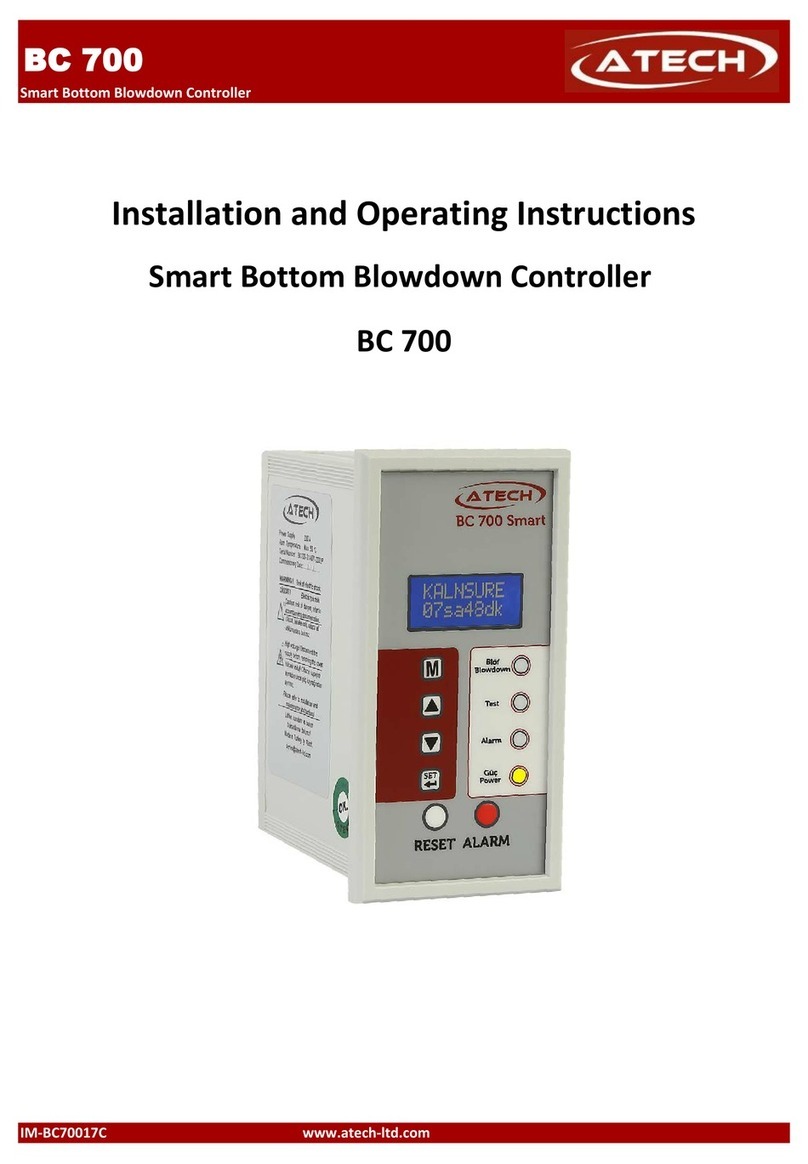

ATECH BC 900 User manual

SMART TDS BLOWDOWN CONTROLLER

IM-BC900-18C

BC 900

www.atech-ltd.com

BC 900

Installation and Operating Instructions

Smart Automatic TDS Blowdown Controller

SMART TDS BLOWDOWN CONTROLLER

1. SAFETY INFORMATIONS 3

2. DESCRIPTION & FUNCTIONS 4

3. TECHNICAL SPECIFICATIONS 6

4. INSTALLATION 6

4.1 Installation 6

4.2 Wiring 7

5. FUNCTIONS and CONFIGURATIONS 9

5.1 Display Definitions and Button Functions 9

5.2 Commissioning - Function Configurations 10

5.2.1 Startup Screen 10

5.2.2 Main Menu 10

5.2.3 Conductivity Set 10

5.2.4 Hysteresis Set 11

5.2.5 Alarm Set 11

5.2.6 Alarm Hysteresis Set 11

5.2.7 Calibration 11

5.2.8 System Mode Auto/Off 12

5.2.9 Valve & Alarm Test 12

5.2.10 Modbus Setup 13

5.2.11 Password 13

5.2.12 Default Settings 13

5.2.13 Software Version 14

6. START UP 14

7. MAINTENANCE 14

IM-BC900-18C Page 2

ATECH ENDÜSTRİYEL ÜRÜNLER SAN. VE TİC. LTD. ŞTİ.

