StreetFox Tadpole Trike Front Hardware

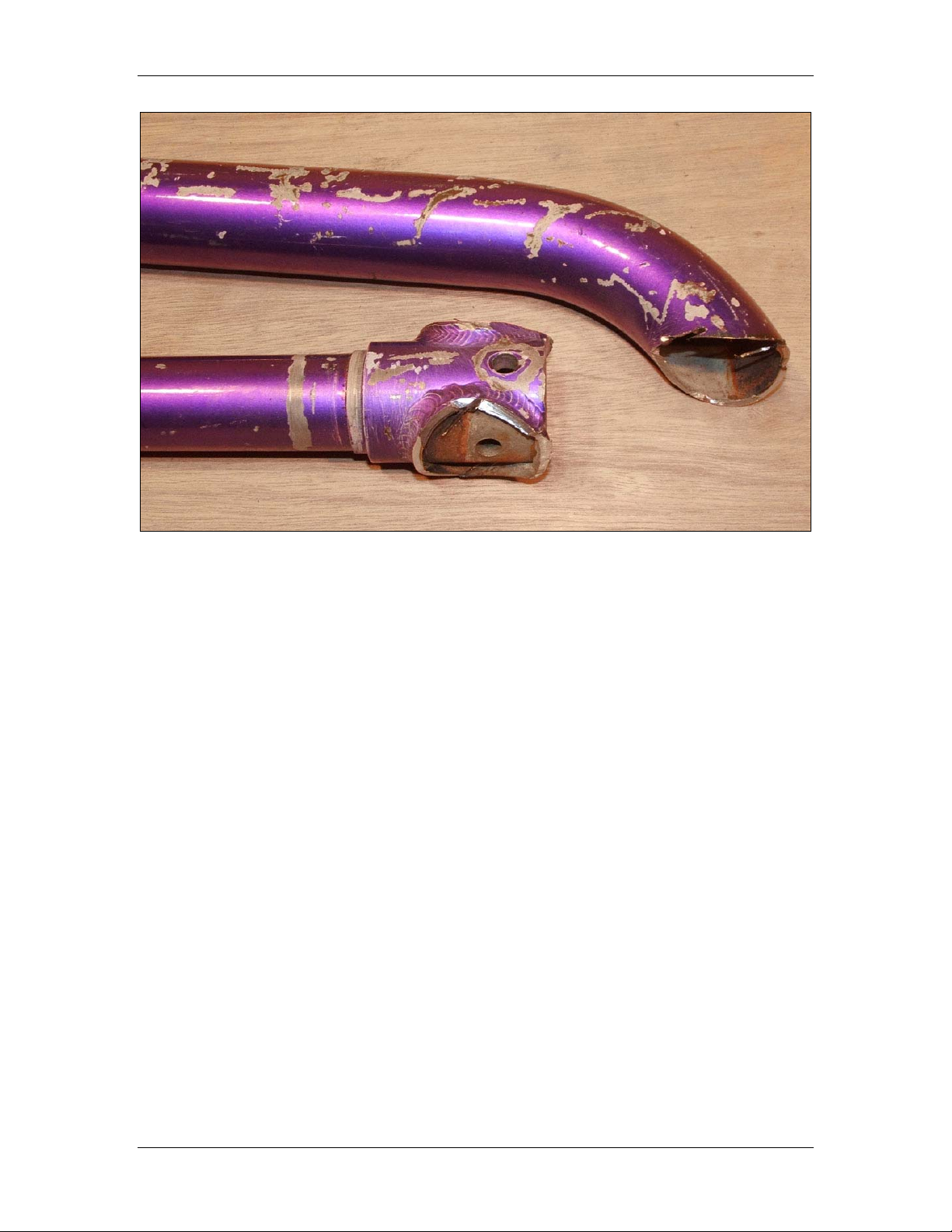

When I say identical, I am not referring to color or brand, but the overall

length and width of the head tube so that both front wheels will be at the

same height when the parts are installed. As shown in Figure 4, I have two

identical head tubes and two matching fork stems that fit into the head tubes.

All of my parts are from at least three different bicycles, but they are

all the same size, and that is all that really matters. If you don't have access

to a large bicycle scrap pile, then you could trim a head tube down an inch or

two to match the other one, but keep in mind that you will also need to cut

the fork threads, and could end up with not enough thread to install the fork

hardware by cutting away too much of the threaded tubing. Also, do not

worry about the condition or size of the fork legs, as they are not being used.

Just make sure that the fork stem is not bent.

Figure 5 - Checking the fork hardware

It doesn't matter if the head tube is from a 1960’s beach cruiser and

the forks are from a competition BMX bike as long as the hardware fits

together properly and the forks spin around without friction. I ended up

using a 20 inch and a 26 inch fork, but again, this doesn't matter, as the fork

legs are soon to be cut from the fork stem. As shown in Figure 5, fork

hardware consists of two bearing cups, a pair of bearings, and at least two

locking nuts. Bearings are inserted into the cups "balls first", and the fork

All content copyright Atomic Zombie Extreme Machines. All rights reserved. 7

www.ATOMICZOMBIE.com