PD30XĆXĆBPAGE 2 OF 8

OPERATING

AND SAFETY PRECAUTIONS

READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

EXCESSIVE AIR PRESSURE

STATIC SPARK

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

WARNING

EXCESSIVE AIR PRESSURE. Can ause personĆ

al injury, pump damage or property damage.

SDo not ex eed the maximum inlet air pressure as stated on the

pump model plate.

SBe sure material hoses and other omponents are able to withĆ

stand fluid pressures developed by this pump. Che k all

hoses for damage or wear. Be ertain dispensing devi e is

lean and in proper working ondition.

WARNING STATIC SPARK. Can ause explosion resulting

in severe injury or death. Ground pump and pumping system.

SUse the pump grounding s rew terminal provided. Use Aro

Part No. 66885Ć1 Ground Kit or onne t a suitable ground wire

(12 ga. min.) to a good earth ground sour e.

SSe ure pump, onne tions and all onta t points to avoid

vibration and generation of onta t or stati spark.

SConsult lo al building odes and ele tri al odes for spe ifi

grounding requirements.

SAfter grounding, periodi ally verify ontinuity of ele tri al

path to ground. Test with an ohmmeter from ea h omponent

(e.g., hoses, pump, lamps, ontainer, spray gun, et .) to

ground to insure ontinuity. Ohmmeter should show 100

ohms or less.

SSubmerse the outlet hose end, dispensing valve or devi e in

the material being dispensed if possible. (Avoid free streamĆ

ing of material being dispensed.)

SUse hoses in orporating a stati wire.

SUse proper ventilation.

SKeep inflammables away from heat, open flames and sparks.

SKeep ontainers losed when not in use.

WARNING Pump exhaust may ontain ontaminants. Can

ause severe injury. Pipe exhaust away from work area and

personnel.

SIn the event of a diaphragm rupture material an be for ed out

of the air exhaust muffler.

SPipe the exhaust to a safe remote lo ation when pumping hazĆ

ardous or inflammable materials.

SUse a grounded 1" min. i.d. hose between the pump and the

muffler.

WARNING

HAZARDOUS PRESSURE. Can result in serious

injury or property damage. Do not servi e or lean pump,

hoses or dispensing valve while the system is pressurized.

SDis onne t air supply line and relieve pressure from the sysĆ

tem by opening dispensing valve or devi e and / or arefully

and slowly loosening and removing outlet hose or piping from

pump.

WARNING HAZARDOUS MATERIALS. Can ause serious

injury or property damage. Do not attempt to return a pump to

the fa tory or servi e enter that ontains hazardous material.

Safe handling pra ti es must omply with lo al and national

laws and safety ode requirements.

SObtain Material Safety Data Sheets on all materials from the

supplier for proper handling instru tions.

WARNING EXPLOSION HAZARD. Models ontaining aluĆ

minum wetted parts annot be used with III.ĆTri hloroethane,

Methylene Chloride or other Halogenated Hydro arbon solĆ

vents whi h may rea t and explode.

SChe k pump motor se tion, fluid aps, manifolds and all

wetted parts to assure ompatibility before using with solĆ

vents of this type.

WARNING

MISAPPLICATION HAZARD. Do not use models

ontaining aluminum wetted parts with food produ ts for huĆ

man onsumption. Plated parts an ontain tra e amounts of

lead.

CAUTION Verify the hemi al ompatibility of the pump

wetted parts and the substan e being pumped, flushed or reĆ

ir ulated. Chemi al ompatibility may hange with temperaĆ

ture and on entration of the hemi al(s) within the

substan es being pumped, flushed or ir ulated. For spe ifi

fluid ompatibility, onsult the hemi al manufa turer.

CAUTION Maximum temperatures are based on me haniĆ

al stress only. Certain hemi als will signifi antly redu e

maximum safe operating temperature. Consult the hemi al

manufa turer for hemi al ompatibility and temperature limĆ

its. Refer to PUMP DATA on page 1 of this manual.

