ATD Tools ATD-2106 User manual

Square Drive………………………………………………………………1/2” (12.7mm)

Bolt Capacity.………………………………………………………………..3/4” (19mm)

Free Speed……………………………………………………………………....7,500 RPM

Max Torque…………………………………………………...1,290 Ō-lbs (1,750Nm)

Required Air Pressure..………………………………………….…90 PSI (6.3 BAR)

Average Air ConsumpƟon………………………………..…..4.3cfm (122 l/min)

Noise Level…………………………………………………………………………….90 dba

Air Inlet…………………………………………………………………….……………….1/4”

Hose Size…………………………………………………………………………….……..3/8”

Net Weight………………………………………………………………...4.6lbs (2.1kgs)

Length……………………………………………………………………...…7.7” (196mm)

ATD-2106

1/2" Composite Air Impact Wrench

Owners Manual

California Prop 65 WARNING: This product contains chemicals including lead, known to the State of

California to cause cancer, birth defects, or other reprodƵĐƟǀĞŚĂƌŵtĂƐŚŚĂŶĚƐĂŌĞƌŚĂŶĚůŝŶŐ

MADE IN TAIWAN TO ATD TOOLS, INC. SPECIFICATIONS

SPECIFICATIONS:

CA Prop 65 Warning:

WARNING: This product contains chemicals including lead, known to the State of California to

cause cancer, birth defects, or other reproducƟve harm. Wash hands ĂŌer handling.

WARNING: Some dust created by power sanding, sawing, grinding, drilling and other

construcƟon aĐƟviƟes contains chemicals known to the State of California to cause cancer, birth defects,

or other reproducƟve harm.

Some examples of these chemicals are:

xLead from lead based paint,

xCrystalline silica from bricks, cement, and other masonry products, and

xArsenic and chromium from chemically treated lumber.

Your risk from exposure varies, depending on how oŌen you do this work. To reduce your exposure to

these chemicals: work in a well-venƟlated area, and with approved safety equipment, such as dust

masks that are specŝĮcally designed to Įůter out microscopic parƟcles.

General Safety Warnings:

WARNING: The instrucƟons and warnings contained in this manual should be read and

understood before using or operaƟng this tool. Do not allow anyone to use or operate this tool unƟl they

have read this manual and have developed a thorough understanding of how this tool works. Failure to

observe any of the following instrucƟons could result in severe personal injury to tool user and

bystanders, or cause damage to the tool and property. Keep this manual for future reference.

Note: The warnings and cauƟons discussed in this instrucƟon manual cannot cover all possible

condiƟons and situaƟons that may occur. It must be understood by the operator that common sense and

cauƟon are factors which cannot be built into this product, but must be supplied by the operator.

WARNING: Use safety equipment. User and bystanders should use safety goggles or safety

glasses with side shields which comply with current naƟonal standards, or when needed, a face shield.

Use an ANSI approved dust mask or respirator when working around metal, wood, and chemical dusts

and mists. This applies to all persons in the work area. Also use non-skid safety shoes, hardhat, gloves,

dust colleĐƟon systems, and hearing protecƟonǁŚŝĐŚĐŽŵƉůŝĞƐǁŝƚŚŶĂƟŽŶĂůƐƚĂŶĚĂƌĚƐwhen appropriate.

RISK OF LOSS OF HEARING

RISK OF EYE OR HEAD INJURY

INHALATION HAZARD

RISK OF INJURY

RISK OF FIRE OR EXPLOSION

WARNING: Dress properly. Do not wear loose clothing or jewelery as they can be caught in

moving parts. Wear restriĐƟve hair covering to contain long hair.

WARNING: Do not reach over or across running machines. Keep proper fooƟng and balance at

allƟmes. Non-skid footwear is recommended when working.

Air Tool Use and Care

WARNING: Air under pressure can cause severe injury. Never point an air tool at anyone or

direct air at yourself or others. It could cause serious injury.

