sparkfun Qwiic Flex Glove Controller SEN-14666 Technical document

Qwiic Flex Glove Controller Hookup Guide

Introduction

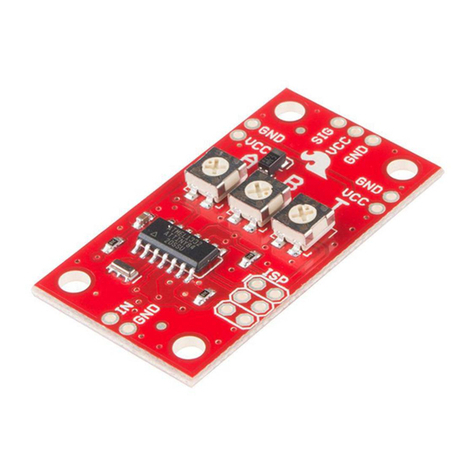

Flex sensors are great for telling how bent something is in a project, but we’ve been running into issues with

durability when using them in wearable applications like gloves. The Qwiic Flex Glove Controller isolates the weak

point to allow for more permanent flex sensor applications. The board has an onboard ADS1015 ADC to I C so we

can get a whole bunch of analog inputs without touching our microcontroller’s ADC pins.

2

SparkFun Qwiic Flex Glove Controller

SEN-14666

Y

O

U

R

A

C

C

O

U

N

T

L

O

G

I

N

R

E

G

I

S

T

E

R

In this hookup guide, we’ll figure out how to pull values from our fingers as well as calibrate the sensor for our

range of motion. We’ll also cover recommended placement and installation to implement these into gloves.

Required Materials

To get started, you’ll need a microcontroller to, well, control everything.

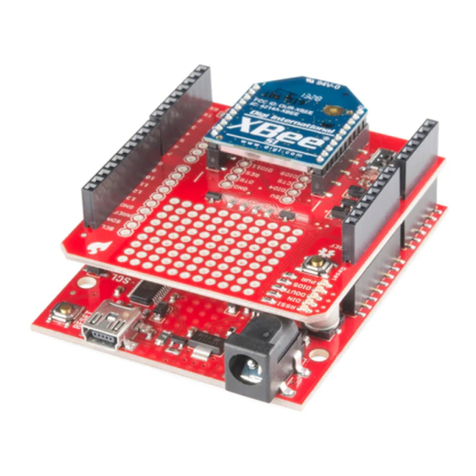

Now to get into the Qwiic ecosystem, the key will be one of the following Qwiic shields to match your preference of

microcontroller:

SparkFun RedBoard - Programmed with

Arduino

DEV-13975

SparkFun ESP32 Thing

DEV-13907

Raspberry Pi 3

DEV-13825

Particle Photon (Headers)

WRL-13774

You will also need a Qwiic cable to connect the shield to your sensor, choose a length that suits your needs.

SparkFun Qwiic Shield for Arduino

DEV-14352

SparkFun Qwiic HAT for Raspberry Pi

DEV-14459

SparkFun Qwiic Shield for Photon

DEV-14477

Qwiic Cable - 100mm

PRT-14427

Qwiic Cable - 200mm

PRT-14428

Qwiic Cable - 500mm

PRT-14429

Qwiic Cable - 50mm

PRT-14426

If you don’t have a sewing needle, we’d recommend grabbing one if you’re trying to add these flex sensors to

some gloves.

Suggested Reading

If you aren’t familiar with our new Qwiic system, we recommend checking out our overview:

WHAT IS QWIIC?

We would also recommend taking a look at the hookup guide for the Qwiic Shield if you haven’t already. Brushing

up on your skills in I C is also recommended, as all Qwiic sensors are I C.

Needle Set

TOL-10405

2 2

I2C

An introduction to I2C, one of the main embedded

communications protocols in use today.

Serial Terminal Basics

This tutorial will show you how to communicate with

your serial devices using a variety of terminal emulator

applications.

You’ll also most likely want to sew these boards into a wearable project, so if you’ve never picked up a needle and

thread before, we’d recommend checking out a how-to on hand sewing.

Hardware Overview

Let’s look over a few characteristics of the ADS1015 so we know a bit more about how our glove controller

behaves.

Characteristic Range

Operating Voltage 2.0V - 5.5V

Operating Temperature -40°C - 125°C

Resolution 12 bit

Sample Rate 128 Hz - 3.3 kHz

Current Consumption 150 µA (Typ.)

