RECOMMENDATIONS AND SUGGESTIONS

2

The instructions for Use apply to several versions of this appliance. Accordingly, you

may find descriptions of individual features that do not apply to your specific appliance.

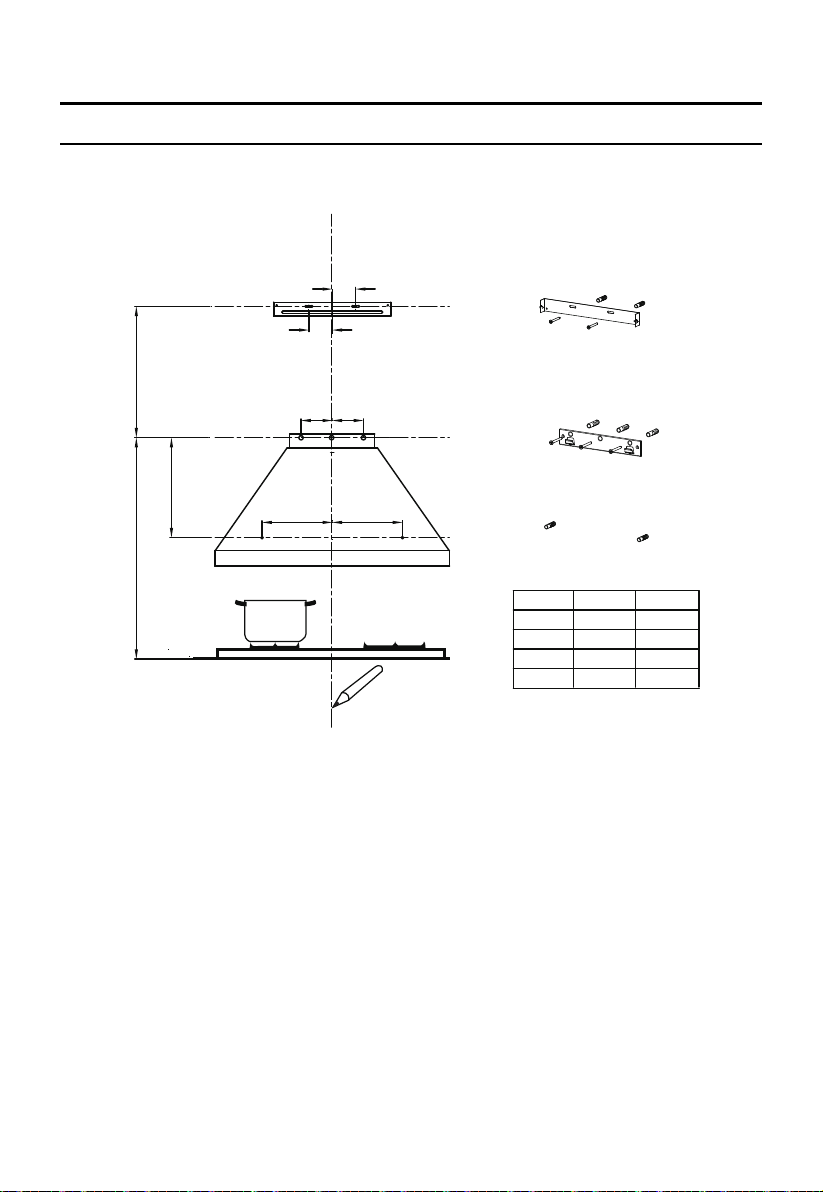

INSTALLATION

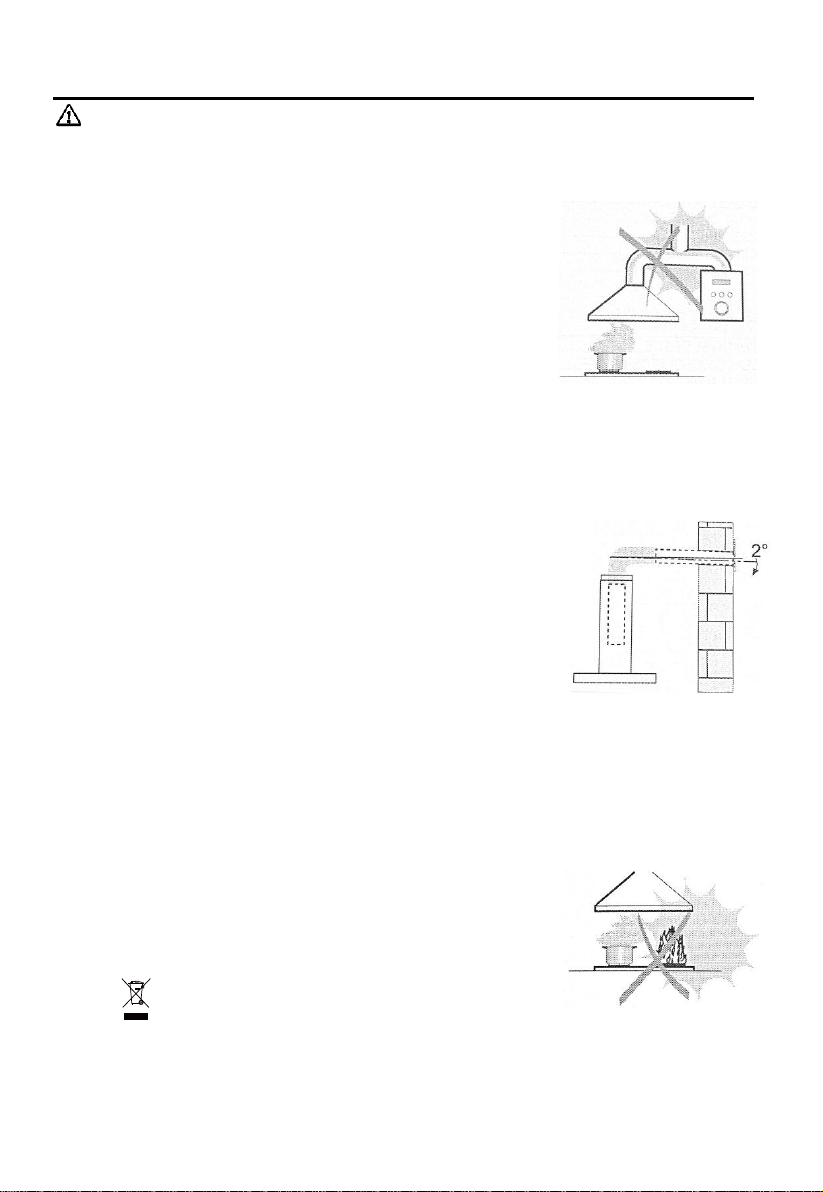

The manufacturer will not be held liable for any damages resulting from incorrect or

improper installation.

Check that the mains voltage corresponds to that indicated on the rating plate fixed to

the inside of the hood.

For Class

I appliances, check that the domestic power supply guarantees adequate

earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter 120mm.

The route of the flue must be as short as possible.

