DISASSEMBLY/ASSEMBLYINSTRUCTIONS

l Neverapply excessive pressureby a holding device which may

cause distortion of a part

l Apply pressureevenly to parts which have a pressfit.

l Apply even pressureto the bearing race that will be pressfitted

to the mating port

l Use correct tools and fixtures when servicing this tool.

l Don’t damage “0” rings when servicing tool.

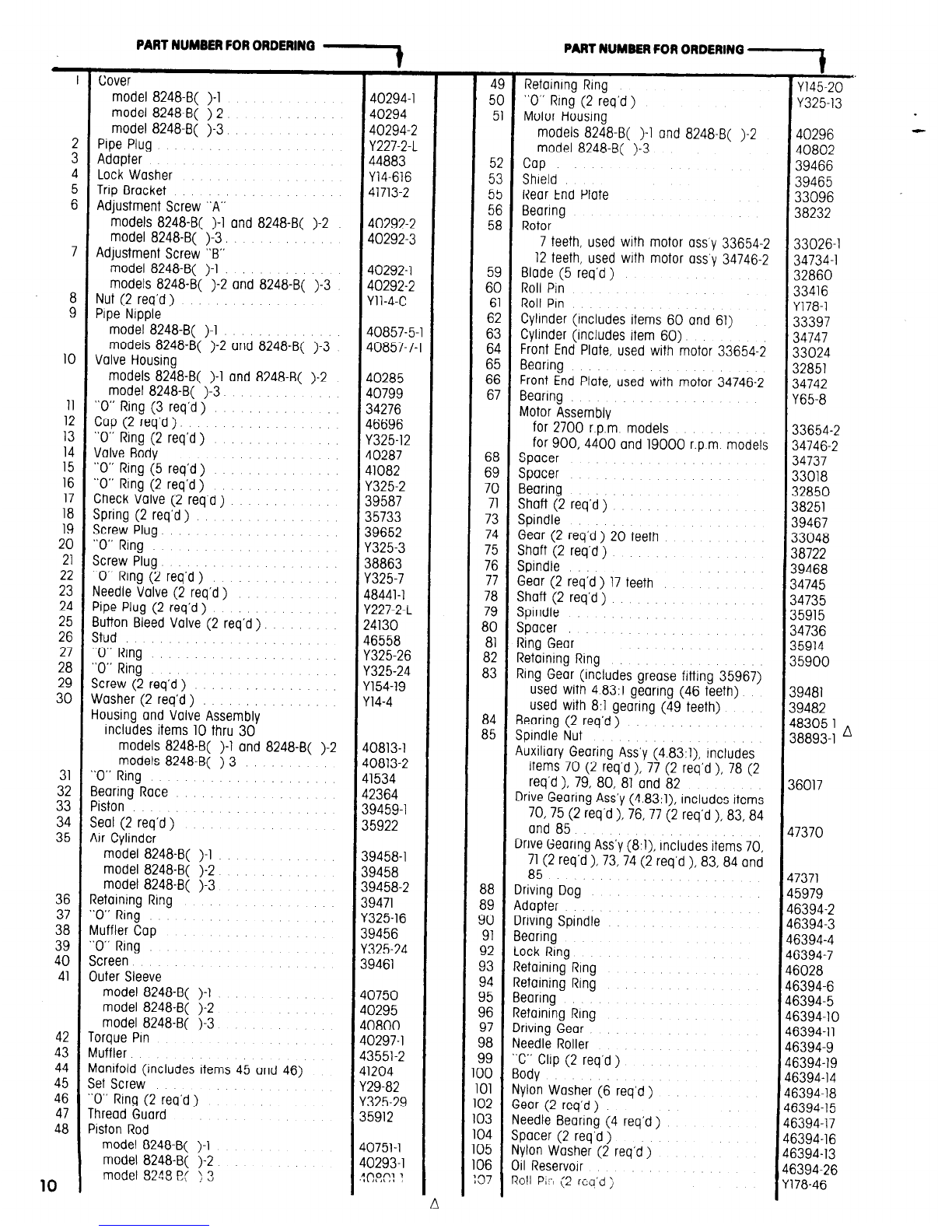

l UseOnlygenuine AROreplacement parts for this tool. When or-

dering, specify par-tnumber,description,tool model number and

serial number.

TWIN DRILL DISASSEMBLY

-Using 3mm hex wrench supplied with unit, loosen both adjust-

ment screws (111)completely. IMPORTANT:Alternately unthread

adjustmentscrews approximately 1/2turn at a time or unthread

screws simultaneously to prevent damaging the unit.

-Remove body and spindle assemblies from adapter (89).

-Remove retainingring (93) and pull spindle(90) and components

from adapter (89).

-Using retaining ring pliers, removeretaining ring (96) from gear

(97).

-Remove needle roller (98) and gear (97).

-Remove retaining ring (94) and lock ring (92) from spindle,

-Bearings (95 and 91) ore pressfit on driving spindle (90).

-Remove “C” clip (99) from adjustment screws,

-Rotate spindle turretwhile pulling outward until o portion of spin-

dle aligns with notch in bodyand removespindle assembly(108)

from body.

-Remove oil reservoir(106).

-Remove nylon washer (105) by bending slightly.

-Remove nylon washer (101)and gear (102).

-Bearings (103) and spacer(104)are loosepartsandwill dropout,

-DO NOTdisassemblespindle(108)unlessit ISnecessaryto replace

a port.

