2

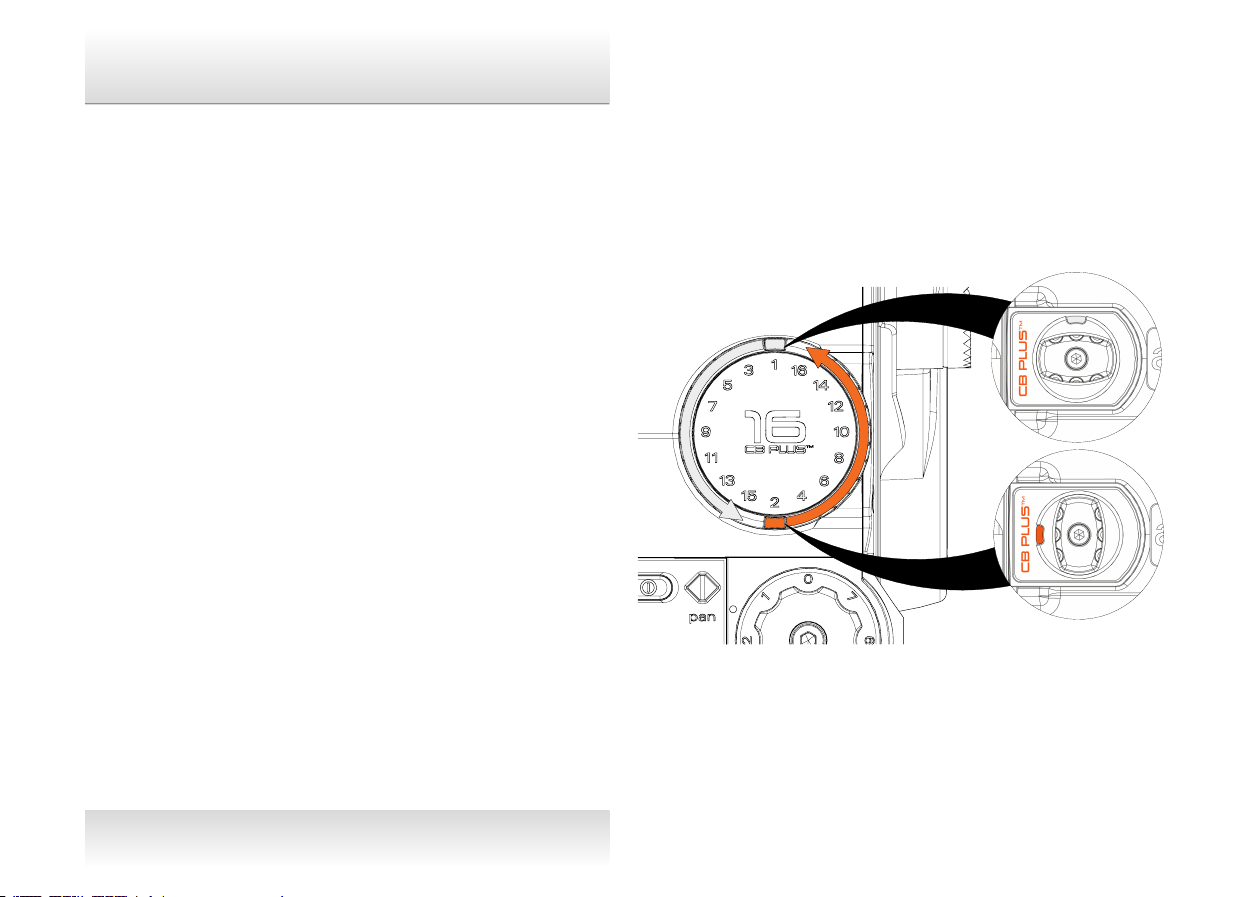

Fig. 2

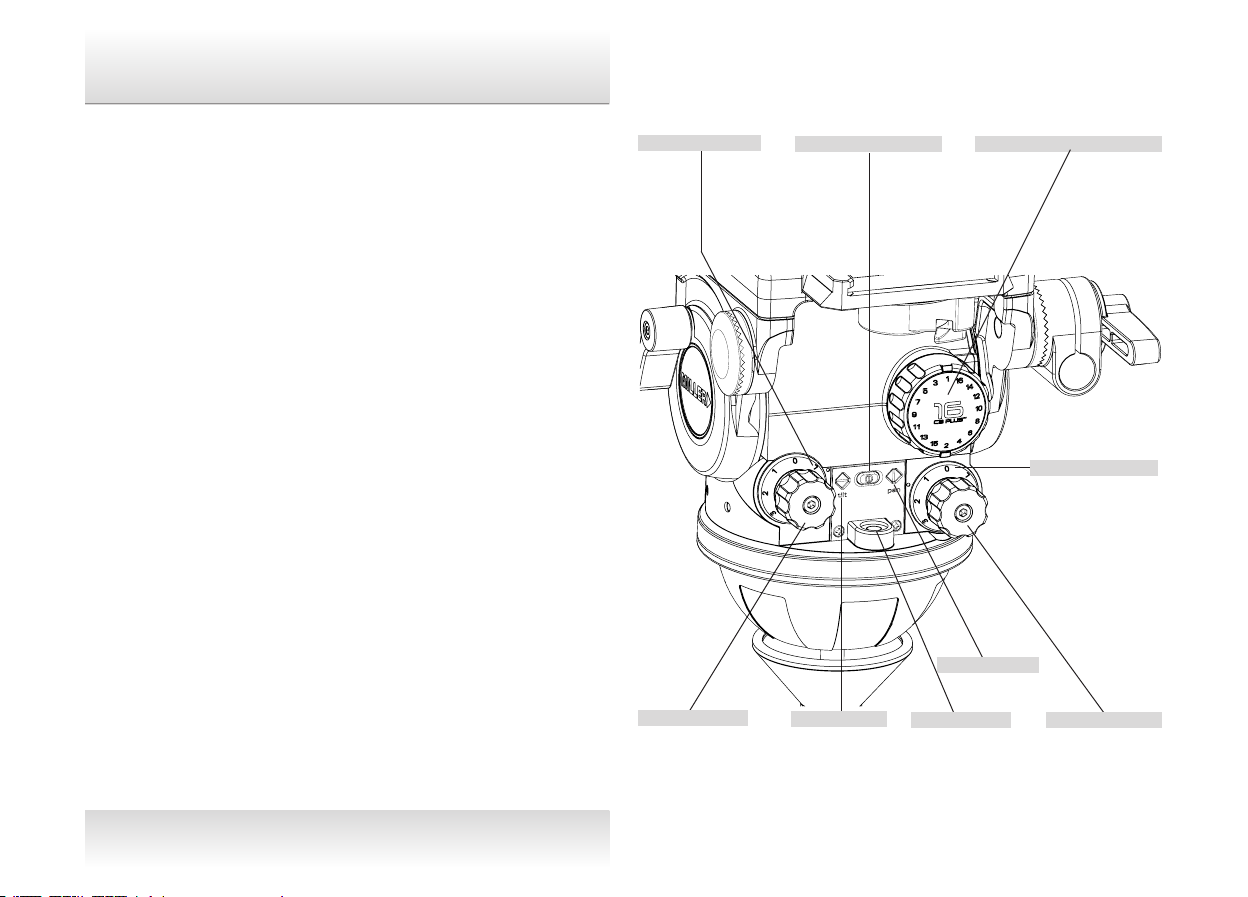

Thank you for purchasing the Arrow

x

Fluid Head. The Arrow

x

Fluid Head has been designed to suit a wide range of cameras,

lenses and accessories as demanded by ENG, EFP, Studio and

Field OB setups.

The robust design and construction of the Arrow

x

Fluid Head

offers maximum stability, accuracy and durability and includes

precision ball bearing mounted Fluid Drag Plate system in the

Pan and Tilt assembly to deliver true uid drag performance over

the entire temperature and payload range.

The Fluid Drag and the Counterbalance system were designed to

provide excellent control and repeatability and offer progressive

equal increments of drag and torque.

The Arrow

x

Fluid Head also offers Illuminated single control

location for operating Pan-tilt, Counterbalance and viewing

Bubble level.

The Arrow

x

Fluid Head will give best performance when used

on a wide range of Miller tripods, including SOLO ENG (#1505),

Sprinter II (#1589, #1580, #1576) and HD (#931) tripod. This will

ensure maximum system stability to suit any professional set-

up. The Arrow

x

Fluid Head will suit most industry standard 100

mm tripods as well, please refer to manufactures’ manual for

mounting details.

