DISASSEMBLY/ASSEMBLY INSTRUCTIONS

Never apply excessive pressure by a holding device which

may cause distortion of a part.

Apply pressure evenly to parts which have a press fit.

Apply even pressure to the bearing race that will be press

fitted to the mating part.

Use correct tools and fixtures when servicing this tool.

Don’t damage “O” rings when servicing this tool.

Use only genuine ARO replacement parts for this tool. When

ordering, specify part number, description, tool model number

and serial number.

GEARING DISASSEMBLY

Clamp tool in asmooth face vise- pistol grip models, clamp on

handle (21) - straight models, clamp on inlet adapter (6).

Remove drive option from tool (chuck, square drive, etc.).

Unthread and remove ring gear (48, 59 or 63) and compo-

nents using a wrench on flats of ring gear.

Remove spindle(s) and gears from ring gear. NOTE: Keep

gears grouped with mating spindle when disassembling

double reduction gearing.

Remove lock nut (53) releasing washer (52) bearings (50)

and spacers (49 and 51).

Do not remove gears (55 or 64) from carrier assembly unless

damage is evident. Gears are press fit onto carrier assem-

blies.

GEARING ASSEMBLY

Assemble spacer (49) and one bearing (50) into ring gear (48,

69 or 63) pressing on outer race of bearing.

Coat shafts of spindle(s) with ARO 33153 grease.

Assemble gears, containing bearings (57) to shafts of mating

spindle.

Assemble carrier assembly to spindle assembly of double re-

duction gearing.

Lubricate sets of gears liberally with ARO 33153 grease (see

“Routine Lubrication Requirements”, page 3).

Assemble spindle(s) and gearing into ring gear. Rotate

spindle and gears to align gear teeth with splines of ring gear.

Assemble spacer (51) and bearing (50) into ring gear, press-

ing on inner race of bearing.

Assemble washer (52) to ring gear, securing with lock nut (53).

Assemble ring gear and components to tool and tighten, using

a wrench on flats of ring gear.

Assemble spacer (54) and drive option to tool.

MOTOR DISASSEMBLY

Remove gearing from tool.

Remove spacer (44) and “O” ring (43).

Tapfront edge of housing to remove motor assembly. Locat-

ing pin (45) should also come out.

Grasp cylinder in one hand and tap drive end of rotor (38) with

a soft face hammer; motor will come apart. NOTE: Bearings

are light press fit on rotor.

Remove end plate (37) and bearing (36) from rotor.

MOTOR ASSEMBLY

Lubricate bearing (36) with ARO 33153 grease and assemble

into end plate (37) pressing on outer race of bearing.

Assemble end plate (37) to rotor, pressing on inner race of

bearing.

Coat five rotor blades (39) with ARO 29665 spindle oil and as-

semble to rotor slots - straight side out.

Coat i.d. of cylinder (40) with ARO 29665 spindle oil and as-

semble over rotor. NOTE: Air inlet slots in end of cylinder must

be aligned with two air inlet holes in end plate (37).

Assemble bearing (42) into end plate (41) pressing on outer

race of bearing.

Assemble end plate (41) to rotor, pressing on inner race of

bearing. Be sure rotor turns without binding.

Insert locating pin (45) into .096” diameter blind hole at bottom

of motor cavity in housing.

Align notches of end plates and cylinder and install motor into

housing, aligning notches with locating pin (45).

Grease and assemble “O” ring (43) to end plate (41).

Assemble spacer (44) to motor.

Assemble gearing to tool.

