AUKS AFC-500CF/4 User manual

1

Technical Manual

FanCoil Unit

(Ceiling&Floor Type)

Service Manual

2

Contents

Part1General description...................................................................................................3

Part2.U n i t .............................................................................................................................5

Part3 Product selection.....................................................................................................31

Part4 Controller ................................................................................................................. 34

Part5 Trouble shooting......................................................................................................43

AUKS-Fan CoilGeneral description

3

P a r t 1General description

1Nomenclature

AUKS-Fan CoilGeneral description

4

2U n i t appearance

Series

Range ofthe A i r Volume(CFM)

Ceiling

&Floor

400CFM

500CFM

600CFM

800CFM

1000CFM

AUKS F a n CoilUnit information

5

P a r t 2.Unit

1.Feature...............................................................................................................................6

2.Specfication...................................................................................................................... 8

3.Capacity amendment......................................................................................................10

4.Demension...................................................................................................................... 14

5.Electrical wiringandconnection...................................................................................15

6.Installation .......................................................................................................................17

7.Explode v i e w ...................................................................................................................22

AUKS F a n CoilUnit information

6

1.Feature

Ceiling floor fan coil unit, as its name suggests, can either be suspended from the ceiling, or floor installed

against the wall.Compared with other fan coil units, it has the following advantages: Suspended from the

ceiling, it occupies no indoor space; Its installation synchronizes with decoration process, with connecting

pipeline buried in the ceiling, making the room more attractive and appealing; It can be alternatively floor

mounted against the wall, as a substitute of a floor standing air conditioner.

Application occasions:

Small super market,restaurant, office, meeting room, parlor o f villa,living room, e t c . Features:

◇ Suspended ceiling, installation under ceiling, saving room space, i t i s v e r y suitable forfamily o r office

place;

◇ Convenient a n d flexible forindoor u n i t installation, canb e installed under t h e ceiling o r o n t h e floor;

◇ WithSetting o r Auto t w o operation modes, multifanspeed, makes y o u feel morecomfortable;

◇ Shell w a s formed b y mold,and t h e appearance i s “slim”, “elegant”, “fashion” a n d “comfortable”;

◇ Special insulation design, achieves high heat insulation efficiency a n d n o condensation o n shell;

◇ Long t e r m a i r filter, t h e w a s h period i s t w o t i m e s longer t h a n normal filter, maintenance i s free;

◇ Adopting l o w noise centrifugal fan, strongw i n d b u t quiet operation, t h e silence design achieves

harmony residential living;

◇ All t h e installation a n d maintenance canb e done i n t h e bottom o f u n i t , saving t h e maintenance space;

◇ Auto-restart(optional);

◇ Standard remote controller a n d optional w i r e d controller;

◇ AUKSiliary e l e c t r i c heater forheat p u m p u n i t , w i t h fastheating a n d l o w ambient temperature

heating functions;

◇ Failure automatic detection, i f t h e r e i s afailure, t h e indicator will flasha n d t h e f a i l u r e codew i l l display

o n t h e w i r e d controller, t h e failure cause i s easier t o b e found..

◇ Ultraslim design, t h e thickness o n l y 2 0 5 mm, a n d h a v e v e r t i c a l and horizontal swingfunction.

AUKS F a n CoilUnit information

7

Function Introduction

T y p e

Item

AFC-**CF/4

400

500

600

800

1000

Comfort

Cooling

●

●

●

●

●

Heating

●

●

●

●

●

3-Speed

●

●

●

●

●

Adjustable ESP

-

-

-

-

-

Auto-restart(Optional)

●

●

●

●

●

Anti-cold w i n d

●

●

●

●

●

Afterheat w i n d blowing

●

●

●

●

●

Timing ON/OFF

●

●

●

●

●

Operation

T i m e display

●

●

●

●

●

Operation modedisplay

●

●

●

●

●

Fanspeed display

●

●

●

●

●

Timing ON/OFF display

●

●

●

●

●

Windangle display

●

●

●

●

●

Sleeping modedisplay

●

●

●

●

●

Health

Washable airfilter

●

●

●

●

●

Freshairinterface

●

●

●

●

●

Installation

Left/right drainage

-

-

-

-

-

Left/right pipeconnection

-

-

-

-

-

Down/back airsuction

-

-

-

-

-

Installation indicating board

-

-

-

-

-

Remarks:●Stands for“YES” -Stands for“NO”

