Ascon Tecnologic - KR5 Line - ENGINEERING MANUAL - Vr. 0.0 PAG. 8

[5] unit - Engineering unit

Available: When a temperature sensor is selected by

[1] SenS parameter.

Range: °c = Celsius;

°F = Fahrenheit.

Note: An engineering unit modification does NOT produce

the automatic re-scaling of all parameters related

with the engineering unit (e.g. alarm thresholds,

proportional band, etc.).

[6] FiL - Digital filter on the measured value

Available: Always.

Range: oFF (No filter) 0.1 to 20.0 s

Note: This is a first order digital filter applied on the measured

value. For this reason it will affect the measured value

but also the control action and the alarms behaviour

.

[7] inE -

Selection of the Sensor Out of Range type

that will enable the safety output value

Available: Always.

Range: our = When an overrange or an underrange is

detected, the power output will be forced to

the value of [8] oPE parameter.

or = When an overrange is detected, the power

output will be forced to the value of [8] oPE

parameter.

ur =

When an underrange is detected, the power

output will be forced to the value of [8] oPE

parameter.

[8] oPE - Safety output value

Available: Always.

Range: -100... 100 % (of the output).

Notes: 1. When the instrument is programmed with one control

action only (heat or cool), setting a value outside of the

available output range, the instrument will use Zero.

E.g.: When heat action only has been programmed,

and oPE is equal to -50% (cooling) the instrument

will use the zero value.

2. When ON/OFF control is programmed and an out

of range is detected, the instrument will perform

the safety output value using a fixed cycle time

equal to 20 seconds.