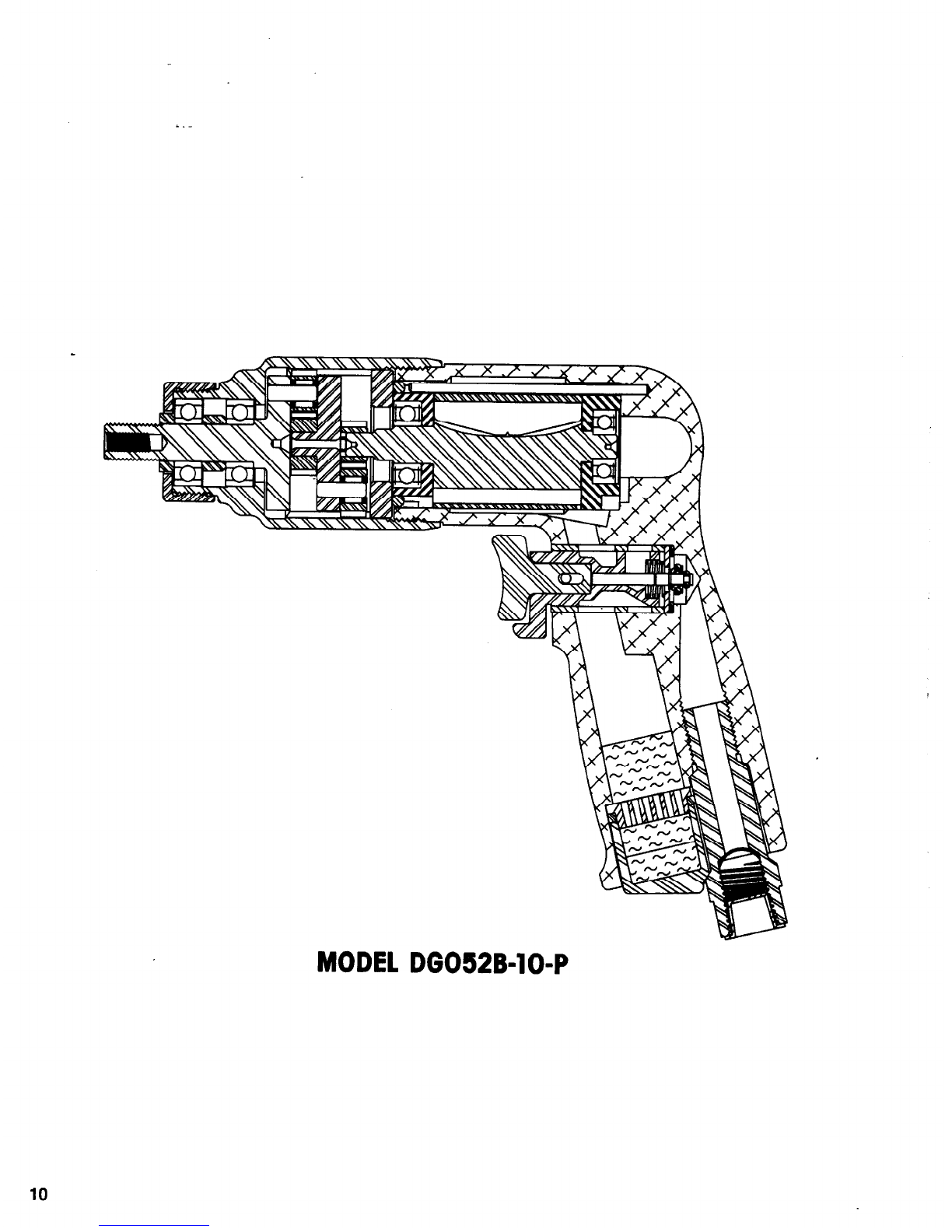

PISTOL GRIP HOUSING DISASSEMBLY

Remove spiral pin (22), driving it out the left side of housing.

Single Direction models: Remove trigger (34) plug (35) valve

assembly (24) and “O” ring (23).

Reversible models: Remove trigger (34) reverse valve (33)

valve bushing (32) spring (31) washer (30) valve assembly

(24) and “O” ring (23).

Remove “O” ring (25) valve (26) “O” ring (27) and retaining

ring (28).

Remove inlet adapter (18) releasing muffler (19) and filler(s)

(20).

Remove screen (9) from inlet adapter (18).

PISTOL GRIP HOUSING ASSEMBLY

Grease “O” ring (23) and assemble into housing (21).

Assemble retaining ring (28) to valve stem (29).

Grease “O” ring (27) and assemble to valve (26).

Assemble valve (26) to valve stem, with smallest diameter of

valve going on valve stem first.

Grease “O” ring (25) and assemble to valve stem, securing

valve (26).

Single Direction models: Assemble valve stem thru plug (35)

and assemble plug into housing (21) aligning .102” diameter

holes in housing and plug.

Reversible models: Assemble washer (30) and spring (31)

over valve stem. NOTE: Assemble washer with “x” facing “O”

ring (23). Assemble reverse valve (33) to valve bushing (32).

NOTE: Position .102” diameter hole thru bushing to align with

slot thru side of reverse valve. Assemble valve stem and com-

ponents thru reverse valve (33) and bushing (32) and as-

semble into housing, aligning .102” diameter holes in housing

and bushing.

Assemble trigger (34) securing with pin (22). NOTE: As-

semble pin from left side of housing.

Assemble filler(s) (20) and muffler (19) to housing, securing

with inlet adapter (18).

Clean and replace screen (9) in inlet adapter.

LEVER THROTTLE HOUSING DISASSEMBLY

Clamp inlet adapter (8) in a smooth face vise.

Unthread housing (1 or 14) using a strap type wrench.

Remove spacer (7) diffuser washer(6) exhaust cap (5) fillers

(4) spring (3) and valve rod (2). NOTICE: Do not remove or

adjust rubber portion ofvalve rod (2) as it is preset atthe facto-

ry.However, if air leakage occurs due to wear, unscrew rubber

portion of valve rod NOT more than one complete turn (coun-

terclockwise).

Reversible models: Remove pin (77) ball (15) valve body

(16) and spring (17).

Remove throttle pin (11) and spring (10).

Remove screen (9) from inlet adapter (8).

LEVER THROTTLE HOUSING ASSEMBLY

_ Assemble spring (10) and throttle pin (11) into housing, align-

ing slot in throttle pin with air inlet holes in housing.