PP30A-XXX-XXX (en) Page 3 of 12

pump. The material inlet supply tubing should not be too

small or restrictive, which will inhibit material flow. The

outlet material volume is governed not only by the air

supply, but also by the material volume available at the

inlet.

yAir supply provided should be filtered to provide clean,

dry air. A filter capable of filtering out particles larger

than 40 microns should be used on the air supply. There

is no lubrication required other than the“O” ring lubricant

which is applied during assembly or repair.

yIf lubricated air is present, make sure that it is compatible

with the “O” rings and seals in the air motor section of the

pump.

NOTE: When using air for powder uidization, make sure

it is ltered and very dry.

INSTALLATION

THE PUMPING SYSTEM MUST BE GROUND-

ED TO PREVENT STATIC DISCHARGE. THIS INCLUDES

THE PUMP AND ALL INPUT AND OUTPUT SUPPLY

LINES AND RELATED SYSTEM DEVICES AND ACCESSO-

RIES. FAILURE TO DO SO CAN RESULT IN EXPLOSION

AND SERIOUS PERSONAL INJURY.

SYSTEM GROUNDING

yConsult local building codes and electrical codes for

specific requirements.

yMust comply with all applicable Local and National

codes for such applications.

yGrounding is accomplished through the ground lug

and strap provided on the pump. Keep the grounding

strap as short as possible.

ySafe operating conditions are the responsibility of the

installer and operator.

ySecure the diaphragm pump legs to a suitable surface

to avoid damage by excessive vibration.

OPERATING INSTRUCTIONS

START-UP

NOTE: PRIOR TO START-UP, MAKE SURE THE GROUNDING

INSTRUCTIONS WERE FOLLOWED.

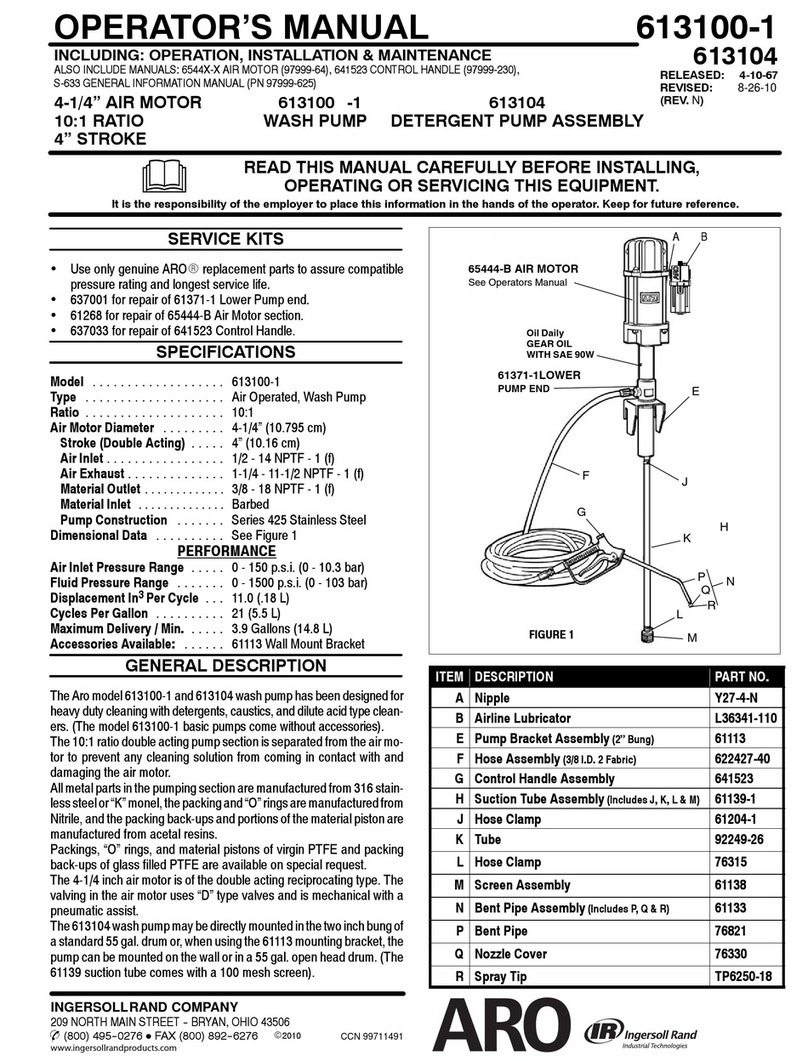

1. Connect air supply to (263) main air supply control valve

(30 - 40 psig / 2.1 - 2.8 bar).

2. Turn the air on.

3. Attach air (or gas) to (248) lter / regulator.

Do not apply excessive Fluidization Gas*

Pressure (refer to note under “Theroy Of Opetration”).