BC 900

CONTENTS

www.atech-ltd.com

Giyim Kent 16. Sok. No: 79 Esenler/İstanbul - Turkey

P : 0.212.438 42 38 F: 0.212.438 42 58

SMART TDS BLOWDOWN CONTROLLER

1. SAFETY INFORMATIONS

Safety!

National and local regulations must be taken into consideration while electrical or mecanical installation.

Warning!

Please make sure to remove the main supply before installation.

Otherwise this may cause damage to the product, personal injuries or even death.

The manufacturer expressly rejects any claims for damage caused by improper installation.

IM-BC900-18C Page 3

BC 900

Installation, commissioning and maintenance of this device must be done by a qualified person in compliance with the

operating instructions. Otherwise device and related equipments may be damaged and personnel may be injured.

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

2. DESCRIPTION & FUNCTIONS

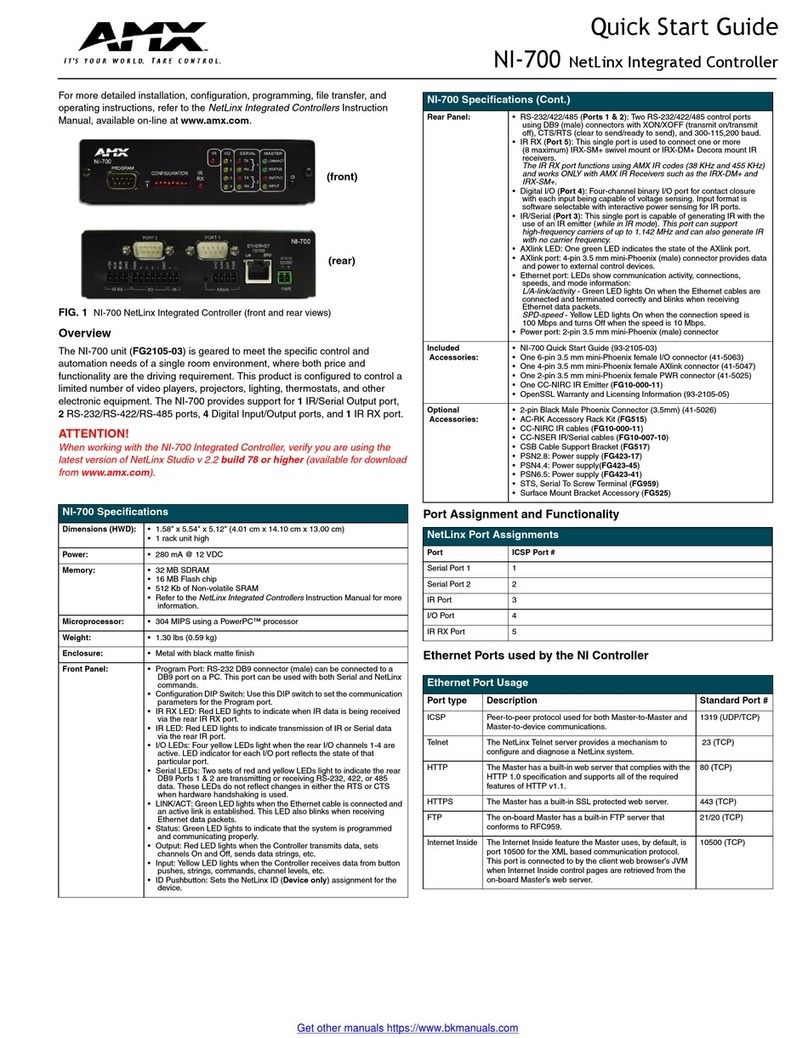

2.1 Typical applications - BCS 950 & BCS 930 Automatic TDS Blowdown Systems

Smart Automatic TDS Blowdown Controller BC 900, detects the electrical conductivity (TDS - Total Dissolved Solids)

of boiler water via the Conductivity Probe CP 950 or CP 930.

