ASAHI AGRU SP 63-S Mobile V3 User manual

Version May 2021 EN 3

agru SP 63 mobile V 3 User’s Manual

Contents

1 Introduction ...........................................................................................................5

2 Safety Messages...................................................................................................5

2.1 The User's Manual ................................................................................................5

2.2 Explaining Icons ....................................................................................................5

2.3 Safety Messages and Information on Remaining Risk .........................................6

2.4 User/Operator Obligations ....................................................................................7

2.5 Worksite Description .............................................................................................7

2.6 Warranty................................................................................................................7

2.7 Transport and Storage ..........................................................................................8

2.8 Identifying the Machine .........................................................................................8

3 Product Description and Principles of Operation ..................................................8

3.1 Intended Use.........................................................................................................8

3.2 Machine Description..............................................................................................8

3.2.1 Component Overview............................................................................................9

3.2.2 Control Unit with Touch Screen.............................................................................9

3.2.3 Specications ......................................................................................................10

3.3 Welding Process Overview .................................................................................10

4 Operation ............................................................................................................11

4.1 Check-out, Turning on, Selecting the Display Language ....................................12

Zeroing the Position of the Movable Carriage.....................................................14

4.2 ConguringtheMachine .....................................................................................14

4.3 Changing Key Parameters of the Welding ..........................................................16

4.4 Entering Traceability Data for the Joint ...............................................................17

4.5 DenitionofWeldingParametersforAdditionalMaterials ..................................18

4.6 Fastening the Mechanical Structure of the Machine ...........................................19

4.7 Welding Process .................................................................................................20

4.7.1 Facing the Component Butts...............................................................................20

4.7.2 Checking Alignment ............................................................................................22

4.7.3 Inserting the Heating Element with or without Preheating ..................................22

4.7.4 Heating Stage .....................................................................................................22

4.7.5 Change-over Stage .............................................................................................23

4.7.6 Joining Stage ......................................................................................................23

4.7.7 Cooling Stage......................................................................................................23

4.7.8 End of Welding....................................................................................................23

4.8 Additional Preparatory Steps for Overhead Welding Operations........................24

4.9 Aborted Welding Process....................................................................................25

4.10 Indication of Joint Status and Possible Errors on the Tag...................................26

5 Printing Pipe Labels and Downloading Welding Reports....................................27

5.1 Downloading Welding Reports to a USB Stick....................................................27

5.2 Showing Reports in Memory, Printing Pipe Label Tags.......................................27

5.3 Using the Extended Report Viewer .....................................................................28

5.3.1 Viewing the Full Welding Report .........................................................................29

5.3.2 Ongoing Job Reporting Scheme and Statistical Overview..................................29

5.4 Deleting Reports from Memory ...........................................................................29

6 System Data........................................................................................................29

6.1 System and Maintenance Information.................................................................29

6.2 Enabling Automatic Heating ................................................................................29

6.3 Service and Repair..............................................................................................30

7 Service and Repair Contact ................................................................................31

7.1 Manufacturer Warranty........................................................................................31

7.2 Technical Documentation ....................................................................................31

7.3 Risk Assessment.................................................................................................31

Version May 2021

4 EN agru SP 63 mobile V 3 User’s Manual

Caution

The machine has to be operated exclusively with

a power supply line equipped with a protective

grounding conductor, as a power supply without

this safety element may cause severe machine

damage. If the machine is operated through a

power supply without a grounding conductor,

this will void any and all warranty under which

the product may be.

Version May 2021 EN 5

agru SP 63 mobile V 3 User’s Manual

1 Introduction

Dear Customer:

Thank you very much for purchasing our product. We are confident that

it will meet your expectations.

The development, manufacture, and check of the mobile, i. e., overhead-

welding-enabled, infrared butt-welding machine for thermoplastics has

been guided by our concern to offer a unit characterized by superior

operation safety and user-friendliness. The unit was manufactured and

checked according to the most recent standards as they are applied, and

bearing ergonomic aspects in mind.

To ensure maximum operation safety, please conform to the appropriate

messages in this booklet and the regulations for the prevention of acci-

dents. Carefully read the User’s Manual to avoid damage to the machine

or hardware in its environment as well as injury.

This manual is applicable to the following machines:

agru SP 63 mobile V 3

Thank you.

2 Safety Messages

This User’s Manual contains important instructions for operating the in-

frared welding machine for thermoplastics safely. Every person who oper-

ates the machine will have to conform to the instructions of this manual.

The machine has been developed and checked with respect to welding

agru pipes and fittings. For welding other makes, no experiential data are

available and/or no liability or warranty can be assumed for the fitness

and the reliable operation of the machine.

2.1 The User's Manual

The User’s Manual is presented according to sections which explain

the different functions of the machine. All rights, in particular the right to

copy or reproduce (in print or electronic form) and distribute as well as

to translate, are reserved and subject to prior written authorization.

2.2 Explaining Icons

The following expressions and icons are used in this User’s Manual to

refer to safety-related issues:

Caution

This icon indicates that non-compliance may result in a haz-

ardous situation that possibly causes bodily injury or material

damage.

Important

This icon indicates important messages related to the correct

use of the machine. Non-compliance may cause problems of

operation and damage to the machine.

Info

This icon indicates tips and useful information for using the

machine more efficiently and more economically.

Version May 2021

6 EN agru SP 63 mobile V 3 User’s Manual

2.3 Safety Messages and Information on Remaining Risk

Protect the power supply cord from cutting edges. Have an authorized

service shop replace damaged cables or lines immediately.

The machine has to be operated with a 230 V, 50/60 Hz power supply with

safety fuse or breaker of 16 A maximum. If power is connected through

a power line manifold, the power supply has to feature an earth-leakage

circuit breaker.

Use only extension cables with the following conductor sections:

– max. length of cable 25 m (80 ft) min. section 2.5 mm²

– max. length of cable 50 m (160 ft) min. section 4.0 mm²

Caution

Parts Under Power

After opening the machine or removing the cover, parts of it

are accessible that may be under power. The machine may be

opened exclusively by an authorized service shop and only

after it was disconnected from power.

Caution

Pipe Facing Tool

Start the pipe facing tool only when it is in its working position.

When facing pipes, do not wear jewellery; if needed, wear a

hair snood or net. It is forbidden to remove shaving from the

machine while the facing process is running. Make sure nobody

is present in this danger zone.

Caution

Heating Plate and Heating Plate Housing

When working with the machine, be extremely cautious while the

heating plate is operating. Since the plate and its housing guard

present a very high temperature during the welding process, it

must not be operated if unobserved, and sufficient distance to

combustible materials in its surroundings has to be ensured.

Do not touch the heating plate or the plate housing. The safety

alerts affixed to it have to be complied with strictly.

Caution

Danger of Bruises and Injury

Do not remain in the danger zone while the machine opens or

closes and be sure not to have your hands between the moving

and the fixed parts of the machine.

