PN 97999-93

Page 4 of 4 612041-X

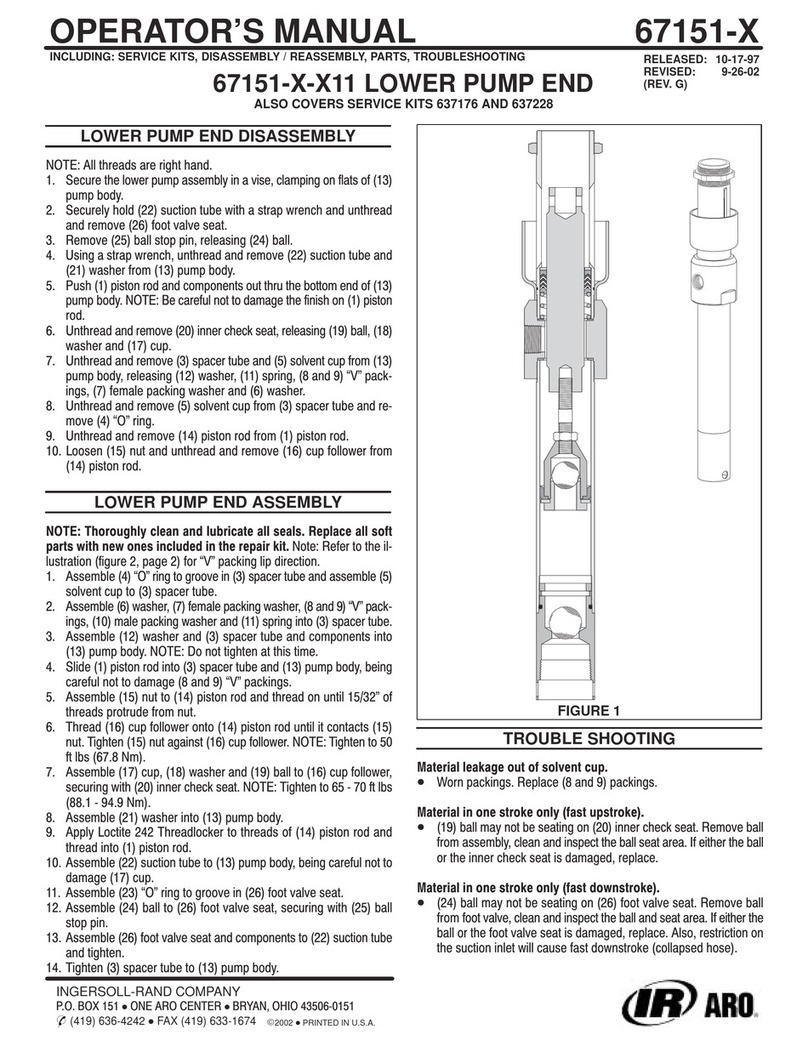

PUMP DISASSEMBLY (continued)

NOTE: Perform steps 8 thru 10 only if 7) spacer and piston assembly

needs servicing.

8. Remove the three 8) screws fromthe 11)valve spacer see figure 4).

9. Remove the 9) valve plate.

10. Remove the 11) valve spacer from the 10) piston assembly.

11. Unthread 13) plunger tipfromthe 15) plungerby usinga wrenchon

the flats ofthe 13) plunger tip and a strapwrench onthe 15) plung-

er. CAUTION:Place the strap wrenchonthe very uppermostpartof

the 15) plunger.

12. Remove 14) “O”ring.

13. Remove 21) dowel pin.

14. Remove 13) plunger tip.

15. Remove 15) plunger.

16. Remove 17) spring from the 18) pump body.

17. Remove 19) “O”ring from the 18) pump body.

18. Using a pipe wrench, unthread and remove the 34) suction tube

from the 18) pump body. CAUTION: Place the pipe wrench on the

very upper most or very lower most part of the 34) suction tube. Do

not damage or dent this tube.

19. Remove 25) “O”ring from the 18) pump body.

20. Grasp the 22) piston rod and remove by pulling straight out.

21. Using a strap wrench on 36) tube, unthread and remove from 18)

pump body. CAUTION: Do not damage or dent this tube.

22. Remove 26) “O”ring from 18) pump body.

23. Remove 24) plug and 23) “O”ring.

24. Clampthe 43) intake valve assemblyina vise. Usinga strap wrench

on 34) suction tube, unthread and remove from valve assembly.

