ATECH TUCANA-06 A User manual

TUCANA-06 A

AUTOMATIC END MILLING MACHINE

FOR LARGE EXTRUSIONS

USER’S MANUAL

1

CONTENTS

1. GENERAL INFORMATION

1.1. Introduction

1.2. Information about of the Distributor

2. MACHINE’S DESCRIPTION AND PURPOSE OF USE

2.1. Machine’s Description

2.2. Accessories

2.3. Technical Features

2.4. Dimensions

3. SAFETY

3.1. Safety Information

3.2. Accident Prevention

3.3. General Safety Information

3.4. Safety Symbols and Their Meanings

4. TRANSPORT OF THE MACHINE

5. INSTALLATION OF THE MACHINE

5.1. Preparation

5.2. Instructions About Safe Connection Of The Machine To The Power Source

6. MACHINE SAFETY DATA

7. OPERATION

7.1. Beginning To Work

7.2. Air Pressure Setting

8. CHANGING THE MILLING CUTTER GROUP

9. MAINTENANCE

9.1. Periodic Checks And Maintenance At The End Of The Working Day

10. INFORMATION ABOUT FAULTY USE

11. COMPONENTS

11.1. Electric Components

11.2. Pneumatic Components

2

1. GENERAL INFORMATION

1.1. Introduction

The user’s manual given by the manufacturer contains information about the machine parts. Each machine operator

should read these ınstructions carefully, and the machine should be operated after fully understanding them.

Safe and efficient use of the machine for long term depends on understanding and following the instructions contained

in this manual. The technical dtawings and details contained in this manual constitute a guide for the operator.

1.2. Information About The Distributor

ATech Machine, Inc.

8539 Ziggy Lane

Gaithersburg, MD 20877 – USA

Ph.: 240-505-1967

Fax: 301-560-6627

info@ATechMachinery.com

*In case of any technical problem please contact your nearest A-TECH dealer or A-TECH head office through the above

mentioned phone, fax or e-mail address.

*Technical labels with the model description of the machine are fixed onto the front side of each machine.

*The machine’s serial number and manufacturing year are stipulated on the technical label.

2. MACHINE’S DESCRIPTION AND TECHNICAL FEATURES

2.1. Machine’s Description

Clamping and knife movement is a pneumatically designed medium recording machine for precise alignment of PVC and

aluminum centering profiles.

The machine has been designed in accordance with the CE Directives.

Heavy duty automatic end milling machine designed for horizontal end milling of large aluminum and vinyl extrusions.

Hydro-pneumatic cutter stack feed.

Adjustable stops for 4 different profiles.

