04 Installation, Commissioning and Maintenance Instructions

Astra cCR System - Operation & Maintenance Manual

Section 1 -

Introductory notes

1. This manual relates solely to the Astra cCR diesel

particulate filter with OAC3cm monitoring system.

2. Check parts received against the parts list sent with the kit.

3. Please note that the system supplied, is wherever possible

designed to be installed on the vehicle with the use of

coventional hand tools only. However, due to variations in

individual vehicle specifications and accessories, specialist

tools may be required.

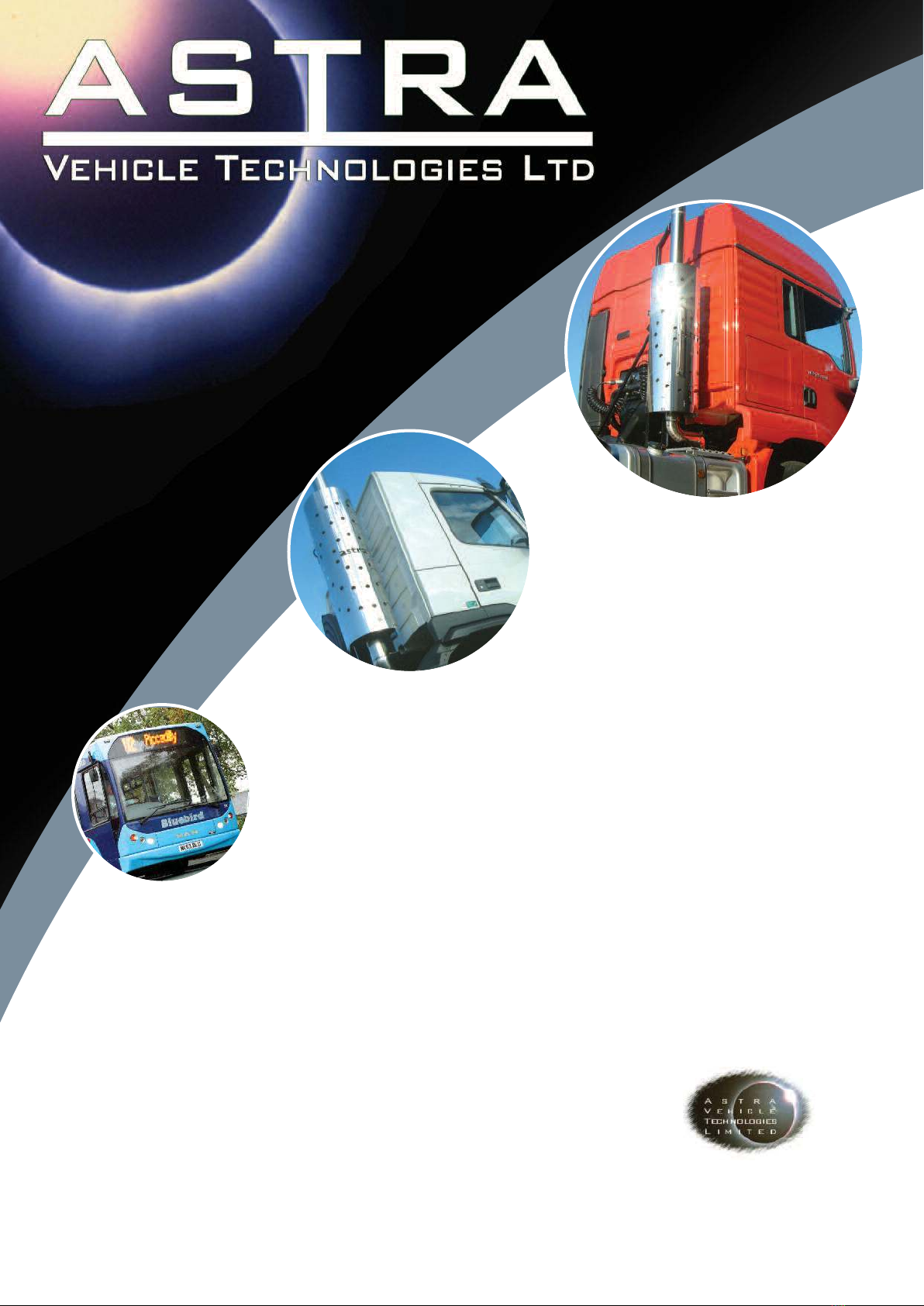

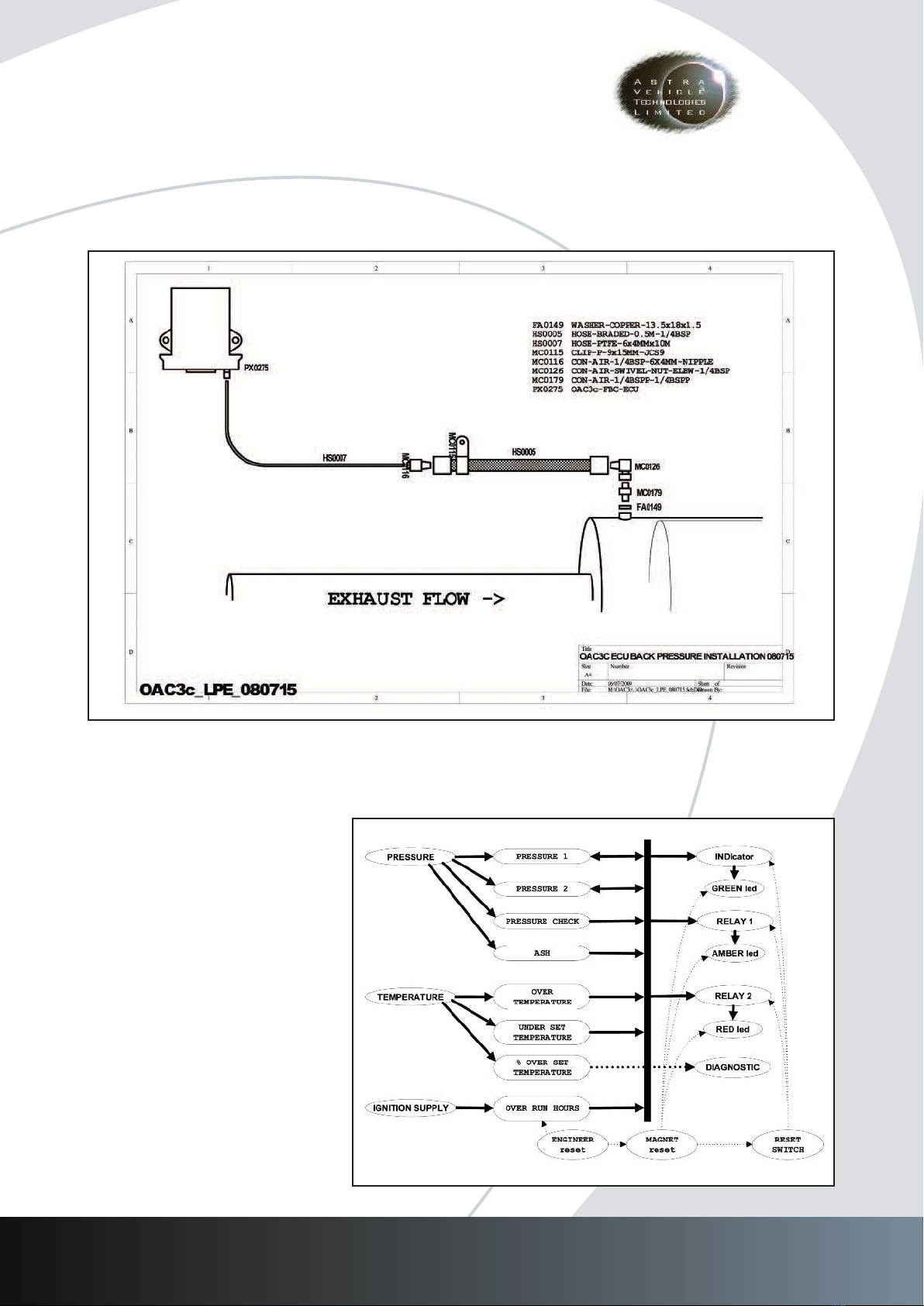

4. Installation and commissioning of the OAC3cm monitoring

module should only be conducted by a competent auto

electrician. Separate data sheets are provided relating to

OAC3cm control parameters.

5. If you are in any doubt about the specification of the

system supplied, please seek advice from Astra, or its

approved installation contractor.

6. Commissioning and/or adjustments to the OAC3cm

monitoring module ECU should only be completed by trained

personnel authorised by Astra Vehicle Technologies Ltd.

A proprietary service interface cable will be required,

together with a laptop computer capable of running a

Hyper terminal programme in Windows XP or earlier. Note :

Laptops running Windows Vista operating systems may

require an additional USB to serial port interface cable and

a free download – Hyper terminal program

Section 2 -

Astra cCRF system description & overview

of parts

The Astra cCRF is a catalysed continuously regenerating filter,