CAUTION Be ertain all operators of this equipment have

been trained for safe working pra ti es, understand it's limitaĆ

tions, and wear safety goggles / equipment when required.

CAUTION

Do not use the pump for the stru tural support of

the piping system. Be ertain the system omponents are

properly supported to prevent stress on the pump parts.

SSu tion and dis harge onne tions should be flexible onĆ

ne tions (su h as hose), not rigid piped, and should be omĆ

patible with the substan e being pumped.

CAUTION Prevent unne essary damage to the pump. Do

not allow pump to operate when out of material for long periĆ

ods of time.

SDis onne t air line from pump when system sits idle for long

periods of time.

CAUTION

Use only genuine ARO repla ement parts to asĆ

sure ompatible pressure rating and longest servi e life.

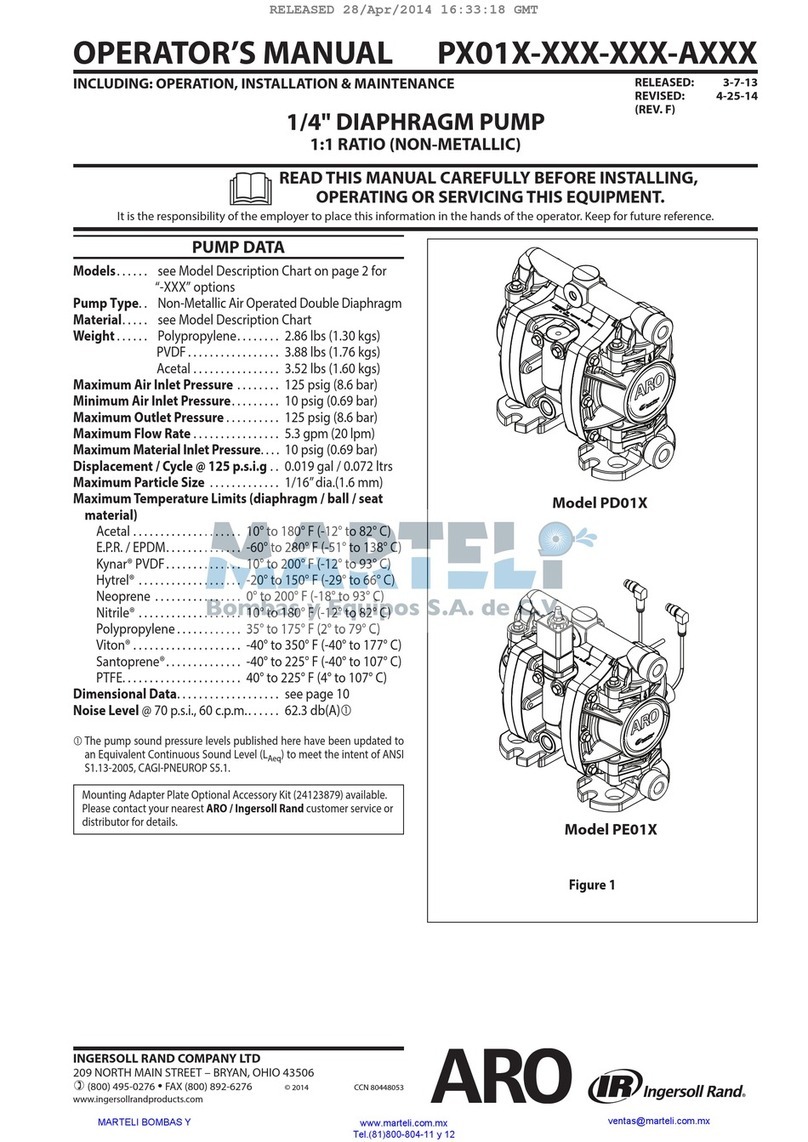

WARNING

CAUTION

NOTICE

= Hazards or unsafe pra ti es whi h ould

result in severe personal injury, death or

substantial property damage.

= Hazards or unsafe pra ti es whi h ould

result in minor personal injury, produ t or

property damage.

= Important installation, operation or

maintenan e information.