Fully guarded end milling area

Pneumatic clamping

Automatic return to start position after horizontal milling operation

2.2. Accessories

STANDARD ACCESSORIES OPTIONAL ACCESSORIES

1- Service Keys 1- Pneumatic Spray Mist Lubrication System

2- Profile Support Conveyor

3- 1 Qty. Pneumatic Vertical Clamp

4- 1 Qty. Pneumatic Horizontal Clamp

5- Air Blow Gun

6- Chip Collector Manifold

2- Custom Made Profile Fixture

3- Custom Made Cutter Stack

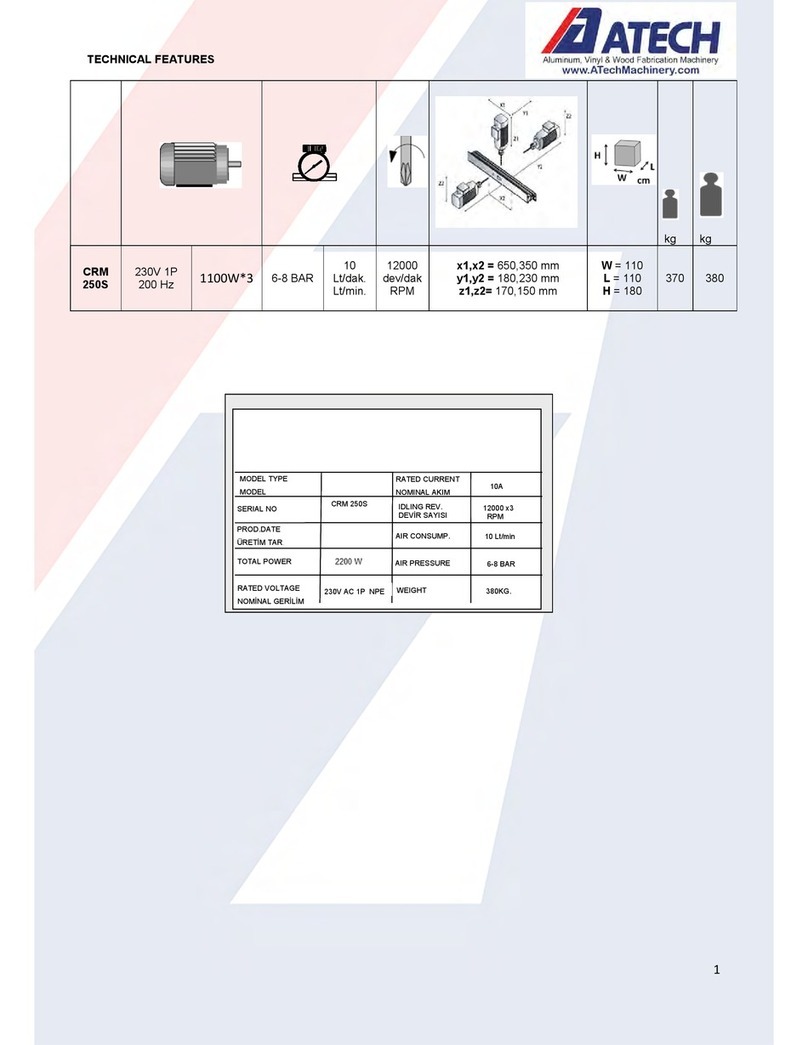

2.3. Technical Features

3

2.4. Dimensions

3. SAFETY

3.1. Safety Information

The symbols shown hereunder are necessary to be read with special attention.

Not reading or observing of them may cause damage to the equipment or personal injury.

The IMPORTANT symbol above is one telling to apply special care and to be careful at carrying out the specified operation.

The CAUTION! symbol above warns you against specific dangers and requires to read the text. Not observing may cause damage

to the equipment.

The above symbol DANGER WARNING, warns you against specific dangers and you have definitely to read them. Negligence

may cause damage to the equipment and bodily injury. Read the user’s manual carefully before using the machine or carrying

out maintenance works.

3.2. Accident Precention

3.2.1. Our machines are manufactured in accordance with EN 60204–1 and EN 292–2 CE safety

directives, which cover national and international safety directives.

3.2.2. It is the task of the employer to warn his staff against risks, to train them on prevention of

accident, to provide for necessary safety equipment and devices for he operator’s safety.

3.2.3. Before starting to work with the machine, the operator should check the features of the machine, learn all details

of the machine’s operation.

3.2.4. Machine should be operated only by staff members, who have read and understood the contents of this manual.

3.2.5. All directives, recommendations and general safety rules contained in this manual have to be observed fully. The

machine cannot be operated in any way for purposes other than those described herein. Otherwise, the

manufacturer shall not be deemed responsible for any damages or injuries. And such circumstances would lead to

the termination of the warranty.

4

3.3. General Safety Information

3.3.1.

The power cable should be led in such a way that nobody can step on it or nothing

can be placed on it. Special care be taken regarding the inlet and outlet sockets.

3.3.2. If the power cable should be damage during operation, don’t touch and unplug it.

Never use damaged power cables.

3.3.3. Don’t overload machines for drilling and cutting. Your machine will operate more

safely with power supply in accordan CE with the stipulated values.

3.3.4. Don’t place your hands between parts in motion.

3.3.5. Use prtective eye glasses and ear plugs. Don’t wear oversize clothes and jewels.

These can be caught by moving.

3.3.6. Keep your working place always clean, dry and tidy for accident prevention and safe

operation.

3.3.7. Use correct illumination fort he safety of the operator. (ISO 8995-89 Standard The

Lighting of Indoor Work System)

3.3.8. Don’t leave anything on the machine.

3.3.9. Don’t use any materials other than those recommended by the monufacturer for

cutting operations on the machine.

3.3.10. Ensure that the work piece is clamped appropriately by the machine’s clamp or vice.

3.3.11. Ensure safe working position, always keep your balance.

3.3.12. Keep your machine always clean for safe operation. Follow the instructions at

maintenance and replacement of accessories. Check the plug and cable regularly. If

damaged, let it replace by a qualified electrician. Keep handles and grips free of any

oil and grease.

3.3.13. Unplug first, before conducting and maintenance works.

3.3.14. Ensure that any keys or adjustment tools have been removed before operating the

machine.

3.3.15. If you are required to operate the machine outside, use only appropriate extension

cables.

3.3.16. Repairs should be carried out by qualified technicians only. Otherwise, accidents amt

occur.

3.3.17. Before starting a new operation, check the appropriate function of protective devices

and tools, ensure that they work properly. All conditions have to be fulfilled in order

to ensure proper operation of your machine. Damaged protective parts and

equipment have to be replaced or repaired properly (by the monufacturer or dealer).