AUKS F a n CoilUnit information

8

2.Specfication

Model

AFC-400CF/4

AFC-500CF/4

AFC-600CF/4

Air Volume

H i Speed

C F M

400

500

600

m 3

/h

680

850

1020

Medium Speed

C F M

300

375

450

m 3

/h

510

638

765

Low Speed

C F M

200

250

300

m 3

/h

340

425

510

Cooling Capacity

H i Speed

W

3600

4514

5406

Medium Speed

W

3075

3837

4595

Low Speed

W

2352

2934

3514

Heating Capacity

H i Speed

W

5418

6767

8115

Medium Speed

W

4605

5752

6898

Low Speed

W

3522

4399

5275

N o i s e Level

dB(A)

≤42

≤45

≤48

FanMotor

FanQuantity

2

2

3

Motor Quantity

1

1

1

Power Input

W

78

93

117

Water FlowVolume

kg/h

620

800

980

Hydraulic Resistance

kPa

16

20

22

Max.Working pressure

M P a

1.6

1.6

1.6

Dimension(W×D×H)

N e t

mm

929×660×205

929×660×205

1280×660×205

Packing

mm

1010×720×280

1010×720×280

1360×720×280

Net/Gross Weight

kg

24/27

25/28

30/35

Inlet/Outlet WaterPipe

R c 3 / 4 ″(DN20)

R c 3 / 4 ″(DN20)

R c 3 / 4 ″(DN20)

D r a i n Pipe

R 3 / 4 ″(DN20)

R 3 / 4 ″(DN20)

R 3 / 4 ″(DN20)

Stuffing Quantity(20/40/40H)

149/300/350

149/300/350

104/222/246

Note:

1 . Cooling capacity t e s t conditions:Air inlet temp.:27℃ DB/19.5℃ WB,Water inlet/outlet temp.:7℃ / 1 2 ℃ .

2 . Heating capacity t e s t conditions:Air inlet temp.:21℃ DB,Water inlet/outlet temp.:60℃.

3 . Noisel e v e l i s tested i n full-anechoic room.

4 . Parameters above mayb e modified a s product improvement. Wekeep t h e right t o change t h e

product specifications without prior n o t i c e .

AUKS F a n CoilUnit information

9

Model

AFC-800CF/4

AFC-1000CF/4

Air Volume

H i Speed

C F M

800

1000

m 3

/h

1360

1700

Medium Speed

C F M

600

750

m 3

/h

1020

1275

Low Speed

C F M

400

500

m 3

/h

680

850

Cooling Capacity

H i Speed

W

7210

9000

Medium Speed

W

6129

7665

Low Speed

W

4687

5862

Heating Capacity

H i Speed

W

10807

13512

Medium Speed

W

9186

11485

Low Speed

W

7025

8783

N o i s e Level

dB(A)

≤48

≤50

FanMotor

FanQuantity

3

4

Motor Quantity

1

1

Power Input

W

190

230

WaterFlowVolume

kg/h

1250

1580

Hydraulic Resistance

kPa

30

40

Max.Working pressure

M P a

1.6

1.6

Dimension(W×D×H)

N e t

mm

1280×660×205

1631×660×205

Packing

mm

1360×720×280

1710×720×280

Net/Gross Weight

kg

33/38

44/50

Inlet/Outlet Water Pipe

R c 3 / 4 ″(DN20)

R c 3 / 4 ″(DN20)

D r a i n Pipe

R 3 / 4 ″(DN20)

R 3 / 4 ″(DN20)

Stuffing Quantity(20/40/40H)

104/222/246

86/173/202

Note:

1 . Cooling capacity t e s t conditions:Air inlet temp.:27℃ DB/19.5℃ WB,Water inlet/outlet temp.:7℃ / 1 2 ℃ .

2 . Heating capacity t e s t conditions:Air inlet temp.:21℃ DB,Water inlet/outlet temp.:60℃.

3 . Noisel e v e l i s tested i n full-anechoic room.

4 . Parameters above mayb e modified a s product improvement. Wekeep t h e right t o change t h e

product specifications without prior n o t i c e .

