ARMOTECH –THE PERFECT MARKER…THE PERFECT GAME

WG SERIES 8

SAFETY RULES FOR HANDLING COMPRESSED

AIR OR GAS MUST BE FOLLOWED AT ALL TIMES!

OPERATING PRESSURES AND INPUT PRESSURE

•Operating pressure range 450 p.s.i. to 1150 p.s.i. (Although some

markers have been known to operate at pressures as low as 330 p.s.i.

or pressures over 1200 p.s.i. it is recommended that the specified

operating pressure of the Armotech marker be used in order to avoid

problems.)

•Never exceed recommended pressures, as this may be dangerous to

you and damaging to the marker.

•Do not leave a pressurized marker or cylinder in direct sunlight or

exposed heat source. Increased temperatures will increase the internal

pressure of the compressed gas or air and could cause problems.

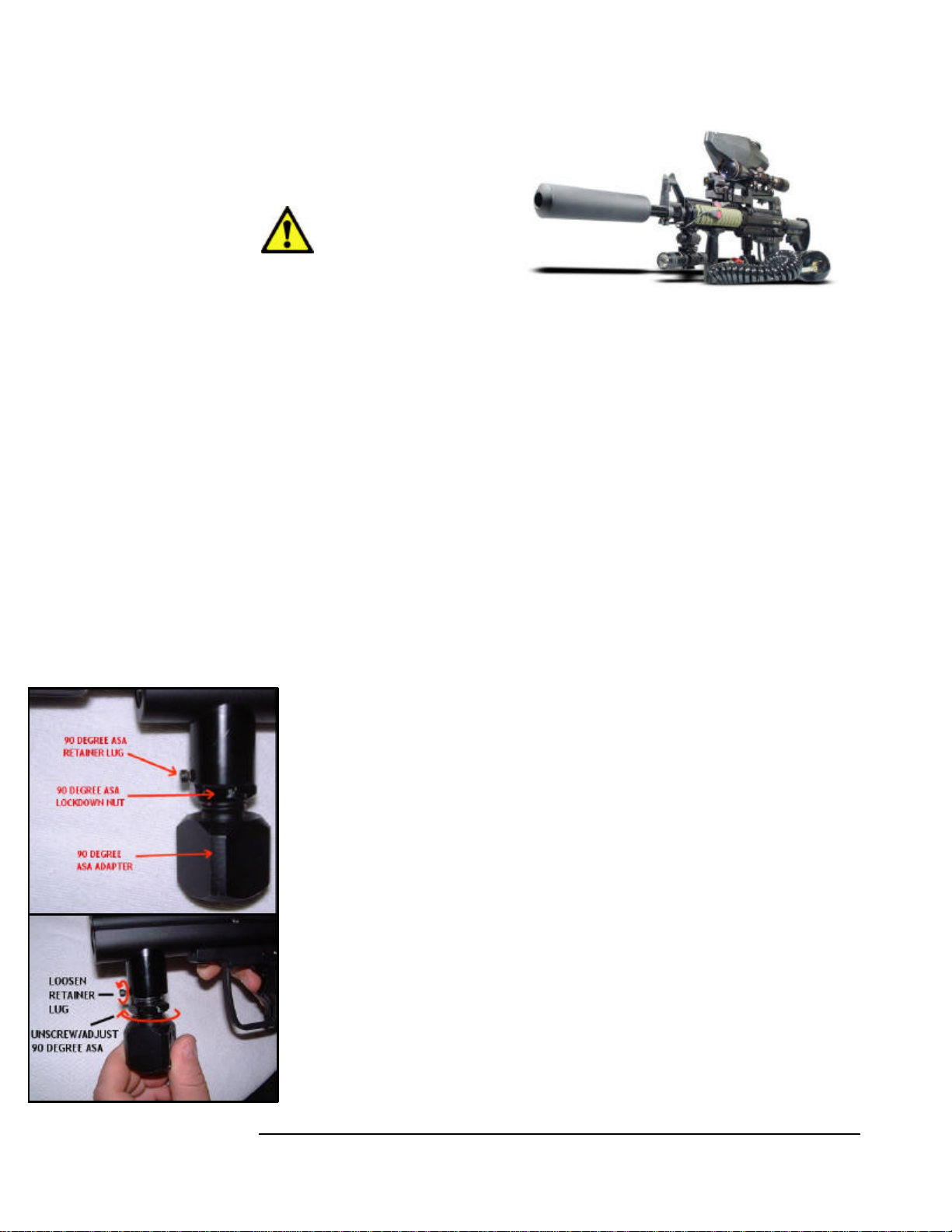

VALVE CYLINDER CONNECTION

•The Valve on a cylinder is to remain screwed into the cylinder. Should it

loosen, the cylinder may detach from the valve with an extremely

dangerous force.

•Every time a cylinder is filled, the connection between the valve and

cylinder must be inspected. If any looseness or leak is detected

between the valve and the cylinder, do not fill. Drain the cylinder and

have it inspected by qualified persons.

•During filling if any looseness or leak is detected between the valve

and the cylinder, filling should be stopped and the cylinder should

immediatelybe drainedtoavoid problems.

FILLING COMPRESSED AIR/GAS

•An overfill of any compressed air or gas cylinder can cause the safety

burst disk on the cylinder to rupture. A cylinder may rupture with

excessive force. Use properly rated disk only for the burst disk.

•A scale must be used for ALL CO2 fills to prevent an overfill. A pressure

gauge must be used for all compressed gas or air fills to prevent

overfills.