WARNING: Always turn oīthe air supply, drain the hose of air pressure and detach the tool

from the air supply before installing, removing or adjusƟng any accessory on this tool, or before

performing any maintenance on this tool. Failure to do so could result in injury.

WARNING: Always check for damaged, frayed or loose hoses and Įƫngs. Have any defecƟve or

damaged parts replaced immediately by quaůŝĮed personnel.

WARNING: Do not carry the tool by the hose. Protect the hose from sharp objects and heat.

WARNING: Always use air hose and couplings with a minimum working pressure raƟng of at

least 1-1/2 Ɵmes the maximum working pressure raƟng of the tool.

WARNING: Do not depress the tool trigger/lever when connecƟng the air supply hose.

WARNING: Do not lock, tape, wire, or otherwise disable the “ON/OFF” valve in the “ON”

posiƟon. The trigger must always be free to return to the “OFF” posiƟon when released.

WARNING: When the tool is not in use, shut oīthe air supply and press the trigger/lever to

drain the air supply line. If the tool is not to be used for a period of Ɵme, Įrst lubricate, disconnect from

the air supply and store in a clean and dry locaƟon at average room temperature.

WARNING: Keep bystanders and children out of the work area while operaƟng this tool.

WARNING: Always keep your work area clean, uncluƩĞred, and well lit. CluƩered or dark areas

invite accidents and injuries. DO NOT work on Ňoor surfaces that are slippery.

WARNING: Do not operate this tool if you areƟred or under the inŇuence of alcohol, drugs, or

medicaƟons that could aīect your ability to use the tool properly.