CAUTION: Do not damage or dent this tube.

25. Usinga wrench onflatsof 22) pistonrod, unthread and remove 39)

nut see figure 4).

26. Remove 38) washer, 37) cupand 35) washer from 22) pistonrod.

27. Remove 32) retaining ring from the 22) piston rod, using retaining

ring pliers.

28. Remove 33) piston from 22) piston rod.

29. Remove two 30) packings where applicable).

30. Remove 31) “O”ring from 22) piston rod.

NOTE: Do not remove 27) groove pin and 28) collar from 22) piston

rod unless damage is evident. Remove 27) groove pin, releasing 28)

collar.

PUMP REASSEMBLY

1. Insertthe 11) valve spacer thruthe bottomofthe 10) pistonassem-

bly see figure 4).

2. Place the 9) valve plate on top ofthe 10) piston assembly, aligning

the three holes with the posts of 11) valve spacer.

3. Fasten the 9) valve plate down using the three 8) screws. Laythis

assembly aside for the moment.

4. Place the 28) collar on the 22) piston rod and secure with 27)

groove pin.

5. Assemble 29) washer next to 28) collar on 22) piston rod.

6. Grease and assemble 31) “O”ring to 22) piston rod.

7. Assemble two 30) packings to 33) piston where applicable).

8. Assemble 33) piston to 22) piston rod, securing with 32) retaining

ring.

9. Assemble 35) washer, 37) cup lips up) and 38) washer onto 22)

piston rod, securing with 39) nut see figure 4).

10. Grease and assemble 23) “O” ring into 24) plug and screw 24)

plug into 18) pump body.

11. Place the 18) pumpbody ina vise androtate it so the materialoutlet

is resting against the vise jaw. CAUTION: Do not clamp the pump

body too tightly.

12. Grease and assemble 26) “O”ring to 18) pump body.

13. Thread 36) tube onto 18) pump body and tighten, using a strap

wrench.

14. Assemble the 22) piston rod up thru the 18) pump body.

15. Grease and assemble 25) “O”ring to 18) pump body.

16. Thread the 34) suction tube to the 18) pump body and tighten, us-

ing a strap wrench.

17. Thread the 43) intake valve assembly to the 34) suction tube and

tighten.

18. Grease and assemble 19) “O”ring into 18) pump body.

19. Place 17) spring into 18) pump body.

20. Assemble 15) plunger over 22) piston rod.

21. Assemble 13) plungertipto 22) pistonrodandinsert 21) dowelpin

to secure plunger tip.

22. Grease and assemble 14) “O”ring to 13) plunger tip.

23. Pull 15) plungerup and thread 13) plunger tip to plunger andtight-

en by using a wrench on flats of 13) plunger tip and a strapwrench

on 15) plunger.

24. Place the 12) gasket over the end of 13) plunger tip.

25. Thread the 7) spacer and piston assembly onto the 13) plunger tip

and tighten.

26. Grease and assemble 16) “O”ring to 18) pump body.

27. Thoroughly grease the inside of the 6) cylinderand assemble over

the 7) spacer and piston assembly, threading onto the 18) pump

body.

28. Assemble 2) washer, 3) “O”ring, 4) spring and 5) button into 1)

capandassemble capto 6) cylinder, tighteningusinga strapwrench.

TROUBLE SHOOTIN

Pump continually cycles.

xCheck for empty material supply. Disconnect the air (from thepump)

replenish material supply.

xCheck for worn or damaged (30) packing or (33) piston.

Material on one stroke only (fast downstroke).

xThe intake valve assembly may not be checking or sealing properly.

Remove the intake valve assembly and inspect. If the valve assem-

bly is damaged, replace with new parts. If the valve assembly is not

damaged, thoroughly clean and reassemble to the pump (see pump

instructions).

Material on one stroke only (fast upstroke).

xCheck for worn or damaged (37) cup. Replace cup (see pump

instructions and figure 4).

Material leakage out the top of the pump body.

xCheck for worn or damaged (30) packing or (33) piston.

Air leakage out of the exhaust holes. (See Air Motor Instructions)

xCheck to see if the (9) valve plate is loose or has become disas-

sembled from the (11) valve spacer.

xCheck for worn or damaged (10) piston assembly.

xCheck for worn or warped (9) valve plate.

xWorn or damaged (14) “O” ring. Replace (14) “O’’ ring.