Caution

Acceptable Work Conditions

The work zone has to be clean and has to have proper lighting.

It is dangerous to operate in a humid environment or close to

flammable liquids. In regard of this, acceptable work condi-

tions have to be ensured (e.g., sufficient distance between the

machine and other functional areas of the workshop).

Overhead work is prohibited, unless:-

• themachineissafelyandsecurelyfastenedandpositioned;

• accesstoalargeareaaroundtheworksiteiscontrolled/limited

•(risk of falling objects); see also Sect. 2.5;

• ahardhatandsafetygogglesareworn(riskoffallingobjectsand

•small blades of shaving during component facing)

• properprotection(e.g.,byshieldingmembranesorfoils)against

•humidity, draughts or airflow if there is any risk that they should

•appear

Important

Power Supply Only through Line with Protective Grounding

Conductor

The machine has to be operated exclusively with a power supply

line equipped with a protective grounding conductor, as a power

supply without this safety element may cause severe machine

Version May 2021 EN 7

agru SP 63 mobile V 3 User’s Manual

damage. If the machine is operated through a power supply

without a grounding conductor, this will void any and all

warranty under which the product may be.

Important

Power Only to Operational Machine

Power must never be applied to the machine before it is com-

pletely installed and ready for operation.

Info

User’s Manual

The User’s Manual has to be available at any time on the site

where the machine is used. If the User’s Manual should come

to be incomplete or illegible replace it without delay. Feel free

to contact us for assistance.

2.4 User/Operator Obligations

• Themachinemaybeoperatedexclusivelybypersonswhoarefa-

miliar with the applicable rules, the guidelines for the prevention of

accidents, and the User’s Manual.

• Themachinemaybeoperatedonlywhenobserved.Onlypersons

who were properly trained by agru or another, authorized organi-

zation and whose training was acknowledged by the appropriate

certificates are allowed to operate and observe the machine. Other

persons must neither operate nor observe it.

• Theoperating/owningorganizationengagestocheckatreasonable

intervals if the machine is operated by the users with the intended

use and under proper guidelines of safe work.

• Themachinemustneverbeoperatedifnotinproperstateofrepair.

Before welding, the user is required to make sure that the state of

the machine is in order.

• Theuserhastomakesurethatonlyonepersonispresentinthe

zone where the machine is operating.

2.5 Worksite Description

• Theconditionshavetofullyensurethatthemachinecannotslide.

As well the segments of the base plate as the mechanical structure

and the base plate have to be securely connected to each other

before any components are clamped fast. In case of (overhead)

welding operations using the mechanical structure without the base

plate, the welding mechanics has to be securely fastened at the

components to be jointed with the supplied belts.

Important

For an overhead operation, the full weight of the mechanical

structure has to be carried by the belts. “Hanging” it from

the components to be jointed, so the clamps would carry its

weight, is prohibited.

• Worksiteaccesslimitationshavetobeprovided.Appropriateequip-

ment to achieve this can be requested from a service point or the

selling entity.

2.6 Warranty

Warranty claims may be raised only if the conditions for warranty given

in the General Terms and Conditions of Sale and Shipment obtain. One

precondition is that proper maintenance according to the required sched-

ule (see Sect. 6.3) is ensured.

Info

The term of warranty under which the welding machine is

shipped is 12 months:-

— from the date of purchase, if the machine is bought as a new

—machine;

Mobile Stumpfschweißmaschine

Typ agru SP 63 mobile V 3

Geräte-Nr. 06421123

Netz 230V 50Hz 1700W IP54

Gewicht ca. 49 kg Baujahr: 2021

Lizenzhersteller

HÜRNER Schweißtechnik GmbH

Nieder-Ohmener Str. 26

D - 32325 Mücke

Typ agru SP 63-mobile

Exklusives Produkt der Fa.

agru Kunststofftechnik GmbH

Ing.-Pesendorfer-Str. 31

A - 4540 Bad Hall

Tel. +43 7258 7900

Fax +43 7528 3863

Version May 2021

8 EN agru SP 63 mobile V 3 User’s Manual

— from the date of first use, if the machine is used independently

—of purchase (e.g. when lent) or if it is not bought as a new

—machine.

2.7 Transport and Storage

During transport, the machine must be at all times in the transport box

it is shipped in.

Important

Ensure that the heating plate, the facing tool, and all movable/

removable parts of the machine are safely stowed away and,

if applicable, secured with the transport lock during transport

at all times (see explanations and figures in Sect. 4.1).

The transport box should also be used to store the machine. The machine

has to be stored in a dry location, be clean or has to be cleaned, and be

locked against unwanted operation.

2.8 Identifying the Machine

Each machine is identified by a name plate. It shows the machine

model (“Typ”), its year of manufacture (“Baujahr”), the serial number

(“Geräte-Nr.”), the rated power (“Netz”), and the manufacturer (“Lizenz-

hersteller”).

3 Product Description and Principles of Operation

3.1 Intended Use

The agru SP 63 mobile V 3 Welding Machine is designed exclusively for

welding thermoplastic pipes and fittings using the butt-welding process

with plasticization by infrared beams.

Only the welding parameters shown on the screen display (prepro-

grammed by the manufacturer or defined by the user) can be selected

for a welding operation. If a modification of preinstalled parameters os

needed exeptionally, contact agru Kunststofftechnik.

It is also part of the intended use to conform to the instructions provided

in the User’s Manual.

Important

The manufacturer can in no circumstances be held liable for

damage or consequential damage that occurs as a result of the

non-compliance with the procedures described in the User’s

Manual, the modification of the manufacturer-programmed

welding parameters, or non-intended use. Any such deviation

or modification will void any and all warranties under which the

product may be.

3.2 Machine Description

The machine can be used as an in-shop installation, and with anodized

aluminum and stainless steel components, it is also suited for clean

room applications. The machine enables users to enter the data that are

relevant for the welding process and for the traceability of the welded

joint. From the entered welding parameters, it calculates automatically

the applicable forces, times, and temperatures and controls the semi-

automatic welding process.

All welding and traceability data are entered either directly at the machine

on its touch screen or read from a transponder card by the transponder

reader. The welding process in monitored in its entirety and saved to

Version May 2021 EN 9

agru SP 63 mobile V 3 User’s Manual

a welding report. All welding reports can the be downloaded to a USB

stick as an abstract, an extended report or as a DataWork database file.

Using the menus displayed on the touch screen, the machine can be

customized to the application in hand (see section 4.3).