AUKS F a n CoilUnit information

1 0

3Capacity amendment

3 . 1 T a b l e o f variable working condition performance forcooling capacity

Table o f variable w o r k i n g condition performance parameter under cooling mode

U n i t : W

Air inlet temperature℃

26℃DB/18. 7℃WB

27℃D B / 1 9 ℃WB

Waterinlet temperature ℃

5

7

9

5

7

9

Model

(CFM)

Water

flow

(kg/h)

Water

pressure

drop

(kPa)

T H

SH

T H

SH

T H

SH

T H

SH

T H

SH

T H

SH

400

430

8.1

2565

1944

2268

1823

1944

1593

2619

2052

2390

1931

2012

1688

550

11.5

2930

2187

2579

2025

2214

1769

3011

2309

2660

2133

2295

1877

650

15.5

3456

2349

3051

2160

2633

1877

3537

2457

3132

2268

2714

2012

750

20

3807

2417

3389

2214

2916

1917

3902

2538

3429

2336

3011

2039

500

600

18

3200

2425

2830

2274

2425

1987

3267

2560

2981

2409

2510

2105

700

24

3655

2729

3217

2527

2762

2207

3756

2880

3318

2661

2863

2341

800

30

4312

2931

3807

2695

3284

2341

4413

3065

3908

2830

3385

2510

900

37

4750

3015

4228

2762

3638

2392

4868

3167

4278

2914

3756

2543

600

750

21.5

3833

2905

3389

2724

2905

2381

3914

3066

3571

2885

3006

2522

850

26.8

4377

3268

3853

3026

3308

2642

4498

3449

3974

3187

3429

2804

950

32.7

5164

3510

4559

3228

3934

2804

5285

3672

4680

3389

4055

3006

1050

39

5688

3611

5063

3308

4357

2864

5830

3792

5124

3490

4498

3046

800

900

14.8

5661

4290

5005

4022

4290

3515

5780

4528

5273

4260

4439

3724

1100

21

6466

4827

5691

4469

4886

3903

6644

5095

5870

4708

5065

4142

1300

28

7627

5184

6733

4767

5810

4141

7806

5422

6912

5005

5988

4439

1500

36

8402

5333

7478

4886

6436

4231

8611

5601

7568

5154

6644

4499

1000

1200

23

7080

5366

6260

5031

5366

4397

7229

5664

6596

5329

5552

4658

1400

30

8086

6037

7117

5590

6111

4882

8310

6372

7341

5888

6335

5180

1600

38

9540

6484

8422

5962

7267

5180

9763

6782

8645

6260

7490

5552

1800

46.8

10509

6670

9353

6111

8049

5292

10770

7006

9465

6447

8310

5627

AUKS F a n CoilUnit information

1 1

variable w o r k i n g condition performance parameter t a b l e (continued)

Unit:W

Air inlet temperature ℃

27℃DB/19. 5℃WB

28℃D B / 2 2 ℃WB

Waterinlet temperature ℃

5

7

9

5

7

9

Model

(CFM)

Water

flow

(kg/h)

Water

pressure

drop

(kPa)