4. Verify that the (253) ow control is fully open.

5. At (248), turn on air (or inert gas) supply. There will be a

3 to 8 second time delay, during which the pump will be

fluidizing any powder left in the pump from an earlier

dispense. This time delay will occur on all start-ups.

OPERATION AND ADJUSTMENT

NOTE: Powder type materials can vary in ow-ability and the

same settings may not work universally. Factors such as den-

sity and humidity can require changing the mixture of ow

rate and uidization air and some experimenting should be

expected.

IMPORTANT: DO NOT TURN FILTER / REGULATOR (248) OFF.

Positive air (or gas) pressure must be supplied to the lter /

regulator to allow the pump to function. Powder will accu-

mulate in the uid caps if the pump is not allowed to expel

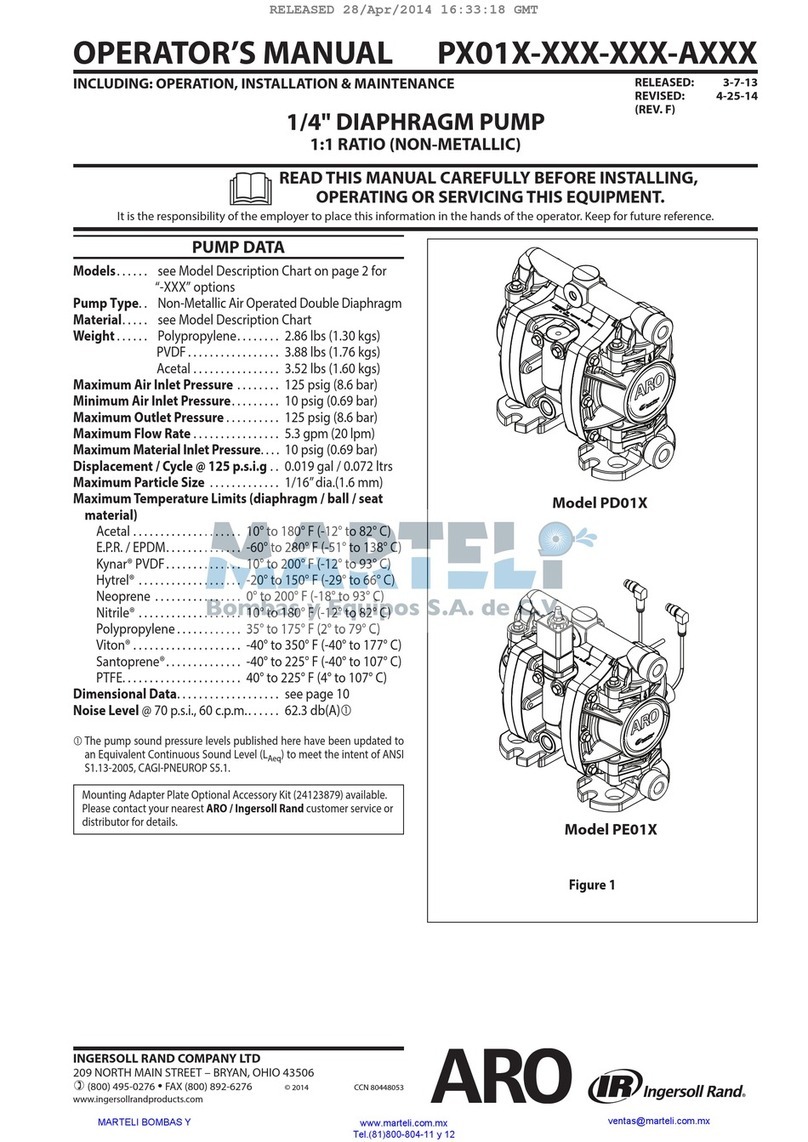

GENERAL DESCRIPTION

The ARO diaphragm pump oers high volume delivery even

at low air pressure and a broad range of material compat-

ibility options available. Refer to the model and option chart.

ARO pumps feature stall resistant design, modular air motor

/ uid sections.

Air operated double diaphragm pumps utilize a pressure dif-

ferential in the air chambers to alternately create suction and

positive fluid pressure in the fluid chambers, valve checks

insure a positive ow of uid.

This diaphragm pump was developed to address the unique

problems associated with pumping dry powders, which can

“pack out” inside the pump fluid chambers, if not kept in a

semi-uid state.

This system incorporates the use of special valves to intro-

duce air or inert gas* into the uid chambers simultaneously

to a pumping cycle in a timed sequence which keeps the

powder in a uidized state during the transfer process.