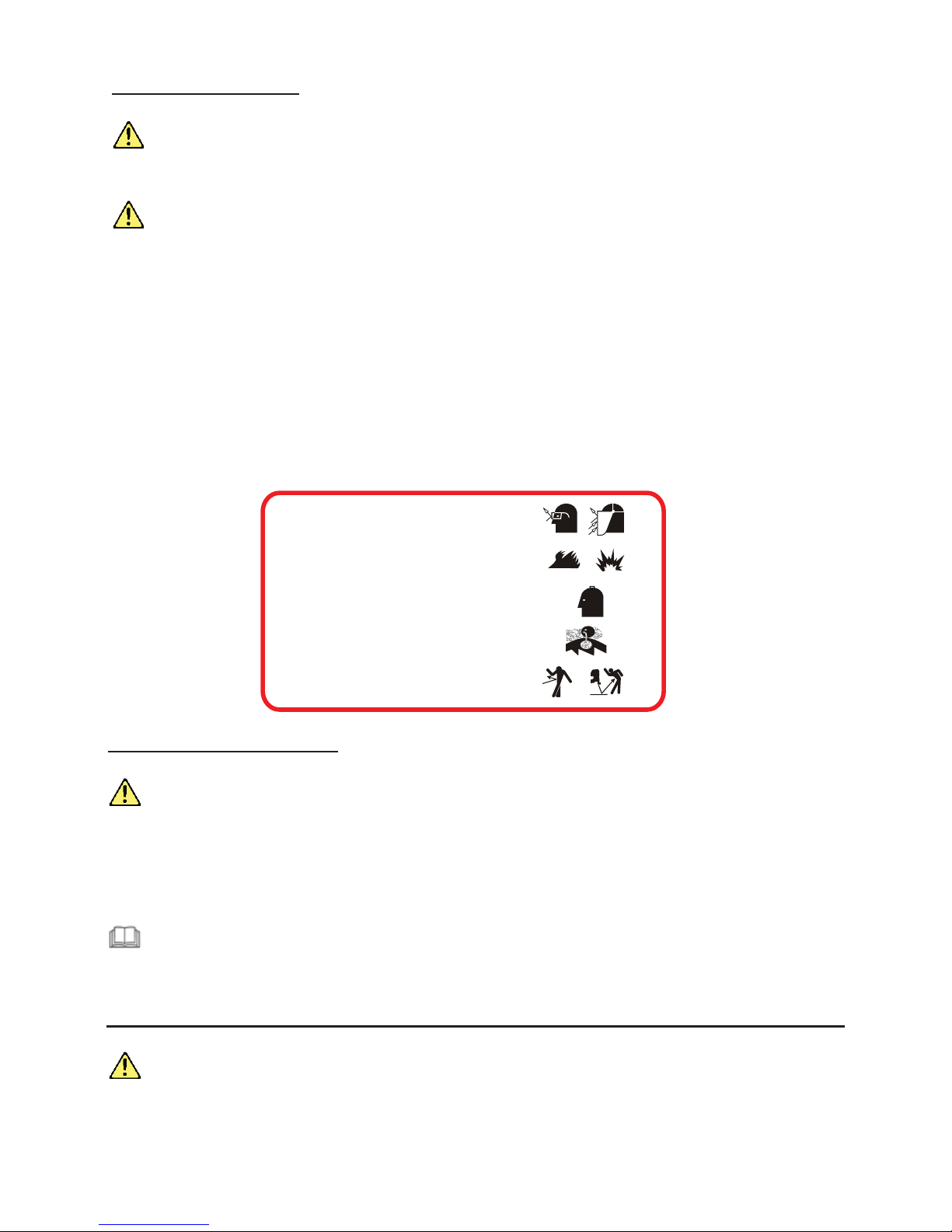

NOTE:

Typical Air Supply InstallaƟon

Always use clean, dry air. Dust, corrosive fumes and/or water in the airline will cause damage to the tool.

Drain the air tank daily. Clean the

air inlet Įlter screen on at least a weekly schedule. The recommended

hook up procedure can be viewed in the above Įgure.

Lubricate the tool’s air motor daily with quality air tool oil. If no airline oiler is used, run 1/2 oz. of oil

through the tool. The oil can be squirted into the tool air inlet or into the hose at the nearest connecƟon

to the air supply, then run into the tool. OverĮůůŝng will cause a reducƟon in the power of the tool.

REPETITIVE MOTION / VIBRATION HAZARDS

WARNING:

Avoid prolonged exposure to vibraƟon. VibraƟon, repĞƟƟve moƟons, or

uncomfortable posiƟons over extended periods of Ɵme may be harmful to your hands and arms. Do not

ignore symptoms or persistent or recurring discomfort, pain, throbbing, aching, Ɵngling, numbness,

burning sensaƟon, or sƟīness. DisconƟnue use of the tool and seek medical advice before resuming use.

ĐŽŶƚĂŝŶŝŶŐŵŽŝƐƚƵƌĞĂďƐŽƌďĂŶƚƌƵƐƚŝŶŚŝďŝƚŽƌƐŵĞƚĂůǁĞƫŶŐĂŐĞŶƚƐĂŶĚĂŶW;ĞdžƚƌĞŵĞƉƌĞƐƐƵƌĞͿĂĚĚŝƟǀĞ

ŵĂLJďĞƵƐĞĚĂƐĂƐƵďƐƟƚƵƚĞKEKdh^dZ'EdK/>ƵƌŝŶŐĐŽŶƟŶƵŽƵƐŽƉĞƌĂƟŽŶƚŚĞƚŽŽůƐŚŽƵůĚďĞ

oiled every 1 to 2 hours. This may be done using an in-line oiler or manually.

If done manually, proceed as follows:

1. Disconnect the tool from the air supply.

2. Place a few drops of air tool oil into the inlet.

3. Connect the tool to the air supply. Run the tool without

load for a few seconds to distribute oil through the tool.

Care and Maintenance

The tool should be lubricated daily (or before each use) with air tool oil (not included).