T H

SH

T H

SH

T H

SH

T H

SH

T H

SH

T H

SH

400

430

8.1

2714

2012

2403

1863

2213

1856

3402

2522

3078

2386

2781

2062

550

11.5

3119

2255

2768

2079

2410

1971

3902

2821

3551

2668

3200

2313

650

15.5

3699

2430

3267

2228

2849

2112

4577

3006

4199

2863

3780

2483

750

20

4037

2511

3618

2282

3161

2140

5063

3149

4617

2911

4131

2570

500

600

18

3385

2510

2998

2324

2761

2316

4244

3146

3840

2977

3470

2572

700

24

3891

2813

3453

2594

3007

2458

4868

3519

4430

3328

3992

2886

800

30

4615

3032

4076

2779

3555

2635

5710

3751

5238

3571

4716

3098

900

37

5036

3133

4514

2847

3944

2671

6316

3929

5760

3632

5154

3206

600

750

21.5

4055

3006

3591

2784

3307

2774

5084

3769

4600

3566

4156

3081

850

26.8

4659

3369

4135

3106

3600

2944

5829

4214

5305

3985

4780

3456

950

32.7

5528

3631

4882

3329

4258

3156

6839

4493

6274

4278

5649

3711

1050

39

6031

3752

5406

3409

4723

3198

7564

4706

6899

4350

6173

3840

800

900

14.8

5988

4439

5303

4111

4883

4096

7508

5565

6793

5266

6137

4549

1100

21

6883

4976

6108

4588

5318

4349

8611

6225

7836

5887

7061

5105

1300

28

8163

5363

7210

4916

6288

4661

10100

6635

9266

6318

8342

5480

1500

36

8909

5542

7985

5035

6976

4724

11173

6950

10190

6426

9117

5672

1000

1200

23

7490

5552

6633

5142

6108

5124

9391

6961

8496

6587

7676

5690

1400

30

8608

6223

7639

5739

6652

5439

10769

7785

9800

7362

8831

6385

1600

38

10210

6708

9018

6149

7865

5830

12633

8299

11589

7902

10434

6854

1800

46.8

11142

6931

9987

6298

8726

5908

13974

8693

12745

8037

11403

7094

AUKS F a n CoilUnit information

1 2

3 . 2 T a b l e o f variable working condition performance forheating capacity

Table o f variable w o r k i n g condition performance parameter under heating mode

Unit:W

Air inlet temperature ℃

18℃D B

20℃D B

Water inlet temperature ℃

40

45

50

60

70

80

40

45

50

60

70

80

Model

(CFM)

Water

flow

(kg/h)

Water

pressure

drop

(kPa)

400

430

8.1

2517

3086

3669

4806

5944

7096

2289

2872

3427

4579

5731

6868

550

11.5

2702

3314

3939

5163

6400

7623

2460

3072

3683

4921

6144

7381

650

15.5

2915

3584

4238

5560

6897

8205

2659

3313

3982

5318

6627

7963

750

20

3057

3768

4451

5830

7224

8618

2787

3470

4181

5560

6954

8347

500

600

18

3144

3854

4582

6003

7424

8863

2860

3588

4280

5719

7158

8579

700

24

3374

4138

4920

6447

7992

9520

3073

3836

4600

6145

7672

9218

800

30

3641

4476

5293

6944

8614

10248

3321

4138

4973

6642

8276

9946

900

37

3819

4707

5559

7282

9023

10763

3481

4334

5222

6945

8685

10426

600

750

21.5

3770

4622

5495

7199

8903

10628

3429

4302

5133

6858

8584

10288

850

26.8

4047

4963

5900

7731

9584

11416

3685

4601

5516

7369

9201

11054

950

32.7

4367

5368

6347

8328

10331

12290

3983

4963

5964

7966

9926

11928

1050

39

4579

5644

6667

8733

10820

12907

4175

5197

6262

8328

10415

12503

800

900

14.8

5269

6460

7681

10062

12444

14856

4793

6014

7175

9586

11998

14379

1100

21

5657

6937

8247

10807

13397

15958

5151

6431

7711

10301

12862

15452

1300

28

6103

7502

8872

11641

14439

17178

5567

6937

8336

11134

13873

16672

1500

36

6401

7889

9319

12206

15124

18042

5835

7264

8753

11641

14558

17476

1000

1200

23

6588

8077

9604

12581

15559

18574

5993

7519

8971

11986

15001

17979

1400

30

7072

8673

10310

13512

16750

19951

6439

8040

9640

12879

16080

19318

1600

38

7631

9380

11092

14554

18053

21478

6961

8673

10422

13921

17346

20845

1800

46.8

8003

9864

11651

15261

18909

22557

7296

9082

10944

14554

18202

21850

AUKS F a n CoilUnit information

1 3

Table o f cvariable w o r k i n g condition performance parameter under heating mode (continued)

Unit:W

Air inlet temperature ℃

21℃D B

22℃D B

Waterinlet temperature ℃

40

45

50

60

70

80

40

45

50

60

70

80

Model

Water

flow

(kg/h)

Water

pressure

drop

(kPa)

