REAR

SHOCK

REAR

SUSPEl•SIOH

SAG

The

rear suspension should sag 2-3 inches

(51-7&mn)

when

sitting

on

the

bike in

nonnal

riding position. This small sag requirement

is

due

to the

A-Trak

chain torque elfminaf:t'r,

which

increases in usable

rear

suspension.

From

our experience

we

recomnend

that

for

motocross racing

2-23f

inches

(51-64nm)

of

sag

is

best .For

trail

riding

use

up

to 3 inches.

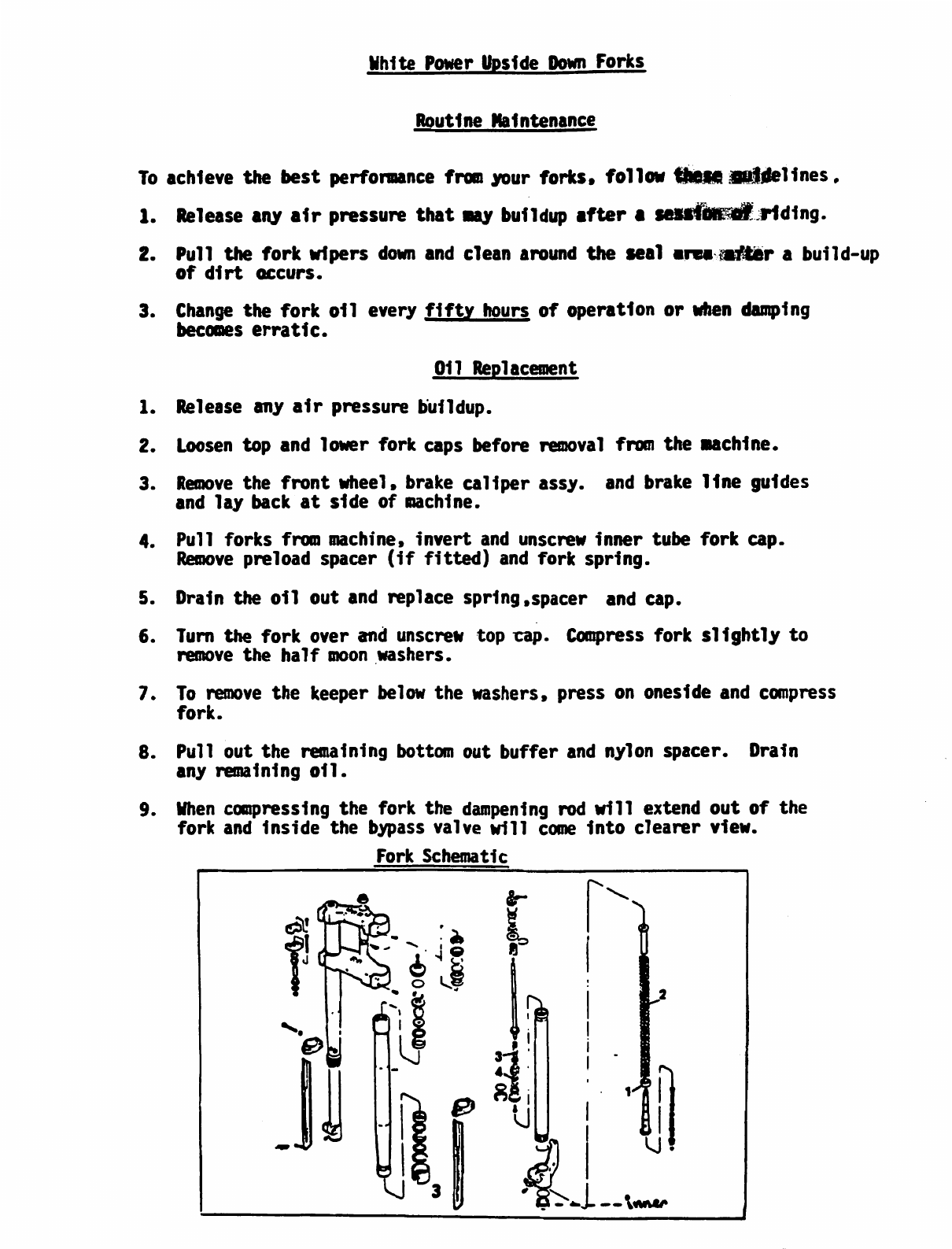

Prop

the bike

up

on

a center stand

so

that

the

rear

wheel

is

off

the ground,

thus unloading the

rear

spring of the bikes weight.

