DRAFT

Page: 7

•Fit the trunking (the following steps describe how to mark up and drill the trunking so that it

can be fitted over the top of the supply pipes and isolation valves):

oPosition the trunking in front of the hot and cold water outlets and with its end

resting on the floor

oRemove and retain the trunking cap

oMark on the back of the trunking the top of the isolation valves and the bottom of the

supply pipes

oUse these marks to make a hole large enough for the pipes and isolation valves to

pass through

oRemove the backing paper from the self adhesive tape on the trunking

oPlace the trunking over the pipes and isolation valves but do not allow the tape to

stick to the wall yet

oUsing a level, ensure the trunking is vertical

oPress the self adhesive tape against the wall to secure the trunking

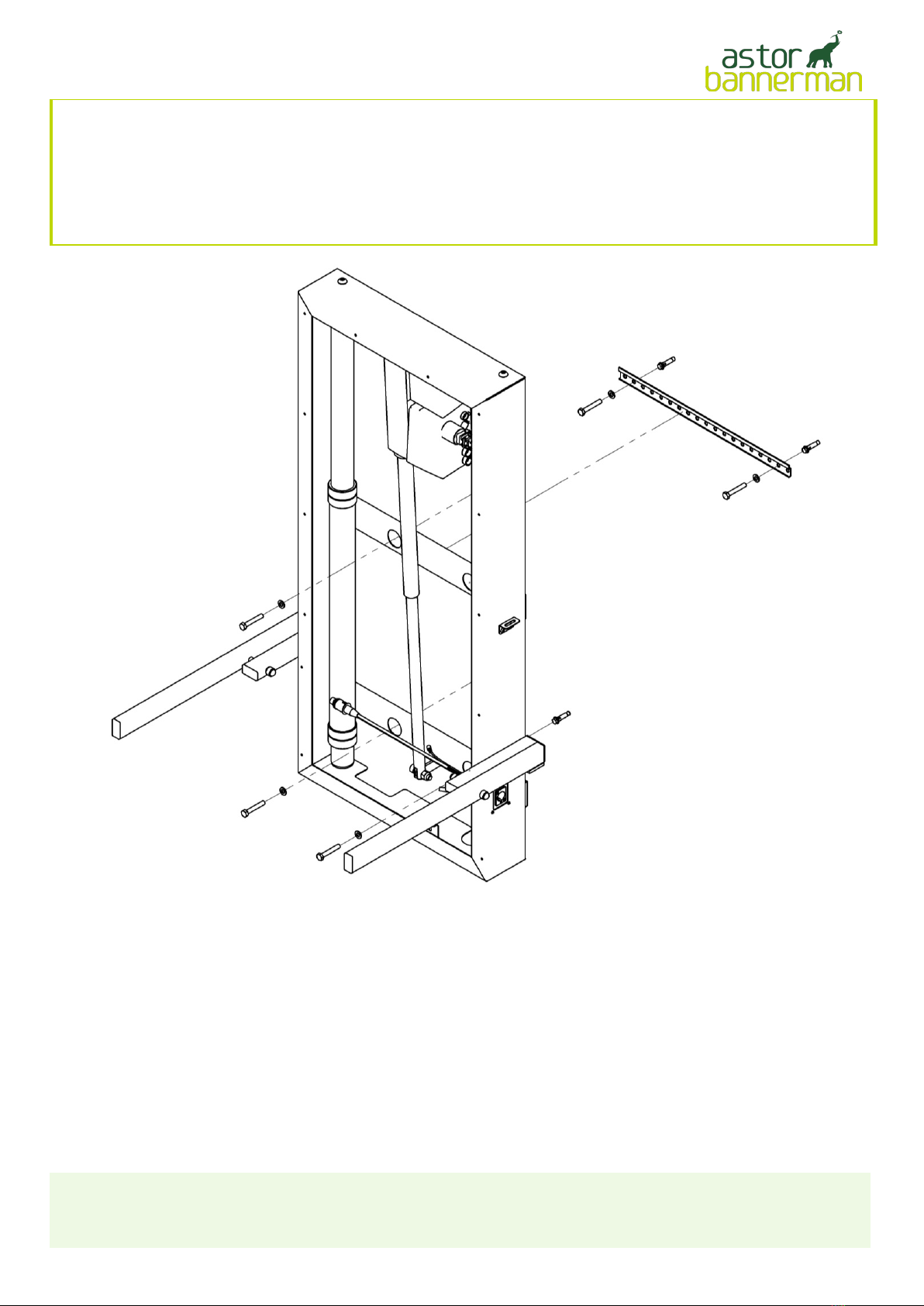

•With assistance, place the rise and fall unit onto the wall ensuring that:

