Audi ST?SIS Instruction sheet

Other Audi Automobile manuals

Audi

Audi A4 2015 Instruction manual

Audi

Audi AS Coupe 2016 User manual

Audi

Audi 2003 A4 Avant User manual

Audi

Audi A8 User manual

Audi

Audi A6 C5 Avant Parts list manual

Audi

Audi R8 2008 User manual

Audi

Audi A6'05 323 Assembly instructions

Audi

Audi RS 5 Cabriolet 2013 User manual

Audi

Audi Q7 2014 User manual

Audi

Audi S3 User manual

Audi

Audi 2003 A8 Owner's manual

Audi

Audi e-tron Sportback 2021 Instruction Manual

Audi

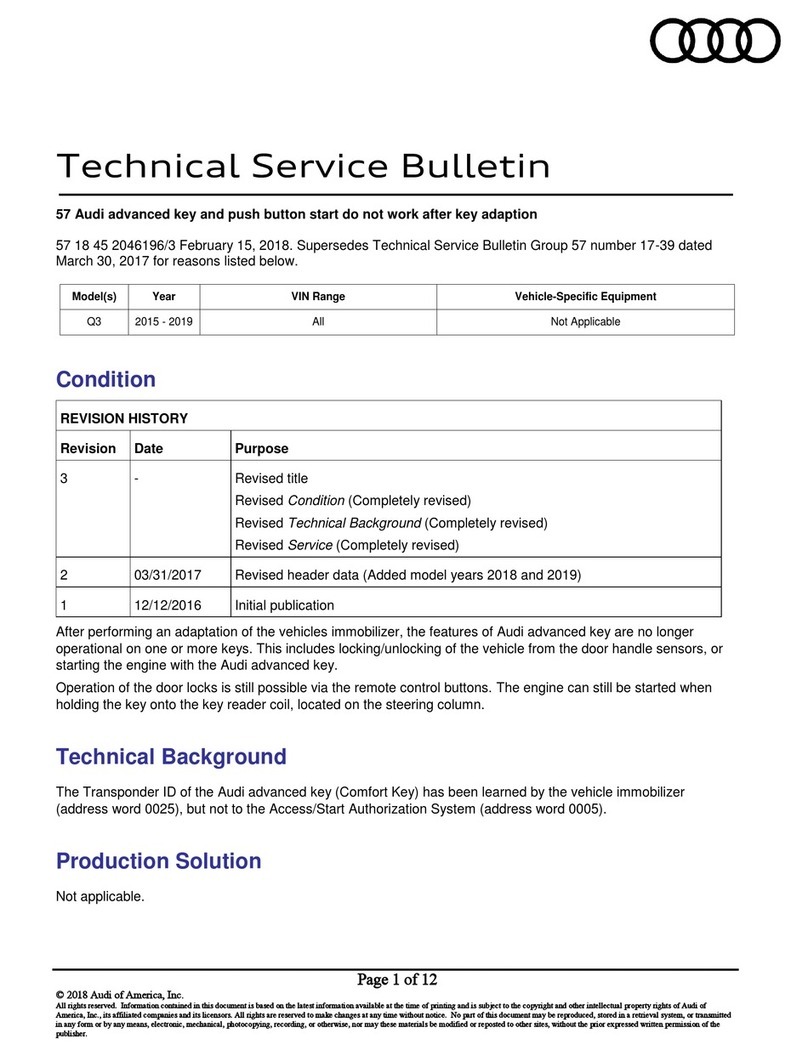

Audi Q3 2015 - 2019 Reference manual

Audi

Audi Avant RS2 1994 Instruction manual

Audi

Audi A4 2021 Instruction Manual

Audi

Audi TTS Coupe 2015 User manual

Audi

Audi A6 Quattro 2008 User manual

Audi

Audi A4 2005 Manual

Audi

Audi TT Coupe 2009 User manual

Audi

Audi RS 7 Sportback 2016 User manual