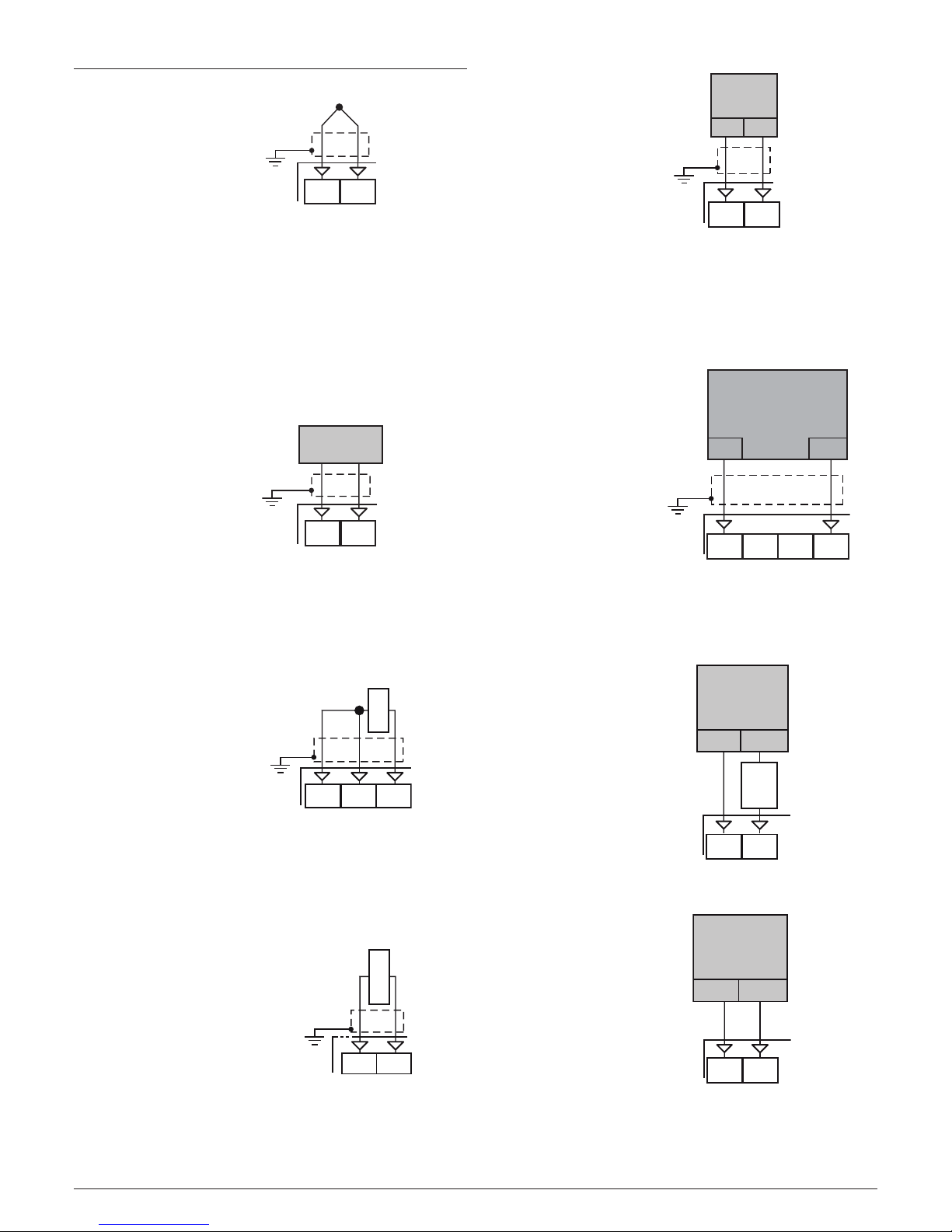

[9] io4.F - I/O4 function selection

Available: Always.

Range: on = Out 4 forced to ON (used as a transmitter

power supply);

out4 = Used as digital output 4;

dG2.c = Digital input 2 for dry contact;

dG2.U= Digital input 2 driven by 12... 24 VDC.

Notes: 1. Setting [9] io4.F = dG2.C or dG2V, the parameter

[24] O4F becomes not visible while [11] diF2

parameter becomes visible.

2. Setting [9] io4F = on the [24] O4F parameter and

the [11]diF2 parameter will NOT be visible.

3. Setting [9] io4F different from dG2.c or dG2.U, the

instrument forces [12] diF2 parameter to nonE.

If [11] diF1 was equal to (SP4 or UPDN) it will be

forced to nonE.

4. The transfer from [9] io4F = on to [9] io4F = Out4

makes parameter [24] O4F visible equal to nonE.

[10] diF1 - Digital input 1 function

Available: Always.

Range: oFF = No function;

1Alarm Reset [status];

2Alarm acknowledge (ACK) [status];

3Hold of the measured value [status];

4Stand by mode of the instrument [status].

When the contact is closed the instrument

operates in stand by mode;

5Manual mode;

6Program Run [transition].

The first closure allows to start program

execution but a second closure restart the

program execution from the beginning;

7Program Reset [transition].

A contact closure allows to reset program execution;

8Program Hold [transition].

The first closure allows to hold program execution

and a second closure continue program execution;

9Program Run/Hold [status]. When the contact

is closed the program is running.;

10 Program Run/Reset [status]:

• Contact closed - Program run;

• Contact open - Program reset;

11 SP1/SP2 selection [status];

12 Binary selection of the set point made by digital

input 1 (less significant bit) and digital input 2

(most significant bit) [status];

13 Digital input 1 will work in parallel with but-

ton while digital input 2 will work in parallel with

the button.

[11] diF2 - Digital input 2 function

Available: When [9] Io4.F = diG2.

Range: oFF = No function;

1Alarm Reset [status];

2Alarm acknowledge (ACK) [status];

3Hold of the measured value [status];

4Stand by mode of the instrument [status].

When the contact is closed the instrument

operates in stand by mode;

5Manual mode;

6Program Run [transition].

The first closure allows to start program

execution but a second closure restart the

program execution from the beginning;

7Program Reset [transition].

A contact closure allows to reset program execution;

8Program Hold [transition]

The first closure allows to hold program execution

and a second closure continue program execution;

9Program Run/Hold [status]. When the contact

is closed the program is running;

10 Program Run/Reset [status]:

• Contact closed - Program run;

• Contact open - Program reset;

11 SP1/SP2 selection [status];

12 Binary selection of the set point made by digital

input 1 (less significant bit) and digital input 2

(most significant bit) [status];

13 Digital input 1 will work in parallel with the

button while digital input 2 will work in parallel

with the button.

Notes: 1. When [10] diF1 = 12, [11] diF2 setting is forced to