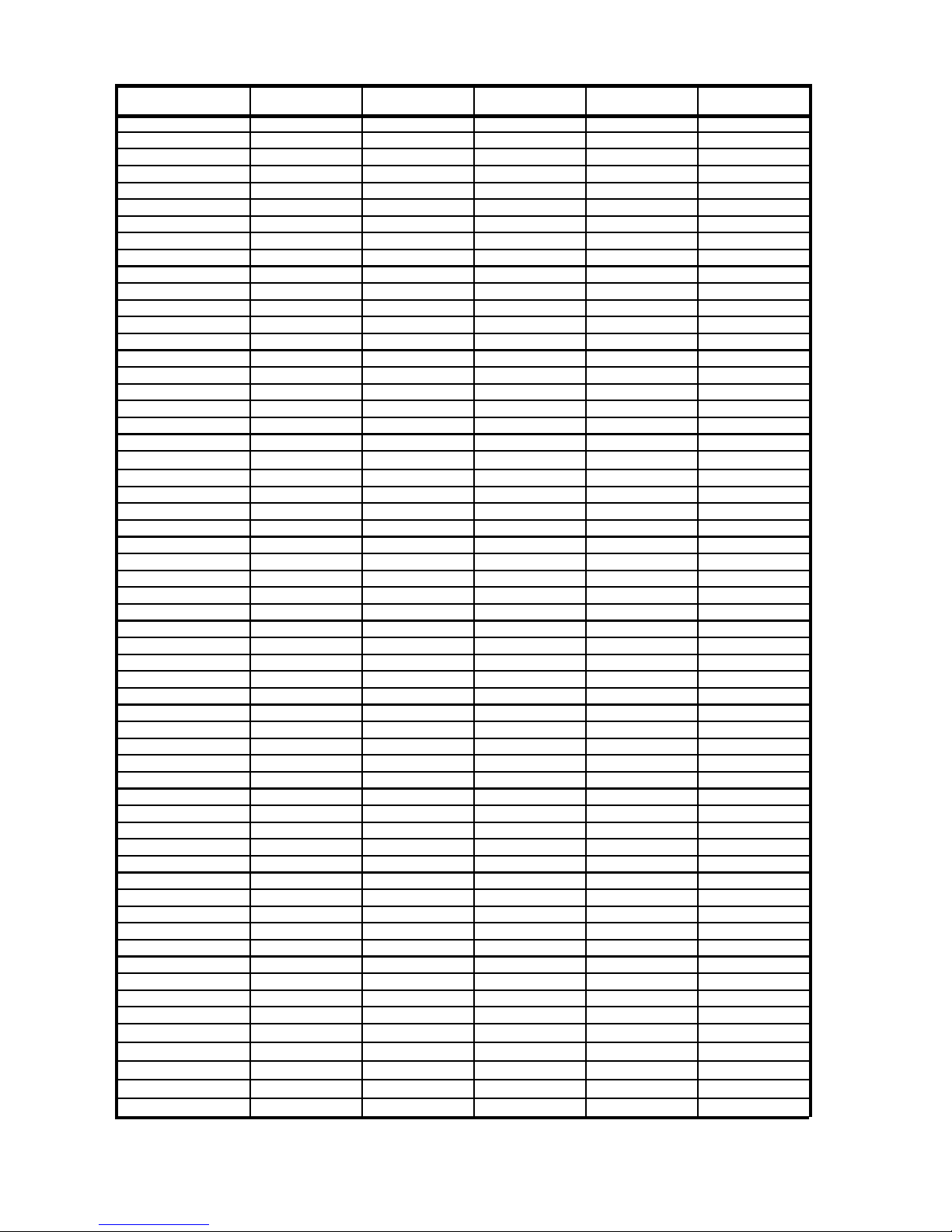

PART NUMBER FOR ORDERING PART NUMBER FOR ORDERING

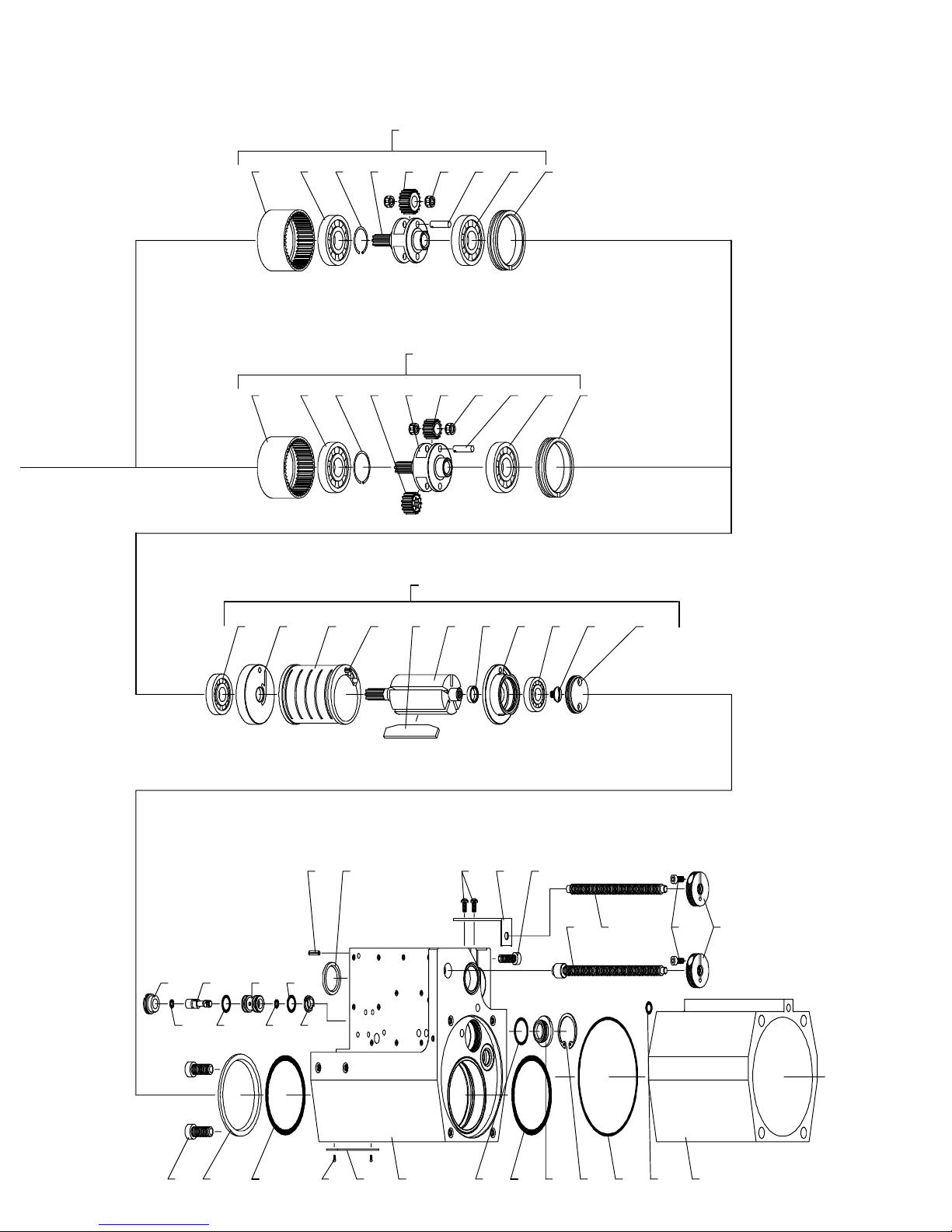

10

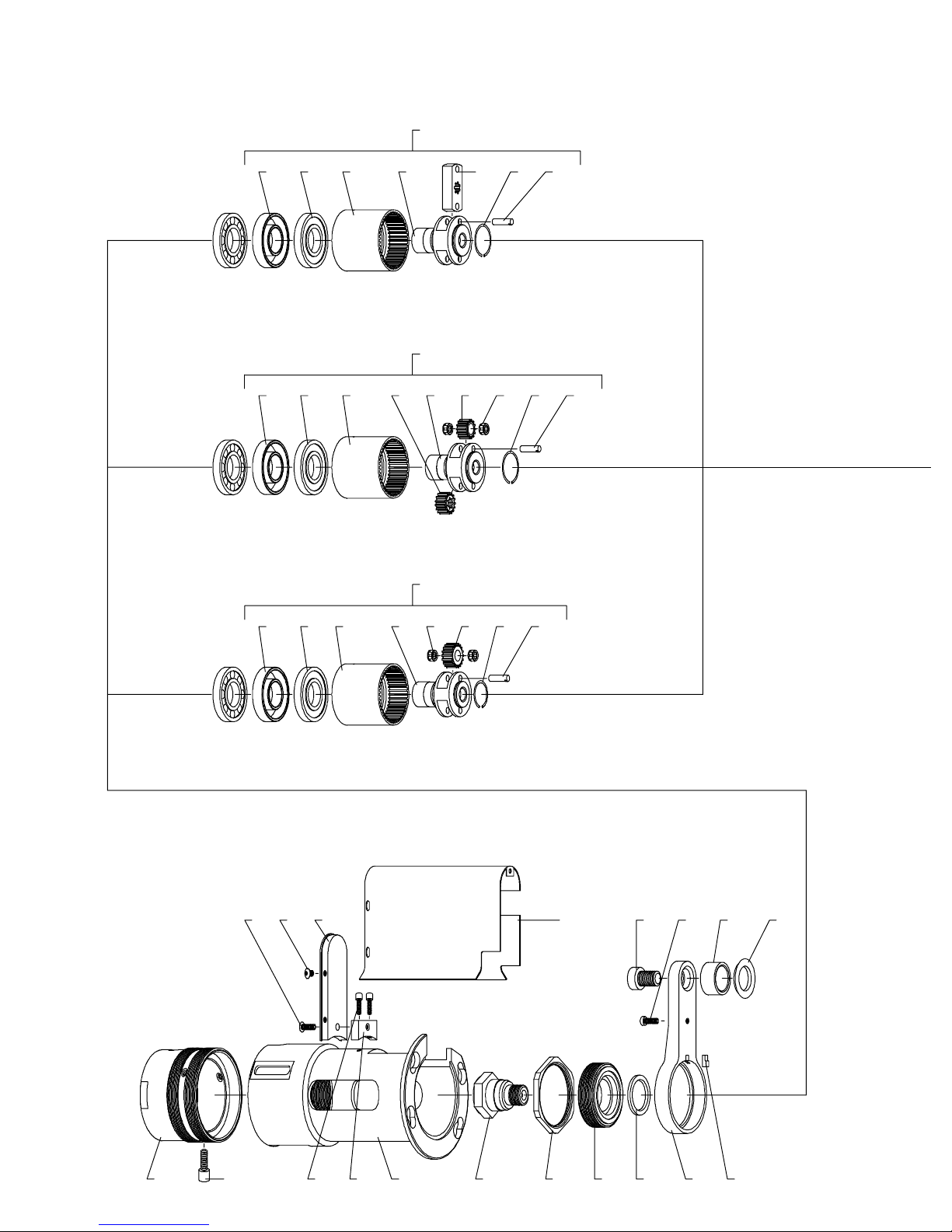

49 Spacer 33711.............................

50 Bearing (2 req’d) 33704.....................

51 Shaft (2 req’d) 40841.......................

52 Bearing (4 req’d) 42271.....................