3.2.1 Component Overview

3.2.2 Control Unit with Touch Screen

Heating Element and Guard

Housing

Facing Tool

Clamps

Dedicated Base Plate for Fac-

ing Tool and Heating Element

Fixed and Mobile Carriage of

Machine Frame

Locking Ball Pin to Secure

Base Plates to Each Other

RFID Transponder Reader

Control Unit with Control Touch Screen

Support Bracket für Facing

Tool and Heating Element

Thumb Screws for Locking

the Outer Clamp

(analogous on the other carriage)

Buzzer (at the front)

Heating Element Connector

(at the back)

Locking Ball Pin to Secure

Base Plates to Each Other

RFID Transponder Reader

Touch Screen Display

Version May 2021

10 EN agru SP 63 mobile V 3 User’s Manual

3.2.3 Specications

agru SP 63-mobile

Power Characteristics

Voltage

Frequency

Total Rated Power

Heating Element

Electrical Cordless Power Facing Tool

Charger for Power Facing Tool

230 V

50/60 Hz

1.7 kW

1.38 kW

18 V, 5.2Ah (on battery, w/ 2 batteries)

220 - 240 V AC, 50/60 Hz, 0.085 kW

Welding Operation Specs

Welding Force

Speed of Cordless Facing Tool

Ambient Temperature (operation)

Ambient Temperature (storage)

Operating Range

Travel Stroke of Movable Carriage

10 - 500 N

approx. 66 rpm (in 2nd gear, speed set to max.)

+ 10°C to + 40°C (50°F to 104°F)

– 5°C to + 50°C (23°F to 122°F)

20 - 63 mm (3/4" - 2-1/2")

approx. 115.5 mm (4-1/2")

Dimensions and Weight

Dimensions (W x D x H)

Mechanical Assy (carriage moved apart)

Electronic Assembly

Mechan. & Electron. on Base Plate

Dedic'ed Base Pl. w/ Facer/H. Elem.

Transport Case

Weight

Mechanical Assembly

Electronic Assembly

Mechan. & Electron. on Base Plate

Facing Tool

Heating Element

Dedic'ed Base Pl. w/ Facer/H. Elem.

Transport Case (w/ mach., access.)

Transport Case, emptyx

544 × 160 × 348 mm (21-7/16" × 6-5/16" × 13-21/32")

300 × 251 × 237 mm (11-7/8" × 9-7/8" × 9-11/32")

575 × 376 × 385 mm (22-5/8" × 14-25/32" × 15-5/32")

260 × 347 × 313 mm (10-1/4" × 13-21/32" × 12-11/32")

800 × 600 × 608 mm (31-1/2" × 23-5/8" × 23-15/16")

15.1 kg (33.2 U.S. lbs)

8.9 kg (19.6 U.S. lbs; on base plate)

33.2 kg (73 U.S. lbs)

4.6 kg (10.1 U.S. lbs)

3.9 kg (8.6 U.S. lbs)

15.3 kg (33.7 U.S. lbs)

89 kg (196 U.S. lbs)

30 kg (66 U.S. lbs)

3.3 Welding Process Overview

The welding process is performed as follows:

Important

Prior to welding, the mechanical structure of the machine has

to be secured, either to the base plate or to the components

to be jointed (see Sect. 4.6).

Connector for Power Cord to

Label Tag Printer

USB Interface

(to connect USB stick or tag printer)

Mains Socket & On/Off Switch

Emergency Stop Switch

Connector for Mechanical

Welding Chassis (control cable to

connector on back of control cabinet of

mechanics)

Status Bar (with product name, welder,

and current moment in time)

Screen Title Line

Touch Screen

Design Navigation Bar with

Control and Menu

Buttons

Area Showing Content Depend-

ing on Context (welding progress,

input keyboards, messages, etc.)

Version May 2021 EN 11

agru SP 63 mobile V 3 User’s Manual

• Thefacingtoolisinsertedbetweenthecarriages,intoitsposition

for clamping the components in the machine, and the clamps them-

selves are adjusted to the spacer pins of the facing tool.

• Thecomponentsareclampedandthefacingdistanceisadjusted.

• Thefacingtoolismovedtoitspositionforfacing.

• Pipeendsareworkedusingthepipefacingtooluntilacontinuous

blade of shaving material forms.

• Pipealignmentischeckedandconfirmedbythewelder.

• Insertionoftheheatingelement;wheninsertingit,theheatingele-

ment has to be clean.

• Aftertheheatingelementwasinserted,closinginthemovablecar-

riage is confirmed, and the pipes close in at the predefined force.

• Whenthecarriagesclosein,theyalsoaligntheheatingelement

exactly in-between the pipe butts.

• Thepipebuttsarethenheatedtothepredefinedtemperature.

• Whentheheatingphaseisover,thepipesaremovedapartauto-

matically to allow for manually removing the heating element.

• Oncetheheatingelementremovalisconfirmed,thepipesclosein

on each other again.

• Thisisfollowedbyasteadyforceincreaseuntilthefusionforceis

reached.

• Thepipethencoolsdownatthepredefinedforce.

• Afterthecoolingtimeisover,theforceisautomaticallyremoved

from the carriages and the pipe or fitting can be taken out of it.

4 Operation

Before putting the machine into operation, review the transport locks and

safety auxiliaries as well as the way the machine is set into its transport

box. Whenever the machine is moved or shipped, it has to be set into

this box and all locks and auxiliaries have to be engaged. The figures

below help with understanding the transport helpers.

Important

Whenever transported, the roll of labels in the printer has to

be removed and the batteries, placed into the cardboard box.

Mechanics and

Electronics on Base

Plate

Tabletop Plate with

Heating Element in it

Guard

Case with

Reducer

Inserts

Cardboard Box for

Facing Tool Batteries

Box for

Extension Cord,

User's Manual

and Other

Accessories

Facing Tool

Label Tag Printer

Charger for Fac-

ing Tool Battery

Version May 2021

12 EN agru SP 63 mobile V 3 User’s Manual

Info

When installing the reducer inserts, place the narrower inserts

into the inner clamps, the broader inserts, into the outer clamps.

The insertion and the removal of the inserts is performed with-

out any tools. The reducers are secured to the clamps by the

force of the magnets only.

4.1 Check-out, Turning on, Selecting the Display Language

Place the machine on a level surface and ensure it cannot slide or secure

it safely at the components to be jointed. Sufficient distance has to be kept

to other areas in the workshop, especially to those in which combustible

materials are used, in order for the heating element temperature of up

to 500°C (930°F) not to be hazardous. When starting the machine up,

remove the transport locks before applying power to the machine if it was

transported before start-up and the locks were engaged. Furthermore,

if the label tag printer ist planned to be used later on, connect it to the

machine and insert the roll of labels before the first welding operation.

Independently of the order of the explanations in this booklet, the steps for

setting the machine up and preparing everything for welding are always

performed in the following order (see the following figures for reference):

1. Open the transport box.

2. Loosen the transport lock pole using the the star knob.

3. Take the dedicated plate for the facing tool and heating element out

of the box, set it on a level surface, making sure it will not slide, and

remove the transport lock of the heating element.

4. Take the base plate with the electronics and the mechanics out of

the box, set it on a level surface, making sure it will not slide, and

remove the transport lock of the movable carriages from in-between

the carriages (unlock the locking ball pin and remove it, then slide

the transport lock out of its seat in the opposite direction).