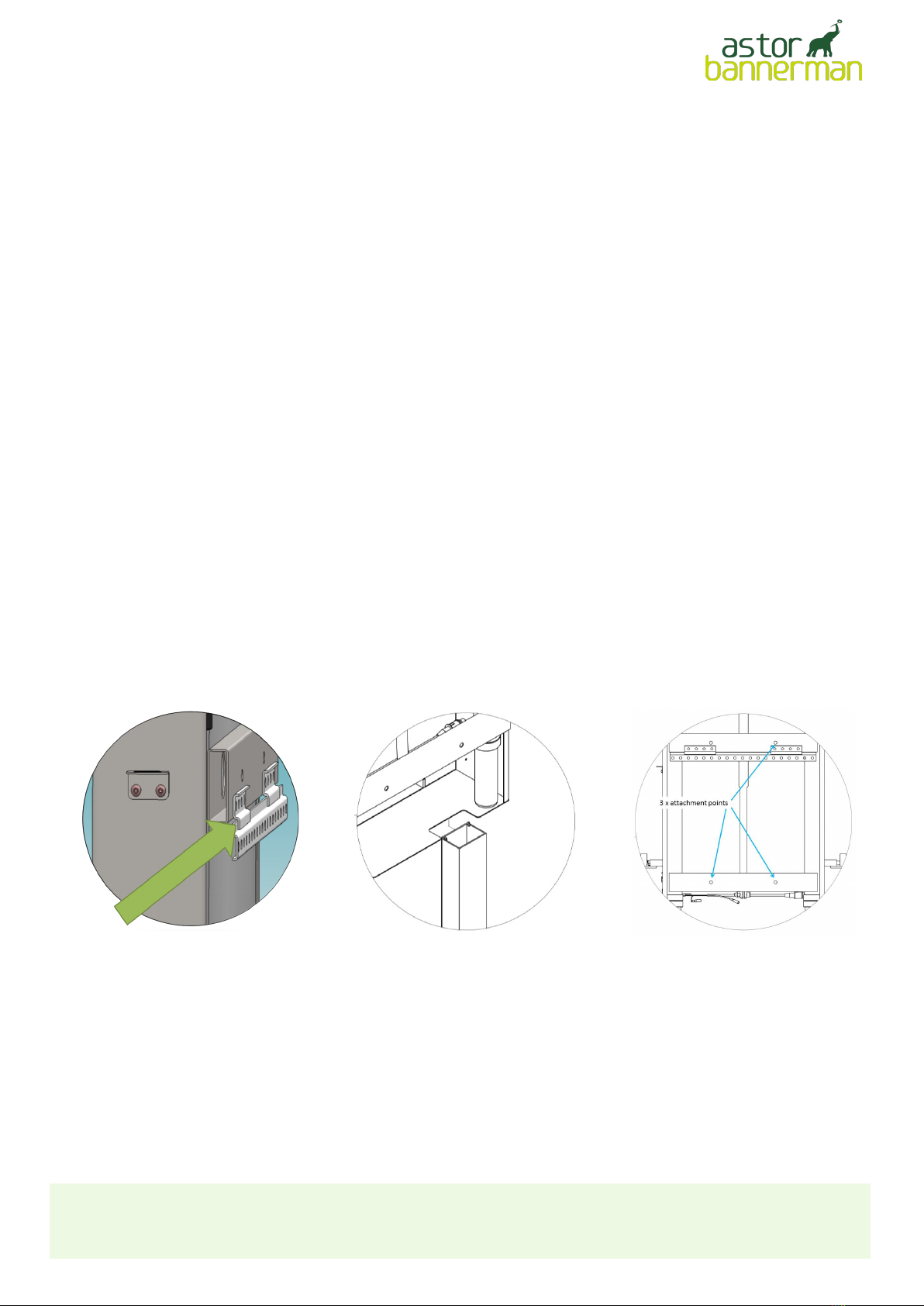

othe two short rails welded to the unit engage with the one on the wall (see Fig 6

below)

othe recess in the underside of the rise and fall unit passes over the trunking

(see Fig 7 below)

•Ensure that the unit is level, then mark the wall through the three attachment points, one on

the upper and two on the lower horizontal beams (see Fig 8, below)

•Remove the unit from the wall and at each of the three marked positions drill a 6mm full-

depth pilot hole

•Open these three holes to accept appropriate fixings

•Fit the fixings into the wall

•With assistance, place the rise and fall unit back onto the wall-mounted rail, ensuring it is

correctly aligned as before

•Fully secure the rise and fall unit to the wall at the three prepared fixing points

•Ensure the previously installed mains supply to the junction box on the wall is switched

OFF

•Electrically connect the rise and fall unit to the fused outlet using the unit's three-core

cable. Ensure there is sufficient slack in the cable to allow the unit to rise and fall

•Fit the handset BEFORE switching the power on

•Secure the handset to the cable tie mount (see diagram on next page for

location of cable tie mount) using the cable tie supplied (see fig 10, p.9)

•Switch on the mains voltage

Check that the Obstacle sensing switch on the arms works properly:

•Operate the lowering function and then lift the right hand arm on the unit to ensure

that the unit stops travelling downwards

•Leave the mains voltage supply switched on

Electrical connection:

Fig 6Fig 7Fig 8

Version 4: 25-09-2019