ATD Tools ATD-10522 User manual

ATD-10522

1/2” DRIVE ELECTRIC IMPACT WRENCH

OWNER’S MANUAL

WARNING: This product contains chemicals, including lead, known to the State of California to cause cancer,

birth defects or other reproductive harm. Wash hands after handling.

Made in China to ATD Tools, Inc. Specications

Visit us at www.atdtools.com

Features:

ͻDelivers 240 Ō.-lbs. of torque for high-demand projects and heavy-duty fastening applicaƟons

ͻAliminum alloy gearhousing provides reliability, durability & lighter weight for easy handling

ͻForward/reverse rocker switch for convenient one-handed use

ͻ1/2" square drive with fricƟon ring system that securely holds sockets andadaptors

ͻSoŌgrip handle for superior ergonomics

ͻBall bearing construcƟon for increased durability

ͻImproved gearbox structure toavoid oil leaks andenhance product performance

ͻPacked in a custom case for easy transport and storage

SpeciĮcaƟons:

ͻRatedVoltage:120V, 60 Hz

ͻInput: 7.5A

ͻMaximum Torque: 240 Ō.-lbs.

ͻNo-Load Speed: 2200 rpm

ͻBlows per Minute: 2,700 bpm

ͻDrive: 1/2” square

39LH

E325983

012009

WARNING: The instrucƟons andwarnings contained in this manual should be read and

understood before using or operaƟng this tool. Do not allow anyone to use or operate this tool unƟl they

have read this manual and have developed a thorough understanding of how this tool works. Failure to

observe any of the following instrucƟons could result in severe personal injury totool user and

bystanders, or cause damage to the tool and property. Keep this manual for future reference.

Note: The warnings and cauƟons discussed in this instrucƟon manual cannot cover all possible

condiƟons and situaƟons that may occur. It must be understood by the operator that common sense and

cauƟon are factors whichcannot be built into this product, but must be supplied by the operator.

WARNING: Use safety equipment. User and bystanders should use safety goggles or safety

glasses with side shields which comply with current naƟonal standards,or when needed, a face shield.

Use an ANSI approved dust mask or respirator when working around metal, wood, and chemical dusts

and mists. tĞĂƌŚĞĂƌŝŶŐƉƌŽƚĞĐƟŽŶǁŚĞŶƵƐŝŶŐƚŚŝƐƚŽŽůdhis applies to all persons in the work area.

Also use non-skid safety shoes, hardhat, gloves, and dust colleĐƟon systems where applicable.

WARNING: Keep bystanders and children out of the work area while operaƟng this tool.

WARNING: Always keep your work area clean, uncluƩered, and well lit. CluƩered or dark areas

invite accidents and injuries. DO NOT work on Ňoor surfaces that are slippery.

WARNING: Do not operate thistool if you areƟred or under the inŇuence of alcohol, drugs, or

medicaƟonsthat could aīect your ability to use the tool properly.

WARNING: Dress properly. Do not wear loose clothing or jewelery as they can be caught in

moving parts. Wear restriĐƟve hair covering to contain long hair.

WARNING: Do not reach over or across running machines. Keep proper fooƟng and balance at

allƟmes. Non-skid footwear is recommended when working.

WARNING:

ƵŶĚĞƌƐŽŵĞĐŝƌĐƵŵƐƚĂŶĐĞƐŝŶƚĞƌĨĞƌĞǁŝƚŚĂĐƟǀĞŽƌƉĂƐƐŝǀĞŵĞĚŝĐĂůŝŵƉůĂŶƚƐdŽƌĞĚƵĐĞƚŚĞƌŝƐŬŽĨƐĞƌŝŽƵƐŽƌ

fatal injury, we recommend persons with medical implants to consult their physician and the medical implant

ŵĂŶƵĨĂĐƚƵƌĞƌďĞĨŽƌĞŽƉĞƌĂƟŶŐƚŚŝƐŵĂĐŚŝŶĞ

dŚŝƐƉŽǁĞƌƚŽŽůƉƌŽĚƵĐĞƐĂŶĞůĞĐƚƌŽŵĂŐŶĞƟĐĮĞůĚĚƵƌŝŶŐŽƉĞƌĂƟŽŶdŚŝƐĮĞůĚŵĂLJ

General Safety Warnings

WARNING: Read all safetywarnings and instrucƟons. Failure to follow all warnings and

instrucƟons may result in electric shock,Įreand/or serious injury or death.