5. Take the facing tool out of the box and set it on its tabletop plate.

6. Take the battery charger out of the transport box.

7. Take the battery out of the carboard box, check the battery level

and charge the batteries as needed.

8. Connect the mechanics and the heating element to the electronic

control unit.

9. Connect the V-lock power cable to its socket and the mains.

10. Switch the machine on and zero the movable carriage position.

11. Insert the reducers into the clamps.

Inside view of the case for the

reducer inserts

Star knob (1 of 2) securing

the base and tabletop

plates, and transport lock

(self-locking pin, right

edge of drawing) of heating

element

Transport lock of carrier bracket

for facing tool and heating

element and of movable

carriage (locking ball pin as the

locking item on the other side of

the bar)

Version May 2021 EN 13

agru SP 63 mobile V 3 User’s Manual

Depending on the piece that is going to be welded, the outer clamps

may have to be repositioned or removed. To do so, loosen the locking

thumb screws and either remove the clamp or re-adjust it and secure it

by tightening the locking screws again.

If the diameter of the pieces to be welded is smaller than the clamp, insert

the reducer inserts. This can be done without using any tools since the

inserts are fastened in the clamps by magnetic attraction.

Important

Pipe clamps and reducer inserts have to be clean or must be

cleaned before welding starts. To insert or remove the inserts,

do not use heavy tools (hammer, wrench). They may damage

the inserts and the magnets.

Important

The surfaces of the heating plate have to be free of grease and

clean, or they have to be cleaned. Clean the heating element

only when it is cold. Refer to a service point for detailed infor-

mation on the procedures for cleaning the heating element.

Important

Make sure all connectors are tight in their sockets and make

sure that the machine is operated only if the conditions for safe

and intended use are met (see also section 2).

After preparing the machine for welding and con-

necting the power supply cord to the mains power

supply, the machine is turned on using the On/

Off switch. The welcome screen, as reproduced

in Display 1, appears on the touchscreen panel.

Touch the appropriate button to select the display

language that the machine will use. If needed,

the system clock will then have to be set, in

which case the relevant screen is displayed (see

Display 24).

After the language was selected, the machine

takes the user to the welder code input screen.

Without a valid welder identification code, the machine does not move

on to the preparation of welding and the welding process, since working

with the machine without a welder identification is prohibited.

Read the welder from a transponder card by

RFID. If no card with the welder identification

code is available, it can also be typed on the

keypad and saved to memory by touching the

button.

Info

All inputs for which a transponder card

is available can be entered by holding

the card in front of the RFID reader.

Info

Depending on the software version in-

stalled in your machine, some screens

may differ slightly on your machine from

the reproductions in this manual.

When the welder code was entered, the movement position of the movable

carriage has to zeroed (see below). Then the machine displays the so-

called default screen (see Display 3). In this display, it is possible to start

the welding process and to customize the configuration of the machine.

Display 1

Display 2

Version May 2021

14 EN agru SP 63 mobile V 3 User’s Manual

The welder will enter all settings and perform all control actions on the

touchscreen panel.

Zeroing the Position of the Movable Carriage

Important

Without zeroing the reference position of the movable carriage,

proper welding is impossible. Therefore, zeroing will be skipped

only when the machine remains at the same spot for the next

welding and no emergency stop was triggered. Zeroing the

carriage is required and cannot be skipped after the machine

was turned on or the emergency stop switch was pressed.

To zero the carriage position, the facing tool has to be removed from

in-between the carriages if it still is positioned between them — the

machine prompts on the screen to do so — , and the button must

then be pressed for confirmation. If the spacer pins of the facing tool are

placed in the recesses of the carriages and possibly refuse to slide out,

press the button. Then, the movable carriage can be moved apart

by pressing the carriage mover button (see the “Important” note at

the beginnig of Sect. 4.7).

The same holds for the heating element. If it is still set on the carrier be-

tween the two carriages of the machine, the user is requested to remove

it. Only after the removal was confirmed by pressing the button,

the process continues.

The same query appears again for the pipes/components that might still

be in the clamps from the last welding operation. They, too, have to be

taken out of them, which has to be confirmed by the button.

When the welder confirms that there are no pipes in the clamps, the

machine asks that the movable carriage be closed in on the fixed one

by holding down the carriage mover button , just as for facing, heat-

ing or joining, until the message “Zero point adjustment” appears on the

screen. When this message is showing, the machine determines the zero

point of the movable carriage as compared to the position of the fixed

carriage, that will apply for the next welding.

When this reference position/zero point was automatically zeroed and

saved to memory in the control unit, the machine asks the welder to

move the carriage apart, which indicated that the machine has now been

zeroed. To move the carriage apart, press the button. The machine

returns to the default screen (see Display 3). Welding can now be started

or parameters can be edited.

4.2 ConguringtheMachine

In the default screen (Display 3), the key param-

eters of the last welding are shown (material,

diameter, and wall thickness along with SDR

rating of the welded pipe). The following current

values show, now or only later, after the welding

was started, along the bottom edge of the screen:

heating element temperature, applied force, input

voltage and current, ambient temperature.

In Display 3, the welder has the possibility to:

• immediatelystartaweldingprocessusing

the same welding parameters as the previ-

ous welding (touch the button and move on to section 4.6);

• enter new component-related and traceability data and another

welder ID code for the next welding (touch the button and

move on to Section 4.3);

Display 3

Version May 2021 EN 15

agru SP 63 mobile V 3 User’s Manual

• changethemachinesettingsintheconfigu-

ration menu (touch the button);

• displayinformationontheweldingsystem

itself and its maintenance/service status

(touch the button and see Sect 6.2 for

reference);

• viewtheoperator’sguidelinesforthejoint-

ing of thermoplastic components (touch the

button; see Display 4 for reference).

Info

Other functionalities that are called

when the default screen is showing, are

explained below in this booklet, includ-

ing how to call them from this screen.

After the button was pressed, the part of the configuration menu

available to all shows. Use the arrow button at the bottom of the menu bar

at the right-hand edge of the screen to browse through the pages of the

configuration menu. The menu has the items listed in the following table.

In the menu, the button depicted at an option means that touching it

will open a submenu in which the configuration itself can be customized.

For functions that the user can enable or disable at their own discretion,

the (on) and (off) buttons indicate the current status. Touching

the button will toggle the function from one to the other state.

Any changes in the configuration menu are saved to memory and will

be used by the machine in the future when the respective configuration

option or the entire menu is quit by pressing the button.

Designation Setting Description / Data to be entered

Report View In a sub-menu, a welding operation can be selected in a list to

display the report recorded of that operation. From this screen, it is

also possible to print a label tag for this welding once again (see

section 5.2).

Select Number of

Labels

In a sub-menu, the number of´label tags (0 - 3) to be printed after

welding for purposes of identification, can be selected.

Select Unit of Length In a sub-menu, the unit of length used for displaying welding data

can be selected: millimeters or inches.

