ASC Roof Edge Protection Class C User manual

Manual

Roof Edge Protection Class C

Conform NEN-EN 13374

Class A,B en C

Gebruikshandleiding

Rechte dakrandbeveiliging

Conform NEN-EN 13374-A

This manual is property of:

ASC Group

Leerlooierstraat 32

4871 EN Etten-Leur

The Netherlands

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

2

Disclaimer

Disclaimer This documentation has been provided with the utmost care by ASC Group.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission from ASC Group. This publication may only be used

for ASC Group products. Typesetting and printing errors reserved.

If you have any questions, please contact ASC Group:

Leerlooierstraat 32

4871 EN Etten-Leur

Nederland

www.ASCGroup.nl

+3176 5413019

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

3

1

Overview 4

1.1

Application 4

Forces 4

1.2

List of components 6

2

Assembly and use 7

2.1

Positioning 7

Sureface 7

Gutter 7

Roof egde 7

Obstacles 7

Maximum height 7

Weather conditions 7

2.2

Personal protective equipment 8

2.3

Opbouw

Fout! Bladwijzer niet gedefinieerd.

2.4

Assembly Instructions 8

2.5

Use 10

Veilig gebruik 10

After a fall into the net 10

Edge board 10

Security 10

Relocation 10

2.6

Chemical products 10

3

Inspection, care and maintenance 11

3.1

The Health and Safety Law 11

Annual control 11

Self-inspection 11

Damages 11

What to do in the event of damage 11

Repair 11

3.2

Transport 12

3.3

Maintenance 12

3.4

Storage 12

4

Componants 13

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

4

1Overview

1.1

Application

A roof edge protection is a structure with handrails to prevent accidents at height.

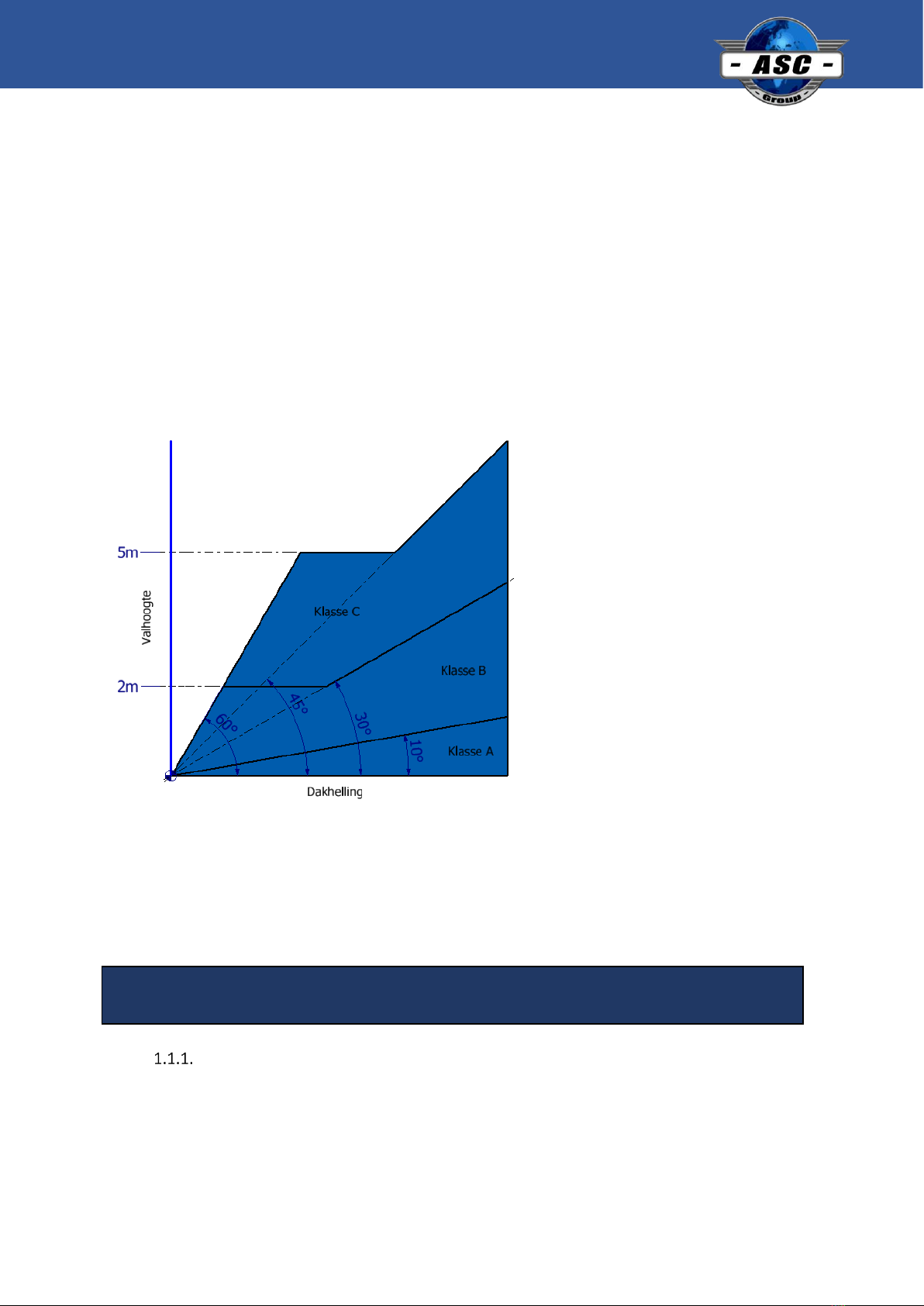

The roof edge protection may be placed if:

−The roof slope is no greater than 60°.

−The fall height is not higher than 5 m

−The subsoil can bear the forces (see 1.1.1)

For roofs higher than 5 m, the roof pitch limit is 45° degrees. For class C, however, it is mandatory to

also install the roof bracket and secure it to the roof boarding.

These conditions are adopted and tested according to NEN-EN 13374. The nets comply with EN 1263-

1 and with assembly they are brought to the correct tension.

ASC Group roof edge protection is not intended for leaning against, sitting on or replacing a

permanent balustrade. If in doubt, always consult your supplier or the manufacturer; contact

information can be found at the front of this document.