The TDS Blowdown Control Valve BCV 900 opens and closes in response to a high TDS signal from Smart Automatic

TDS Blowdown Controller BC 900. Keeps open until conductivity of the boiler water drops.

If the conductivty is lower than the set point the TDS Blowdown Control Valve BCV 900 remains closed.

Please refer to "BCV 900 Installation and Operation Manual for Automatic TDS Blowdown Control Valve" and

"CP 950 or CP 930 Installation and Operation Manual for Conductivity Probe" for detailed information

before assembly.

1- BC 900 TDS Blowdown Controller 4- BCV 900 TDS Blowdown Control Valve

2- CP 950 or CP 930 Conductivity Probe 5- Valve

3- PC F20 Probe Connection Te 6- Check Valve

IM-BC900-18C Page 4

BC 900

www.atech-ltd.com

Figure 1 Application of Automatic TDS Blowdown Control System / BCS 930 & BCS 950

1

2

3

5

4

6

Drenaja

Buhar Kazanı

SMART TDS BLOWDOWN CONTROLLER

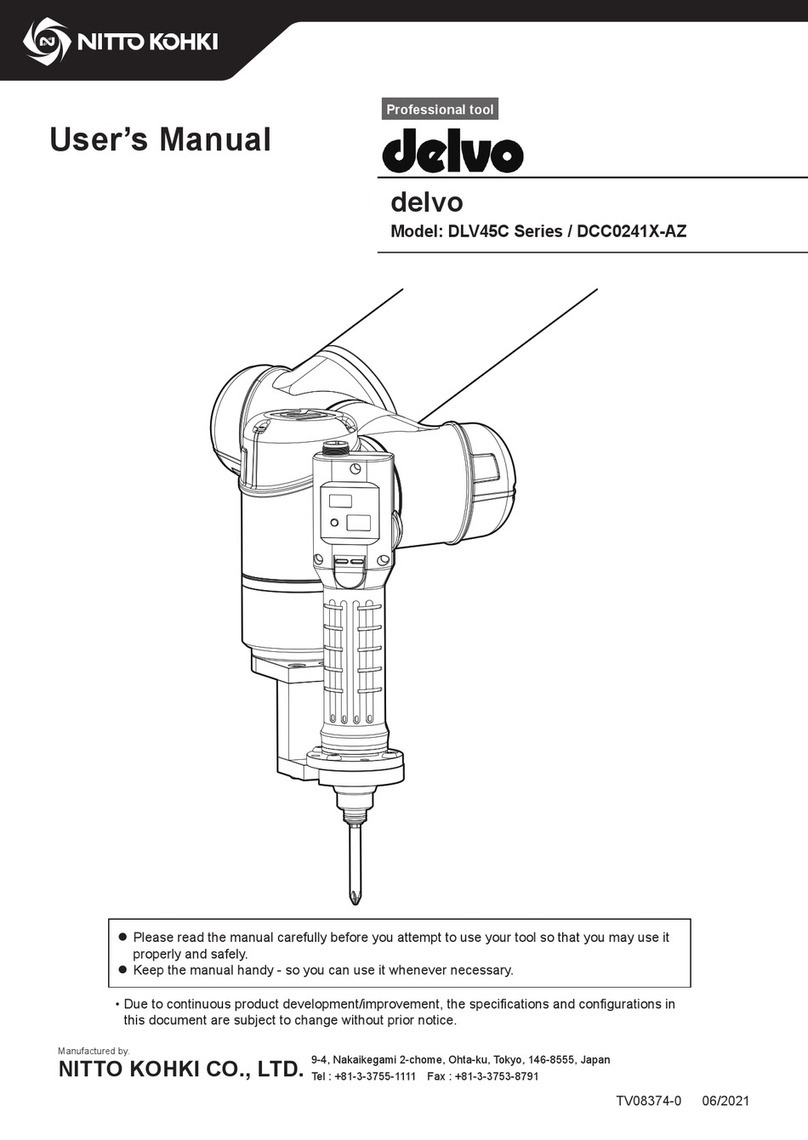

2.2 Typical applications - BCS 920 Automatic TDS Blowdown Systems

Smart Automatic TDS Blowdown Controller BC 900, detects the electrical conductivity (TDS - Total Dissolved Solids)

of boiler water via the Conductivity Probe CP 920.