400

430

8.1

2190

2744

3313

4465

5617

6740

2062

2616

3199

4351

5489

6626

550

11.5

2332

2958

3570

4807

6030

7267

2204

2830

3442

4665

5902

7125

650

15.5

2517

3185

3840

5162

6499

7807

2389

3043

3712

5034

6357

7693

750

20

2659

3342

4039

5418

6812

8205

2503

3200

3882

5276

6669

8077

500

600

18

2735

3428

4138

5577

7016

8419

2575

3268

3996

5435

6856

8277

700

24

2913

3694

4458

6003

7530

9076

2753

3534

4298

5825

7371

8898

800

30

3144

3978

4795

6447

8116

9750

2984

3801

4635

6287

7939

9608

900

37

3321

4174

5044

6767

8508

10248

3126

3996

4849

6589

8330

10088

600

750

21.5

3280

4111

4963

6688

8413

10096

3088

3919

4792

6518

8222

9926

850

26.8

3493

4430

5346

7199

9031

10884

3301

4238

5154

6986

8839

10671

950

32.7

3770

4771

5751

7732

9734

11694

3578

4558

5559

7540

9521

11523

1050

39

3983

5005

6049

8115

10202

12290

3749

4792

5815

7902

9989

12098

800

900

14.8

4585

5746

6937

9348

11759

14111

4317

5478

6698

9110

11491

13873

1100

21

4883

6193

7473

10063

12623

15214

4615

5925

7205

9765

12355

14916

1300

28

5270

6669

8038

10807

13606

16344

5002

6371

7770

10539

13308

16106

1500

36

5567

6996

8455

11343

14261

17178

5240

6699

8128

11045

13963

16910

1000

1200

23

5732

7184

8673

11688

14703

17644

5397

6849

8375

11390

14368

17346

1400

30

6104

7742

9343

12581

15782

19020

5769

7407

9008

12209

15447

18648

1600

38

6588

8338

10050

13512

17011

20436

6253

7966

9715

13177

16639

20138

1800

46.8

6961

8747

10571

14182

17830

21478

6551

8375

10162

13810

17458

21143

AUKS F a n CoilUnit information

1 4

4 . Demension

AFC-400CF/4, AFC-500CF/4

AFC-600CF/4, AFC-800CF/4

AFC-1000CF/4

AUKS F a n CoilUnit information

1 5

5 . Electrical wiring a n d connection

AUKS F a n CoilUnit information

1 6

Introduction o f control board QFPD-3F-HCE2 (PCB) sockets

Neutra

linsert

Primary of

transformer

Electric

heater

Line for

electric

heater

Line

insert

Heat

water

valve

Cold

water

valve

Water

pump

Indoor f a n output

High

M i d

L o w

Neutral

4-DIPswitch

W a t e r level

switch

Air return

temperature

Wiredcontrol

receiver

3-DIP

switch

Step motor

output

Display

board

Secondary of

transformer

AUKS F a n CoilUnit information

1 7

6 . Installation

6 . 1 Preparation andequipments before installation

◇ W o r k preparation

Required materials a n d major devices:

a . Thefancoilt o b e u s e d shallhave t h e conformity certificated issued b y t h e factory, o r quality appraisal

documents.

b . Thestructural a n d installation type, outlet direction, w a t e r inlet position o f t h e fancoilu n i t shallmeett h e

requirement o f design and installation.

c.Themajor materials a n d accessories forinstallation shallh a v e specifications a n d types t h a t meett h e

design requirements a n d b e provided w i t h conformity certificates b y t h e factories.

d . Electrical hammers, manual and power drills, adjustable wrenches, socket wrenches, steelsaws,t u b e

p l i e r s , hand hammers, bench vices, thread t a p s , thread reamers, horizontal ruler, plum b o b , hand

pumps, pressure t a b l e a n d g a s welding t o o l s .

◇ Working condition

a . Thefancoila n d i t s major p a r t s and accessories a r e arrived a t t h e w o r k site,t o o l s needed for

installation a r e provided and site,water a n d power source forinspection before installation a r e

available.

b . Structural construction i s complete, including waterproof layer w o r k s o n t h e roof, indoor w a l l s a n d f l o o r

finish i s complete.

c.Theposition a n d dimension o f t h e installation meett h e requirements o f design, d r y p i p e installation o f

t h e a i r conditioning systemi s complete a n d t h e elevation o f t h e reserved p o r t o f t h e branch pipe

connecting t o fancoilmeett h e requirement.