Measure

the distance

between

the center

of

the axle to the center

of

the

left

side

na.noer

plates

rear

attactunent screw as

shown

on

figure 4. This distance

is

the extended

travel length.

Take

the bike

off

the stand

and

sit

on

it

in your

normal

riding positon.

Measure

the

new

distance

between

the center

of

the axle

to the center

of

the

left

side

number

plates

rear

attachment screw. This

distance

is

the usable travel length. Subtract the usable travel length

from

the extended travel length

and

the difference

between

the

two

is

the

suspension sag.

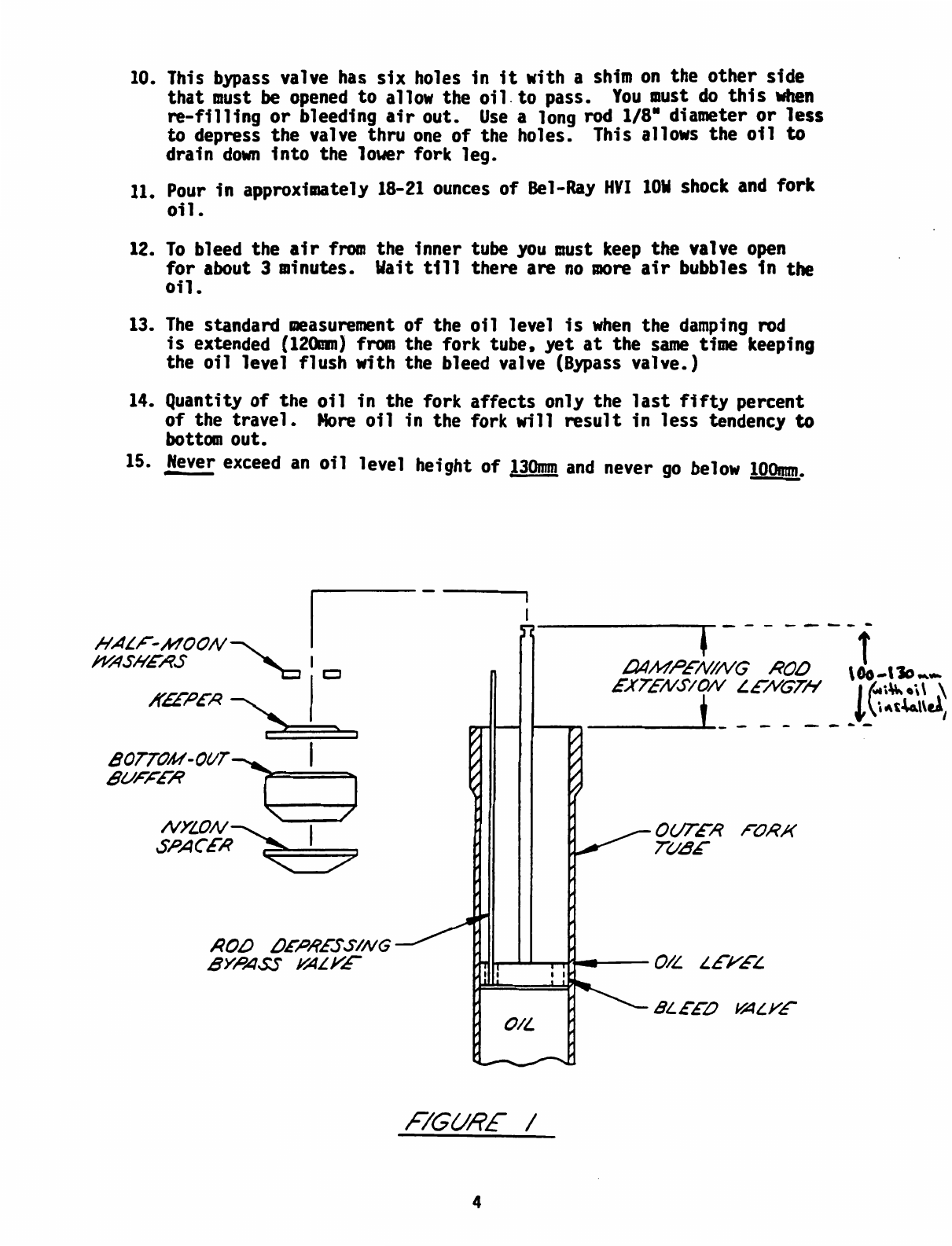

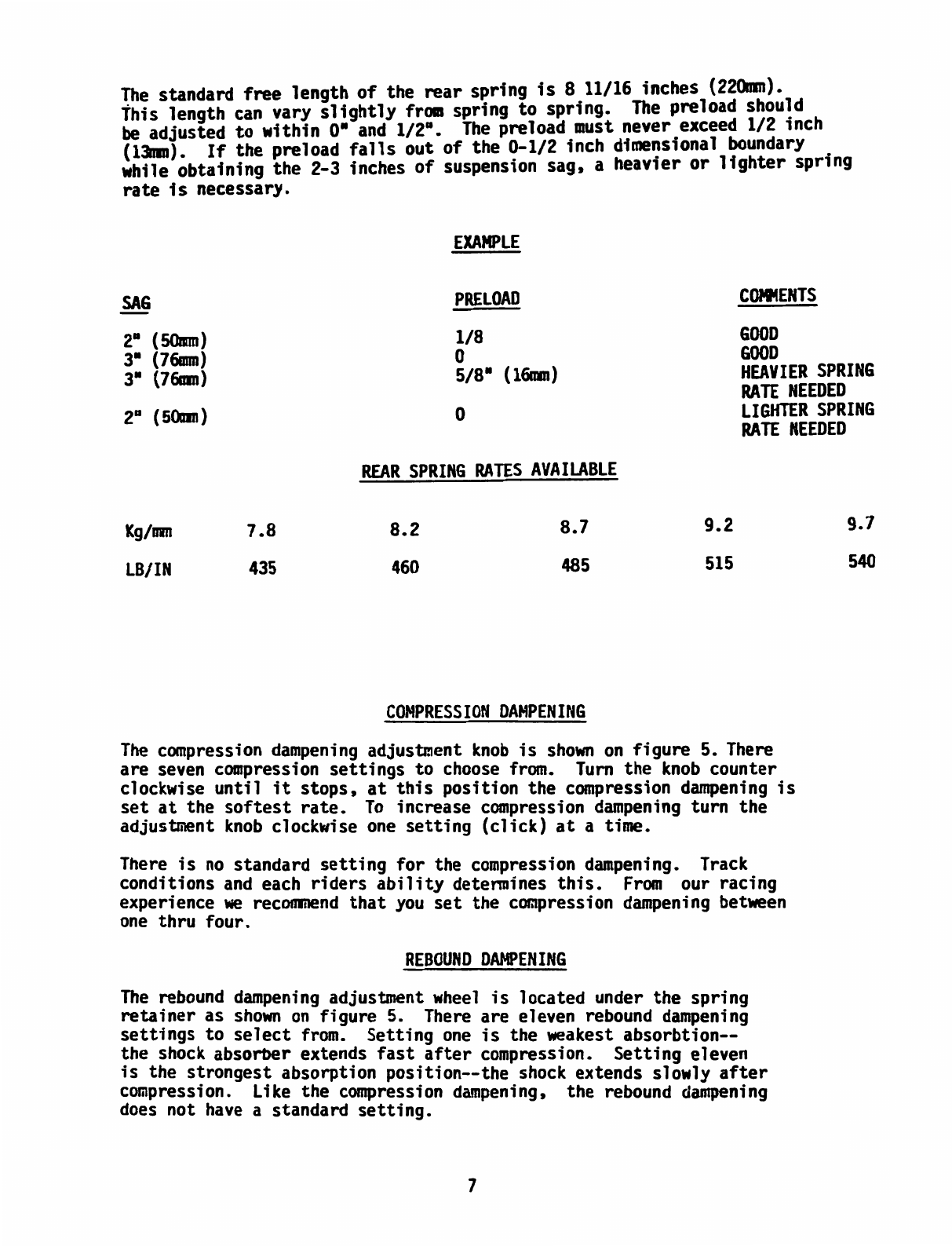

EXTENDED

TRAVEL

LEl~GTH

-

USABLE

TRAVEL

LENGTH

EXffNL)ELJ

LENGTH

'OMPRESS£0

~£'NGTH

l

F/Gt/l?E

~

=

SUSPENSION

SAG

CONPllESSION

ALJJf/STE,4

Pl<£L0Af)