:NOTE Air tool oil is available at major hardware stores. ^ηϭϬǁĞŝŐŚƚŽŝůŽƌĂŶLJŚŝŐŚŐƌĂĚĞƚƵƌďŝŶĞŽŝů

:NOTE Avoid the misuse of thicker oil which may lead to reduced ƉĞƌĨŽƌŵĂŶĐĞŽƌŵĂůĨƵŶĐƟŽŶ

:NOTE Any excess oil may be propelled from the air exhaust area ƐŽŬĞĞƉƚŚĞƚŽŽůƉŽŝŶƚĞĚŝŶĂƐĂĨĞĚŝƌĞĐƟŽŶ

ϰŌĞƌŽƉĞƌĂƟŶŐƚŚĞƚŽŽůĂŶĚďĞĨŽƌĞƐƚŽƌŝŶŐƚŚĞƚŽŽůĚŝƐĐŽŶŶĞĐƚƚŚĞĂŝƌŚŽƐĞĂŶĚƉůĂĐĞϰŽƌϱĚƌŽƉƐŽĨĂŝƌ

tool oil into the air inlet, then reconnect the air hose and run the tool for approximately 30 seconds to

evenly distribute the oil throughout the tool.

ϱǀŽŝĚƐƚŽƌŝŶŐƚŚĞƚŽŽůŝŶĂŚƵŵŝĚĞŶǀŝƌŽŶŵĞŶƚĂƐƚŚĂƚƉƌŽŵŽƚĞƐƌƵƐƟŶŐŽĨŝŶƚĞƌŶĂůŵĞĐŚĂŶŝƐŵƐůǁĂLJƐ

oil the tool before storage.

6. When the tool is seriously damaged or beyond repair, please dispose of properly. Recycle if possible.

Never incinerate this tool.