The TDS Blowdown Control Valve BCV 915 opens and closes in response to a high TDS signal from Smart Automatic

TDS Blowdown Controller BC 900. Keeps open until conductivity of the boiler water drops.

If the conductivty is lower than the set point the TDS Blowdown Control Valve BCV 915 remains closed.

Please refer to "BCV 900 Installation and Operation Manual for Automatic TDS Blowdown Control Valve" and

"CP 920 Installation and Operation Manual for Conductivity Probe" for detailed information before assembly.

1- BC 900 TDS Blowdown Controller 4- TP 920 Temperature Sensor

2- CP 920 Conductivity Probe 5- BCV 915 TDS Blowdown Control Valve

3- PC D32 Probe Chamber 6- SF - Steam Separator

IM-BC900-18C Page 5

Figure 2 Application of Automatic TDS Blowdown Control System / BCS 920

BC 900

www.atech-ltd.com

1

2

5

3

4

Dranage

Steam Generator

6

SMART TDS BLOWDOWN CONTROLLER

3. TECHNICAL SPECIFICATIONS

Enclosure : IP 40 - EN 60529

Maximum ambient temperature : 55 °C

Main supply voltage : 230 V +/– 10 %, 50/60 Hz

115 V +/– 10 %, 50/60 Hz (Opsiyonel)

Frequency : 50 Hz

Maximum power consumption : 3 VA

Material : Plastic

Output signal : 4-20 mA, Relay contacts

Indicators and adjustors : 1 yellow LED for indicating “Power”,

1 green LED for indicating “Blowdown”,

1 red LED for indicating “Test”,

1 red LED for indicating “Alarm”,

1 button “ALARM” for checking alarm,

1 button “RESET” for resetting the alarm,

4 pushbuttons for parameter settings.

Dimensions (height x depth x width) : 144 x 110 x 72 mm

Weight : 0,5 kg

4. INSTALLATION

Installation, commissioning and maintenance of this device must be done by a qualified person in compliance

with the operating instructions.

4.1 Installation to panel

Smart Bottom Blowdown Controller BC 700 is front panel mounting enclosure type and can be applied to the front

panel with two screw clamps supplied.

Allow 20 mm minimum clearance all round the unit for air circulation.

Figure 3 Panel cut out dimensions of Smart Bottom Blowdown Controller BC 900

Please refer to "BCV 900 Installation and Operation Manual for Automatic TDS Blowdown Control Valve" and

"CP 920, CP 930 or CP 950 Installation and Operation Manual for Conductivity Probe" for detailed information

before assembly.

IM-BC900-18C Page 6

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

4.2 Wiring

Wiring between controller and valve actuator, 3x1 mm2cable can be used. Wiring between controller and probe,

5x1 mm2screened (shielded) - (LIYCY) cable can be used. The locations of terminals should not be changed.

If it is considered that the controller has phase connetiction to terminal 11 to terminal 18, then the terminal 1

through 10 of the controller should never be connected to the terminal 11 through terminal 18.

Otherwise, this could cause damage to equipment and even damage to people.

Wiring for BCS 950 & BCS 930 Automatic TDS Blowdown Systems

Figure 4 TDS Blowdown Controller BC 900 electrical connection diagram for BCS 950 & BCS 930 Blowdown Systems

Wiring for BCS 920 Automatic TDS Blowdown Systems

Figure 5 TDS Blowdown Controller BC 900 electrical connection diagram for BCS 920 Blowdown Systems

Note: Relays shown in de-energised state.

If it is considered that the controller has phase connetiction to terminal 11 to terminal 18, then the terminal 1

through 10 of the controller should never be connected to the terminal 11 through terminal 18.

Otherwise, this could cause damage to equipment and even damage to people.

Warning!

At the all phase inputs of the controller, must be used 3A fuse (non-delay type).