53 Gear (2 req’d) 46417.......................

54 Spindle 49368.............................

55 Gear 34574...............................

56 Snap Ring 40842..........................

57 Ring Gear 49301...........................

58 Gearing Assembly 4.0:1 ratio 49269..........

59 Gear (2 req’d) 46416.......................

60 Spindle 49305.............................

61 Snap Ring 40843..........................

62 Gearing Assembly 7.43:1 ratio 49270.........

63 Spindle 49367.............................

64 Ring Gear 49300...........................

65 Paired Bearing 33235......................

66 Paired Spacer 44900.......................

67 Gearing Assembly 4.0:1 ratio 49271..........

68 Spindle 49304.............................

69 Gearing Assembly 7.43:1 ratio 49272.........

70 Splined Driver 34488.......................

71 Gearing Assembly 1:1 ratio 49273............

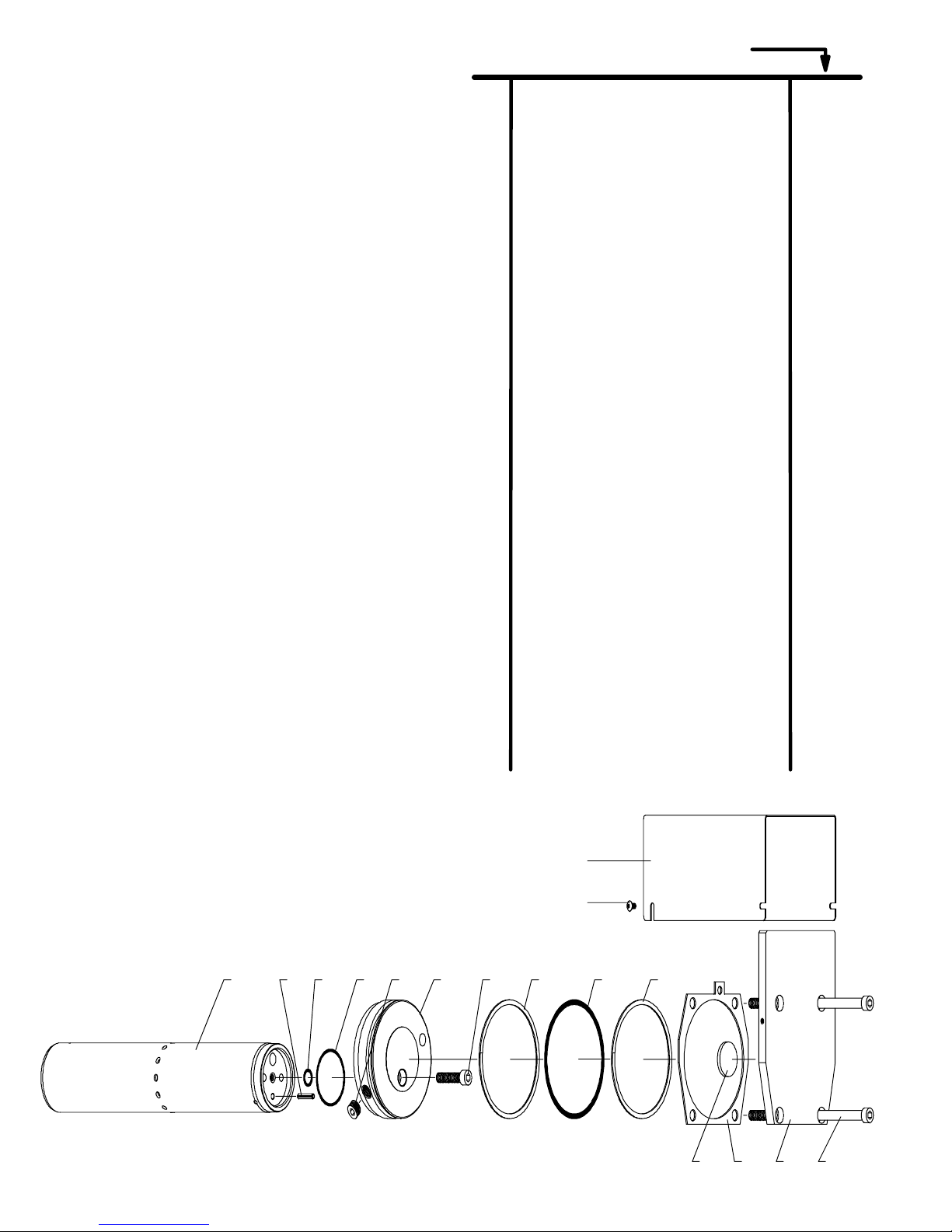

72 Spacer 49759.............................

73 Torque Arm

for models FA104A--011 thru --015 04560041.....

for all other models 49345..................

74 Cap Screw

for models FA072A--( ) Y154--33...............

for models FA104A--( ) 49281...............