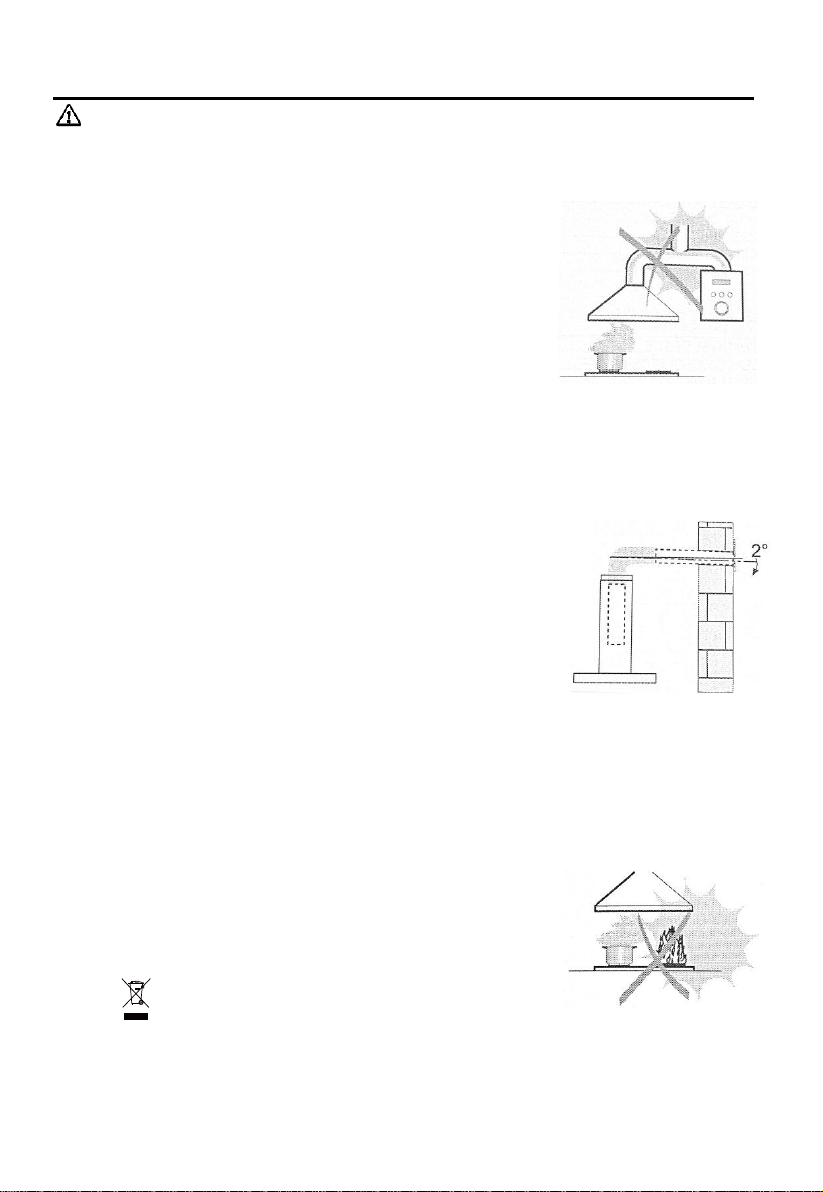

Do not connect the extractor hood to exhaust ducts carrying combustion flumes

(boilers, fireplaces, etc.).

If the instructions for installation for the gas hob specify a greater distance specified

The minimum distance between the supporting surface for the cooking vessels on the hob and the

lowest part of the range hood is 650 mm.

Regulations concerning the discharge of air have to be fulfilled.

The symbol is packaging indicates that this product may not be treated as household

waste. Instead it shall be handed over to the applicable collection point for the recycling of

electrical and electronic equipment. By ensuring this product is disposed of correctly, you

will help prevent potential negative consequences for the environment and human health,

which could otherwise be caused by inappropriate waste handling of this product. For more

detailed information about recycling of this product, please contact your local city office,

your household waste disposal service or the shop where you purchased the product.

above, this has to be taken into account.

If the supply cord is damaged, it must be replaced by the manufacturer or its service

agent or a similarly qualified person in orderto avoid a hazard.

The air must not be discharged into a flue that is used for exhausting fumes from appliances burning

gas or other fuels(notapplicable to appliances that only discharge the air back into the room).

USE

The extractor hood has been designed exclusively for domestic use to eliminate

kitchen smells.

Never use the hood for purposes other than for which it has been designed.

Never leave high naked flames under the hood when it is in operation.

Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that

it does not engulf the sides.

Deep fat fryers must be continuously monitored during use: overheated oil can burst

into flames.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lackof experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

personresponsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

There shall be adequate ventilation of the room when the range hood is used at the

same time as appliances burning gas or otherfuels (not applicable to appliances that

only discharge the air back into the room).

There is a fire risk if cleaning is not carried out in accordance with the instructions.

Do not flame under the range hood.

“CAUTION: Accessible parts may become hot when used with cooking appliances”.

MAINTENANCE

The cooker hood and its filter should be cleaned regularly according to the instruction.

Switch off or unplug the appliance from the mains supply before carrying out any

maintenance work.

Clean the hood using a damp cloth and a neutral liquid detergent.

The ap

pliance uses 4 hob elements at most.