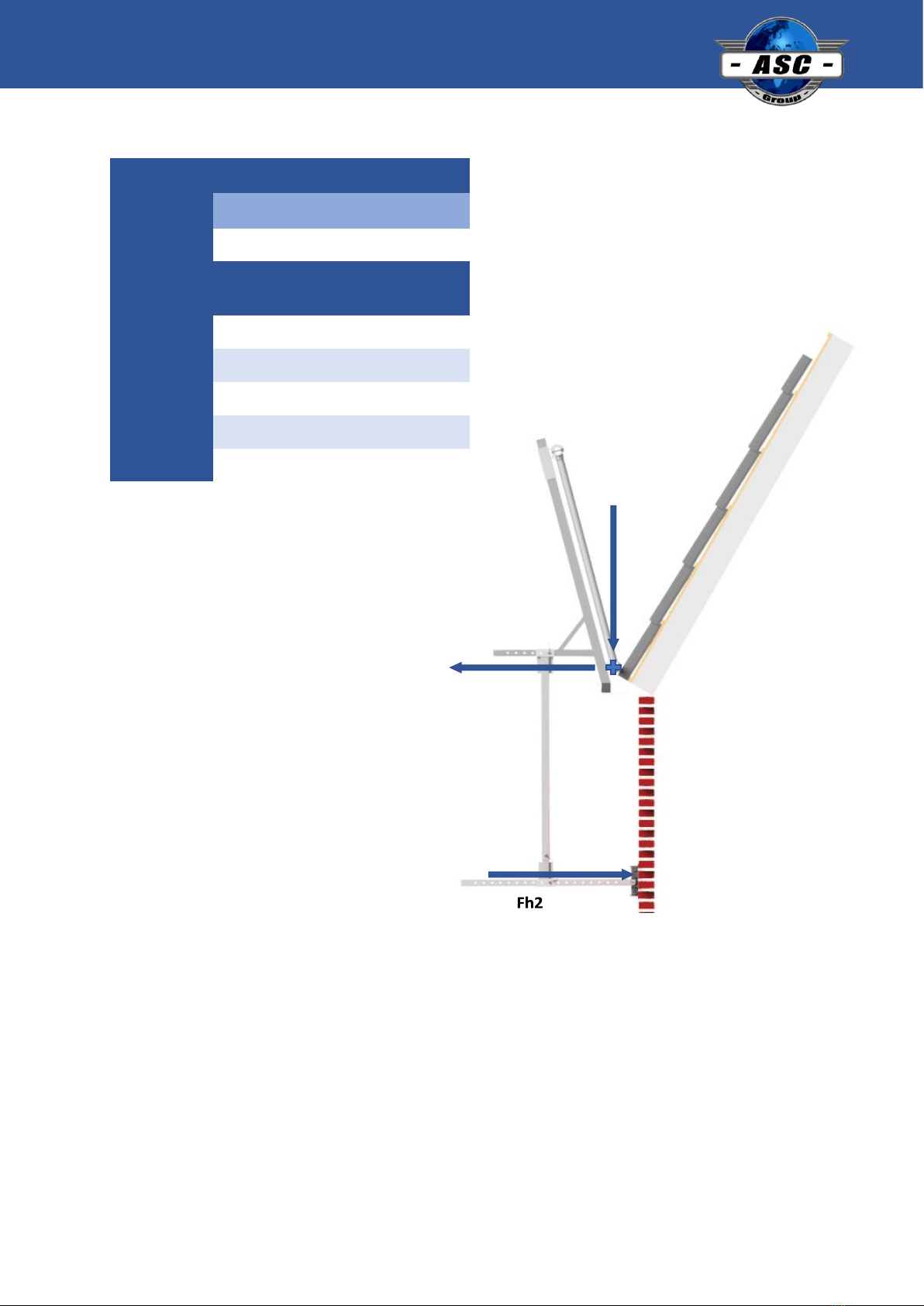

Forces

From the standard, the following loadings follow: The vertical force includes its own weight.

A roof edge protection should be constructed by secured persons.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