◇Operation process

a . Theprocess:Preliminary inspection →Workpreparation →Testrunning o f t h e motor→Heat

exchanger w a t e r pressure t e s t →Manufacturer a n d installation o f t h e suspension bracket →Installation

o f fancoil→Pipe connection →Inspection

b . Before installing t h e fancoil, t h e case and surface heat exchanger o f e a c h motorshall b e checked for

damage, rusting a n d other defects.

c.Each f a n coilshallundergo power-on testing, during w h i c h t h e r e shall b e n o attrition between t h e

mechanical p a r t s and n o leakage i n t h e electrical p a r t s .

d . Each f a n coilshallundergo water pressure testing ,w i t h t h e t e s t i n g intensity equaling 1 . 5 t i m e s t h e

w o r k pressure. Observe for2 - 3 m i n after t h e pressure i s set,t h e r e shallb e n o leakage.

e . Thefancoilshall b e suspended horizontally w i t h t h e suspension bracket installed even and secured, a t

correct position. Thesuspension rod shall n o t b e allowed t o swayf r e e l y . Theconnection between t h e

rod and t h e t r a y shallb e secured evenly w i t h t w o n u t s .

f.Theconnection between cold/heat medium w a t e r pipe a n d t h e fancoilshallb e structured w i t h steelo r

copper pipe ,w i t h connecting p i p e being straight. Thetightening shallb e applied a t t h e h e x connector

w i t h aw r e n c h t o prevent t h e copper p i p e frombeing damaged. I t i s suggested t h a t t h e condensed

w a t e r pipe b e structured w i t h softmaterial. When t h e length o f t h e h o s e i s n o t greater t h a n 300mm, a

transparent rubber pipe shallb e used, w i t h aclampt o a v o i d leakage a n d correct slopesot h a t t h e

condensed w a t e r cansmoothly f l o w t o designated position a n d t h e r e will b e n o still water o n t h e water

plate.

g . Theconnection between t h e f a n coila n d t h e cold/heat medium pipe shallb e madeafter t h e system

cleaning a n d pollution discharge t o avoid heat exchanger jams.

h . Access doors shallb e provided fort h e buried installed horizontal fancoiland t h e falseceiling ,fort h e

convenience o f t h e removal a n d service o f t h e u n i t .

◇ Quality standard

Items t o b e ensured:

a . Thefancoilb e installed stably a n d securely.

Inspection method: Measure w i t h ahorizontal ruler a n d aplumb.

b . Noleakage a t t h e connection between t h e f a n coila n d i t s inlet a n d outlet water pipes i s permitted. The

pipe o f condensed water shall h a v e aslopemeeting t h e training requirement and tight connection t o t h e

vent a n d a i r return chamber.

Inspection method: Measuring w i t h aruler, observation a n d checking t h e testing records.

c.Basic i t e m s : Thevent o f t h e fancoilshallb e tightly connected w i t h n o a i r leakage.

Inspection method: Observation.

AUKS F a n CoilUnit information

1 8

Protection o f finished products:

a . After t h e fancoilsa r e shipped t o t h e site,measures shall b e t a k e n t o keep t h e m i n good condition a n d

t o place t h e m i n a n orderly manner. Thef a n coilsshallb e protected fromrainy a n d snowy weathers.

b . When w o r k i n g i n winter, completely d r a i n w a t e r fromt h e fancoilafter water pressure testing, t o prevent

i t frombeing frozen.

c.Thefancoilshallb e installed immediately after i t i s delivered t o t h e sitea n d careshould b e t a k e n

during t h e cross w o r k i n g w i t h other process, t o protect t h e finished products frombeing bumped.

Qualityissues t h a t require attention:

Preventive measures f o r issues occur frequently

a . Since t h e surface heat exchanger canb e easily damaged b y t h e coldtemperature during winter

weathers, i t i s required t o discharge a l l w a t e r after t h e w a t e r pressure testing, t o avoid such damage.

b . Since fancoilscanb e easily damaged d u e t o bumps during movement, t h e y shall b e placed i n asingle

row a n d gently handled

c.Since fancoilheat exchangers canb e easily jammed, n o fancoil(after connected t o i t s p i p e )shall b e

p u t t o operation before cleaning a n d pollution discharge, t o prevent i t frombeing jammed.

d . Since t h e condensed w a t e r p l a t e o f afancoilcanb e easily jammed, t h e foreign matters i n t h e p l a t e

shallb e removed before t h e fancoilcanb e operated, t o ensure smooth flowo f t h e condensed water.

