ASC Stairway Tower User manual

Manual

ASC Stairway Tower

Conform NEN-EN 1004 –IM –NL x EN x DE x FR

This manual is property of:

ASC Group

Leerlooierstraat 32

4871 EN Etten-Leur

The Netherlands

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

2

Disclaimer

Disclaimer This documentation has been provided with the utmost care by ASC Group.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission from ASC Group. This publication may only be used

for ASC Group products. Typesetting and printing errors reserved.

If you have any questions, please contact ASC Group:

Leerlooierstraat 32

4871 EN Etten-Leur

Nederland

www.ASCGroup.nl

+3176 5413019

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

3

Table of contents

Manual 1

1

Overview 4

1.1

Application 4

1.2

List of components 4

2

Assembly and use 5

2.5

Positioning of the Stairway Tower 5

Sureface 5

Obstacles 5

Maximum height 5

Weather conditions 5

2.6

Personal protection equipment 5

2.7

Assembly 6

2.8

Assembly Instructions 6

2.9

Use 7

Extension/increase 7

Maximum permissible weight 7

Stabilization 7

Sideboard set 7

Security 7

Relocation 8

2.10

Chemical products 8

3

Inspection, care and maintenance 8

3.1

The Health and Safety Law 8

Annual control 8

Self-inspection 8

Damages 8

What to do in the event of damage 8

Repair 9

3.2

Transport 9

3.3

Maintenance 9

3.4

Storage 9

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

4

1Overview

1.1

Application

The Stairway tower is intended to be used to provide access to other structures. This scaffold is not

intended to be used to execute work. If in doubt, always consult your supplier or manufacturer; the

contact information is at the front of this brochure.

1.2

List of components

1. 7-rung Frame

2. 4-rung Frame

3. Platform without trapdoor

4. Stairway

5. Guardrail stairway inside

6. Guardrail stairway outside

7. Horizontal brace

8. Diagonal brace

9. Double horizontal brace with foldable frame

10. Wheel 200mm

11. (Tele)Stabilizer

12. Locking clips

A Stairway Tower should be constructed by at least two people.

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

5

2Assembly and use

2.5

Positioning of the Stairway Tower

Sureface

Always place the scaffolding a stable and horizontal surface. Make sure that the scaffolding cannot

sink into the ground. In addition, the general slope of the surface may not be steeper than 1 degree.

So, at a height of 4 meters, the deviation may amount to a maximum of 4 cm.

Obstacles

Position the scaffolding in such a way that no danger to the user can arise when descending. Pay

attention to obstacles on the ground and/or obstacles at height.