3.3.18. Don’t use machines with improper functioning buttuons and switches .

3.3.19. Don’t keep flammable, combustive liquids and materials next to the machine and

electric connections.

3.4. Safety Symbols And Meanings

Electric warnings.

Use protective goggles.

If main connection cable is

damaged during operation, do not

touch it and disconnect the main

plug from main socket.

Use protective earmuffs.

When machine is working, do not

make your hand close to saw blade.

Use protective gloves when

changing the saw.

Keep working environment clean,

dry and tidy.

Read operating instructions

carefully before using or

maintaining the machine.

5

4. TRANSPORT OF THE MACHINE

4.1.1. The transport should be done by qualified personnel only.

4.1.2. The machine should be transported by lifting with proper equipment (not touching the ground

during the transport).

4.1.3. Keep the carton box packing of the machine for future use.

5. INSTALLATION OF YOUR MACHINE

5.1. Preparation

5.1.1. The machine’s dimension are shown in the Technical Features page. Place the machine onto an even ground

or on the double tray tool cabinet, which is delivered as option.

5.1.2. The machine should be located approx. 50 cm away from the back wall. The power connection plug is located on

the rear side of the machine.

5.1.3. The machine should be located on an even and solid ground.

5.1.4. At the portable end milling machine PANDA all parts are delivered ready for use.

5.2. Instructions For Safe Connection Of The Machine To The Power Source

5.2.1. The phase elektric cable socket has to be in accordance with the machine’s plug

5.2.2. Your machine should be operated with 400 V ~ 60 Hz.

5.2.3. Plug the machine into a grounded socket.

5.2.4. Check the power source voltage. It has to be in accordance with the values stipulated on the machine’s type label.

Saw Rotation Direction

To correct the rotation direction of the saw blade, plug in the machine and follow these instructions:

1. Press the Start button.

2. Press the cutting head down until the blade guard opens.

3. Press the Stop button. Observe the rotation direction of the saw blade through the open part of the blade guard.

If the saw blade rotates in reverse direction: The electric socket connections have to be checked and

corrected by a qualified electrician. The rotation direction of the saw blade should not be defined before

testing.

6. MACHINE SAFETY DATA

6.1.1. It is not allowed to operate the machine with the protective cover and other protective equipment removed.

6.1.2. Lifting, installation, electric, pneumatic maintenance of the machine should be carried out by qualified personnel

only.

6.1.3. Routine maintenance and scheduled maintenance should be carried out by qualified personnel after unplugging the

machine and disconnecting the air supply first.

6.1.4. Ensure that the machine has been cleaned, tested and maintenance before starting to operate.

6.1.5. Check the safety devices, power cable and moving parts regularly. Don’t operate the machine before having replaced

defective safety devices or faulty parts

6.1.6. Not change the milling saw blade group without pressing the emergency stop button and closing the main switch

and disconnecting the air and open the protective cover. With the cover open, the machine is secured with a safety

switch to avoid any danger.

6.1.7. Keep foreign materials away from the working area of the machine, keep away from the machine’s moving parts.

The safety data have been defined above. In order to prevent physical damage or damage to the

equipment, please read the safety information carefully and keep the manual always in an easy

accessible place.

7. OPERATION

7.1. Beginning To Work

7.1.1. Ensure that the machine table and all kind of parts are clean and dry. Degrease and dry the machine table.

7.1.2. Clean all surfaces of the machine from chip and foreign particles. Use eye glasses for protection.

7.1.3. Check with the appropriate keys that the milling cutters are tightened well.

7.1.4. Check the milling cutters for wear, bending and breaking. Replace them if damaged.

7.1.5. Our portable end milling machine PANDA is used for working of non-ferrous materials, aluminum and PVC mullion

profiles to make “T” connections.

7.1.6. For the T joint, touch the profile with the 4-way rotary system in the center section, which is in the moving section.

NOTE: The milling length of the mullion profile can be adjusted precisely by loosening the stopper on the machine and fixing

it at the desired length.

7.1.7. Tighten the profile with two clamps on the machine by pressing the “Clamps” button on the panel.

6

Don’t start to process the work piece before ensuring that it is clampded properly.

7.1.8. Press the “Motor” button to rotate the milling cutters.

7.1.9. You can start the cutting process by pressing the green "I" button. Once the machine has finished cutting, it will

automatically return to its initial position and the clamps will open automatically.

7.1.10. The speed of the saw can be adjusted from the speed adjustment valve on the side.

Press the “Emergency Stop” button in any adverse situation during the operation.

7.2. Air Pressure Setting

For the pneumatic system to operate properly, the air pressure must be 6-8 bars. Do not operate at lower pressures than

6 bars. Read the manometer on the conditioner to calibrate and check the air pressure.