Qualityrecords:

a . Qualityinspection review t a b l e fora i r treatment chamber building and installation subw o r k .

b . Self-inspection a n d mutual inspection records.

c.Workinspection formforpreliminary inspection w o r k s

d . Inspection record t a b l e forincoming equipments.

Installation precaution

◇ Considerations o f noise a n d vibration

a . Canvass jointsshallb e installed between t h e machine and t h e a i r return/feed pipes t o prevent

secondary n o i s e a n d vibration fromtraveling fromt h e fancoilt o a i r pipes a n d t h e n t o t h e building.

b . Air flowrate shallb e considered when selecting t h e sizeo f a i r return/feed pipes t o minimize t h e n o i s e

level.

Notes:L o w speed a i r pipes a r e usually u s e d fora i r conditioners. The“constant pressure” method i s most

commonly u s e d t o determine t h e size,whereby t h e attrition l o s s o f t h e straight section o f ap i p e i s defined

a s 0.1mmAq/m, a n d t h e sizecanb e determined u s i n g a n “air p i p e ruler”. Thewidth/height ratio o f a

rectangular a i r d u c t shall b e w i t h t h e range o f 1 ≤ W / H ≤ 4 .

Thea i r speed o f agrille t y p e feed v e n t usually i s 3 m / s .

Thea i r speed o f agrille t y p e return vent usually i s 2.5m/s.

Thea i r speed o f afresha i r louver usually i s 2.0m/s.

◇ Cautions

a . Theu n i t shallb e installed b y professionals w h o familiar w i t h t h i s t y p e o f products a n d know t h e

applicable l o c a l rules;

b . During t h e installation, t h e unit shallnever b e moved b y grasping t h e fanblade a n d volute b y hands;

c.Theu n i t shallb e securely suspended fromaw e l l fixedpoint w i t h enough strength t o bear t h e weight o f

t h e u n i t a n d i t s vibration during operation; Theu n i t shall b e kepthorizontal, o r t h e condensed w a t e r

mayoverflow;

d . I f t h e a i r d u c t p o r t does n o t matcht h e port o f t h e a i r f e e d vent, connect t h e t w o w i t h aa i r duct

connection o f variable section prepared in-situ.

e . I t i s suggested t h a t aflexible connecting p i p e and t a p e sealing a r e used when connecting water outlet

pipe ,w i t h atorque not higher t h a n 205.6N.m(21Kgf.m)t o a v o i d water leakage d u e t o cracking.

f.Heatpreservation a n d e x t r a valves shall b e provided fort h e inlet a n d outlet water pipes;

AUKS F a n CoilUnit information

1 9

g . Afilter shallb e installed a t t h e inlet opening o f t h e coldw a t e r p u m p t o prevent t h e heat exchanger from

being polluted a n d blocked;

h . As forfancoils without aa i r filter, i n s t a l l afilter screen o v e r t h e a i r return opening ,t o prevent d u s t from

jamming t h e finso f t h e fancoila n d t o ensure t h e heat exchanging effect;

i . Before wiring, check i f t h e voltage, frequent a n d phases o f t h e power supply a r e a s required b y t h e unit.

Apower voltage deviation n o t greater t h a n 10% o f t h e rated value i s preferred.

j.Aswitch control shared b y several u n i t s o f different models i s strictly banned.

k.Thetemperature o f t h e u n i t shallb e n o lower t h a n 5 ℃ (t o a v o i d condensation) when coldw a t e r i s used,

a n d n o higher t h a n 8 5 ℃(usually60℃)when h o t water i s u s e d a n d t h e w a t e r shall b e clean.

6 . 2 U n i t installation

The distance between indoor unit a n d obstacle

Unitsuspension

◇ Select the suspension foundation

Thesuspension foundation i s astructure o f either wooden frameo r

reinforced concrete. It mustb e firmand reliable to bear a t l e a s t 4t i m e s

weight o f itself and capable o f bearing vibration forl o n g periods;

◇ Fixing o f suspension foundation

Fixthe suspension bolts either a s shown i n the picture o r b y asteel o r

wooden bracket;

◇ Adjust the relative positions o f the suspension hooks to ensure the indoor

unit i s level i n a l l directions. Useaspirit level to ensure this, otherwise

waterleakage, a i r leakage e t c . willb e resulted;

◇ Tighten the nuts and ensure that the hooks a r e tightly connected to the nuts and sMDms,a n d t h e r e i s n o

phenomenon o f v i r t u a l hanging;

◇ A f t e r the unit i s installed ensure i t i s secure and does not shake o r sway.