Maximum height

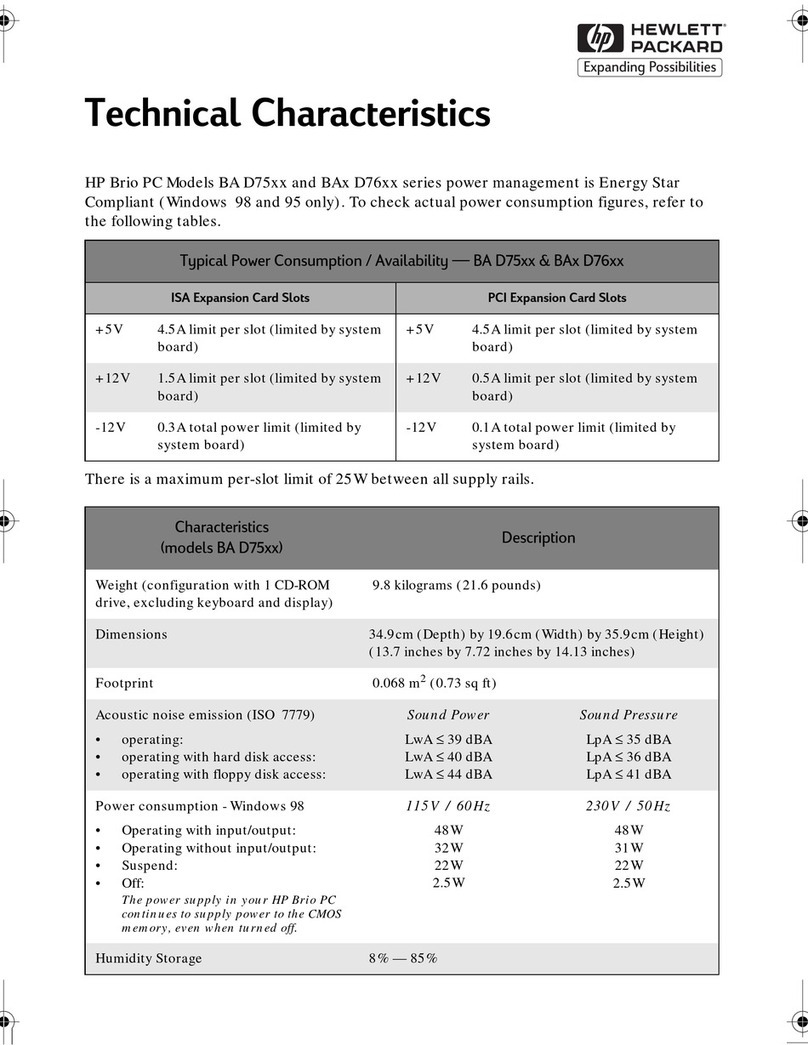

This depends on the placement and type of scaffolding (see Table 1).

Tabel 1. Maximum Height.

* This is the maximum platform height; it only applies to scaffolds with stabilizers (not fixed).

Anchor the tower every 4 meters. There are several possibilities for anchoring which may vary

depending on the situation. The method of anchoring should always be determined on site by an

expert (the most common method is steel wall anchors in combination with screw eyes).

Weather conditions

Consult the weather report to determine safety in various weather conditions. Consider the following

conditions and use common sense. At wind force 6 or higher a scaffold may not be used.

Also, any materials such as canvas that are installed must be removed.

Precipitation

Remove snow and ice from the scaffolding before starting work. If necessary, sprinkle sand on the

work floor to prevent slippage.

Cold

Avoid using Stairway Tower at temperatures below freezing.

2.6

Personal protection equipment

•Always wear work gloves, safety shoes and a safety helmet.

•When working at height, use a life-line.

Type of scaffolding

Indoors

(without wind)

Outdoors

(with wind)

Fixed

Stairway Tower

With Stabilizer

12 mtr *

8 mtr *

20 mtr

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

6

2.7

Assembly

For checking for damage: see section 3.

There are no tools required for assembling a Stairway Tower. For Staiway Towers from five meters

onwards, it can be useful to use a rope (with or without an accessory) to lift the components.