5

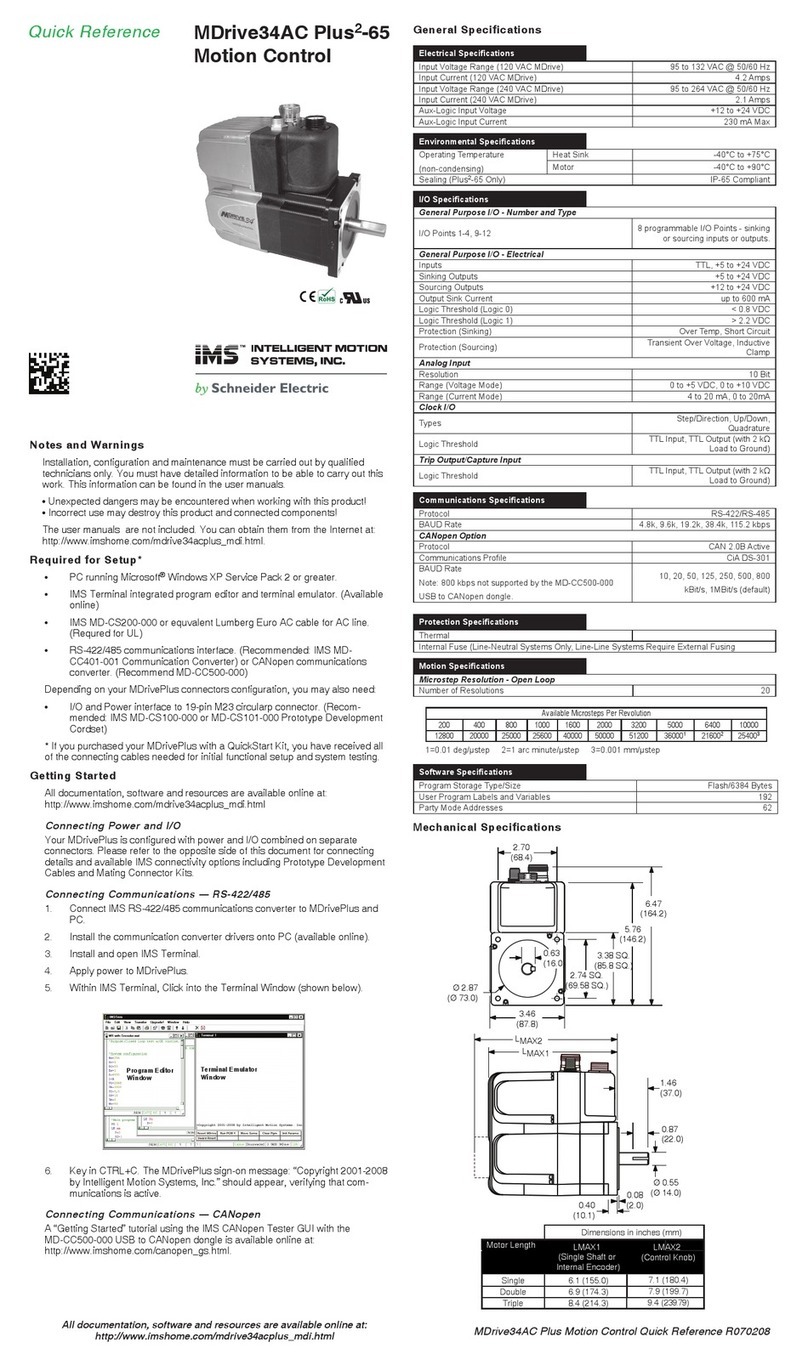

Table 1

*= Maximum possible calculated force.

Static Load[kN]

Class

Fh1

Fh2

Fv

A+B*

0,8

2,4

1,8

Roof

Inclination

Dynamic Load[kN]