I C Address 0x48 (default), 0x49, 0x4A, 0x4B

Pins

The characteristics of the available pins on the magnetometer are outlined in the table below.

Pin

Label

Pin

Function

Input/Output Notes

3.3V Power

Supply

Input Should be between 2.2V - 3.6V

GND Ground Input 0V/common voltage.

SDA I C Data

Signal

Bi-directional Bi-directional data line. Voltage should not exceed power supply

(e.g. 3.3V).

SCL I C Clock

Signal

Input Master-controlled clock signal. Voltage should not exceed power

supply (e.g. 3.3V).

Optional Features

Qwiic Shield for Arduino & Photon Hookup

Guide

Get started with our Qwiic ecosystem with the Qwiic

shield for Arduino or Photon.

2

2

2

The Qwiic Flex Glove controller has onboard I C pull up resistors, which can be removed by removing the solder

from the jumper highlighted below. Only remove this solder if you are using your own pullups on the I C lines.

The I C address of the board can be changed using the jumpers on the back of the board. The address selection

pin is connected to the center pad of each jumper, the below table shows the addresses available when the

address selection pin is tied to each of the 4 available pads.

Pin Address

GND 0x48 (Default)

VCC 0x49

SDA 0x4A

SCL 0x4B

The location of the jumpers is shown in the below image.

2

2

2

The holes in the bottom corners of the board are used for sewing the board into the gloves of your choice.

Make sure you don’t crease the flex sensors as this will break the sensor!

Hardware Assembly

If you haven’t yet assembled your Qwiic Shield, now would be the time to head on over to that tutorial.

QWIIC SHIELD FOR ARDUINO PHOTON HOOKUP GUIDE

With the shield assembled, SparkFun’s new Qwiic environment means that connecting the sensor could not be

easier. Just plug one end of the Qwiic cable into the Flex Glove Controller breakout, the other into the Qwiic Shield

of your choice and you’ll be ready to upload a sketch and figure out how bent your fingers are. It seems like it’s too

easy to use, but that’s why we made it that way!

You may want to integrate this board into some gloves, after all, that’s what it was originally designed for. If you’re

looking to get sensors on 8 fingers, you’ll need 4 glove boards, and if you have 4 boards on the same I C bus,

you’ll need to use every address available to the ADS1015. So get started by changing the addresses of your

boards so no two boards share the same address.

