ADSE 650 / USER MANUAL / Reference V15-D2-0174-0 / February 2023 3/79

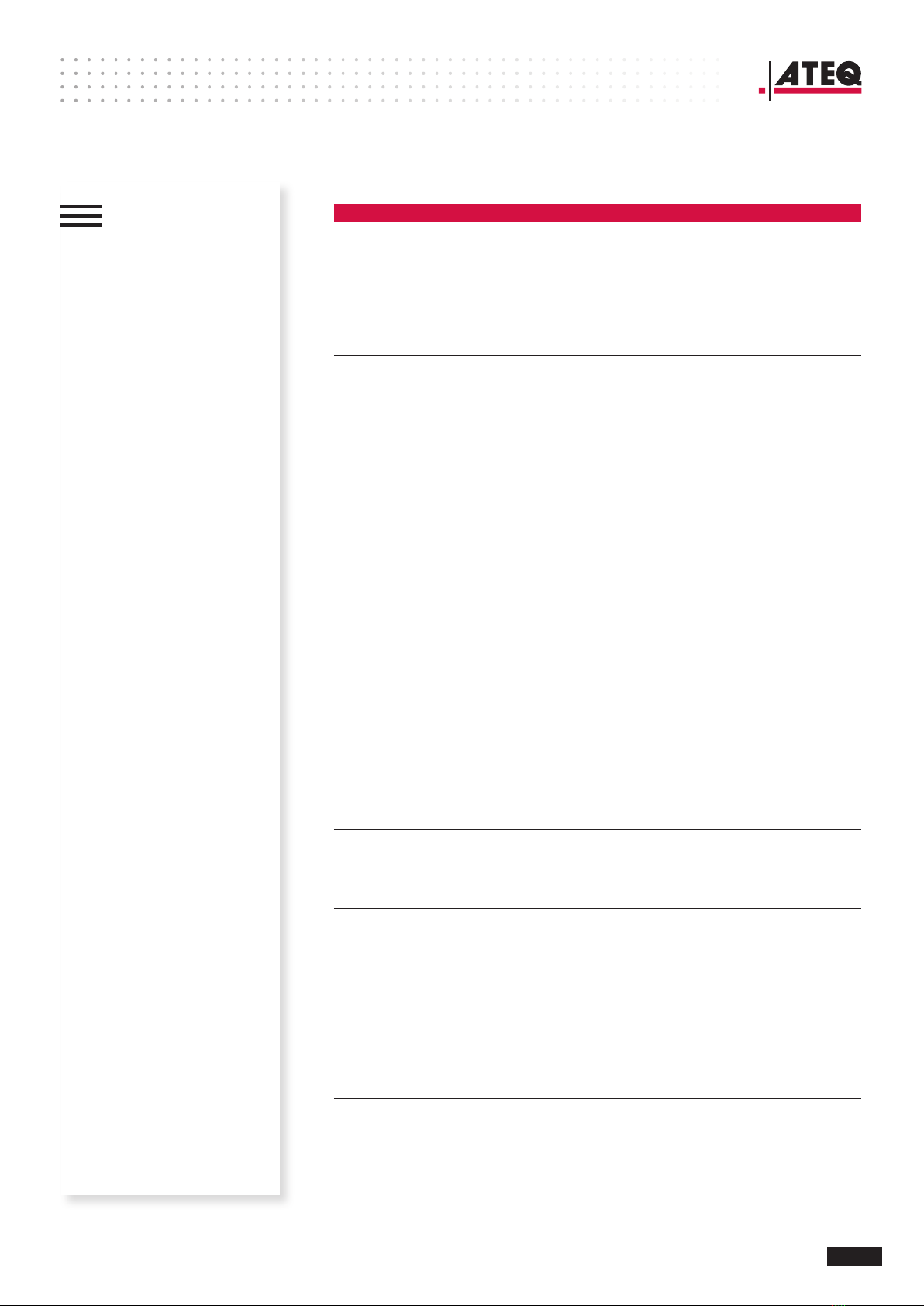

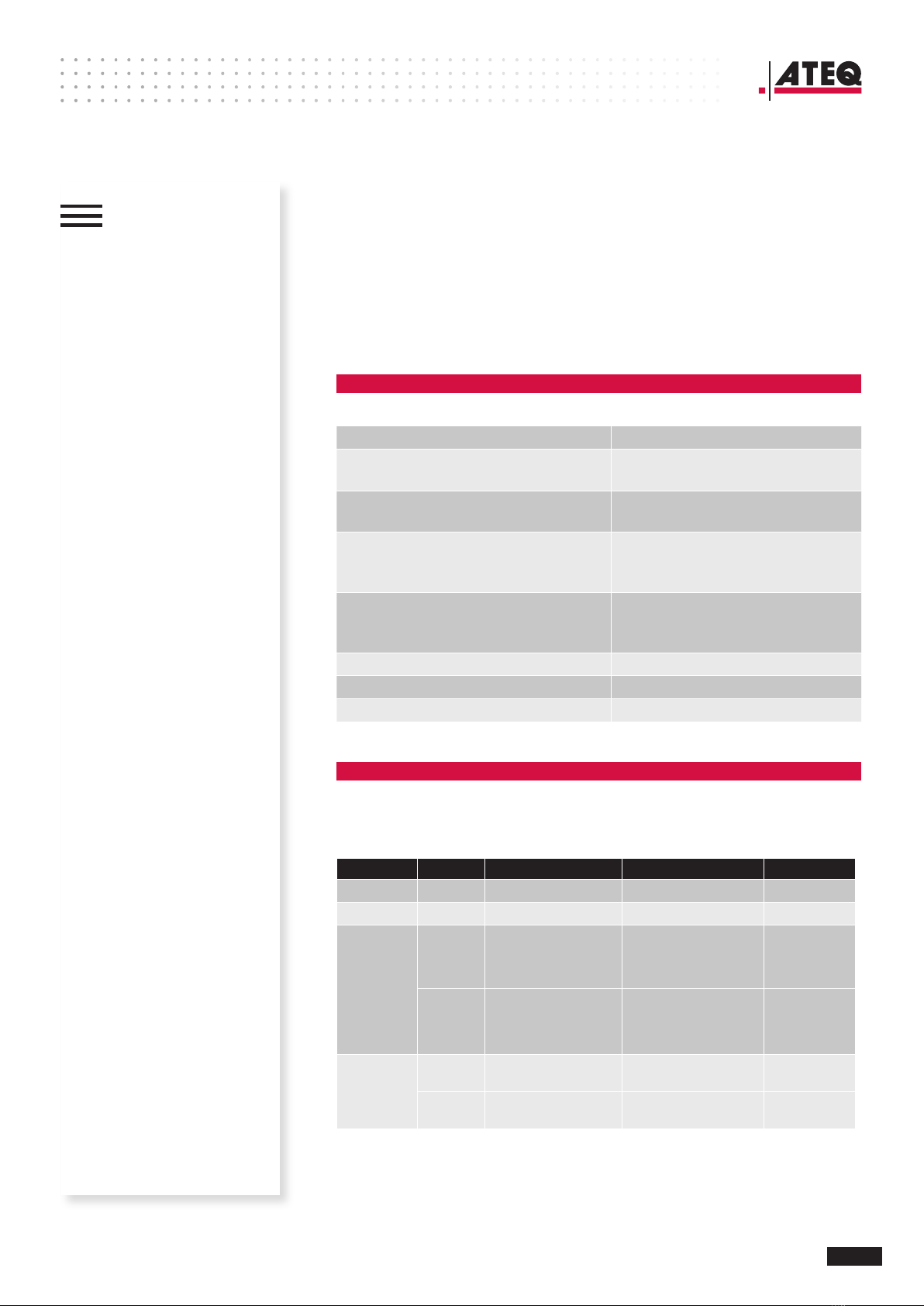

Exhaustive Table of Content

Revision of the Manual

Contact

Safety Advisory

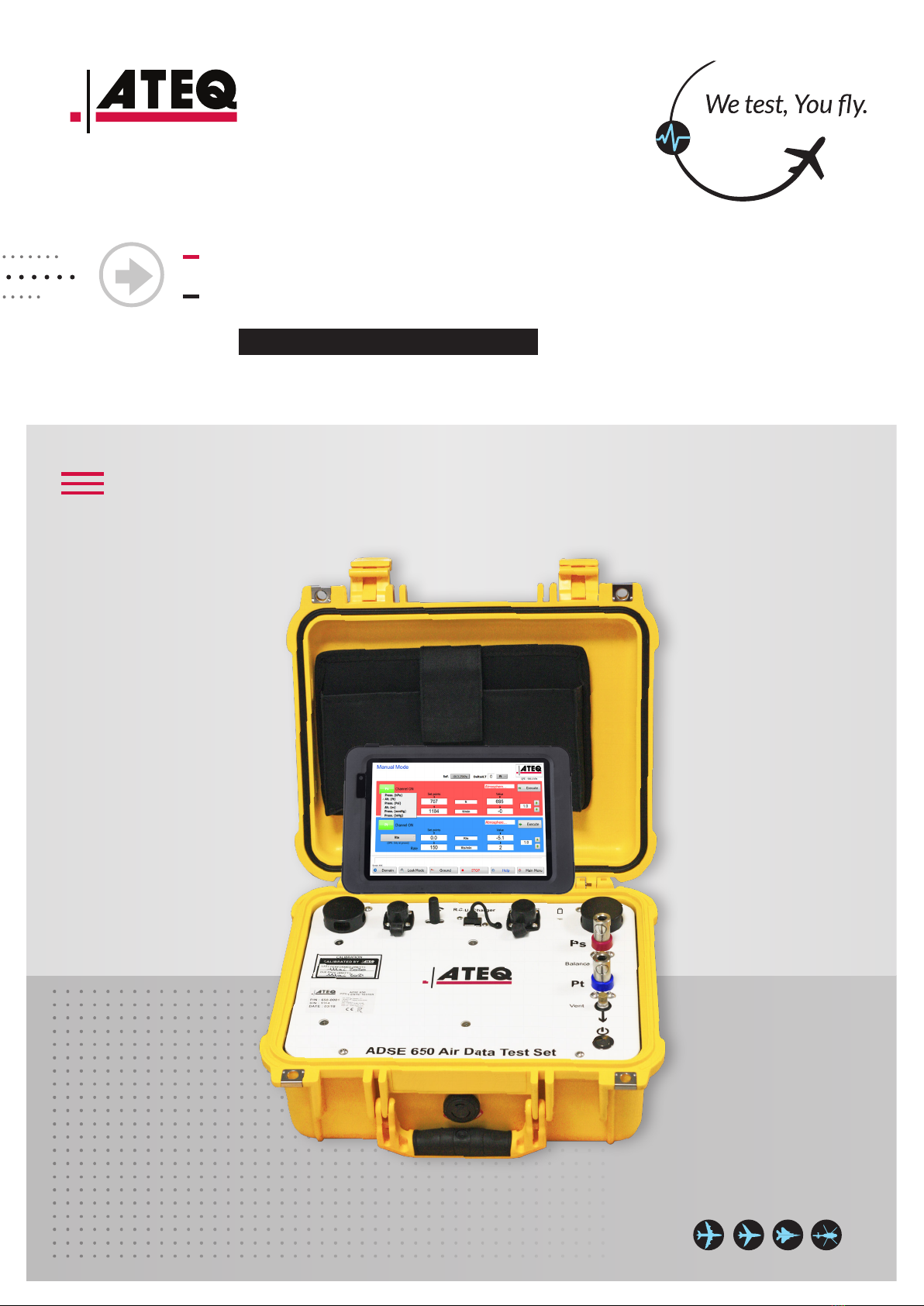

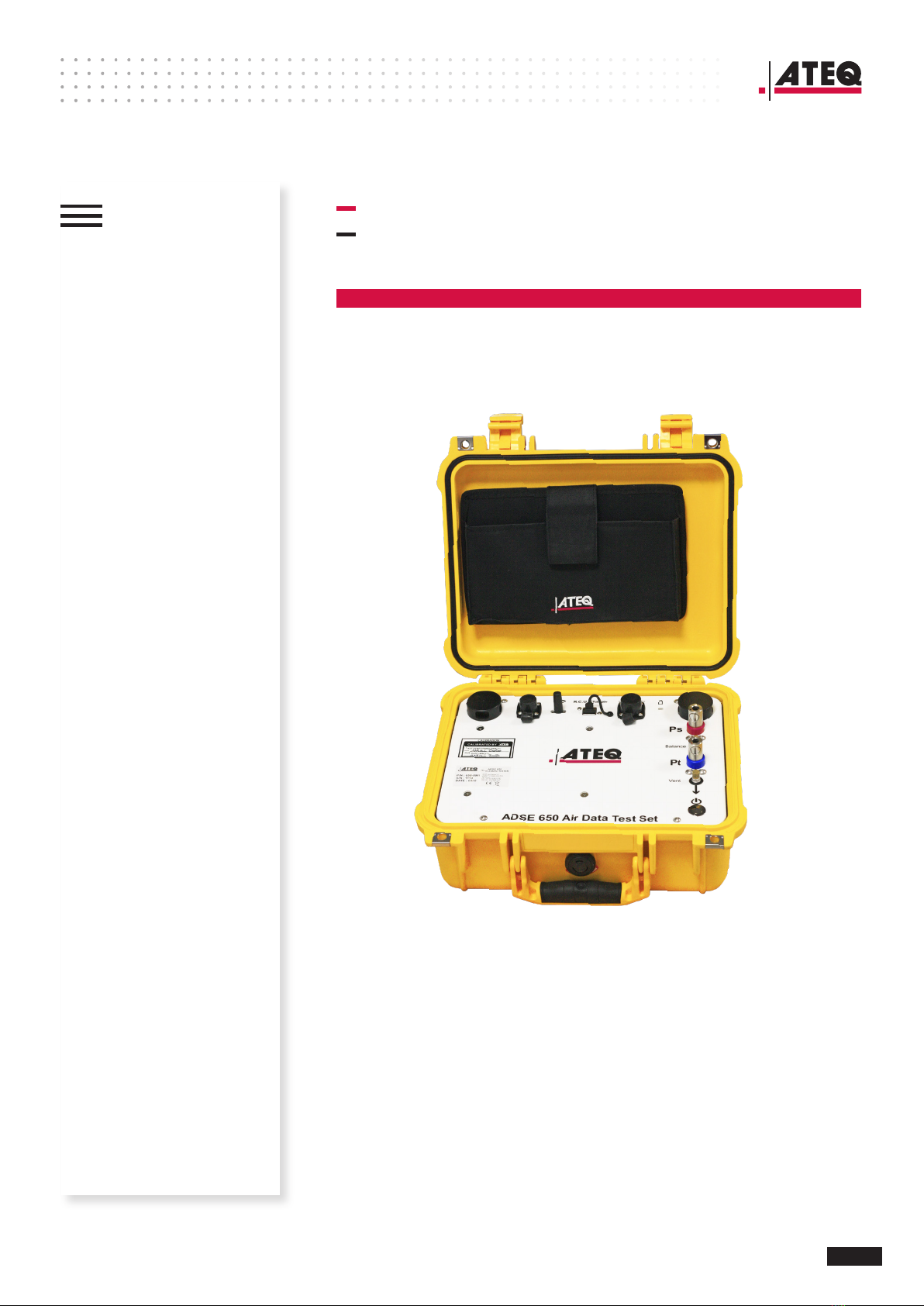

PRESENTATION

General

Applications

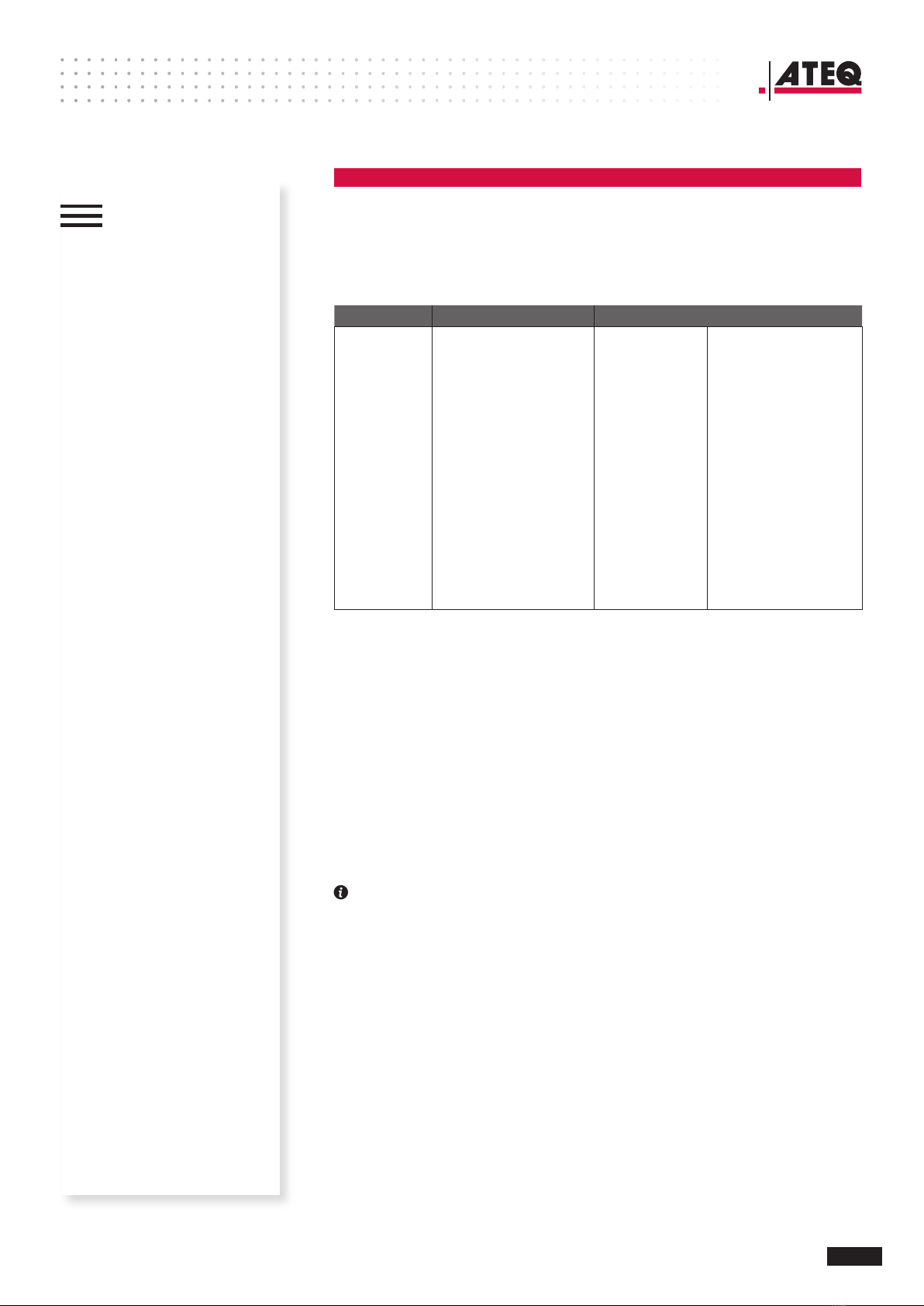

Characteristics

Units, Range and Precision

Domain Flight Option

Technical description

USER ACCESS

ADSE 650 RCU front panel

ADSE 650 EPU front panel

GETTING STARTED

Initial Procedures

OPERATOR INTERFACE

Starting software

Access to the ight domains

Measure/Manual Mode

Automatic program mode

File Manager

General Information

Help on line

Exiting the software

Keyboard conguration

Manual grounding

MAINTENANCE

Low Level Maintenance

Autotest Function

Maintenance Plan

Error and warning list

OPTIONS

1/ RCU link-serial Option

2/ EPR Option

3/ Cabin Pressure Option

4/ Outow Valve Option

SAFETY INFORMATION

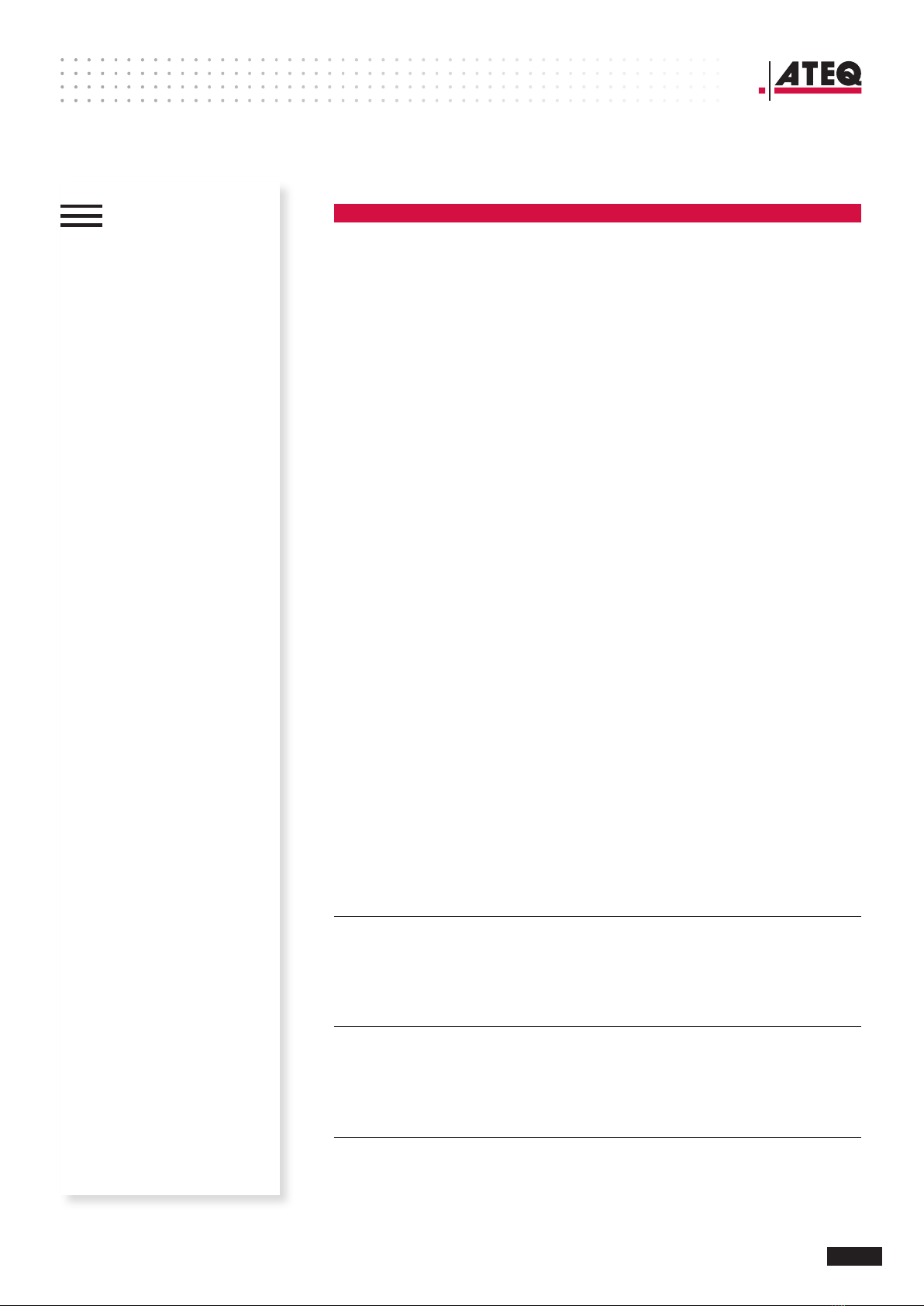

EXHAUSTIVE TABLE OF CONTENT

.../...

Access to the ight domains............................................................................................ 20