B 10°

5,5

3,9

0.5

B 30°

5,3

3,8

1.4

B 45°

4,7

3.4

2.8

B 60°

3,8

2,8

3,9

C 30-60°

6,1

4,1

4,3

Fh1

Fv

Roofinclination

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

6

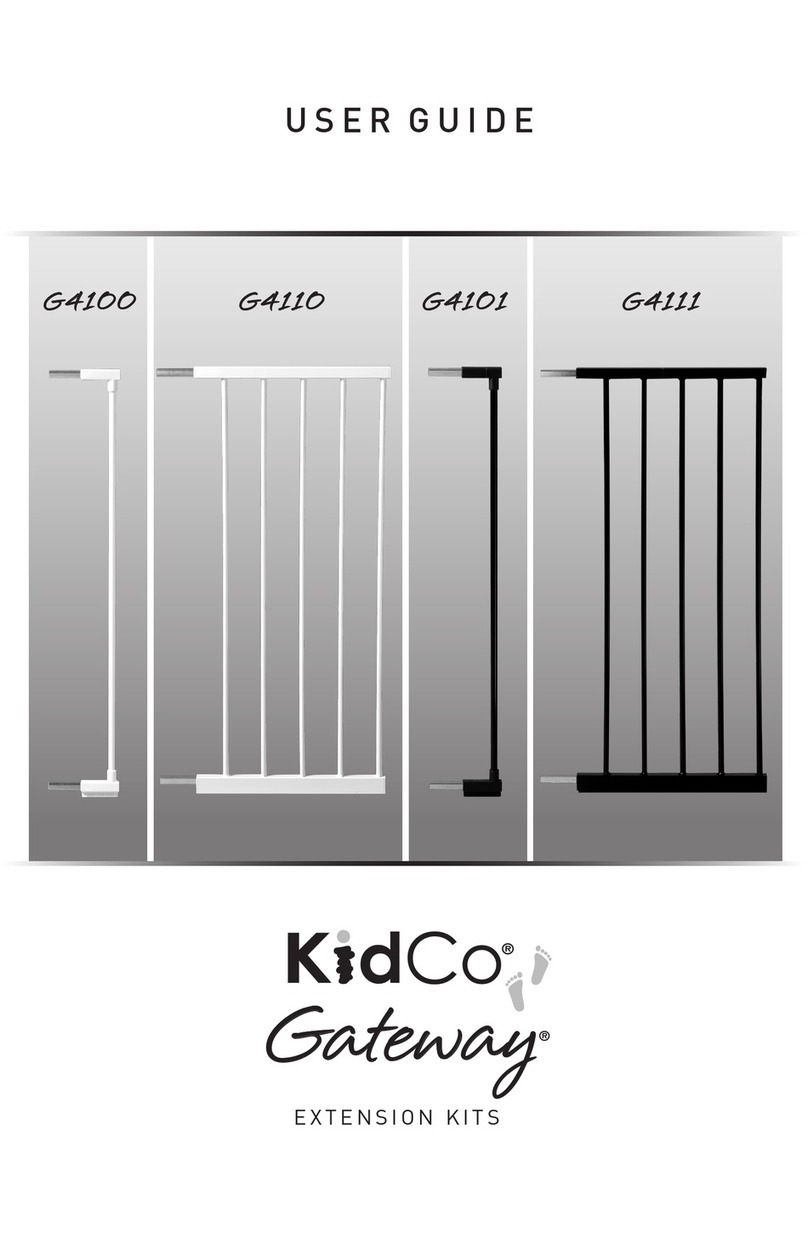

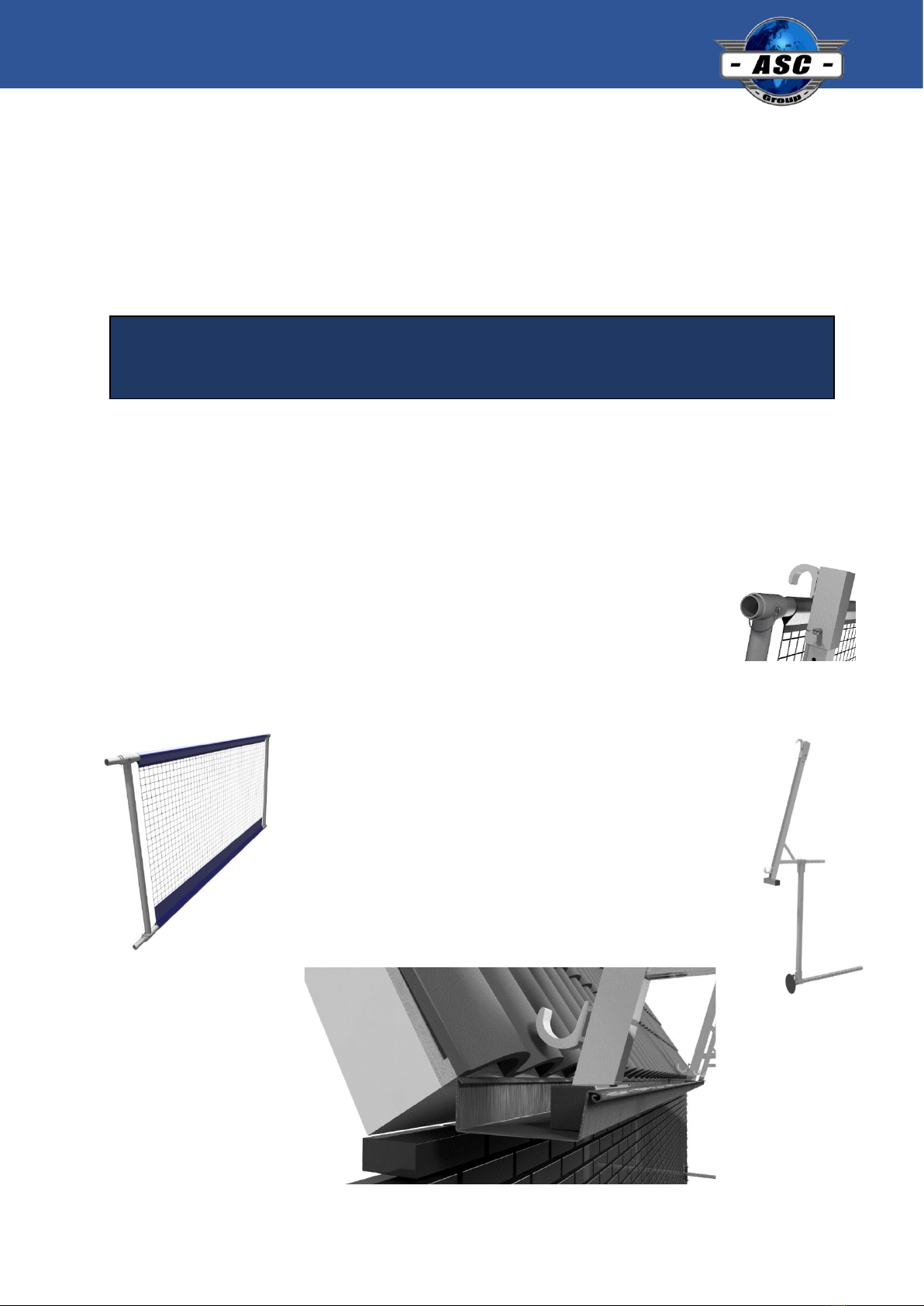

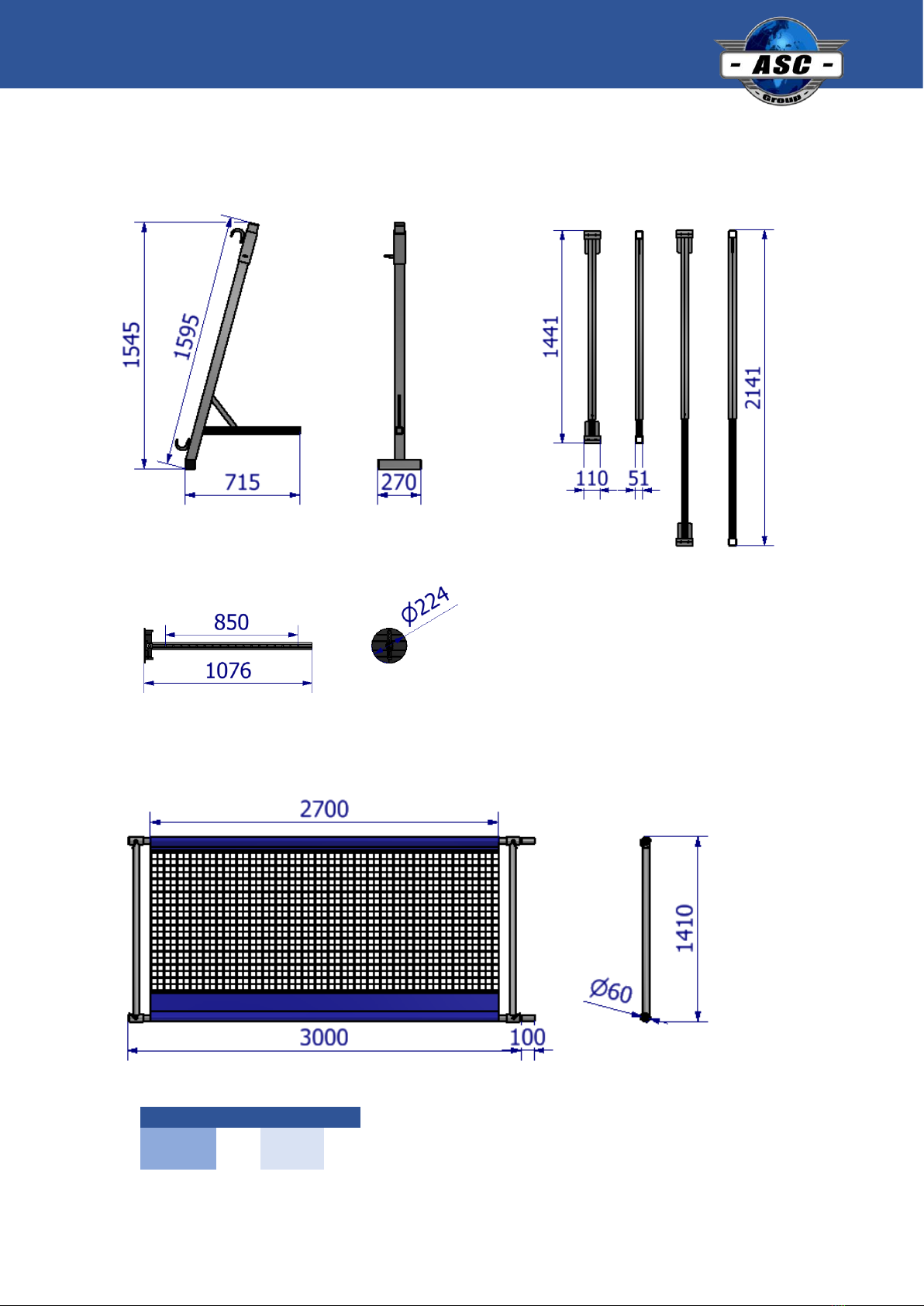

1.2

List of components

➢Example set 10meter

Amount

Discription

EAN-Code

5

Roof edge protection - Pitched roof post

8719998993103

2

Roof edge protection - Frame 3m

8719998993080

2

Roof edge protection - Frame 2m

8719998993097

2

Roof edge protection –Safetynet with integrated toe board 3m

8719998993066

2

Roof edge protection –Safetynet with integrated toe board 3m

8719998993073

Nr.