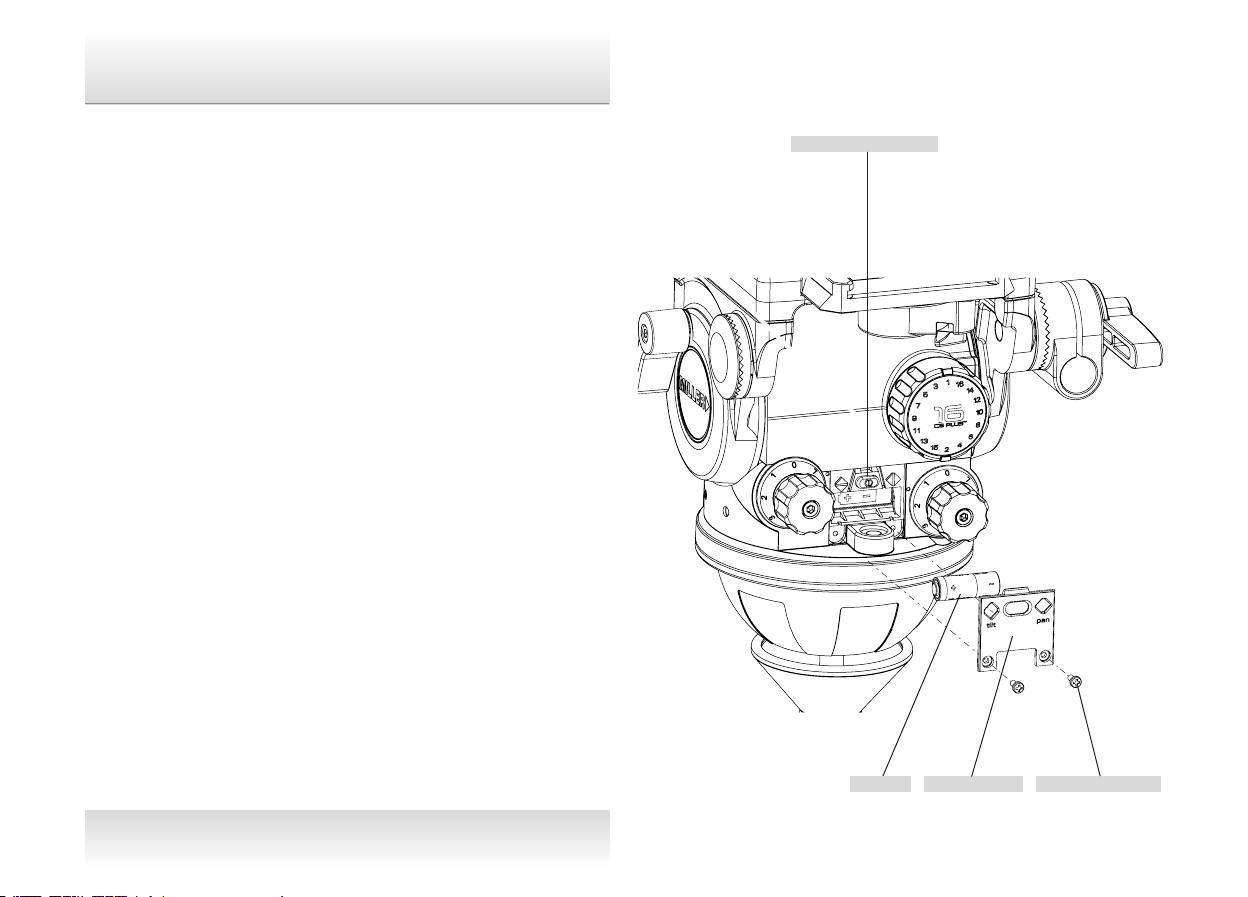

Introduction Safety Instructions

Attaching / removing the camera

Please use this manual to familiarise yourself with the operation

of the Arrow

x

Fluid Head and observe these instructions

to prevent any damage to your equipment. Ensure that all

equipment is operating correctly and free from defects and

damage, also please ensure that the tripod is steady, secure and

that the bowl is approximately horizontal when attaching the

camera. The operator is responsible for the safe operation of this

piece of equipment.

•Do not exceed the maximum payload capacity of the Fluid

Head.

•Do not leave the camera unattended on the Fluid Head.

•Do not release the SLIDING PLATFORM LOCK whilst the

camera is at an angle.

•Do not adjust the tripod whilst the camera is attached to the

Fluid Head.

•Ensure PAN HANDLE CLAMP and CLAMP NUT is securely

tightened.

•Apply TILT LOCK when adding/removing equipment from

the camera or when attaching/removing the camera from the

Fluid Head.

•Hold camera securely whilst changing Counterbalance, Pan

Drag or Tilt Drag settings.

•Hold the camera securely whilst releasing the QUICK

RELEASE KNOB.

•Hold camera securely whilst adjusting the CLAMP NUT to

level the Fluid Head.