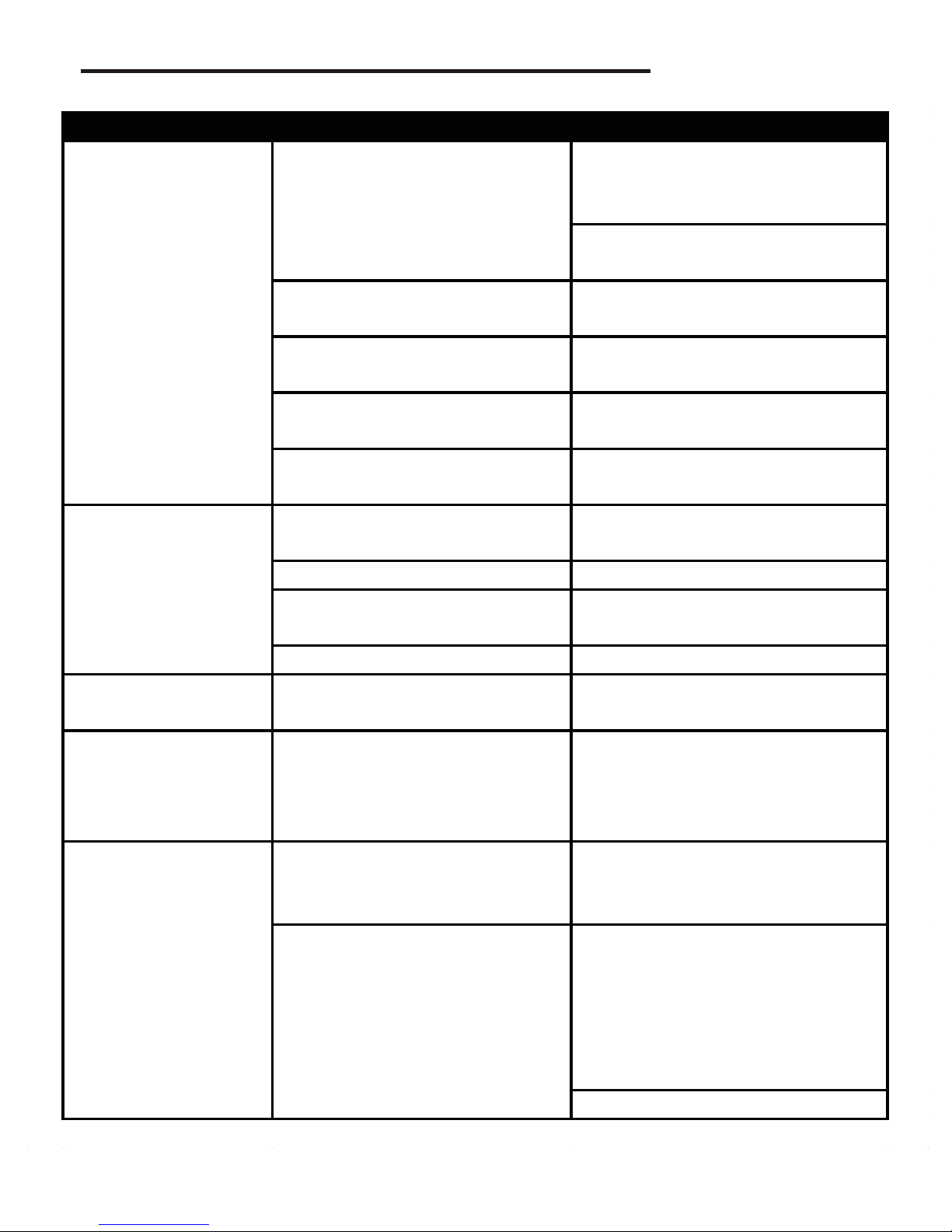

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

A) Add diesel fuel into air inlet to

Ňush motor. And then add air tool

oil to lubricate it.

Low air pressure Check the compressor gauge and

adjust the compressor regulator

Dry or rusty motor Lubricate the tool with air tool oil

No oil in tool Lubricate the tool with air tool oil

Lack of lubricaƟon Lubricate the tool with air tool oil

Regulator set in wrong posiƟon Adjust regulator

Low pressure Check the pressure of the air inlet

to be sure it is at 90 PSI

Worn impact mechanism Replace parts

Doesn't impact totally

but can run free

Seriously worn or damaged parts

of impact set

,ĂǀĞƚŚĞƚŽŽůƌĞƉĂŝƌĞĚďLJĂƋƵĂůŝĮĞĚ

service center or technician

Self running Trigger system:

1) Valve stem won't move back

2) Rusty or deformed steel ball

3) Rusty or cracked spring

1) Water in tank A) Drain tank. Oil tool and run unƟl

no water is evident. Oil tool and run

1-2 seconds

B) Install a water separator/Įlter.

NOT: Separators only work

properly when the air passing

through the separator is cool.

Locate the separator/Įlter as far as

possible from the compressor.