75 Key 49264................................

76 Seal 37389................................

77 Lock Nut 49299............................

78 Nut 49302................................

79 Adapter

3/8”--24 UNF--2B thread 49303--1..............

1/2”--20 UNF--2A thread 49282..............

#33 Jacob’s taper 49274...................

9/16”--18 UNF--2B thread 49303--2.............

Collet 49518..............................

80 Cover

for models FA072A--( ) 49339...............

for models FA104A--( ) 49362...............

81 End Cap 49338............................

82 Screw (4 req’d) Y211--11......................

83 Screw Y211--14..............................

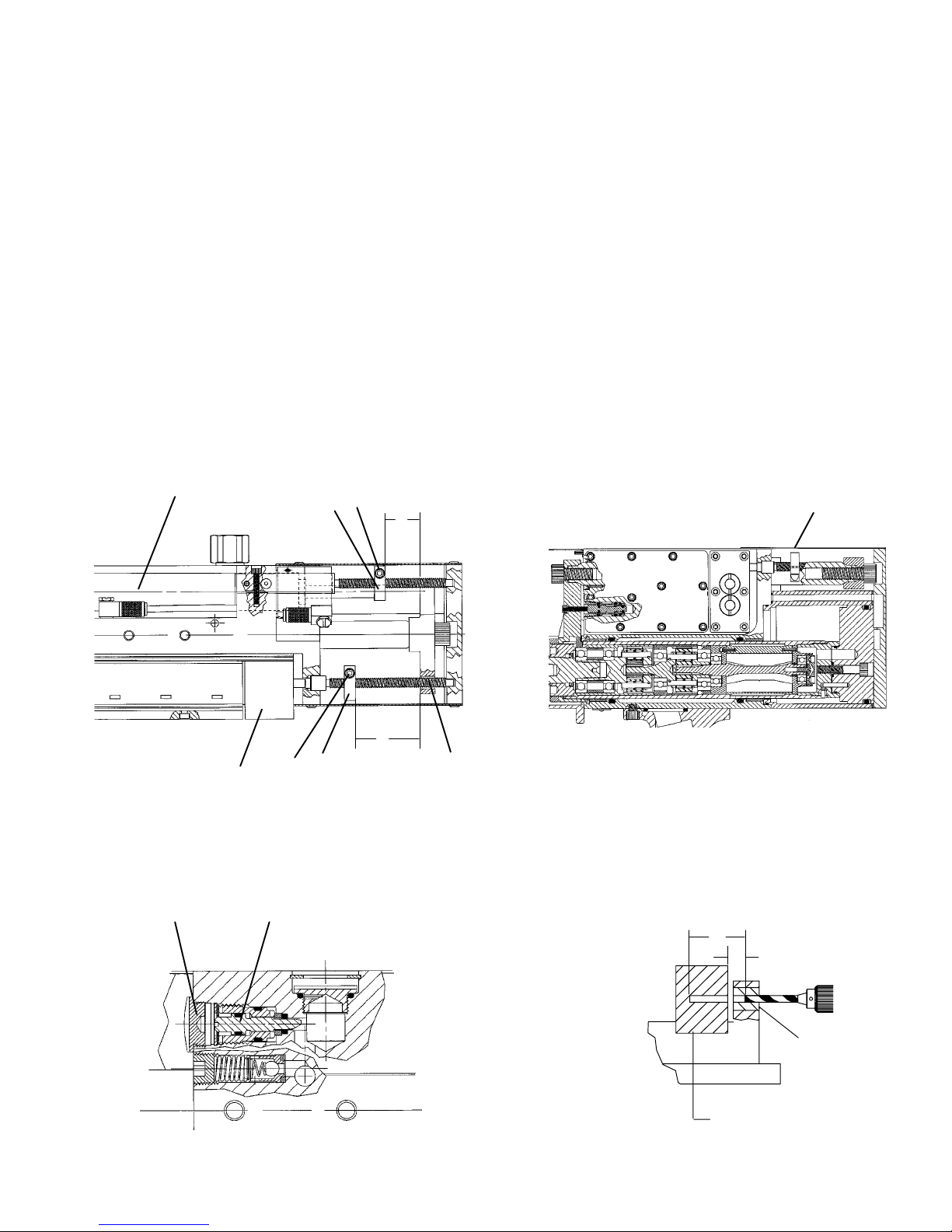

84 Nose Housing (see pages 13 and 14)

85 Mounting Block 49350......................

86 Cap Screw (2 req’d) Y154--31..................

87 Cap Screw (3 req’d) Y99--40..................

88 Adapter (see pages 13 and 14)

89 ‘‘O” Ring (6 req’d) Y325--16....................

