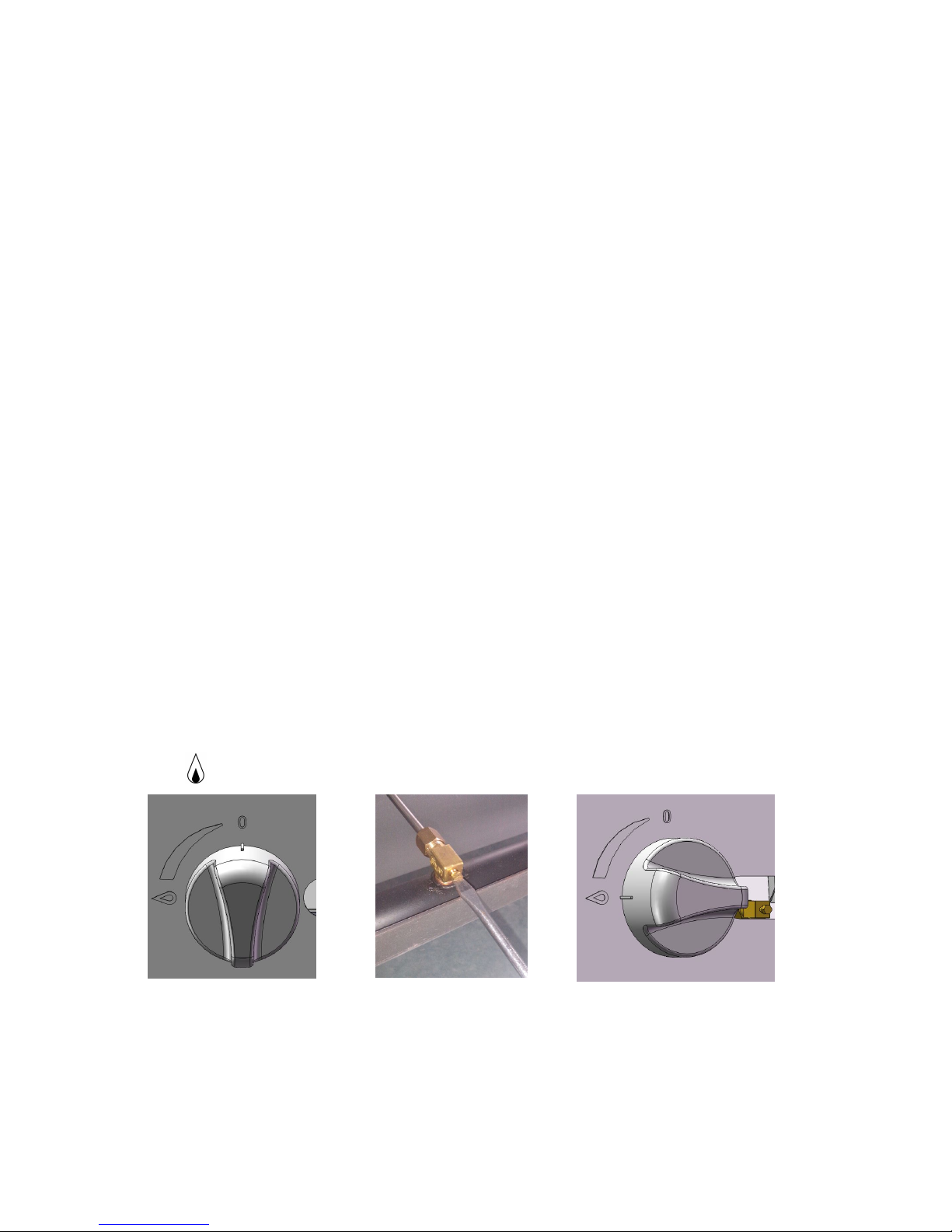

●Unplug pressure gauge after you accomplish pressure testing, then

install needle type pressure joint screw arbor. Important: must screw

joint screw arbor, to prevent gas escape!

It’s very important to debug the new stove. Through the comprehensive

system test of equipment, we can ensure function and safety performance of

products. Discovering any potential problems before use (such as

equipment’s placement, ventilation, operation, etc), can avoid costly

7. Safety Notices and Precautions

Warning! For your safety, do not place petrol and other flammables nearby.

Please keep clean and free of flammables surroundings. (Read ANSI Z83.14B,

Warning! Any erroneous installation, adjustment and refit may cause property

damage or personal injury and maintenance failure. Read the instructions

carefully before installation and using.

Warning! Operation instruction must be placed in a conspicuous location.

When customers smell gas in the process of using, should take safety

precautions immediately. Immediately turn off the main gas valve, extinguish

all heat and flames, and call 911. Safety information can be obtained from

your local gas suppliers.

When using this equipment, safety precautions should always

be followed, including the following:

The hot plates/cooktops burners, cooking grates and outside surfaces may

become hot after use, so you must be careful to touch;

During operation, do not directly touch burners and cooking grates;

Turn off the equipment as repairing, maintaining and cleaning;

If the equipment has any problems of equipment damage, gas piping leaks,

igniter or valves damage, or lose product accessories, do not operate, and

call for the service immediately;

The use of attachments not recommended or sold by the manufacturer may cause

fire, personal injury or even death;

The equipment is used for cook, not available for any other use;

The equipment does not contain any user-serviceable parts. Dealers or

technicians will repair it. Do not take apart any spare parts without