro offers endless connection options to fit virtually any

installation imaginable. LED tape strips can be installed in series (strips

connected or wired end-to-end) or in parallel (multiple legs of LED strips

or series of strips wired directly to a single power supply).

LED tape lighting power requirements are based on several factors,

including your configuration (Straight Run, Center Feed/Loop Back or

Array), voltage drop, and the length limitations of the LED tape lighting.

TYPICAL CONFIGURATIONS

Straight Run

Only one end of the

LED strip is powered.

Multiple strips can be

connected in a series for

a continuous run. LEDs

farther away from the power supply may appear dimmer due to voltage

drop, especially if longer wires are used in between to connect strips.

Center Feed / Loop Back

Either power two

equal legs of tape

lighting from the

center or loop back

and power both

ends of the LED

tape. These

configurations will

produce more

consistent brightness and color over the length of the strip. A loop back

is excellent for room perimeter tray ceiling or cove lighting.

Array

An array uses two or

more legs of various

lengths wired to a

power supply in a

parallel connection.

You will need to

calculate total

wattage used in an array to guard against overloading the power supply.

Choosing a power supply

Refer to the charts below for the recommended maximum lengths of LED

tape lighting based on your configuration and choose a power supply

rated greater than your needs – you cannot overpower LED tape lighting.

The LED power requirements shown below are based on 100% full power

brightness levels and do not represent every possible installation scenario.

Do not use a standard 120V AC wall dimmer with your power supply unless the

power supply clearly states that it is dimmable with AC dimmers.

For power supply options visit armacostlighting.com/power-supply.

Maximum length of LED tape based on configuration type and power supply

Power Supply Straight Run Center Feed / Loop Back

6 Watt 3.3 ft (1.0m) Not recommended

15 Watt 10.5 ft (3.2m) 9.0 ft (2.75m)

30 Watt 24.0 ft (7.3m)* 20.0 ft (6.0m)

60 Watt 24.0 ft (7.3m)* 48.0 ft (14.6m)

*Due to voltage drop, exceeding 24-foot lengths will cause LEDs farthest from the

power supply to appear dimmer. It is okay to use a higher wattage power supply,

however, it will not reduce the impact of voltage drop.

Array power supply calculation

Due to voltage drop, longer lengths of LED tape will use fewer watts per

foot than shorter lengths. The total watts used in an array layout depend on

the wattage requirement of each leg and overall voltage drop within your

connection wires. A leg can be a single LED strip or series of strips connected

end-to-end. Various legs are wired in parallel directly to the power supply.

Calculate the wattage for each leg by multiplying watts per foot by the

length of LED lighting in the leg. Include only the lengths of LED tape

in your calculation, not the connecting wires. Add each leg’s wattage

requirement together to determine the total watts needed to power your

array and select a power supply that exceeds the total watts needed.

Length of leg

(LED tape light only) 1 to 5 feet 6 to 11 feet 12 to 15 feet

Watts used per foot 1.8 watts/ft 1.6 watts/ft 1.4 watts/ft

POWER

SUPPLY

POWER

SUPPLY

LEG 1 LEG 2

POWER

SUPPLY

POWER

SUPPLY

LEG 3

LEG 1

LEG 2