Select Temperature

Unit

In a sub-menu, the temperature unit used for displaying welding data

can be selected: centigrade or degrees Fahrenheit.

Buzzer if ON: The audible signal that validates certain steps in the process

is turned on;

if OFF: At the end of the respective steps no signal can be heard.

Set Volume of

Buzzer

In a sub-menu, the volume of the audible signal that the machine

emits to validate the execution of a given step in the process can be

set.

Automatic Heating In a sub-menu, a time, for instance on the following morning, can be

pre-set when the heating element will start heating up automatically

(see sub-section 6.2).

New Report View if ON: The Report View option of the menu calls an extended and

more powerful report view, which allows in-depth assessment and

analysis (this report view requires entering a Supervisor Code that

authorized persons, e. g. a project manager, can set and enter

themselves);

if OFF: The Report View option of the menu calls the standard, less

detailed report view of welding operations (this report view is also

displayed if the option is enabled, but the entered access code for

the new, extended report review is entered incorrectly).

Display 4

Version May 2021

16 EN agru SP 63 mobile V 3 User’s Manual

Bead Force while

Welding

if ON: During welding, the diagram depicted on the screen

represents the force exercised on the welding bead (i. e., for

instance, no force in the heating stage, as the applied force is not

exercised on the bead);

if OFF: The force depicted by the diagram in the course of the

welding process is the value exercised on the force transducer.

Select Language In a sub-menu, the display language of the machine can be selected

(see Display 1 for reference).

Automatic Mode if ON: steps of the process where the movable carriage of the

machine actually moves can be performed by starting its movement

using the carriage mover button in the lower left corner of the

screen; once started, the movable carriage will move to the left or to

the right for the proper duration computed by the machine for the

currently ongoing welding process step or available in the recorded

process data of a previous welding operation (see the “Important”

note at the beginnig of Sect. 4.7);

if OFF: steps of the process where the movable carriage moves re-

quire the carriage mover button to be used as an on-demand switch,

i. e., to be maintained in the pressed state for the full duration for

which the carriage is meant to move to the left or to the right. In this

event, it is under the welder's responsibility to monitor the duration

of the movement and the position of the moving carriage.

While the configuration menu is being displayed, two more buttons can be

seen in the navigation bar at the right-hand edge of the screen. The

button gives access to the system settings of the welding machine. They

are meant for specialized staff supposed to set up, service or, if failed,

repair the machine; therefore, they are not described in this booklet.

Just as the system settings, the extended operation settings of the

welding system, which can be accessed by touching the button,

are protected by a second access code, which will be disclosed only to

supervising staff with the operator. The parameters below can be custom-

ized in the extended set of settings after entering that code.

Designation Setting Description / Data to be entered

Memory Control if ON: The machine refuses further welding operations when the

memory is full;

if OFF: The machine overwrites the oldest report when the memory

is full.

Set Date/Time In a sub-menu, date and time can be set, provided no service of the

machine is currently due.

Delete Reports In a sub-menu, it is possible to delete all welding reports currently in

memory; the reports will be deleted only after another tweo safety

warnings were confirmed.

Enter Additional

Parameters

In a sub-menu, the characteristic welding parameters can be defined

for product/materials that are not available in the control software.

Enter Inventory

Number

In a sub-menu, the identifier can be entered by which the machine

has been entered in the inventory of its operator.

4.3 Changing Key Parameters of the Welding

In the default screen (see Display 3), it is possible

to change the specific parameters for the joint to

be welded. To do so, press the button. The

screen that allows selecting the material of the

components that are going to be welded, is then

displayed on the screen (see Display 5).

Info

The first selection screen may comprise

not only component materials, such as

PVDF or PP, but also so-called prod-Display 5

Version May 2021 EN 17

agru SP 63 mobile V 3 User’s Manual

ucts. A product is a parameter set of technical welding param-

eters either in memory ex works or defined by the user (see

Sect. 4.5 for reference); one of the parameters of the set is the

material of the component. In user-defined parameter sets, the

product name is at the user’s discretion. If one product has sev-

eral thermoplastic materials for which welding parameters exist

in memomry, after selecting that product the user is prompted

to select the material used in the upcoming welding operation.

If there is only one material for it, the machine moves on to

the diameter selection screen, just as after the selection of a

material rather than a product on the first selection screen.

To select a product or a component material, touch the appropriate button

on the screen. Analogous screens will follow that allow selecting, for the

component that is going to be welded, its diameter, its wall thickness,

and its SDR value. After every selection made, the machine switches to

the next selection screen.

Standard products/materials can be selected on those screens. Further-

more, the machine enables the jointing of additional products/mateirals,

i. e., additional parameter sets of characteristic welding data which are

either defined as additional parameter sets ex works before the machine

ships or set up by the user themselves (see Sect. 4.5).

Additional parameter sets are under an access code that has to be en-

tered and confirmed by touching the button, as soon as they are

accessed using the additional-parameter button . To whom this code

is disclosed is at the machine operator’s discretion.

The Product/Material or Material selection screens will always be show,

even if there is only one material or product in memory. All other selec-

tion screen appear only when a selection is actually possible. If, e. g.,

there is only one diameter in memory for a given material, no diameter

selection screen will be displayed.

Important

The machine must never be used to weld pipe materials, diam-

eters, and thicknesses other than those available in the welding

parameter screens. The manufacturer is in no circumstances

liable for damage or consequential damage that occurs as a

result of deviations from these pipe data or of modifications or

attempted modifications to the control software. Furthermore,

this will cancel any claims to warranty expressed for the ma-

chine. To make a material available in this screen, it has to be

entered previously with all its technical welding parameters in

the configuration menu.