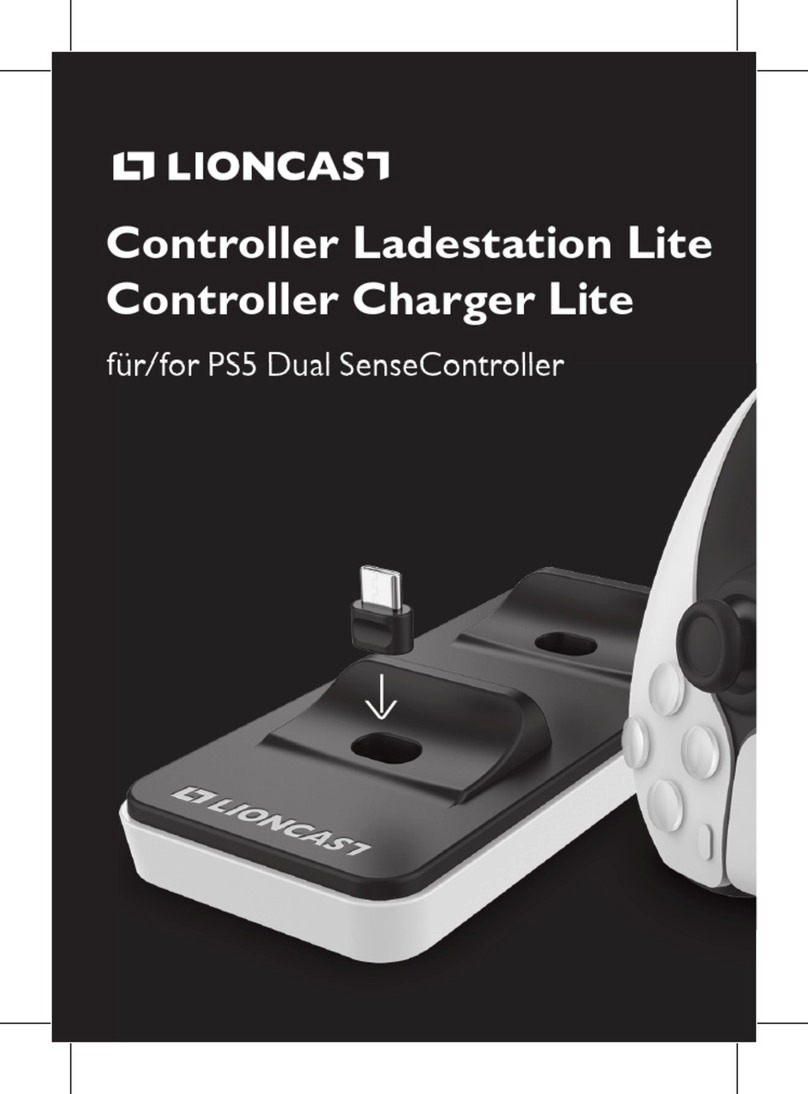

Now we want to attach our boards to our gloves. We’ve found it best to sandwich the board between two layers of

gloves to keep the sensor flush with the finger. To accomplish this, we’ll sew the board to the outer layer of the

inner glove. First, lay the glove out flat and place the board on the glove so that the ends of the flex sensors reach

the tips of the fingers.

s

Once you have the sensor laid out on the glove, take a marker and mark the point where the sewing hole touches

the glove.

Now simply sew the points to the available mounting holes on the sensor, The finished product should look like the

below glove.

Now it’s time to hide the circuitry under a second glove. Go ahead and put the just the fingers of the second glove

on, then slip the flex sensor down the gap between the the two layers of fabric. Sensors are shown at various

states of this process in the image below.

Now just plug Qwiic cables to connect both boards together, then plug one board into your microcontroller so we

can get readings from the glove.

Library Overview

Note: This example assumes you are using the latest version of the Arduino IDE on your desktop. If this is

your first time using Arduino, please review our tutorial on installing the Arduino IDE. If you have not

previously installed an Arduino library, please check out our installation guide.

Before we get into getting data from our flex sensors, let’s look at the available functions in the library. We’ve

written a library to control the flex sensors. You can snag this library through the Arduino Library Manager. Search

for SparkFun ADS1015 Arduino Library and you should be able to install the latest version. If you prefer

manually downloading the libraries from the GitHub repository, you can grab them here:

DOWNLOAD THE SPARKFUN ADS1015 ARDUINO LIBRARY (ZIP)

Let’s get started by looking at the functions that set up the flex controller.

Setup and Settings

boolean begin(uint8_t deviceAddress = BNO080_DEFAULT_ADDRESS, TwoWire &wirePort = Wire); — By

default use the default I2C address and use Wire port. Otherwise, pass in a custom I C address and wire

port.

uint16_t getAnalogData(uint8_t channel); — Returns the uncalibrated analog value from the sensor.

float getScaledAnalogData(uint8_t channel); — Returns a value between 0 and 1 based on calibration.

Won’t work properly without first running calibrate()

void calibrate(); — Used to calibrate the sensor and map the flexible range to values given by the user.

While running calibration, simply flex each sensor to the minimum and maximum that it will be used in your

project.

void setMode(uint16_t mode); — Set mode of the sensor. Mode 0 is continuous read mode, mode 1 is

single-shot

uint16_t getMode(); — Get’s the read mode of the ADS1015.

getCalibration(uint8_t channel, bool hiLo) — Get the high or low calibration value for a certain

channel. if hiLo is true, getCalibration() will return the high calibration for the given channel.

setCalibration(uint8_t channel, bool hiLo, uint16_t value) — Sets the high or low calibration value

of a channel without using the automatic calibration function. Allows for manual calibration.

2

https://github.com/sparkfun/SparkFun_ADS1015_Arduino_Library/archive/master.zip

resetCalibration() — Resets the calibration to 0.

void setGain(uint16_t gain); — Pass in different values for different gains

uint16_t getGain(); — Get’s the gain of the ADS1015. This will return 16-bit hex value. The values and

their corresponding gains are listed below.

0x0E00 : ± 0.256V

0X0000 : ± 6.144V

0X0200 : ± 4.096V

0X0400 : ± 2.048V

0X0600 : ± 1.024V

0X0800 : ± 0.512V

0X0A00 : ± 0.256V

void setSampleRate(uint16_t sampleRate); — Sets the sample rate for the ADS1015, pass in the below

16-bit values to change to the corresponding sample rate.