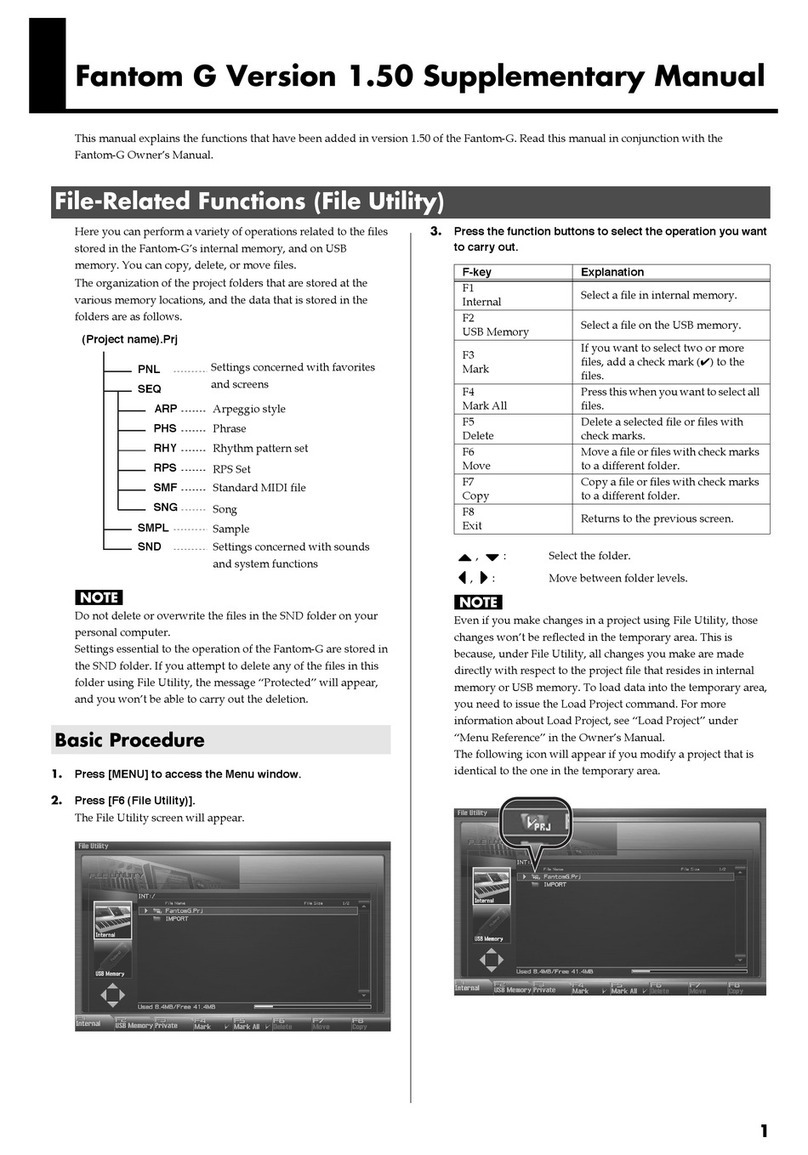

2.8

Assembly Instructions

1. Sort the diagonal (8) and horizontal (7) braces by length. Check that all materials meet the annual

inspection labels and inspect all materials for damage. If in doubt, contact ASC or your dealer with

any questions. Aluminum Scaffolding must only be assembled by people with sufficient and

proven experience.

2. Insert the wheel uprights (10) with casters into the frame (1) (without locking pins) along the

bottom edge. Apply the brakes evenly to the wheels.

3. Attach a horizontal brace (6) on its side to the upright and allow the brace

to rest on the ground.

4. Now click the horizontal brace to the other

frame, both frames will now stand.

5. Place the diagonal brace (8) on the 2nd rung of the frame and click on the 6th

rung of the opposite frame. A cross is now formed.

6. Place the stairway (4) from the opening in the (walkthrough) frame (1) to the

other frame.

7. The base section must now be leveled and, if necessary, adjusted with the adjustable wheel

uprights (by turning the nut) The maximum angle of inclination is 1%.

8. Place the stabilizers (11) and make sure they are firmly on the ground, always place a stabilizer

linkage under a rung (against shifting) It is recommended to use 4 pieces, but in any case use 2.

9. Place the inner guardrail (5) on the Stairway Tower. Secure it with the

locking clips.

10. Place the next two frames (1) on the base frames and secure the

frame with a locking clip.

11. Place the guardrail outside (6) on the inside of the (walkthrough) frame.

Check all components (use the list of components) that are required for assembly,

are present and undamaged. Damaged components should not be used.

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

7

12. Place the platform (3) on the 7e rung of the base-section. The platform will be

next to the stairway.

13. Repeat steps 9 to 13 until the desired height is achieved. Raise the parts using a rope.

14. Now install the double horizontal brace (with foldable frame) (9) next to the platform on at hip

and knee height.

15. Finally place the side board holders to the upright (just below the clips) on the top work floor and

place the side boards (or kick edges) in the slots of the side board holders.

2.9

Use

Extension/increase

Never elevate the scaffolding with a tool. Therefore, do not use stairs, ladders, crates or steps on the

scaffolding unless the stairs or ladder are intended to be part of the scaffolding.

Maximum permissible weight

Please read on the sticker on the platform what the maximum load is. Each ASC Group scaffold may

be loaded to a maximum of 200 kg/m2 and never more than 375 kg in total. This means on average:

two people with (hand) tools. The maximum horizontal load is 30 kg.