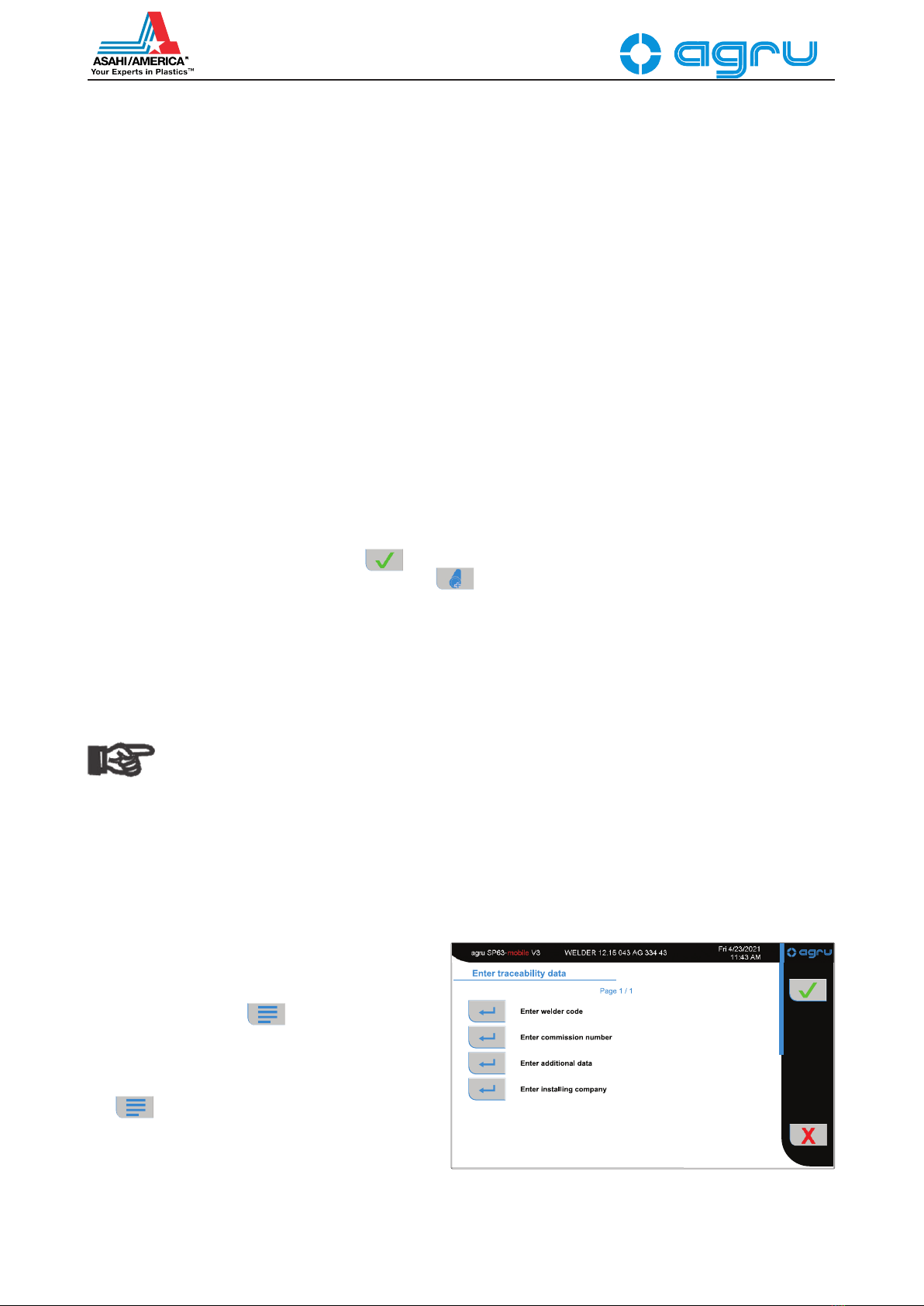

4.4 Entering Traceability Data for the Joint

On the screens that allow changing the techni-

cal parameters for the upcoming welding opera-

tion, by touching the button, it is possible

to access the traceability data for the joint and

change them as needed (see Display 6).

Independently of accessing them by touching

the key, the welder identification code has

to entered after switching the machine on (see

Sect. 4.1 and Display 2), as no welding operation

is allowed without a valid welder code.

The machine displays a menu that allows selecting the traceability

information to be changed (see Display 6). You can confirm all cur-

Display 6

ATH-7701-238-RT-990129

Version May 2021

18 EN agru SP 63 mobile V 3 User’s Manual

rent data — those from the previous welding — by simply touching

the button.

Change any data that require modification by touching the key at

the appropriate menu option. Depending on the kind of data you want to

change, the machine displays either a numeric keypad (see Display 2)

or an alphanumeric keyboard (see Display 7). To confirm and save your

data input to memory on the data input screen, touch the button.

4.5 DenitionofWeldingParametersforAdditionalMaterials

The extended set of settings in configuration

menu (see section 4.2) has an option “Enter Addi-

tional Parameters” for defining the technical data

the machine should use when welding materials

not currently available in system memory.

If no additional, operator-defined welding param-

eter set has been saved to system memory, the

screen for the product name appears, to start

the input of a full parameter set (see below). If

there are, the parameter set overview shows and

presents them line by line (see Display 8).

The button to the left of an entry in the additional welding param-

eter overview opens the menu for managing

the additional parameter sets. It offers re-entering

all parameters of the set just selected, editing its

individual parameters, deleting it, and deleting all

additional parameter sets. Again, select the de-

sired option by touching the button next to it.

Instead of the menu, a screen that allows enter-

ing the product name to be saved to the new

parameter set is shown if the button next to

a blank line was touched. After this, in a series of

individual screens enter all welding parameters

that the parameter set should hold and set on/off

values such as whether or not the components have to be aligned before

facing, to the desire state using the toggle switch. Confirm

every value by touching the button, to move on to the next screen.

Starting from the management menu, the re-enter parameter set option

has the same effect, except the individual input screens are not blank.

They will hold the values currently set for the parameter set that was

previously selected in the overview, by touching the button next

to it to open the management menu.

Selecting the edit parameter set option in the management menu will show

a table-style overview of the previously selected

parameter set (see Display 9). The individual

parameters shown here depend on which on/off

values are set to on in that parameter set. The

menu-like overview of the on/off values of the

set, in which they can be enabled and disabled,

is accessible by the button. The individual

parameter values can be edited after touching

the value itseld in the overview table, thereby

opening an input screen for that value. When

editing parameter sets, too, every change has

to be confirmed by the button.

Display 7

Enter Commission Number

Display 9

Display 7

Display 8

Version May 2021 EN 19

agru SP 63 mobile V 3 User’s Manual

Both kinds of deletion in the additional parameter management

menu — deletion of the welding parameter set previously selected in the

overview list and deletion of all additional welding parameters — require

the subsequent confirmation of two warning messages.

Info

If the product/material that was used in the last welding opera-

tion is deleted, the product/material selection screen (refer to

Sect. 4.3) opens automatically upon closing the parameter set

management, then the configuration menu, and a new product/

material has to be selected.