Select a ight domain....................................................................................................... 20

Creating a ight domain ................................................................................................... 22

Editing, renaming and deleting a ight domain ................................................................. 23

Access to the Measure/Manual Mode............................................................................. 24

Changing the unit on th Ps and Pt channels ...................................................................... 25

Activating a channel......................................................................................................... 26

Generating on the Ps or Pt channel .................................................................................. 27

Outow indicators........................................................................................................... 28

Leak test .......................................................................................................................... 29

Return to the ground........................................................................................................ 30

Displaying the current ight domain ................................................................................ 31

Automatic program mode ............................................................................................... 32

Writing a new program .................................................................................................... 33

Editing, Renaming and deleting a program le.................................................................. 36

Executing a program ........................................................................................................ 37

Operating Mode......................................................................................................... 44

File format fo the data recorded by the semi-automatic program ............................... 45

File Manager.................................................................................................................... 46

General Information........................................................................................................ 47

Parameters ...................................................................................................................... 48

User settings............................................................................................................... 48

RS232 ......................................................................................................................... 48

Wi-Fi........................................................................................................................... 49

Ground ....................................................................................................................... 49

Reference ................................................................................................................... 50

Calibration .................................................................................................................. 50

Password ......................................................................................................................... 52

Enter a password ............................................................................................................. 54

Ground function .............................................................................................................. 55

Languages........................................................................................................................ 56

Help on line ..................................................................................................................... 57

Exiting the software........................................................................................................ 57

Keyboard conguration .................................................................................................. 58

Numerical keyboard......................................................................................................... 58

Alpha-Numeric Keyboard ................................................................................................ 58

Manual grounding ........................................................................................................... 59

MAINTENANCE 60

Low Level Maintenance................................................................................................... 60

Autotest Function ........................................................................................................... 60

Maintenance Plan............................................................................................................ 66

Error and warning list...................................................................................................... 67

OPTIONS 18

1/RCU link-serial Option................................................................................................. 69

2/EPR Option .................................................................................................................. 70

3/Cabin Pressure Option................................................................................................. 73

4/Outow Valve Option.................................................................................................. 75

SAFETY INFORMATION 77

Operating environment .................................................................................................. 77

Safety for lithium Polymer battery use ........................................................................... 77

Important instructions (for service personnel only) ....................................................... 78

Recycling ......................................................................................................................... 78