90 Valve Sleeve 44979........................

91 ‘‘O” Ring (5 req’d) 15066....................

92 Spool 49323..............................

93 Spring 13006..............................

94 ‘‘O” Ring Y325--16............................

95 Cap Screw 49330..........................

96 ‘‘O” Ring (2 req’d) Y325--110....................

97 Set Screw Y23--52...........................

98 Feed Tube

for models FA072A--( ) 49307--1...............

for models FA104A--( ) 49307--2...............

99 ‘‘O” Ring Y325--12............................

100 ‘‘O” Ring Y325--9............................

101 Retaining Ring Y145--8.......................

102 Seal Washer 46955........................

103 Valve Insert 49358.........................

104 Ball 44967................................

105 Spring 39679..............................

106 Retaining Ring Y147--1--K.......................

107 Spring 59342--2..............................

108 Pipe Plug Y227--2...........................

109 ‘‘O” Ring Y328--6............................

110 Washer 49349.............................

111 ‘‘O” Ring Y325--11............................

112 Insert 49327...............................

113 ‘‘O” Ring Y325--7............................

114 Meter Needle 49348........................

115 Washer 20194.............................

116 Retaining Ring Y147--50.......................

117 Cap Screw 49346..........................

118 Spacer 49359.............................

119 ‘‘O” Ring (2 req’d) Y325--11....................

120 ‘‘O” Ring (2 req’d) Y325--5....................

121 Body 49333...............................

122 Plunger 49332.............................

123 Nut 49351................................

124 Swivel Fitting (2 req’d) 59903................

125 Connector (2 req’d) 59764--004...................

126 Tube 44632--004--K...............................

127 Control Assembly

for models FA072A--( ) 49356...............

for models FA104A--( ) 49268...............

128 Retaining Ring (included with item 129)

129 Hydraulic Check Assembly

for models FA072A--( ) 49357...............

for models FA104A--( ) (includes knurled knob) 49366..

130 Adjustment Knob (models FA072A only) 49297.

131 Roll Pin (models FA072A only) Y178--114.........

132 Set Screw (models FA072A only) Y29--139.......

133 Inlet Adapter 47206........................

134 Cap Screw (10 req’d)(included with item 135) Y154--39....

135 Logic Assembly 49354......................

136 Cap Screw (6 req’d) Y154--39..................

137 Valve Assembly 49355......................

138 ‘‘O” Ring Y325--122............................

139 Cap Screw (4 req’d) Y99--40..................

140 Handle 49041.............................

141 Muffler Pad (2 req’d) 48443--1..................

142 Screen (2 req’d) 40199.....................

143 Retaining Ring (2 req’d) Y147--62...............

144 Roll Pin Y178--22.............................

145 Screen 40199.............................

146 Nameplate

for standard models 48881..................

for EU models 04334470.......................

147 Screw (2 req’d) Y60--20......................

148 Label (3 req’d)(not shown) 49530.............

149 Label (2 req’d)(not shown) 49531.............

150 Label (2 req’d)(not shown) 49532.............

151 Screen 49163.............................

152 Muffler Pad 49162..........................

153 Plate 49161...............................

154 Label (EU) (not shown) 49882...............

155 Label (EU) (3 req’d) (not shown) 04334488........

156 Label (EU) (2 req’d) (not shown) 04334496........

157 Handle Kit 49520..........................

158 Label (EU) (not shown) 49883...............

159 Motor

for models FA072A--( ) 41522...............

for models FA104A--( ) 49370...............

160 Label (EU) Direction (not shown) 49923.......