IM-BC900-18C Page 7

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

Wiring for CP 920 Conductivity Probe and TP 900 Temperature Probe at BCS 920 TDS Blowdown Systems

Figure 6 Wiring for CP 920 Conductivity Probe and TP 900 Temperature Probe at BC 900 TDS Blowdown Controller

Blue and Red cables at CP 920 Conductivity Probe, shoud be connectted to the BC 900 TDS Blowdown Controller as

three cables thanks to a junction box as showed at Figure 6. Red cables must be connected to therminals 1 and 2,

Also blue cable must be connected to terminal 3 at BC 900 TDS Blowdownd Controller.

Connect screen to earth (blue wire)

TP 920 Temperature Probe's cables must be connected terminal 4 and 5 at BC 900 TDS Blowdownd Controller.

IM-BC900-18C Page 8

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

5. FUNCTION AND CONFIGURATIONS

5.1 Display Definitions and Button Functions.

LCD Screen

Enter or return to main menu

Blowdown Led

Scroll up menus and

increase digits Test Led

Scroll down menus and Alarm Led

decrease digits

Power Led

Enter to functions, submenus

and pass to next digit while

changing a function value

Alarm Reset Buton Alarm Test Buton

button is used to enter main menu or return to main menu.

and buttons are used to scroll down or up function menus in main menu and also is used to change the

numerical values. Those buttons increase or decrease digits.

button is used to enter to functions, submenus and is used to pass the next digit while changing

a functions value.

After change the last digit, button accepts the whole value and returns to main menu.

To return to the main menu without making any changes, press the button

IM-BC900-18C Page 9

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

5.2 . Changing Function Configurations

5.2.1 Startup Screen

When device is powered, the screen likes the figure on the left.

Then conductivty value, will be seen on the screen of the conrtroller

5.2.2 Enter Commissioning

Hold down button for 5 seconds to enter commissioning mode.

To obstruct unauthorized interferences, BC 900 has password protection.

and buttons change each digit and button passes the next digit.

After change the last digit, button accepts the password and if it is true, it

automatically enters the main menu.

5.2.3 Conductivity Set Point

This function is used to set the conductivity value of blowdown.

Set Point is the TDS level at which the valve will open.

Set point should set in accordance with the

boiler manufacturers recommendations.

For example, 6.000 µS/cm value would be appirate

for fire tube / shell steam boilers.

IM-BC900-18C Page 10

www.atech-ltd.com

BC 900

SMART TDS BLOWDOWN CONTROLLER

5.2.4 Hysteresis Set

This function is used to prevent fluctuations of the valve when opening and closing.

When The TDS has increased above the Set Point, and the TDS blowdown valve has

been opened until the TDS drops below the hysteresis of the SP.

It can be selected 5% of set conductivity value.

5.2.5 Alarm Set

Smart Blowdownd Controller BC 900 provides alarm relay output when conductivity

level gets over the value adjusted with this function.

Alarm relay released at this TDS level.

5.2.6 Alarm Hysteresis Set

A damping effect for turbulent conditions.

Normally 5% of alarm figure would be enough.

5.2.7 Calibration

This function is used to define waters conductivity value taken properly from boiler.

When taking water sample from boiler and calibrating the controller, the boiler must

be at operating pressure and temperature. To take more appropriate sample for

measuring and calibrating, Atech Sample Cooler SC 9 is recommended.

For the best accuracy, calibrate the controller with the

TDS as close as possible to the Set Point.

Check the calibration weekly to ensure optimum

performance.

IM-BC900-18C Page 11

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

5.2.8 System Auto / Off

In this mode can be setted as "System Run" that gives An automatic blowdown or

"System Off" that the timer will give no blowdown.

"System Auto"

This mode gives an automatic blowdown, and is the usual

mode selected.

"System Off"

In this mode, the blowdown controller will give no

blowdown. Automatic blowdown is prevented on this boiler.

5.2.9 Tests outputs (Valve and Alarm)

This function is used to test the Blowdown Control Valve BCV 900 and

the alarm function working properly.

With this function, can be test to open or close the

Blowdown Control Valve.

The valve will be open for 2 minutes. Before the test duration

is finished, when button is pressed the valve will be

closed.

With this function, the alarm relay can be testted.