0X0000 : 128 Hz

0X0020 : 250 Hz

0X0040 : 490 Hz

0X0060 : 920 Hz

0X0080 : 1600 Hz

0X00A0 : 2400 Hz

0X00C0 : 3300 Hz

uint16_t getSampleRate(); — Returns the sample rate according to the above list of sample rates.

Example Code

Now that we know how our library works, let’s go ahead and get started pulling values from our flex sensors.

Example 1 - Basic Readings

To get started with the first example, open up File > Examples > SparkFun ADS1015 Arduino Library >

Example1_BasicReadings. In this example, we begin by creating an ADS1015 object called fingerSensor and

then initializing our sensor object in the setup() loop. We then get the values from each finger by looping through

and reading each channel on the ADS1015. The code for this is shown below.

#include <SparkFun_ADS1015_Arduino_Library.h>

ADS1015 fingerSensor;

void setup() {

Wire.begin();

Serial.begin(115200);

if (fingerSensor.begin(Wire, 100000, ADS1015_ADDRESS_GND) == false) {

Serial.println("Device not found. Check wiring.");

while (1);

}

}

void loop() {

uint16_t data;

for (int finger = 0; finger < 2; finger++) {

data = fingerSensor.getAnalogData(finger);

Serial.print(finger);

Serial.print(": ");

Serial.print(data);

Serial.print(",");

}

Serial.println();

}

Uploading this sketch and opening the Serial Monitor to 115200 bps will yield an output somewhat like the below

image.

Single Sensor Output - click the image for a closer look

Example 2 - Setup hand

In this example, we’ll see how to setup an entire hand of flex sensors. To get started with this example, open up

File > Examples > SparkFun ADS1015 Arduino Library > Example2_SetupHand. In this example, we create

two ADS1015 objects, naming them indexSensor and pinkySensor to correspond with their locations on the

glove. We also create an array with 4 spots to hold the data for the hand called hand . We then populate hand

with values from each sensor. The code that accomplishes this is shown below.

#include <SparkFun_ADS1015_Arduino_Library.h>

ADS1015 pinkySensor;

ADS1015 indexSensor;

uint16_t hand[4] = {0, 0, 0, 0};

void setup() {

Wire.begin();

Serial.begin(115200);

if (pinkySensor.begin(Wire, 100000, ADS1015_ADDRESS_SDA) == false) {

Serial.println("Pinky not found. Check wiring.");

while (1);

}

if (indexSensor.begin(Wire, 100000, ADS1015_ADDRESS_GND) == false) {

Serial.println("Index not found. Check wiring.");

while (1);

}

}

void loop() {

uint16_t data;

for (int finger = 0; finger < 2; finger++) {

hand[finger] = indexSensor.getAnalogData(finger);

hand[finger + 2] = pinkySensor.getAnalogData(finger);

}

for (int finger = 0; finger < 4; finger++)

{

Serial.print(finger);

Serial.print(": ");

Serial.print(hand[finger]);

Serial.print(" ");

}

Serial.println();

}

Uploading this sketch and opening the Serial Monitor to 115200 bps will yield an output somewhat like the below

image.

Full Glove Output - click the image for a closer look

Example 3 - Calibration

The second example will show us how to calibrate our flex sensor so we get 0 when our finger is closed and 1

when it is open. To get started, open up File > Examples > SparkFun ADS1015 Arduino Library >

Example3_Calibration. In this example we will calibrate our sensor’s maximum and minimum values in order to

find the range for our sensor.

#include <SparkFun_ADS1015_Arduino_Library.h>

#include <Wire.h>

ADS1015 fingerSensor;

void setup() {

Wire.begin();

Serial.begin(115200);

if (fingerSensor.begin(Wire, 100000, ADS1015_ADDRESS_GND) == false) {

Serial.println("Device not found. Check wiring.");

while (1);

}

Serial.println("Calibrating, send 'e' when finished");

}

void loop() {

uint8_t incoming;

do

{

fingerSensor.calibrate();

if(Serial.available())

{

incoming = Serial.read();

}

} while (incoming != 'e');

Serial.println("Calibrated");

for (int channel; channel < 2; channel++)

{

Serial.print("Channel ");

Serial.print(channel);

Serial.print(": ");

for (int hiLo = 0; hiLo < 2; hiLo++)

{

switch (hiLo)

{

case 0:

Serial.print("Low: ");

Serial.print(fingerSensor.getCalibration(channel, hiLo));

break;

case 1:

Serial.print(" High: ");

Serial.print(fingerSensor.getCalibration(channel, hiLo));

break;

}

}

Serial.println();

}

}

The sensor is initialized in the same manner as the first example, then our loop() begins calibrating the sensors.