Components

1

Post

2

Standard post

3

Wall bracket Horizontal

4

Wall bracket Vertical

5

Netframe

6

Tube 3 meter

7

Tube 2 meter

8

Net 3 meter

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

7

2Assembly and use

2.1

Positioning

Sureface

Always place the roof edge protection on a stable surface. Make sure that the

longitudinal inclination of the roof is no more than 2 degrees. For class B and C,

we recommend also installing the roof edge bracket.

Make sure that the foot plate that leans against the wall always has its entire

surface against the wall.

Gutter

The gutter is large enough that the upright can be stable in it. A plastic gutter is not strong

enough. All other gutters will have to be tested with the forces indicated in Table 1. In principle

all zinc gutters should be able to do the job if they are properly supported.

Roof egde

Make sure the roof edge against which the roof edge protection stands is

sufficiently strong and high enough so that the roof edge protection cannot

slide over the edge or break the roof edge.

Obstacles

Position the roof edge protection in such a way that no danger can arise when working. Make sure

that no tripping hazards can arise from obstacles on the roof.

Maximum height

There is a maximum height of 20 m for placement.

Weather conditions

Consult the weather report to determine safety in various weather conditions. Consider the following

conditions and use common sense.

Wind force

Precipitation

Remove snow and ice from the roof and eave protection before working. If necessary, sprinkle sand

on the roof to prevent slippage.

Cold

Do not use the roof edge protection at ambient temperatures below freezing.

At wind force 5 or higher, a roof edge protection device may not be used.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

8

2.2

Personal protective equipment

Always wear work gloves, safety shoes and safety helmet.

2.3

Assembly

Aluminum roof edge protection devices may only be constructed by competent persons. According

to regulations, each person assembling the roof edge protection must be secured with a fall arrest

line.

For checking for damage: see chapter 3.

No tools are required when assembling a roof edge protection. Roof edge protection devices are

not designed to be lifted or hung as a whole.