WARNING: Before conneĐƟng a tool to a power supply, always check to ensure the power supply

corresponds to the voltage on the nameplate of the tool. A power supply with avoltage greater than

that specŝĮed for thetool can result in serious injury to the user, as well as damage to the tool. Using a

power supply with a voltage less than the nameplate raƟng is harmful to the motor. If in doubt, do not

plug in the tool.

NOTE:Double insulated tools are equipped with a polarized plug (one blade is wider than the

other). This plug will Įt in a polarized outlet only one way. If the plug does not Įt fully in the outlet,

reverse the plug. If it sƟll doesn’t Įt, contact a quaůŝĮed electrician to installa polarized outlet. Do not

change the plug in any way.

WARNING: To reduce the risk ofelectric shock,DO NOT use indamp condiƟons, on wet surfaces,

or expose to rain. Do not plug in this tool or operate it with wet hands or while standing in water.

WARNING: Never use the cordfor carrying, pulling or unplugging the power tool. Grasp plug

and pull to disconnect from outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately.

WARNING: Do not carry the power tool with your Įnger on the switch. Ensure the switch is in

the oīposiƟon before plugging the tool into the power outlet. In the eventofa power failure while a

tool is being used, turn the switch oīto prevent surprise starƟng when the power is restored.

WARNING: Always remove the powercord from the electricoutlet whenmaking adjustments,

changing parts, cleaning or working on the tool.

WARNING: Care shouldbe taken to arrange the cord so it will not be stepped on, trippedover,

or otherwise subjected to damage or stress.

WARNING: Never aƩempt to plug in or operate equipment with defecƟve or damaged wires,

power cord or power cord plug. Have any defecƟve or damaged parts replaced immediately by quĂůŝĮed

personnel.

Electrical Safety Warnings

WARNING: Avoid body contact with electrically grounded surfaces. There is an increased riskof

electric shock if your body is grounded.

WARNING: If the work area is not equipped with a permanently installed Ground Fault Circuit

Interrupter outlet (GFCI), use a plug-in GFCI between the power tool or extension cord and the power

receptacle.

WARNING: If an extension cord is necessary, use only ‘Listed’ extension cords. If used outdoors,

they must be marked “For Outdoor Use”.

WARNING: Use of improper size or gauge of extension cord may cause unsafe or ineĸcient

operaƟonof your tool,or cause damage to your tool. Be sure your extension cord is rated to allow

suĸcient current Ňow to the motor. If in doubt, always use a larger gauge cord. Be sure to checkthe

voltage requirements of the tool to your incoming power source.

NOTE:The table below shows the correct size to use according to cord lengthand the amperage

draw of the tool (speciĮed on the nameplate). When in doubt, use the next heavier gauge. The smaller

the gauge number, the heavierthe cord. (AWG= American Wire Gauge).

Minimum Gauge for Extension Cords (AWG)

(when using 120 volts only)

Ampere RaƟng Total Length of Cord in Feet (meters)

More Than Not More Than 25' (7.6m) 50' (15m) 100' (30.4m) 150' (45.7m)

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

NOTE:The term “powertool” in thewarnings referstoyour electricallyoperated (corded) power

tool or baƩery operated (cordless) power tool.

WARNING: Beware ofall power lines, electrical circuits, water pipes and other mechanical

hazards in your work area, parƟcularly thosebelow the work surface hidden from the operatorsview.

UnintenƟonal contact with these hazards may cause personal injury or property damage.

Power Tool Use and Care

WARNING: Do not force the power tool. Use the correct power tool for yourapplicaƟon. The

correct power tool will do the job beƩer and safer at the rate for which it was designed.

WARNING: Do not use the power tool ifthe switch loses its funcƟon. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

WARNING: Do not operate power toolsinexplosive atmospheres, suchas in the presence of

ŇĂmmable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

WARNING: Make sure that stored or idle power tools areout of the reachofchildren and do not

allow persons unfamiliar with the power toolorthese instrucƟons to operate the power tool. Power

tools are dangerous in the hands of untrained users.

WARNING: Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condiƟons that may aīect the power tools operaƟon. If damaged, have the power

tool repaired before using it. Many accidents are caused by poorly maintained power tools.

WARNING: If devices are provided for the connecƟon of dust extracƟon and collecƟon faciliƟes,

ensure thatthese are connected andproperly used.

WARNING: Remove adjusƟng keys or wrenches before turning the toolon. A wrench or a key

that is leŌaƩached to a rotaƟng part of the tool may result in personal injury.

WARNING: Have your power tool serviced by a quĂůŝĮed repair person using only idenƟcal

replacement parts. This will ensure that the power tool is safe.