To calibrate the sensors, simply flex them to their maximum and minimum bend radii, then send an e over the

Serial Monitor when you’re finished. This will save the current calibration and show you the values that have been

saved. Uploading this sketch and opening the Serial Monitor to 115200 bps will yield an output somewhat like the

below image once you’ve sent e and saved the calibration.

Calibration Output - click the image for a closer look

Example 4 - Calibrated Hand

You don’t necessarily want to calibrate your hand every single time you put on a glove with the flex controllers built

in, so let’s figure out how to manually set our calibration if we know it already. To get started, open up File >

Examples > SparkFun ADS1015 Arduino Library > Example4_ManualCalibration. We can see in the

preamble to our code that we have an array of all of our calibration values, which were obtained using the previous

example sketch. We then use a loop in the setup function along with our setCalibration() function to set the

individual calibration values. The code for this is shown below.

#include <SparkFun_ADS1015_Arduino_Library.h>

#include <Wire.h>

ADS1015 pinkySensor;

ADS1015 indexSensor;

float hand[4] = {0, 0, 0, 0};

uint16_t handCalibration[4][2] = {

//{hi , low}

{722, 1080},//index

{600, 980},//middle

{680, 900},//ring

{736, 907} //pinky

};

void setup() {

Wire.begin();

Serial.begin(115200);

//Begin our finger sensors, change addresses as needed.

if (pinkySensor.begin(Wire, 100000, ADS1015_ADDRESS_SDA) == false)

{

Serial.println("Pinky not found. Check wiring.");

while (1);

}

if (indexSensor.begin(Wire, 100000, ADS1015_ADDRESS_GND) == false)

{

Serial.println("Index not found. Check wiring.");

while (1);

}

//Set the calibration values for the hand.

for (int channel; channel < 2; channel++)

{

for (int hiLo = 0; hiLo < 2; hiLo++)

{

indexSensor.setCalibration(channel, hiLo, handCalibration[channel][hiLo]);

pinkySensor.setCalibration(channel, hiLo, handCalibration[channel + 2][hiLo]);

}

Serial.println();

}

}

void loop() {

for (int channel = 0; channel < 2; channel++)

{

//Keep in mind that getScaledAnalogData returns a float

hand[channel] = indexSensor.getScaledAnalogData(channel);

hand[channel + 2] = pinkySensor.getScaledAnalogData(channel);

}

for (int finger = 0; finger < 4; finger++)

{

Serial.print(finger);

Serial.print(": ");

Serial.print(hand[finger]);

Serial.print(" ");

}

Serial.println();

}

Uploading this sketch and opening the serial monitor will show a stream of calibrated values. Use these to scale

any other variable you’d like in your project.

Calibrated Hand Output - click the image for a closer look

Resources and Going Further

Now that you’ve successfully got your Qwiic Flex Glove Controller up and running, it’s time to incorporate it into

your own project!

For more information, check out the resources below:

Schematic (PDF)

Eagle Files (ZIP)

ADS1015 Datasheet (PDF)

Qwiic Landing Page

GitHub Repos

Product

Arduino Library

SparkFun Product Showcase: Qwiic Flex Glove Controller

Need even more inspiration for your next project? Check out some of these related tutorials:

AS726X NIR/VIS Spectral Sensor Hookup

Guide

It's now easier than ever to measure and characterize

how different materials absorb and reflect different

wavelengths of light. The AS726X spectral sensors

allow you to detect wavelengths in the visible range

(VIS) and near infrared range (NIR)!

Qwiic HAT for Raspberry Pi Hookup Guide

Get started interfacing your Qwiic enabled boards with

your Raspberry Pi. This Qwiic connects the I2C bus

(GND, 3.3V, SDA, and SCL) on your Raspberry Pi to

an array of Qwiic connectors.

Table of contents

Other sparkfun Controllers manuals