IM-BC900-18C Page 12

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

5.2.10 Modbus Setup (Optional)

This function is used to set Modbus address baud rate and infrared master/slave

configuration, and verifies the number of units on the IR bus

5.2.11 Password

This function is used to change the password of the device.

Press button to enter to function menu.

and buttons increase or decrease digits and

button shift right to the next digit.

After change the last digit, button accepts the new

password.

It is important that if the default pass code is changed that the new value is noted

and kept safe.

Default password 000

New password

5.2.12 Default Settings

If the default settings are needed, "Default Settings" function could be selected from

the menu.

To select "Default Settings", press button for 5 second on this function.

After confirming "Ok" on the screen, will be returned to the

menu. Default settings as below :

Conductivity Set Point : 5.000 uS/cm

Hysteresis : 300 uS/cm

Alarm : 9.500 uS/cm

Alarm Hysteresis : 300 uS/cm

System Run/Off : System Run

IM-BC900-18C Page 13

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

5.2.16 Software Version

Allows the software version to be viewed.

6. COMMISSIONING

• Be sure that all phase and neutral ends are connected to the right terminals on BC 900 Smart Automatic Bottom

Blowdown Controller before energyz.

• Be sure that all function values are adjusted correctly.

• Be sure that all wiring made correctly in compliance with "Automatic TDS Blowdown Valve BCV 900 Installation

and Operating Instructions"

• Be sure that all wiring made correctly in compliance with "Conductivity Probe CP 920, CP 930 or CP 950 Installation

and Operating Instructions"

7. MAINTENANCE

Please make sure to remove the main supply before detach the device.

Warning! Otherwise this may cause damage to the product, personal injuries or even death.

The device is not subject to repair and / or maintenance other than by authorized

service personnel.

When any fault situation occurs or maintenance is necessary, please contact with “

“Atech Service Department”

It is recommended to perform the function tests regularly.

IM-BC900-18C Page 14

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

IM-BC900-18C Page 15

BC 900

www.atech-ltd.com

SMART TDS BLOWDOWN CONTROLLER

IM-BC900-18C

BC 900

www.atech-ltd.com

ATECH ENDÜSTRİYEL ÜRÜNLER SAN. VE TİC. LTD. ŞTİ.

Giyim Kent 16. Sok. No: 79 Esenler/İstanbul - Turkey

P : +.90.212.438 42 38 F: +.90.212.438 42 58

Table of contents

Other ATECH Controllers manuals

Popular Controllers manuals by other brands

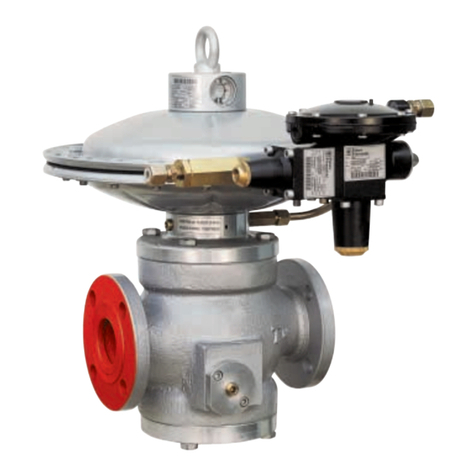

PIETRO FIORENTINI

PIETRO FIORENTINI REVAL 182 Technical manual

Neptronic

Neptronic BT100S Specification & installation instructions

DROPSA

DROPSA ADVANCED LUBRICATION CONTROLLER INSTRUCTION AND PRODUCT DATA SHEET

ZIMO

ZIMO MX31FU instruction manual

EINHELL

EINHELL CE-JS 8/1 operating instructions

STORK TRONIC

STORK TRONIC ST710-KPLVR.112S Wiring diagram

Parker

Parker 700-00028-0 Information manual

Asentria

Asentria TeleBoss 830 user manual

BIFFI

BIFFI ALGAS-QA Series Instruction and operation manual

Samson

Samson 2357-31 Mounting and operating instructions

Federal Signal Corporation

Federal Signal Corporation UltraVoice Installation, operation and service manual

ESP Safety

ESP Safety UPES-50D operating manual