WARNING: Avoid prolonged exposure to vibraƟon. VibraƟon, repĞƟƟve moƟons, or

uncomfortable posiƟons over extended periods of Ɵme may be harmful to your hands and arms. Do not

ignore symptoms or persistent or recurring discomfort, pain, throbbing, aching, Ɵngling, numbness,

burning sensaƟon, or sƟīness. DisconƟnue use of the tool and seek medical advice before resuming use.

WARNING: Adopt a comfortable posture whilemaintaining secure fooƟng and avoiding

awkward or oībalance postures. Changing posture during extended tasks can help avoid discomfort and

faƟgue.

Repetitive Motion / Vibration Hazards

The voltage specifications on the rating plate must correspond with the supply voltage.

Before attempting to use your tool, familiarize yourself with all operating features and safety requirement.

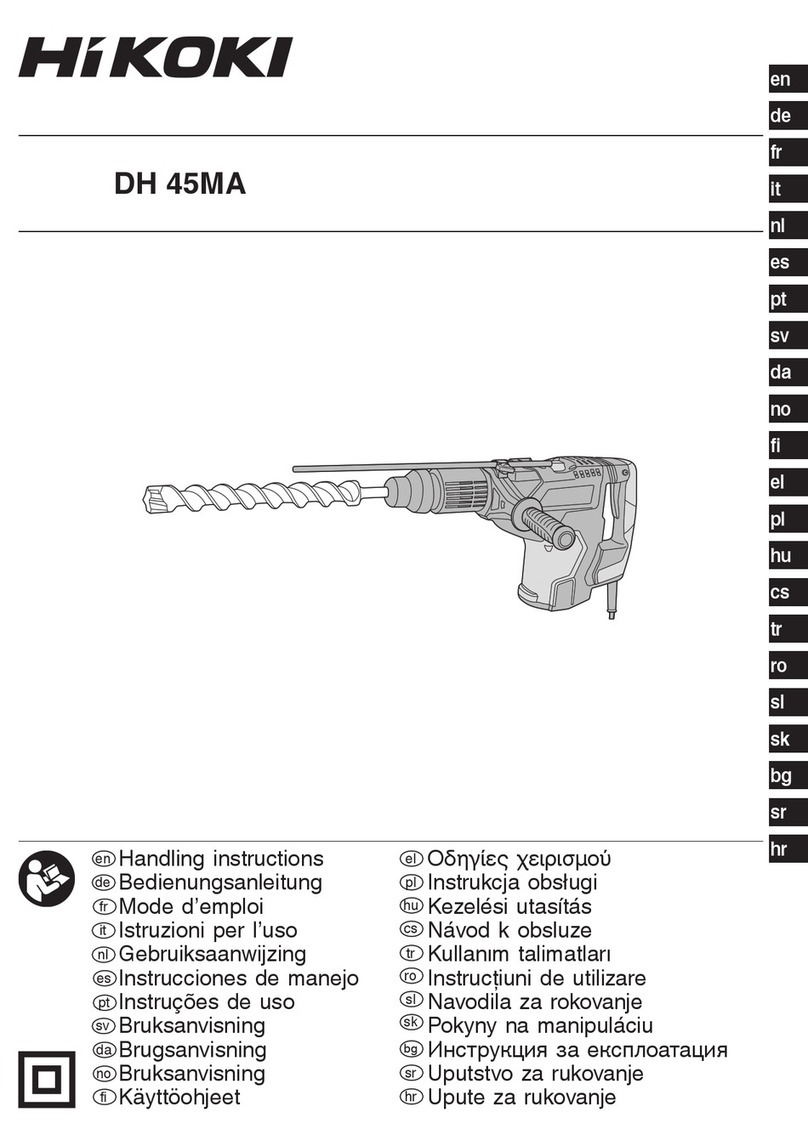

1. Switch

2. Brush Cap

3. Gear Housing

4. Handle

5. Motor Housing

Switch

This impact wrench is equipped with a rocker switch that switches rotation from clockwise to counter-clockwise

easily, allowing fasteners to be broken loose. Pressing the lower part of the switch causes the impact wrench to

move clockwise; pressing the upper part of the switch causes the rotation to reverse.

Install/remove socket

To install a socket on the anvil, align the hole of the socket with the anvil, push firmly.

To remove a socket from the anvil, pull the socket out firmly.