2.4

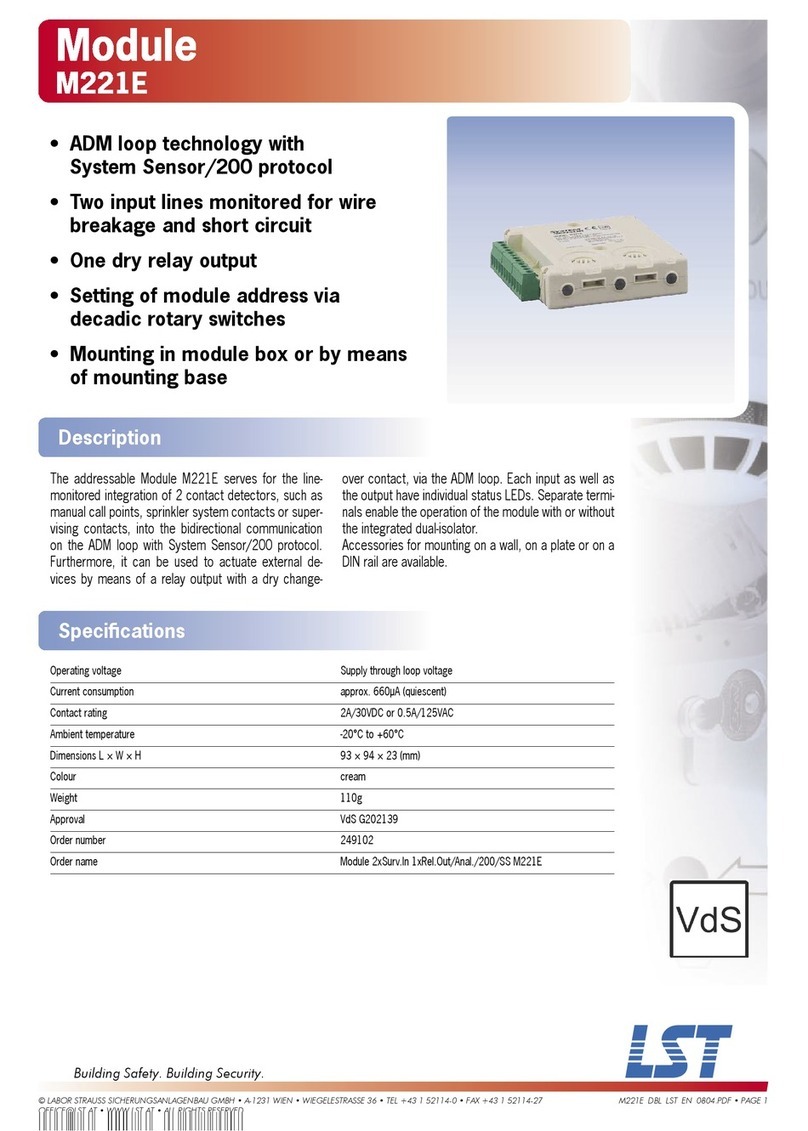

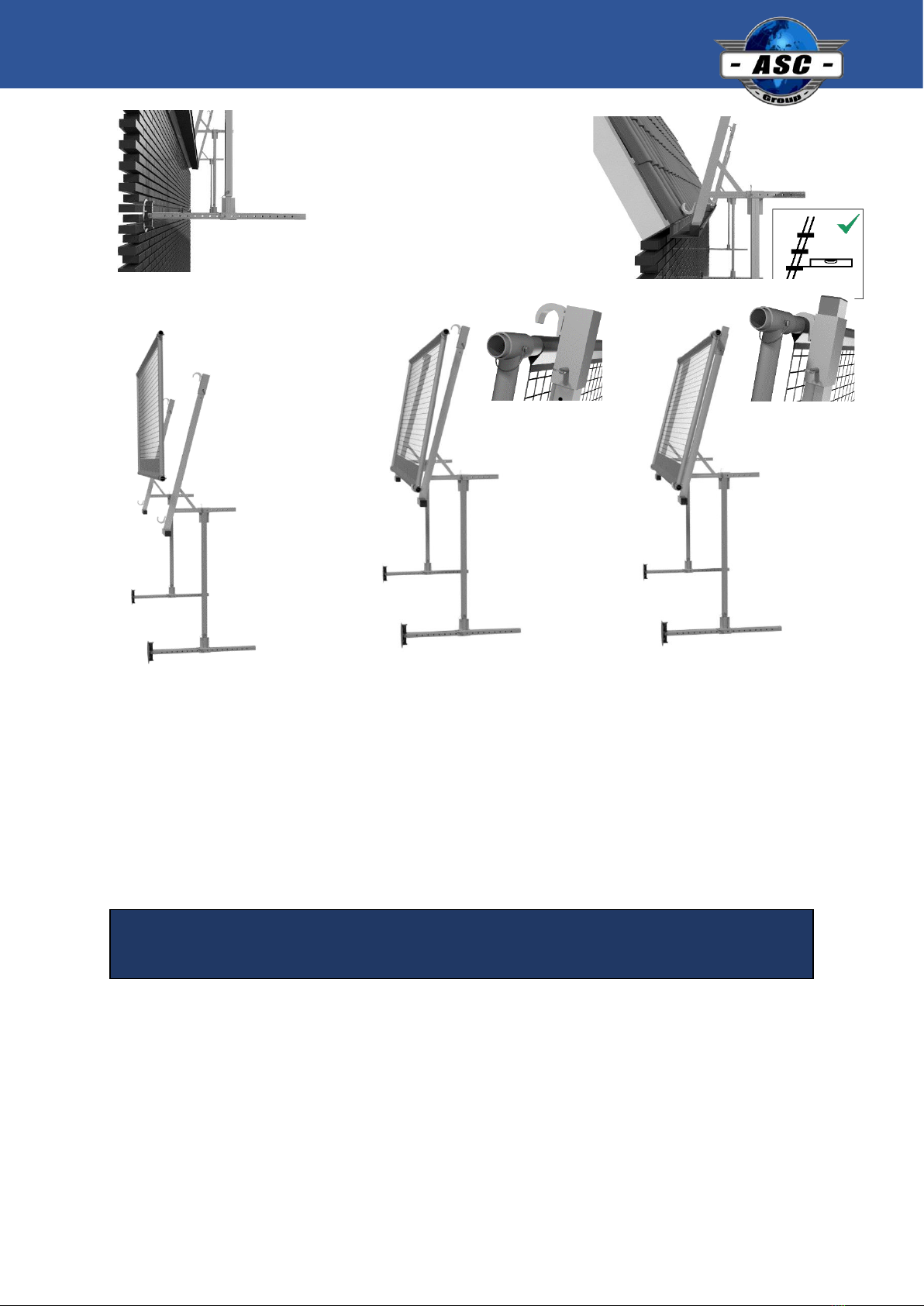

Assembly Instructions

1. Prepare the gutter post for use (see picture on the right).

2. Pull out the locking bolt and slide the clamp cap up about 7.5 cm.

3. Measure the width of the gutter.

4. The distance between the post and the slide bar is approximately the width of

the gutter.

5. Slide the lower stabilizer all the way back until the wall plate falls against the

slide rod.

6. Prepare the net frame for use (see picture on the left)

7. Slide the two tubes into the net with the coupling pins

to 1 side. Make sure there is a piece of tube left at

both ends.

8. Slide the net frames over the tubes on both sides and

secure with 4 locking clips.

9. Place the gutter post in the gutter with the base

placed as close to the roof as possible.

Using the component list, check that all the parts required for the required for

the assembly are present and undamaged. Damaged parts may not be used.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

9

10. Adjust the stabilizer bar to

the correct distance and

secure it again with two

locking pins. This stabilizer

bar must sit horizontally.

11. Place the next post about

2.5 meters further on.

12. Insert the net frame into the lower hook.

When doing so, make sure the flap is on the roof side.

13. Place the net against the post and press the clamp cap with the hook around the top tube.

Make sure the blocking bolt shoots back into the hole.

14. If you want to attach more lengths of net, repeat steps 1 through 13 until you have enough

nets. You only need to add 1 extra upright per net.

15. Connect the tubes by sliding them over the pins and securing them with the locking clip.

Please note that there should never be more than

3 meters between the uprights.

In doubt? Use an additional upright.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

10

2.5

Use

Veilig gebruik

The roof edge protection is not intended for leaning against or sitting on.

After a fall into the net

After the fall protection has done its job, i.e. after every fall into the net, the fall protection must be

inspected again by a certified body.

Edge board

The toe board is incorporated into the net.

Security

After a job, never leave the roof edge unattended.

Relocation

A roof edge protection is movable per section. A section consists of 2 uprights and a net.

Please note:

•Move the roof edge protection preferably with two persons.

•Make sure that you are secured against falling at the edge of the roof.

•Make sure that the roof edge protection cannot touch overhanging cables or other objects.

2.6

Chemical products

Before use, check that:

•All parts are still present

•All parts are still properly attached

•All parts are free of large dents and/or cracks

•There are any changes in the environment that may affect safe use

•All locking clips are correctly in place and the couplings are closed

•The net is free of tears and/or fraying.

Avoid contact with acids and chemical products. These can cause corrosion to

the aluminium, which can affect the strength of the aluminium.

Do not attach a winch, hoist or rope to the roof edge protection.

Never use an eaves guard near

non-insulated, electrical installations or machinery.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

11

3Inspection, care and maintenance

Occupational health and safety law states that you must work safely at heights.