-To disassemble,using aflat bottomtype punch orsimilar tool and

an arbor press, remove gear (113)from spindle (125). CARE

SHOULDBETAKENTOREPLACEGEAR(113)INTHESAMEPOSI-

TIONWHENREASSEMBLING.Thegearis assembledwith teeth up

on turret stamped “T”. The gear is assembled with teeth down

on turret stomped “B”.

-Remove spindle (125) from sleeve (122)carefully, as six rollers

(120) are loose parts and will drop out. NOTE:Thrust race (121)

ISpressfit on spindle.

-Using a “C” type washer that properly fits spindle, pressthrust

race off spindle.

-Remove oil seal (124).

-If link bearing (114)and sleeve (122)are removedfrom turret, it

will be necessaryto removethe foam strip (117)first. Liftone end

of foam strip and pull so it slides thru notch under link bearing.

-Using a propersizepunchandan arborpress,removelink bearing.

-Press sleeve thru remaining distance in turret,

TWIN DRILL ASSEMBLY

-Pack bearingsand coatgearswith a goodgradeof bearinggrease

when assembling.Saturateoil reservoirswith a good multigrade

10W/30 oil

-When fitting sleeve(122),it is Importantthat the slot in the sleeve

lines up with the groovein the backface of the turret. Pushfoam

strip (117)intothe groovein theturret(widestsideacrossgroove),

The center of the strip should be under the sleeve and the two

ends should meet at the point opposite the sleeve.

-Press the link bearing(114)overthe small end ofthesleeve,keep-

ing the 5mm hole in the link bearing aligned with the 5mm hole

in the turret.TOmaintain alignment, usea 5mm pin insertedthru

the bore in the link bearing and the turret.

-Assemble oil seal (124)to spindle.

-Assemble thrustrace (121)to spindle, pressingan upto theshoul-

der. Becertain thrust race is pressedon and squarely seated,or

prematurefailure of the bearing may occur.

-Drop the thrust race into the boreof the sleeveassembledin the

turret.

8

-Place asmall amount of greaseonspindleand positionthetwenty

needlerollers(123)betweenthe oil seal(124)andthrustrace(121)

-Place asmall amountofgreaseonshoulderbetweenthetwothrust

races and position the six rollers (120) on spindle.

-Slide spindle into sleeve,insuringfoamstrip is keptout oftheway

-Place a few drops of oil into sleeveand pushspindle firmly down

into sleeve.

-Hold spindle in position and turn turret assemblyover with gear

end up.

-Apply a small amount of greaseto needle cage (116)and slide

cageoverthe end of the spindle, into the boreof the link bearing

-Place washer (115)over spindle.

-Be certain gear is positioned correctly on spindle. Position with

teethup on turretstomped “T”. Positionwith teethdown onturret

stamped“B”. IMPORTANT:When pressinggear on spindle, allow

on end play of .001”.

-Press roll pins (107) into 1/8” diameter holes in turret. Assemble

Setscrews (109) to spindle.

-Insert a dummy adjustment screw (111),or a shaft of the same

diameter,thru bodyfromthe backor adaptersideof bodyto main-

tain alignment of parts to be assembled into body.

-Assemble one nylon washer (101)over dummy screw and down

into body.

--Assemble bearing (103), spacer (104) and other bearing (103)

to gear (102).

--Assemble gear with bearingsto dummy screw, with largest por-

tion of gear going on screw first.

-Assemble one nylon washer (101)to screw.

-Assemble nylonwasher(105) to screw,bending slightly to gothru

hole in body.

-Assemble oil reservoir(106) into body and position holes for roll

pins sothey will align with roll pins of spindle when spindle is as-

sembled to body.

-Assemble spindle (108) to bodyand screw,aligning roll pins with

holes in oil reservoirand extended portion of spindle with notch

in body.

-Assemble spring washer (110)and one nylon washer (101)to ad-

justment screw (111).

-Assemble screw (111)to unit,while at the sametime withdrawing

dummy screw from unit.

-Assemble “C” clip to screw (111)to secure screw to unit.

-Assemble bearings (91 and 95) to driving spindle (90)

-Assemble gear(97) to drivingspindle(go), aligning holethru gear

with hole in spindle.

-Assemble needle roller (98) thru gear and spindle.

-Assemble retaining ring (96) over gear and needle roller.

-Assemble lack ring to spindle over bearing (95) and assemble

retaining ring (94) to lock ring.

-Assemble driving spindle and components to adapter (89) and

secure with retaining ring (93).

-Assemble the twin drill body assemblyto the adapter and lock

ring, alternatelythreading adjustmentscrews into lock ring, simi-

lar to disassembly.

-Refer to “spindle adjustment”, page 3

GEARING DISASSEMBLY

-Using wrenches on flats of adopter (89) and ring gear (83), un-

thread adapter from gearing.

-Using wrenches onflats of driving dog (88) and spindle nut (85),

unthread and removedriving dog from spindle. Removespindle

nut (85) also.

-Thread adjustmentscrews (6 and 7) all the way back and push

the piston rod (48) all the way forward to expose wrench flats

of motor housing (51) from the outer sleeve (41).

-Using wrenchesonfiats of ring gear and motorhousing,unthread

gearing from motor housing

-If tool hasdouble gearing,unthreadring gear(83) from ring gear

(81).

-Grasp ring gearin one hand and tap thethreadedendof thespin-

dle with a softfaced hammer;spindle and componentswill loos-

en from ring gear.

-Remove bearing(s)andshaftsfromspindleto removeplanetgears.