designed to virtually eliminate or remove the harmful pollutants

from a diesel engine exhaust.

The Astra cCRF system is a second generation continuously

regenerating diesel particulate filter (or trap) for heavy

commercial vehicles & buses.

Astra cCRF employs a "passive" regeneration method requiring

no additives, thus utilising using advanced gas exchange

techniques. During normal vehicle operation, frequent excursions

to high exhaust temperatures, allow the activity of a precious

metal coated catalyst to oxidise NO to NO2. NO2 subsequently

acts as the catalyst to ensure that soot particles combust as they

are collected in the filter.

Astra cCRF systems are truly "second generation" technology

as they employ a combination of the latest high activity, fast

reacting stainless steel oxidation catalysts, with the proven

durability of high efficiency Silicon Carbide particulate filters.

Astra cCRF filters are also zone coated with a proprietary

combination of base and precious metals to enhance filter

regeneration reliability and NOx performance.

Typical reductions achieved are:-

Carbon Monoxide (CO) > 90%

Hydrocarbons (HC) > 90%

Nitrogen Monoxide (NO) to

Nitrogen Dioxide (NO2) shift < 20%

Total NOx : Neutral or slight benefit

Particulate matter mass (PM) > 90%

Particulate count (PM) > 99%

In addition, the Astra cCR system is designed to replace the

sound attenuating function of the original silencer assembly.

Every Astra cCR system is manufactured from high grade 304

stainless steel, and is modular in construction allowing the filter

element to be removed for cleaning (* see notes).