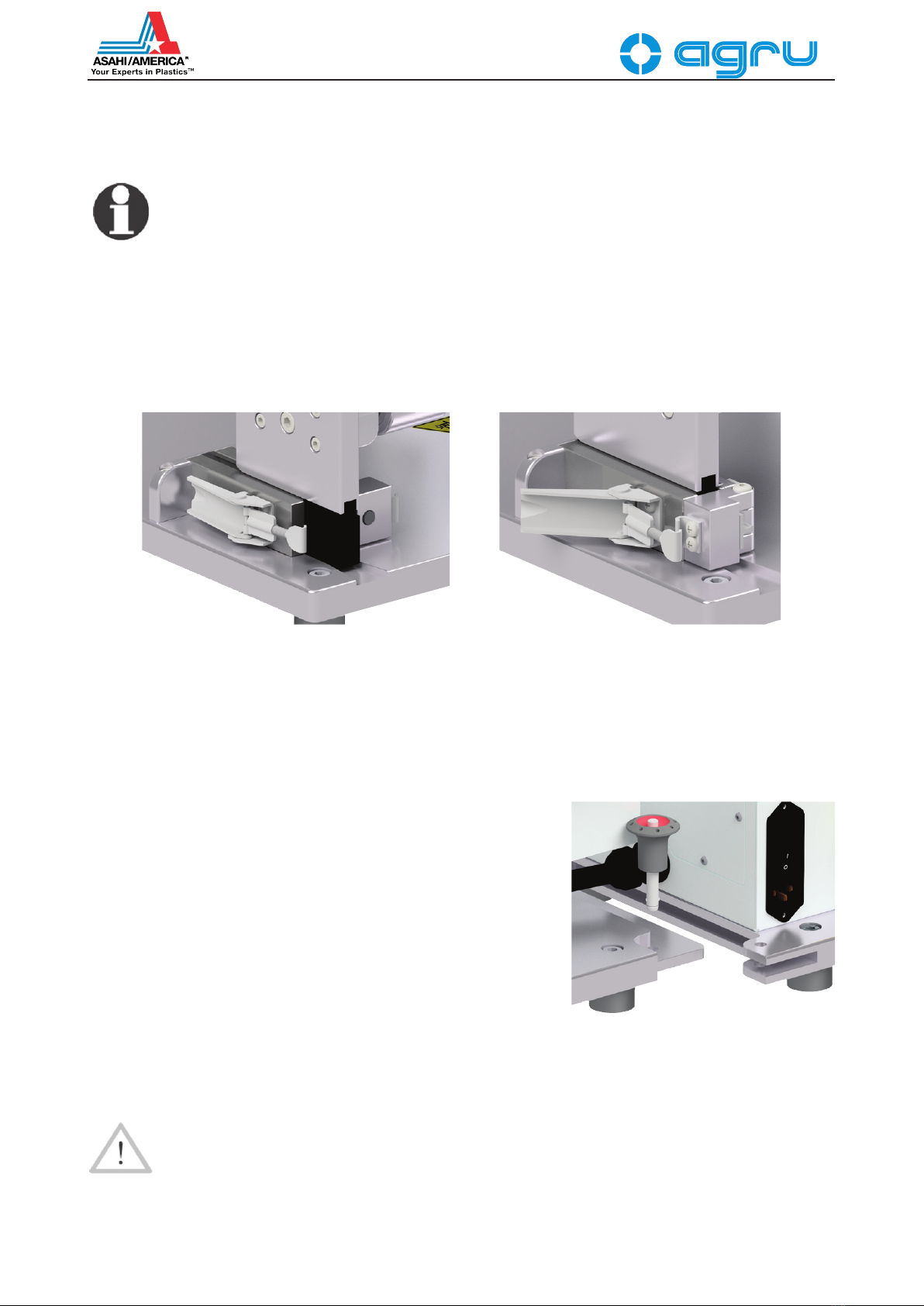

4.6 Fastening the Mechanical Structure of the Machine

The mechanical structure (chassis) of the machine is fastened to or

unfastened from the base plate using the lock frames that the black

anodized-aluminum legs of the structure plug into (see left-hand drawing

for reference). The leg is secured inside the frame by the fastening latch

at its back (seen only in the right-hand drawing), which, in turn, is kept

in place by the lock flap hooked into the fastening latch and then tilted

towards the back, along the leg. The traction excercised on the fasten-

ing latch by the flap can be adjusted by shortening or lengthening the

threaded pin that hooks into its mate at the edge of the latch.

The grooves in the base plate help slide the legs of the mechanical

structure into the lock frames into which the plug.

Prior to fastening or unfastening the mechanical structure, discon-

nect all electrical and control cables; reconnect only when

done.

A second step of fastening the mechanical structure to the base

plate, when it is not planned to use it separate from the plate, is to

lock the plates to each other by sliding the one into the other and

securing it using the locking ball pins at the front right and back

left corner of the plate of the electronic control unit (see drawing

to the right, which only shows the locking ball pin at the rear). To

unlock a locked pin, push down the head of the pin inside the head.

To conclude the preparations of the welding process, connect

the two control cables: the one shown on the drawing to the right to the

connector at the back of the mechanical structure and the one from the

heating element to that on the right-hand side — when looking at the

keypad — of the electronic control (see Sect. 3.2.2).

Caution

When the mechanical structure is properly fastened to the base

plate, the fastening elements ensure a safe welding operation.

If the machine is used without the base plate, make sure that it

is positioned safely — including sufficiently far away from flam-

mable and combustible substances — at the components to be

jointed and that any needed means and auxiliaries of support

are indeed used.

Version May 2021

20 EN agru SP 63 mobile V 3 User’s Manual

Display 10

Caution

When they are not being used and held by the support between

the carriages of the machine, the facing tool and the heating

element have to be inserted by their bars meant to hold them,

into the respective opening of the tabletop support (see draw-

ing to the right).

4.7 Welding Process

With or without calibrating/zeroing the carriage position (see at the end

of Sect. 4.1), the machine returns to the default screen (see Display 3).

If technical welding parameters or traceability data have to be changed

or entered and this has not been done before, it is still possible at this

point after pressing the button (see Sect. 4.3 and 4.4). If it is not

needed, the welding process, with the current welding parameters and

traceability data, is started by pressing the button.

Info

Possibly the welder has to wait for the heating element to

reach the nominal temperature. This would then be indicated

on the screen. If the temperature difference between actual and

nominal is large, an additional delay may occur during which

the final temperature is adjusted.

When the welding process was started, the screen first shows a message

telling that the automatic mode is either on or off, that is, moving the

movable carriage either requires the carriage mover button in the lower

left corner of the screen just to be pressed once to start them and then

they are performed automatically, or require the button to be pressed all

the time for the movement to be performed for its full duration (refer to

the explanation of the automatic mode in the table in Sect. 4.2).

Important

The carriage mover button in the lower left corner of the screen

(see Displays 10, 11) that has to be held down to perform an

action involving movement of the carriage — automatic mode

off — or to be touched to start that movement — automatic

mode on — may be represented in three different ways:

= The next action involving movement will be to close the

carriage in on the other one, towards the point of jointing.

= The next action involving movement will be to move the

carriage apart, away from the point of jointing.

= At this point, the welder has to confirm a step of the pro-

cess and, as a consequence, the movable carriage will move

automatically (with automatic mode both on and off) for a short

distance or not at all (with automatic mode off, rather than the

round carriage mover button with a check mark in the lower

left corner, the key-shaped OK/confirmation button in the

upper right corner of the screen will be used for this kind of

confirmation).

4.7.1 Facing the Component Butts

The welding process starts by the insertion of

the facing tool, then the clamping of the com-

ponents (see Display 10). For the machine to

switch a next step, the preceding step has to be

confirmed using the carriage mover button (see

the “Impotant” note at the beginnig of Sect. 4.7).