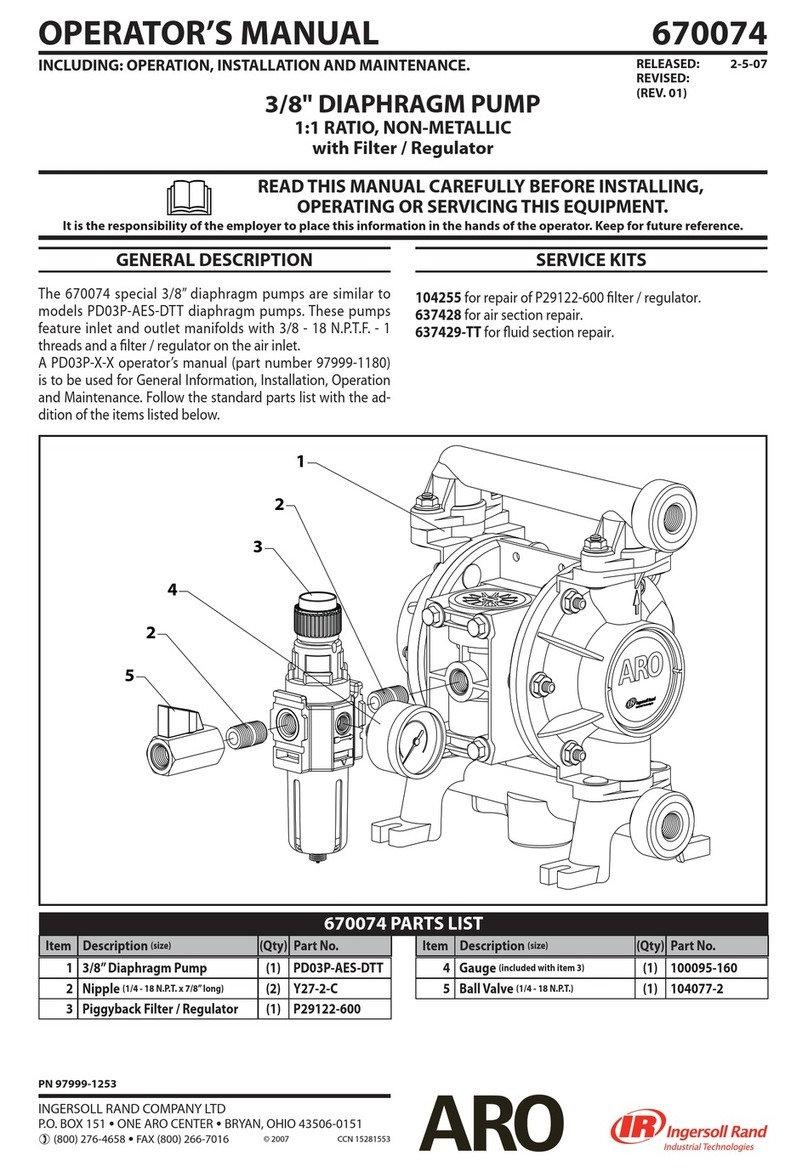

THEORY OF OPERATION

The main air distribution valve (252) is a double pilot actu-

ated four-way valve. It is a slave to the pump major air valve.

The distribution valve recognizes the signal from two pump

major air valve (259) ports (air dumps). These signals are con-

verted into alternating output pressure distributions, which

are injected into the uid chambers during the pumping cy-

cle to uidize the powder as the diaphragm moves through

the discharge stroke.

The ow of air supplied to the uid chamber is controlled by

the (248) filter / regulator. Under normal operating condi-

tions, this is the primary control.

When air is supplied to the filter / regulator (248), the dis-

tribution valve directs the ow of air into the uid chamber

that will dispense rst for 3 to 8 seconds. The time delay then

supplies the start signal to open the main pump air supply

valve. When the pump diaphragm reaches the end of the

discharge stroke, it reverses direction. The distribution valve

then shifts and shuts off the fluidizing air to the first fluid

chamber as it applies a burst of air to the second uid cham-

ber and uidizes the powder in the second chamber.

The air induction orice (76) increases the air velocity prior

to injection point because of the orice and it prevents clog-

ging of the injector feed line.

NOTE: The restart valve (258) is a bleed valve which will stop

the pump and then restart the pump by re-initiating the time

delay cycle.

*NOTE: Use of other gases: Using only a gas to operate a 3”

pump can be rather expensive because of the high volume

needed. Separate air / gas inputs allow the uidizing feature

of this pump to utilize special inert gas, such as Nitrogen or

Argon (air), if necessary and still allow use of standard com-

pressed shop air for the pumping function.

The ability to introduce special gas also means special ma-

terials could be injected through the fluidization lines. Ap-

plications may include such materials as colorants, foaming

agents, additives, neutralizers, etc.

AIR AND LUBE REQUIREMENTS

EXCESSIVE AIR PRESSURE. Can cause pump

damage, personal injury or property damage. The

pump air supply must be limited to 50 psig (3.4 bar)

maximum inlet air pressure.

yThe air supply line or hose to the pump should be ad-

equately sized to carry a sufficient volume of air to the