C) Install an air dryer

Replace parts

Moisture blowing out

of tool

2) Water in air lines/hoses

Tool runs slowly down

or doesn't work

'rit or gum in motor

B) Disassemble tool & repair it

Worn ball bearing Replace Ball bearing

Reduced Torque

dƌŽƵďůĞƐŚŽŽƟŶŐ

ATD-2106

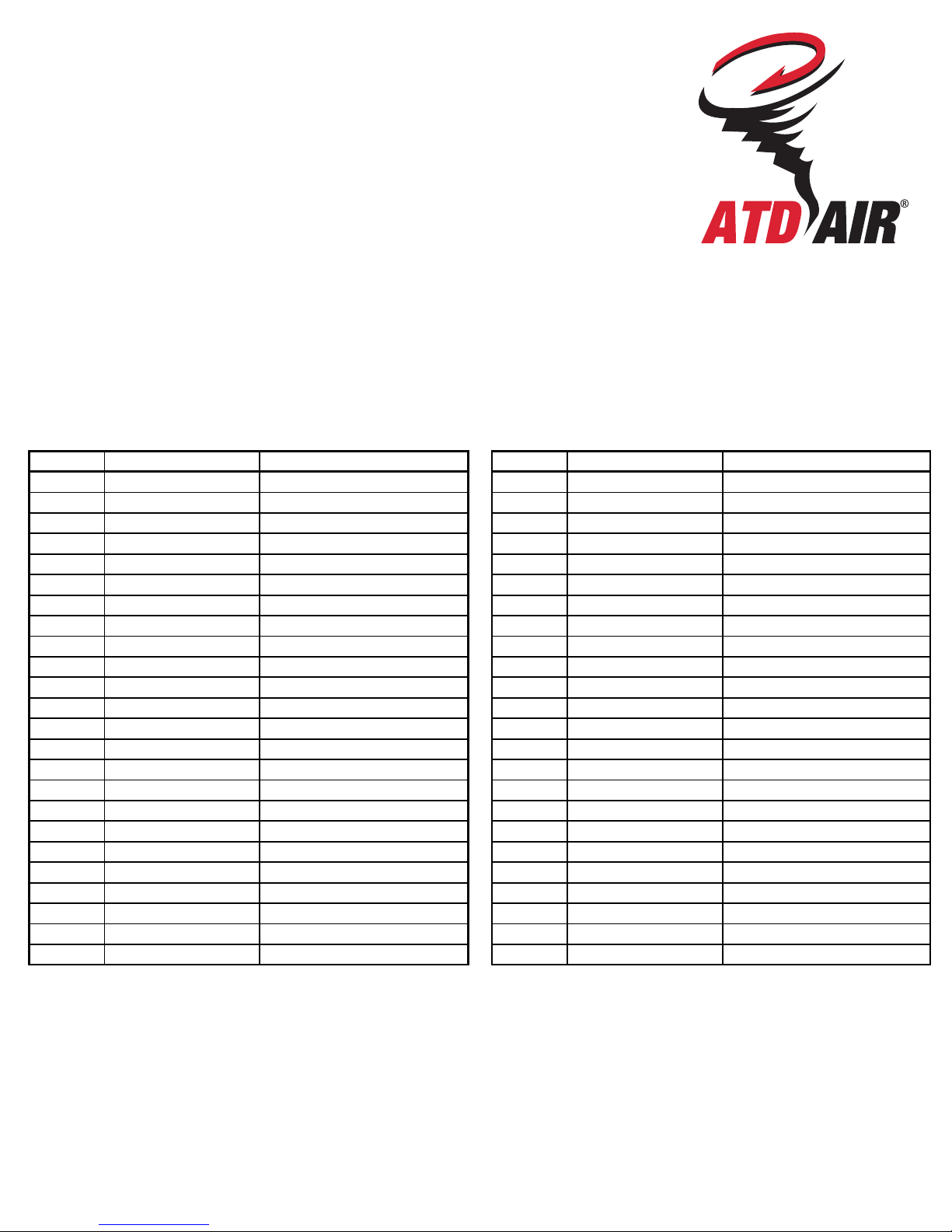

ITEM# ORDERING PART# PART DESCRIPTION ITEM# ORDERING PART# PART DESCRIPTION

1 PRT2106-01 HAMMER CASE 24 PRT2106-24 WASHER

2 PRT2106-02 INSERTS RECOIL (M5) 25 PRT2106-25 AIR CHANNEL GASKET

3 PRT2106-03 GREASE FITTING (1/8”) 26 PRT2106-26 MOTOR HOUSING

4 PRT2106-04 ANVIL BUSHING 27 PRT2106-27 REGULATORKNOB

5 PRT2106-05 FRONTGASKET 28 PRT2106-28 CAP SCREW (M5

ǘ6L)