Important

Make sure that the plate carrying the

facing tool and the heating element is

set on a surface where it can sit safely

and does not slide throughout the entire

welding process.

Version May 2021 EN 21

agru SP 63 mobile V 3 User’s Manual

First, the machine asks the operator to insert the facing tool into posi-

tion 1. This is the position for clamping the components. In this position

the spacer pins of the facing tool do not sit in the recesses of the clamp

bodies in which they are during facing. Slide the facing tool in-between

the carriages of the machine in position 1 and confirm it is in place by

pressing the carriage mover button (see the “Important” note at the

beginnig of Sect. 4.7).

When the facing tool is located between the components, with automatic

mode enabled, the machine closes the movable carriage in on the facing

tool. Without automatic mode, hold down the carriage mover button

(see the “Impotant” note at the beginnig of Sect. 4.7)

When the mobile carriage has been moved in on the fixed one, clamp

the components to be jointed into the clamps. While the screen that

requests this of the welder can be seen, it is

possible, using the Minus and the Plus buttons,

to decrease or increase the distance the carriage

will travel during facing (see Display 10). When

the facing distance is as desired, confirm by

pressing the carriage mover button , and the

machine moves the carriage apart for the next

process item, or, with automatic mode disabled,

hold down the carriage mover button (see

the “Important” note at the beginnig of Sect. 4.7).

The next process item is to move the facing tool

from position 1 to position 2, the position for

facing proper. Again, the screen requests this of the welder. To move

the facing tool, release its position lock. When it sits in position 2, press

the carriage mover button (see the “Important” note at the beginnig

of Sect. 4.7).

Info

Prior to the facing process, checking the direction and the speed

of the rotation of the power facer is recommended.

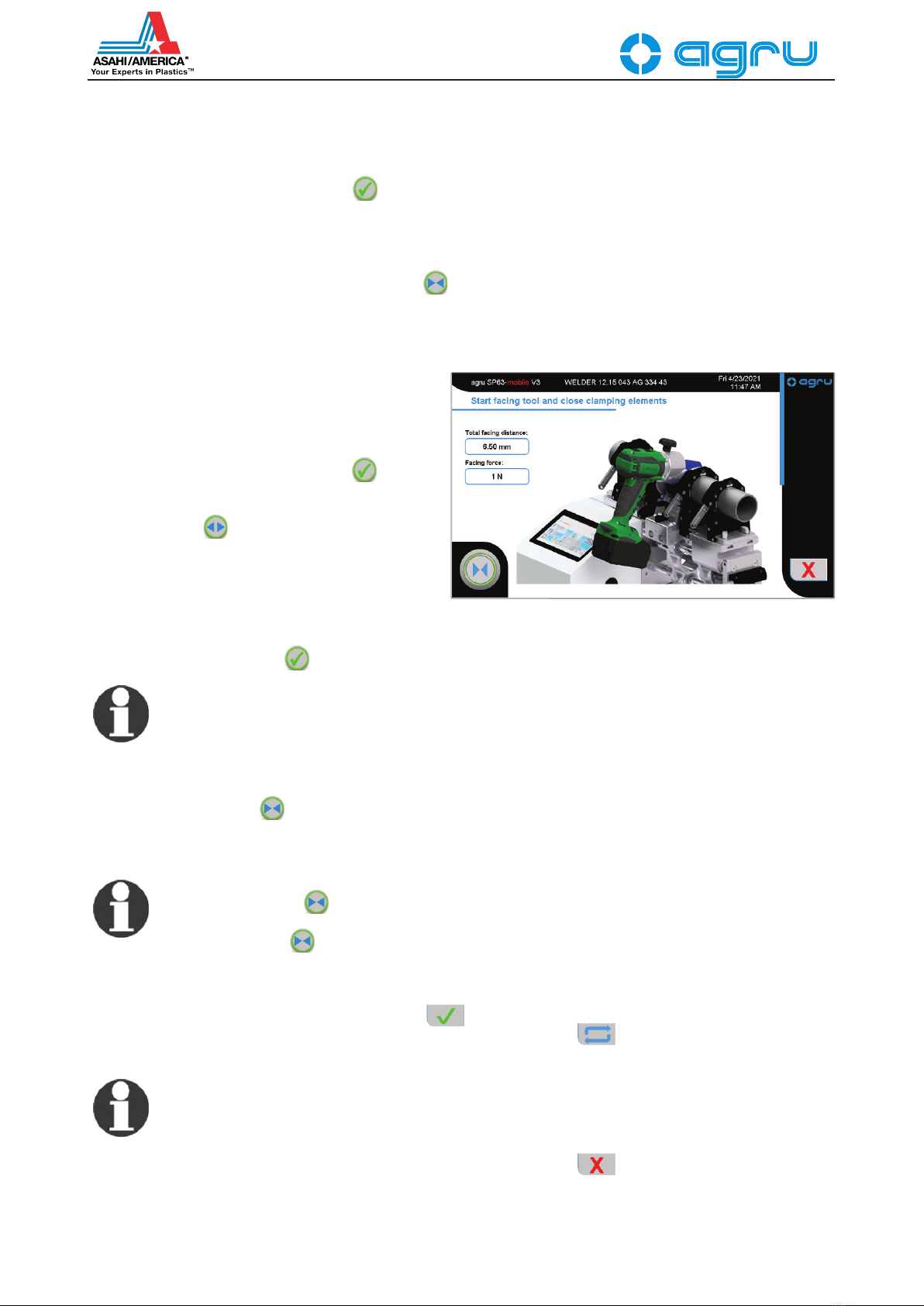

The machine then asks the welder to start the facing tool. Do as you are

requested, using the On/Off switch of the power facer, and hold down the

carriage mover button until the machine moves the carriage apart

automatically (see Display 11). This indicates that the facing process is

correct, considering the previously set facing distance. Then switch the

facing tool off at its On/Off switch.

Info

If the mover button is released before the carriage moves

apart, the facing tool pauses to allow for removing shavings;

holding down the button again to resume facing.

When the machine has moved the carriage apart, the facing tool can be

removed from in-between the pipes. Visually check the components and,

if they are o.k., confirm this by pressing the button. If the result

of facing is poor, the process can be repeated after pressing the

button. To face the ends once again, in most cases the pipes have to be

re-adjusted in the clamps.

Info

If an error occurs during facing, the machine moves the mobile

carriage apart, displaying the corresponding error message.

The facing process can be aborted at any time by pressing the

button.

Display 11

Table of contents

Popular Welding System manuals by other brands

FRONIUS

FRONIUS FDV 80 operating instructions

Elettro C.F.

Elettro C.F. TIG 4080 instruction manual

FRONIUS

FRONIUS TPS/i Robotics TWIN Push operating instructions

Uni-Mig

Uni-Mig RAZOR CUT 45 PFC operating manual

Alfain

Alfain PEGAS 161 E softswitch operating manual

Truweld

Truweld ARWSC900 Operation manual