Operating Instructions

Functions

UNPLUG THE IMPACT WRENCH BEFORE PERFORMING ANY MAINTENANCE

Ɣ 'RQRWDWWHPSWWRPDNHDQ\DGMXVWPHQWVZKLOHWKHWRROLVLQRSHUDWLRQ

Ɣ &OHDQRXWDQ\DFFXPXODWHGGXVWUHJXODUO\

Ɣ 'RQRWDOORZSHWUROHXPEDVHGSURGXFWVWRFRPHLQWRFRQWDFWZLWKSODVWLFSDUWVDVWKH\FRQWDLQ

chemicals that can damage, weaken or destroy plastic.

Ɣ 7KLVLPSDFWZUHQFKZLOOUHTXLUHOXEULFDWLRQDIWHUFRQWLQXRXVKRXUVRULQWHUPLWWHQWKRXUVRIXVH

Remove the screws for the gear box as shown below (two on each side), and lubricate the gears.

8VH([[RQ0RELOOXEULFDQWV/,7+6+&3//%RUHTXLYLODQWWROXEULFDWHDVQHHGHG

Ɣ 'DPDJHGFDUERQEUXVKHVEXUQWEURNHQRUOHVVWKDQPPPXVWEHFKDQJHG

Maintenance

Problem Possible Causes Likely Solutions

Tool will not start. 1. Cord not connected.

2. No power at outlet.

Internal damage or wear. (Carbon

brushes or switch, for example.)

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered,

turn off tool and check circuit breaker.

If breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

Have technician service tool.

Tool operates slowly. 1. Excess pressure applied to workpiece.

2. Power being reduced by long or small

diameter extension cord.

1. 'HFUHDVHSUHVVXUHDOORZWRROWRGRWKHZRUN

2. Eliminate use of extension cord.

If an extension cord is needed, use one with

the proper diameter for its length and load.

See Extension Cords in GROUNDING section.

Performance

decreases over time. Carbon brushes worn or damaged. Have qualified technician replace brushes.

Excessive noise

or rattling. Internal damage or wear.

(Carbon brushes or bearings, for example.) Have technician service tool.

Overheating. 1. Forcing tool to work too fast.

2. %ORFNHGPRWRUKRXVLQJYHQWV.

Motor being strained by long or

small diameter extension cord.

1. Allow tool to work at its own rate.

2. Wear ANSI-approved safety goggles and

NIOSH-approved dust mask/respirator while

blowing dust out of motor using compressed air.

Eliminate use of extension cord.

If an extension cord is needed, use one with

the proper diameter for its length and load.

See Extension Cords in GROUNDING section.

Follow all safety precautions whenever diagnosing or servicing

the tool. Disconnect power supply before service.

Ɣ 7KHEUXVKHVVKRXOGFKHFNHGSHULRGLFDOO\IRUUHSDLU/RRVHQWKHSODVWLFFDSVORFDWHGRQWKHVLGHRIWKH

motor housing to reveal the spring and brush assembly.

Ɣ :KHQUHSODFLQJWKHROGFDUERQEUXVKHVWKHQHZEUXVKHVPXVWVOLGHLQWRWKHEUXVKKROGHUHDVLO\

'2127)25&(%586+(6,1727+(+2/'(5

Ɣ 7KHQRUPDOVL]HRIWKHFDUERQEUXVKHVLVVKRZQEHORZ

Troubleshooting

ITEM# ORDERING PART# PART DESCRIPTION ITEM# ORDERING PART# PART DESCRIPTION

1PRT122-1 SCREW STX48F 2PRT122-2%EARING%USH

2PRT122-2 SPRINGWASHER/ĭ 26 PRT122-26 WASHER/ĭ8.2X7.2

PRT122- WASHER/ĭ 27 PRT122-27 PIN/ĭ8X

4PRT122-4GEAR%OX 28 PRT122-28 NEE'LE %EARING\HK8121

PRT122- SEALING RING %USHING 29 PRT122-29 COUPLE GEAR

6PRT122-6 FRICTION %EARING PRT122- WASHER/ĭ8Xĭ16X.