6 PRT2106-06 ANVIL COLLAR 29 PRT2106-29 SCREW (M5)

7 PRT2106-07 O-RING (P7) 30 PRT2106-30 TRIGGER

8 PRT2106-08 ANVIL 31 PRT2106-31 O-RING 3x1

8 PRT2106-08A 2" ANVIL (OPTIONAL) 32 PRT2106-32 SPRINGPIN(

2ǘ22L)

9 PRT2106-09 HAMMER PIN 33 PRT2106-33 SPRING PIN (

3ǘ18L)

10 PRT2106-10 HAMMER 34 PRT2106-34 BUSHING

11 PRT2106-11 HAMMERCAGE 35 PRT2106-35 VALVE STEM

12 PRT2106-12 BALL BEARING(6002) 36 PRT2106-36 SPRING

13 PRT2106-13 FRONTEND PLATE 37 PRT2106-37 EXHAUSTDEFLECTOR

14 PRT2106-14 ROTOR 38 PRT2106-38 MUFFLER

15 PRT2106-15 ROTORBLADE 39 PRT2106-39 MUFFLER

16 PRT2106-16 PIN

)3ǘ8.7L*

40 PRT2106-40 O-RING (P16)

17 PRT2106-17 SQUARE RING 41 PRT2106-41 O-RING (

17ǘ1.5)

18 PRT2106-18 CYLINDER ASSEMBLY 42 PRT2106-42 O-RING (17.17ǘ1.78)

19 PRT2106-19 REGULATOR 43 PRT2106-43 WASHER

20 PRT2106-20 SPRING 44 PRT2106-44 AIR INLET

21 PRT2106-21 STEEL BALL (1/8”) 45 PRT2106-45 HANDLE RUBBER

22 PRT2106-22 O-RING 31x1.5 SK PRT2106-SK SPRING AND SEAL KIT

23 PRT2106-23 REAR GASKET HK PRT2106-HK HAMMER KIT

ATD-2106

WARRANTY

1 YEAR REPLACEMENT WARRANTY

THIS WARRANTY AND CONFIRMED RECEIPT (S) SHOULD BE RETAINED BY THE CUSTOMER AT ALL TIMES

The warranty is only made available by returning the product to the point of sale.

PURCHASD FROM:________________________________________________

DATPURCHASD: ________________________________________________

INVOI/ZIPT NUMR:_________________________________________

Your ATD-2106 is warranted for a period of 12 months from the original date of sale. Any consumable items

are covered by a 90 day warranty. This warranty is valid for defects in workmanship or materials only and

is handled at the point of sale.

The warranty given on this tool is against defects in workmanship and materials only. Any misuse, abuse

or accidental damage is not covered by warranty. The following acƟons will also result in the warranty

being void:

ͻIf the tool has been operated on a supply pressure other than that speciĮed on the tool.

ͻIf the tool shows signs of damage or defects caused by or resulƟng from abuse, accidents or alteraƟons.

ͻIf the tool is disassembled or tampered with in any way.

Note: Warranty excludes consumable parts such as carbon brushes, baƩeries, drill and driver bits and

chucks, etc.

[Aĸx receipt or invoice here for safe keeping]

Table of contents

Other ATD Tools Impact Driver manuals

Popular Impact Driver manuals by other brands

Central Pneumatic

Central Pneumatic 53176 Assembly and operating instructions

MasterForce

MasterForce 241-0418 Operator's manual

OEM Tools

OEM Tools 24670 Operating instructions and parts manual

Makita

Makita TD110D instruction manual

MasterCraft

MasterCraft 7381 instruction manual

Makita

Makita DTD153 instruction manual

Paoli Avvitatori

Paoli Avvitatori DP 217 Operating and maintenance manual

Scheppach

Scheppach 7906100717 Translation of original operating manual

Makita

Makita DTW800 instruction manual

Makita

Makita 6918FD instruction manual

ETC Tools

ETC Tools 91-250 manual

Kilews

Kilews SKC-PTM-200 Operation and maintenance manual