5

Component Installation Notes

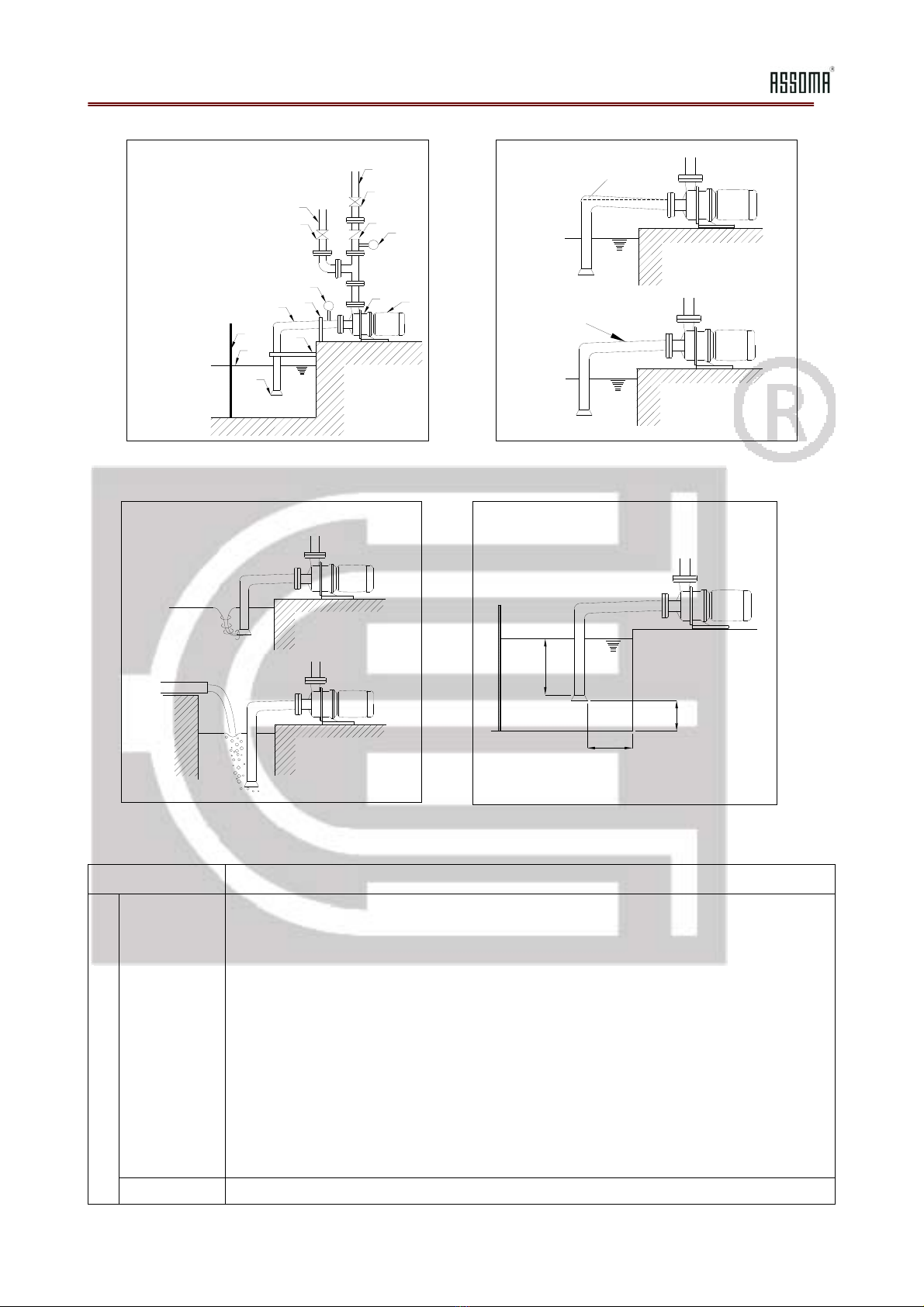

piping the closest tank wall to prevent circulation (see Fig. 4.4).

(2)The submerge depth of the suction pipe inlet should be at least 0.5m or at

least 2D below the liquid surface (see Fig. 4.4).

(3)There should be a distance of at least 1.5D between the bottom of the tank

and the suction pipe inlet (see Fig. 4.4).

(4)If there are two or more inlet piping in the same tank, they should be placed

at least 3D apart to prevent mutually disrupting each other’s flow.

Foot valve Install a foot valve if negative suction or upward suction is used (see Fig. 4.1).

Self-priming

cylinder

(1)For upward suction applications, install a self-priming cylinder to protect the

pump from running dry due to a faulty foot valve.

(2)The self-priming cylinder should provide a minimum liquid level that is at

least 0.5 m above the pump opening.

Control

valve

(1)A control valve should be installed on the suction piping to facilitate

maintenance or repairs. This valve should be open at all times and should

only be closed when there is a need to remove the pump from the system.

(2)A valve with a low piping loss, such as a gate valve, is recommended as the

control valve.

Filter (1)Filters can introduce an unpredictable increase in piping resistance in the

suction system. Therefore, unless absolutely necessary, filters should not be

installed on the suction system.

(2)If filters have to be used, make sure they are cleaned regularly to maintain an

unobstructed flow to the pump.

Vacuum

gauge

(1)The vacuum gauge material should be resistant to the pumped liquid;

otherwise, a pressure gauge diaphragm should be used.

(2)If the vacuum gauge reading fluctuates during operation, either cavitation has

occurred or air bubbles are being sucked into the system.

Discharge System

General

requirements

(1)The discharge piping should be properly secured and supported to prevent

placing excessive stress on the pump.

(2)For systems with a negative suction, priming piping is recommended (see

Fig. 4.1).

(3)The flow velocity of the liquid should not exceed 3 m/s.

(4)For safe operation, discharge piping components must be able to withstand

the pressure generated by the pump.

Priming

piping

Upward suction systems without a self-priming cylinder should have priming

piping installed.

Pressure

gauge

(1)Pressure gauge selected should be able to measure above the maximum

operating pressure of the pump.

(2)The pressure gauge material should be resistant to the pumped liquid;

otherwise, a diaphragm should be used.

(3)A valve can be installed to cut off pressure to the pressure gauge to facilitate

pressure gauge maintenance and to prolong the gauge’s service life.

(4)If the pressure gauge reading fluctuates during operation, either cavitation

has occurred or air bubbles are being sucked into the system.

Check valve A check valve should be installed under the following condition(s):

(1)When the discharge piping is long.

(2)Discharge static head exceeds 10 m.

(3)Discharge pressure exceeds 1.0 kg/cm2and flow velocity exceeds 2.5 m/s.