3.1

The Health and Safety Law

The Working Conditions Decree is a concrete elaboration of the Safe Working at Height Act. It states

that everything above 2.50 meters is 'working at height' and is therefore a situation with increased

risk of injury. This also means that all materials must be properly manufactured and checked in a

quality cycle. ASC Group tests all materials and performs strength calculations. The user must also

have the material inspected annually for defects. In addition, an RI&E must be conducted for each

project. It should determine whether this form of roof edge protection is suitable for the intended

use.

Annual control

Make sure all your roof edge protection devices are inspected annually by an approved inspector.

ASC Group can perform this inspection for you. In the net, in accordance with 1263-1, there are extra

pieces of net. These pieces of netting are intended to remain attached and should be checked every

year by a competent person. After four years, the net must be replaced.

Self-inspection

You can also inspect your ASC roof edge protection devices yourself. Before each use, you should at

least check the parts for damage (see section 2.5). We definitely recommend larger companies to do

a monthly inspection of all components and to record this inspection. If you are in doubt about any

damage, consult an authorized inspector.

Damages

Examples of the most common damages in aluminum roof edge protection:

•Loose parts: if a welded part is loose, the protection is rejected.

•Dents and/or holes: if there is a large dent in the aluminum or even a crack or hole in it, the

protection is rejected.

•Contamination: If there is too much concrete, paint or other non-removable contamination

on the parts, the security is rejected. You can no longer judge whether the parts are still in

one piece.

What to do in the event of damage

If you find any damage and you feel it is not repairable, you should discard the part and replace it. If

a repair is possible, contact ASC Group for further information.

Repair

Repairing a component must be carried out by a certified body or person.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

12

3.2

Transport

•Always transport parts in accordance with legislation.

•Stack the parts correctly when transporting; never put heavier parts on top of the stack.

•Never place (sharp) objects in the net and do not use the net as a lashing strap to secure

other materials.

•Preferably transport parts standing up by securing them to the wall.

•Handle the material with care. Do not drop parts on a hard surface; this may reduce the

quality of the material.

3.3

Maintenance

•Make sure the material is clean, especially the connecting pins. The tubes should go in and

out of each other easily.

•Replace missing and broken parts in a timely manner.

3.4

Storage

Store components of the scaffolding preferably in a dry, clean, dark and frost-free place.

Alle rechten voorbehouden.

Niets uit deze uitgave mag worden verveelvoudigd, opgeslagen in een database of openbaar gemaakt, in enige vorm of op enige wijze, hetzij elektronisch,

mechanisch, opnamen, of enig andere manier, zonder voorafgaande toestemming van ASCGroup.