Stabilization

Stabilizers must always be installed. Stabilizers are supplied in an

adjustable version.

They are placed on a scaffolding which is placed against a building as

shown in figure A and a freestanding scaffold as shown in figure B.

Sideboard set

Sideboards are always required on the platform being worked on.

Security

Do not leave a stairway tower unattended in a public place for an extended period. If this is

nevertheless necessary, the scaffolding can be secured to a fixed object with a ring lock. To do this,

put the ring lock through one of the frame's compartments and attach an anti-climb device.

Before use, please check that:

•All parts are still present

•All the parts are still properly attached

•The tower is still perpendicular

•The stairway tower is clean

•There are any changes in the surroundings which may affect safe use

•The brakes are working on the wheel

•The stabilizers are touching the ground

•All locking clips are correctly in place

Never use a Stairway Tower near

non-insulated, electrical installations or machinery.

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

8

Relocation

A stairway tower can be moved by dismantling and rebuilding it. After moving the scaffolding, it must

be put back into plumb; therefore, go through the checklist again from Section 2.9.

2.10

Chemical products

3Inspection, care and maintenance

According to the regulations one must work safely at heights. On an ASC Mobile Tower, it is not

obligatory to wear extra fall protection (provided that the recommendations in this manual have

been followed).

3.1

The Health and Safety Law

The Working Conditions Decree is a concrete elaboration of the Safe Working at Height Act. It states

that everything above 2.50 meters is 'working at height' and is therefore a situation with increased

risk of injury. This also means that all materials must be properly manufactured and checked in a

quality cycle. ASC tests all materials and performs strength calculations. The user must also have the

material inspected annually for defects.

Annual control

Your ASC Mobile Tower must be inspected for any defects annually by an expert. The ASC Group can

perform this control for you.

Self-inspection

The ASC Mobile Tower can be inspected by yourself. Before each use, always check the components

for any damage. We certainly recommend larger companies to do a monthly inspection of all

components of the Mobile Towers and to record this inspection. If you are in doubt about damage,

consult an accredited inspector.

Damages

Examples of the most common damages on aluminium scaffolding;

•Components: if a claw or a sport is loose, the mobile scaffolding must be rejected.

•Dents and or holes: if there is a big dent in the aluminium or even a crack or hole, the

scaffolding must be rejected.

•Contamination: if there is too much concrete, paint or other non-removable contamination

on the components, the scaffolding must be rejected; after all, you can no longer judge

whether the components are still intact.

What to do in the event of damage

If there is any damage, which cannot be repaired, the component must be taken out and replaced. If

repairing is possible, please contact ASC Group for further information.

Avoid contact with acids and chemical products. These can cause corrosion to

the aluminium, which can affect the strength of the aluminium.

All rights reserved. Nothing herein should be stored in automated database or made public in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, without prior permission from ASC Group. This publication may only be used for ASC products.

9

Repair

3.2

Transport

•Always transport the components in accordance with the locally applicable legislation.

•Stack the components correctly for transport; never place the heavy components on top.

•Transport the components of a scaffolding, preferably standing, f.e in a carrier.

•Handle the material with care. Do not drop components onto a hard surface; this can reduce

the quality of the material.

3.3

Maintenance

•Make sure the scaffolding material is clean, especially the connecting pins. The frames should

go in and out easily.

•Make sure the pawl of the hook of the diagonal and horizontal braces is clean. If necessary,

lubricate it with a little oil. The same applies to the wheel spindle.

•Replace missing and broken parts in time.

3.4

Storage

Store components of the scaffolding preferably in a dry, clean, dark and frost-free place.

Repairing a component must be carried out by a certified body or person.

Table of contents

Other ASC Desktop manuals

Popular Desktop manuals by other brands

Moxa Technologies

Moxa Technologies BXP-A100 Series Hardware user manual

HP

HP Compaq dc7600 MT supplementary guide

HP

HP Compaq Presario supplementary guide

Digital Equipment

Digital Equipment VAX 4000 Model 300 Installation

Roland

Roland Fantom-G none Supplementary manual

Radio Shack

Radio Shack TRS-80 III Operation manual