Follow the steps below for air pressure settings.

7.2.1. Pull up the conditioner adjustment knob.

7.2.2. The pressure increases when the knob is turned clockwise, while the pressure decreases when it is turned counter-

clockwise.

7.2.3. When you read the 6-8 Bar pressure setting on the pressure gauge, lock the conditioner setting knob.

7.2.4. The conditioner unit accumulates the water contained in the air system into the collection container so as not to

damage the pneumatic system components. Automatically removes water collected when air is supplied to the

machine.

7.2.5. The oil recommended by the manufacturer in the conditioner is TELLUS C 10 / BP ENERGOL HLP 10 / MOBIL DTE

LIGHT / PETROL OFFICE SPINDURA 10.

8. CHANGING THE END MILL CUTTER STACK

When you want to remove the milling cutter for any reason and replace it with a new one, follow the sequence

below:

8.1.1. Disconnect the machine from the electric and air connections.

8.1.2. Remove the cover by removing both covers connection.

8.1.3. Remove the milling shaft support sheet metal.

8.1.4. Using an allen key, remove the nut with the appropriate wrench.

8.1.5. Remove cutter stack using protective gloves.

8.1.6. For the height adjustment of the cutter, use thin washers located at the top and bottom of the

cutter.

8.1.7. Compare the cutter stack heights with the profile to be end milled.

8.1.8. Tighten the nut by doing the reverse operations when removing the cutters..

WHEN REPLACING THE CUTTER STACK, ENSURE THE CUTTERS ROTATE IN THE CORRECT DIRECTION.

NOTE: Ensure that the cutter stack has been tightened properly.

8.1.9. Check the cutter stack before use. The cutter stack has to be placed onto the shaft properly (no vibration). Don’t use

blunt, damaged cutters. Chech the machine by running it at least 20 sec. in idle position.

9. MAINTENANCE

9.1. Periodic Checks And Maintenance At The End Of The Working Day

9.1.1. Disconnecting electrical and air power the machine first.

9.1.2. Remove all burr and foreign materials from the machine. If it is necessary to clean the inside of the protection cover,

lift and clean it wearing protective gloves because of the cutters. Use protective eye glasses.

9.1.3. Clean and dry the machine table.

Milling Shaft Support Sheet Metal

32

Nut

7

9.1.4. Apply a protective oil film onto the milling cutters and the unpainted parts of the machine to provide protection

against corrosion.

10. INFORMATION ABOUT FAULTY USE

Here are our suggestions to get rid of immediate problems. If the fault can not be rectified or if you encounter a fault other

than those listed below, please contact the technical service.

TROUBLES CAUSES REMEDY

Low surface quality (at aluminum

and similar materials);

Rough surface,

Large chip,

Not homogenous surface,

Saw blade traces visible

Not cooling the saw blade surfaces.

Lubricating the saw blade cutting

surfaces,

Using of cooling liquid.

Using of damaged or blunt saw

blade or the saw rotating in reverse.

Check the saw blade teeth. Replace if

necessary. Check the electricity.

Saw blade moves to quick. The cutting speed is too high fort he

material. Decrease the cutting speed.

Motor does not work (Start button

is pressed, not working) No power supply to the machine. Check the electric cable connections.

Check the electric power sockets.

Motor is working but the pneumatic

clamp piston do not work.

The air supply connections are

missing, or the air pressure is too

low.

Check the air compressor connections.

Adjust the air pressure between 6-8 Bar

on the conditioner.

The saw blade rotates in reverse

direction.

The electric connection or the

power cable is wrong.

Let the electric connections carry out by

a qualified electrician.

11. ELECTRIC COMPONENTS

11.1. ELECTRIC COMPONENTS 11.2. PNEUMATIC COMPONENTS

PART NAME QTY

ELECTRIC MOTOR 1

MOTOR PATCHER 1

POWER CABLE 4x1,5 mm 3,5 m

ELECTRIC PLUG 1

PART NAME QTY

FRC 1/8 D MINI CONDITIONER 1

VALVE 1

PNEUMATIC CLAMP 2

Table of contents

Other ATECH Power Tools manuals

Popular Power Tools manuals by other brands

Jet

Jet JAT-120 Operations & parts manual

Vibration Therapeutic

Vibration Therapeutic VT027 User Manual & Tech Specs

Central Machinery

Central Machinery 31849 Assembly & operating instructions

Bosch

Bosch PBH 2800 RE operating instructions

VINCENT

VINCENT VP-16 Operation & maintenance manual

Ryobi

Ryobi RPD680 Original instructions