AtJ./l/STEll

t t

COMPl?ESSfLJ

LENGTH

'

F!Gt./l?E 5

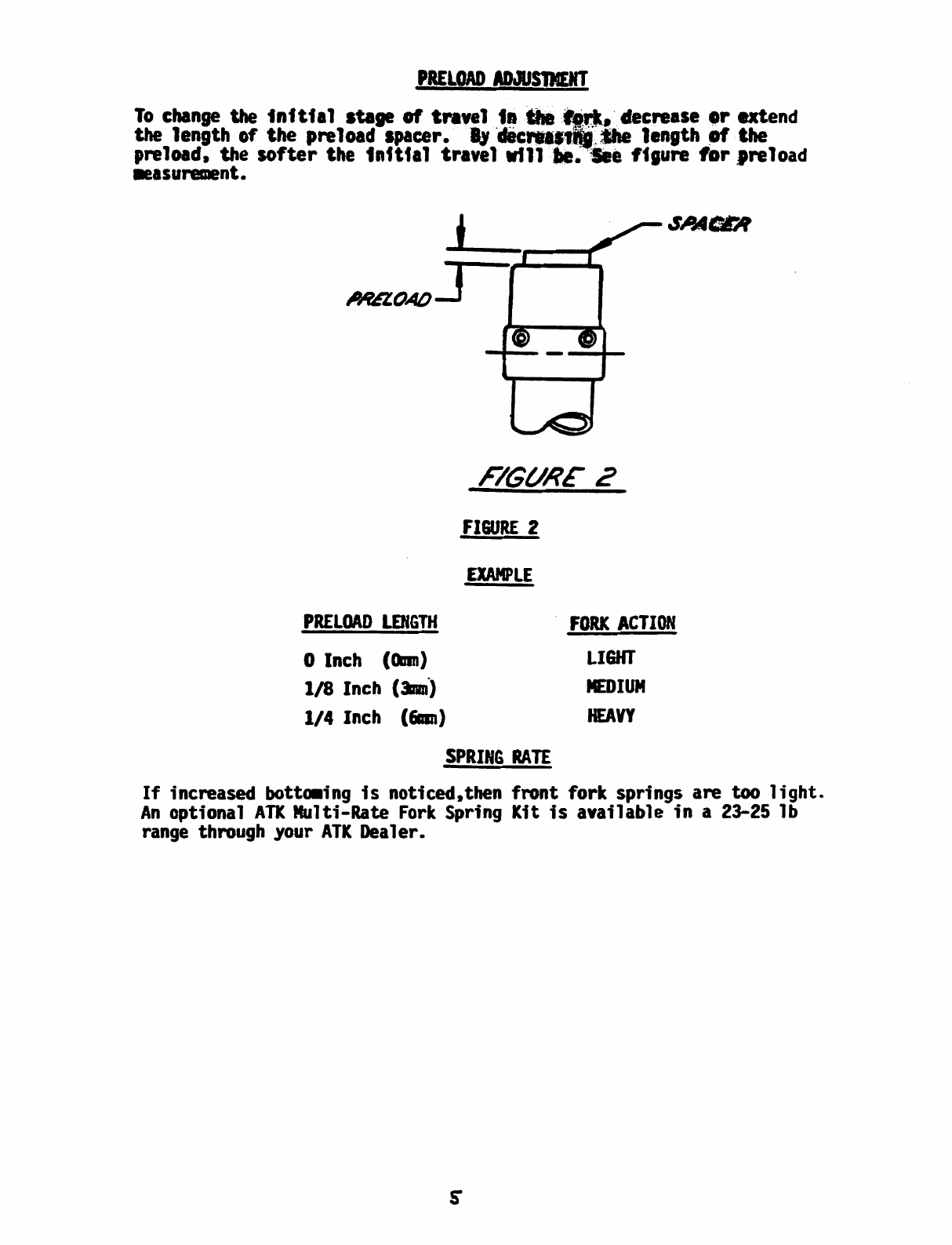

To

achieve your desired suspension

sag

it

will be necessary to adjust

the

rear

shock's preload as

sho~n

on

figure 5.

The

preload equals the

free

length

of

the

rear

spring

minus

the compressed length

of

the

spring.

FREE

LENGTH

-

COMPRESSED

LENGTH

=

PRELOAD

6