7PRT122-7 WASHER 1PRT122-1%AFFLE

8PRT122-8SNAP RING 2PRT122-2SCREW/ST4X6C

9PRT122-9O-RING/ĭ8Xĭ1.PRT122- STATOR

1PRT122-1SPIN'LE 6PRT122-6 REAR COVER

11 PRT122-11 IMPACT%LOCK 7PRT122-7SCREWST4X16F

12 PRT122-12 STEEL %ALL/ĭ 8PRT122-8 SCREW/ST4X18F

1PRT122-1SPRING 9PRT122-9HAN'LE COVER

14 PRT122-14 STEEL %ALL/ĭ7.14 41 PRT122-4SWTICH

1PRT122-1GEARSHAFT 42 PRT122-42 HOUSING

16 PRT122-16 GEAR 44 PRT122-44 %RUSH HOL'ER

17 PRT122-17 WASHER/ĭ8.1Xĭ16X4PRT122-4CAR%ON %RUSH

18 PRT122-18 %RACKET 46 PRT122-46 %RUSH HOL'ER CAP

19 PRT122-19 SEALING RING 47 PRT122-47 COR'CLAMP

2PRT122-2GEAR%OX COVER 48 PRT122-48 SCREW/ST4X16C

21 PRT122-21 CIRCLIP FORHOLE 49 PRT122-49 COR'

22 PRT122-22 %ALL %EARING/61.2RS PRT122- COR'SLEEVE

2PRT122-2ARMATURE 1PRT122-1FELTRING

24 PRT122-24 %ALL %EARING/68.2Z 2PRT122-2O-RING

ATD-10522

WARRANTY

1 YEAR LIMITED WARRANTY

THIS WARRANTY AND CONFIRMED RECEIPT(S) SHOULD BE RETAINED BY THE CUSTOMER AT ALL TIMES

385&+$6(')520 _______________________________________

DATE PURCHASED: ____________________________________________

INVOICE/REC,(37180%(5BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

<RXU$7'LVZDUUDQWHGIRUDSHULRGRIPRQWKVIURPWKHRULJLQDOSXUFKDVHGDWH

)RUDSHULRGRIRQH\HDUIURP\RXUSXUFKDVHGDWH$7'7RROV,QFZLOOUHSDLURUUHSODFHDWLWVRSWLRQZLWKRXWFKDUJH\RXU

$7'SURGXFWLILWZDVSXUFKDVHGQHZDQGWKHSURGXFWKDVIDLOHGGXHWRDGHIHFWLQPDWHULDORUZRUNPDQVKLSZKLFK\RXH[SHULHQFHG

during normal use of the product. This limited warranty is your exclusive remedy.

To access the benefits of this warranty, contact your supplier, or point of sale directly. You may be advised to return the product

under warranty, freight prepaid, to your supplier for warranty determination.

,IWKLV$7'SURGXFWLVDOWHUHGDEXVHGPLVXVHGPRGLILHGRUXQGHUJRHVVHUYLFHE\DQXQDXWKRUL]HGWHFKQLFLDQ\RXUZDUUDQW\ZLOO

EHYRLG:HDUHQRWUHVSRQVLEOHIRUGDPDJHWRRUQDPHQWDOGHVLJQV\RXSODFHRQWKLV$7'SURGXFWDQGVXFKRUQDPHQWDWLRQVKRXOG

not cover any warnings or instructions or they may void the warranty. This warranty does not cover scratches, superficial dents, and

other abrasions to the paint finish that occur under normal use. It also does not cover noremal wear items such as but not limited to

brushes, batteries, drill bits, drill chucks, pads or blades.

6XEMHFWWRWKHODZLQ\RXUVWDWH

(1) Your sole and exclusive remedy is repair or replacement of the defective product as described above.

$7'LVQRWOLDEOHIRUDQ\LQFLGHQWDOGDPDJHVLQFOXGLQJEXWQRWOLPLWHGWRORVWSURILWVDQGXQIRUHVHHDEOHFRQVHTXHQFHV

7KHUHSDLUDQGUHSODFHPHQWRIWKLVSURGXFWXQGHUWKHH[SUHVVOLPLWHGZDUUDQW\GHVFULEHGDERYHLV\RXUH[FOXVLYHUHPHG\DQGLV

provided in lieu of all other warranties, express or implied. All other warranties, including implied warranties and warranties of

merchantability or fitness for a particular purpose are disclaimed and, if disclaimer is prohibited, these warranties are limited to

one year from your date of purchase of this product.

Some states’ laws do not allow limited durations on certain implied warranties and some states’ laws do not allow limitations on

incidental or consequential damages. You should consult the law in your state to determine how your rights may vary.

[Affix receipt or invoice here for safe keeping]

Table of contents

Other ATD Tools Impact Driver manuals

Popular Impact Driver manuals by other brands

Chicago Pneumatic

Chicago Pneumatic CP7731C Operator's manual

Campbell Hausfeld

Campbell Hausfeld XT001000 operating instructions

Chicago Pneumatic

Chicago Pneumatic CP772H Series Operator's manual

Hitachi

Hitachi WH 12DM2 Handling instructions

Makita

Makita DTD154 instruction manual

Performax

Performax 241-9891 owner's manual