13

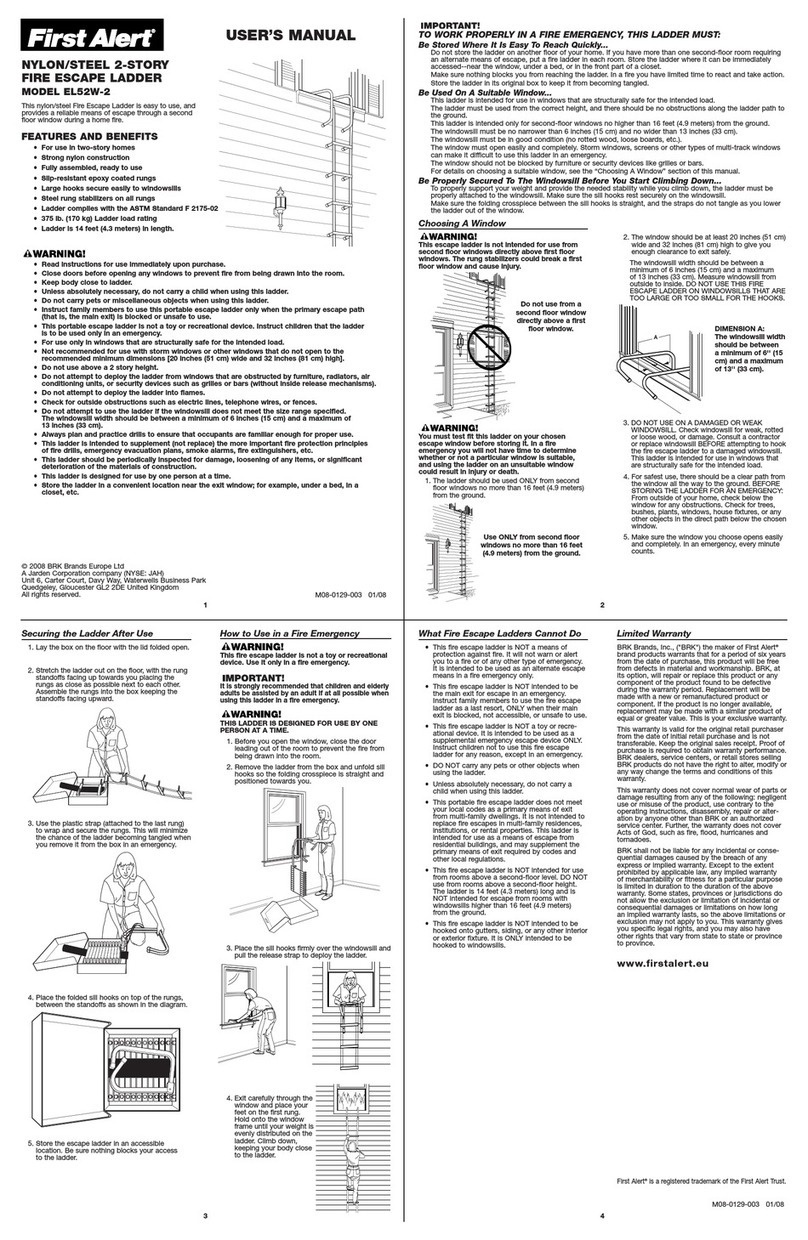

4Componants

Post 4,5 Kg

Hanger 1 4,2 Kg

Hanger 1 1.9 Kg

Netframe

Weight

Net

Frame

3000

2,1

11,5

Kg

2000

1.4

8,0

Kg

Table of contents

Popular Home Safety Product manuals by other brands

AOSafety

AOSafety Eye Gear Lexa Specifications

AOSafety

AOSafety Nassau Rave ANSI Z87.1 Specifications

Jippie's

Jippie's 836339 Instructions for use

CareTech

CareTech Grace+ Service manual / technical handbook

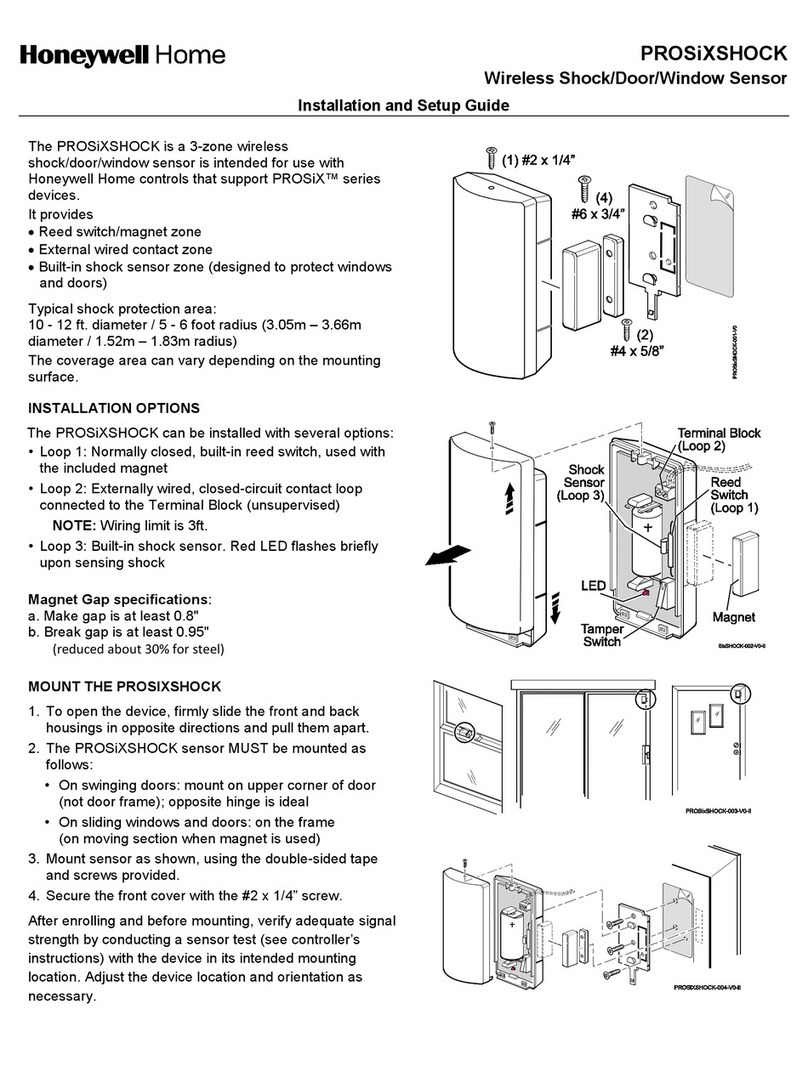

Honeywell Home

Honeywell Home PROSiSHOCK Installation and setup guide

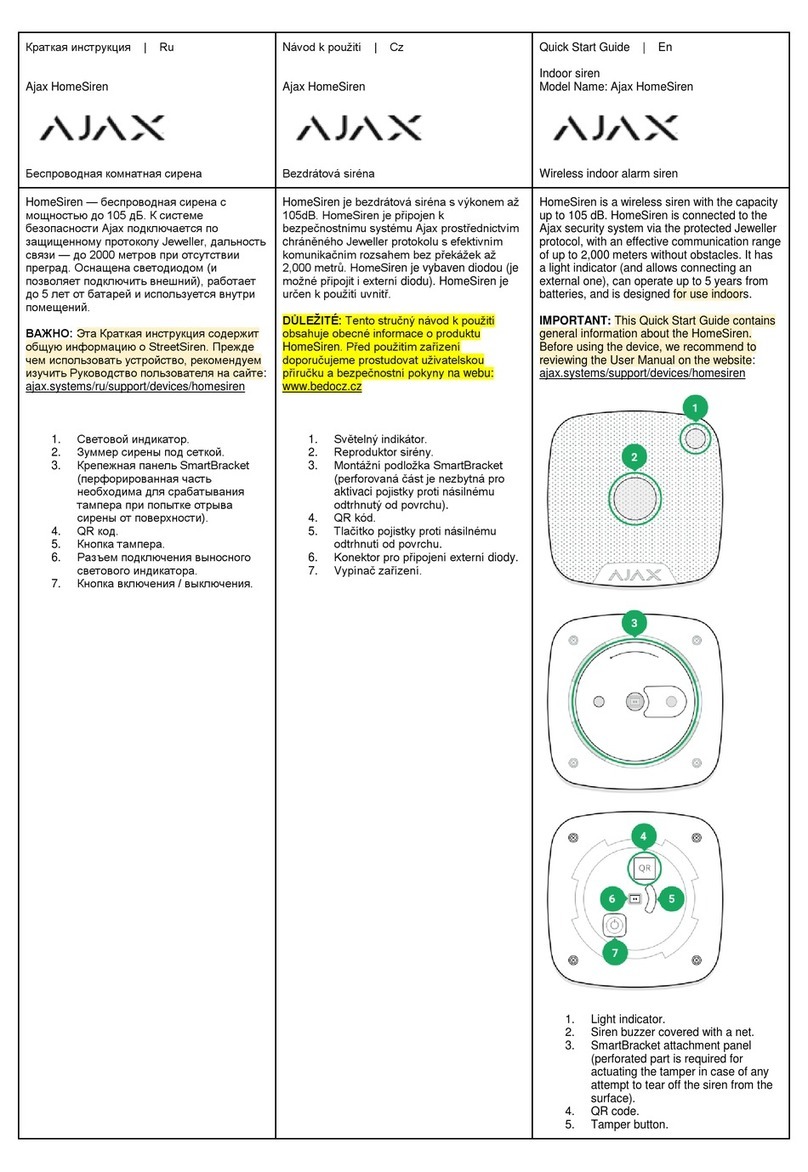

AJAX Systems

AJAX Systems HomeSiren quick start guide