Drainagep i p e installation

◇ Thedrain p i p e should b e properly insulated to prevent the generation o f condensation,seep i c t u r e a s

follows:

Heatinsulation material: rubber insulation pipe w i t h t h e thickness o f moret h a n 8 m m

◇ Drainage pipe musth a v e adownward gradient (1 /5 0 1 / 100).If t h e d r a i n p i p e i s installed u p s a n d

downs, i t w i l l cause w a t e r backflow o r leakage e t c .

Thepipe should not risea t any point.

AUKS F a n CoilUnit information

2 0

◇When finish installation,please carry out the drainage test to ensure that the water flow through the

pipeline fluently, and carefully observe the junction to ensure that there is no water leakage at the

junction. If the unit is installed in the newly built house, strongly recommend that this test taken before

the ceiling installation. Even it is the heating only unit, this test is unavoidable.

6.3Electrical connection precaution

Warning

Installation of electric items must be carried out by qualified, professional technicians. An isolated circuitry

should be fixed with whole-pole disconnection devices, which is with at least 3mm gap of touch point. .

Power supply and indoor to outdoor connection should use special cable. Providing the necessity of

installation or replacement, the professional technician of service store appointed by manufacturer must

be required, while self-operation by users is prohibited.

Incaseofany electric shock accident, thecreepage protection devices /power supply on-off and breaker

mustberequired w i t h power supply.

Machine mustbeearthed surely.Ifnot, it’ll beprobably caused creepage.

T h e power cordshallconsist w i r e s of227IEC53(RVV) typespecified inGB5023 orthose ofequivalent

grades orabove .Secure thew i r e s w i t h fixtures, sothat theterminals will not easily dislodge under

external forces. Incorrect connection orfixing maycause afireorother hazards. T h e internal and external

connecting cableshallconsist w i r e s of245IEC57(YZW) typespecified inGB5013 orthose ofequivalent

grades orabove.

N o t i c e

T h e earth line isneither allowed toconnect togas pipe, water pipeorcircuitry oftelephone orlighting rod,

nor totheearth line ofother devices.

Others

●Please connect thepower cordaccording totheinstructions ofthecircuit diagram.

●Securely and firmly connect thew i r e s totheterminal holder w i t h cablefixtures, toprevent theexternal

forcesfromacting onthew i r e s and causing dangers.

6 . 4 Pressure testing andtest runwithwater.

Preparation before test run

◇ Before initial operation, please remove foreign matters i n t h e w a t e r t r a y , plastics and around t h e fancoil

a n d check i f t h e installation points o f t h e w a t e r pipes a n d t h e cables a r e correct.

◇ Before initial operation, t h e w a t e r inlet a n d outlet valves o f t h e u n i t shallb e closed firstand t h e pipe

systemo f t h e cooling w a t e r b e cleaned before opening t h e valves.

◇ Duringt h e initial operation, t h e ventilation v a l v e o n t h e water return pipe shallb e opened t o exhaust t h e

a i r fromt h e fancoila n d t h e pipeline.

Pressure testing a n d test runwithwater

Before carrying out system pressure testing for an AC system equipped with a buriedly and horizontally

installed fan coil, a pressure testing plan shall be prepared and a proper pressure test pump be selected.

The test conditions shall be carefully noted during the testing and the pressure change of he system shall

be monitored from time to time.

Be careful about t h e following when preparing t h e pressure t e s t plan:

a . Theventilation v a l v e o n t h e w a t e r collecting head shall b e opened before adding water t o t h e fancoil.

W a i t e u n t i l t h e a i r i n t h e fancoili s emptied before closing t h e valve.

b . Pressure t e s t shall b e carried out a t atemperature o f 5 ℃o r above, otherwise t h e r e shallb e

anti-freezing measure i n place.

c.During t h e w a t e r pressure t e s t , t h e pressure shallb e increased i n astaged, slowa n d uniform manner.

W a i t u n t i l t h e water p u m p i s stopped a n d w a t e r pressured stablebefore carefully check i f t h e r e i d w a t e r

This manual suits for next models

4

Table of contents

Other AUKS Air Conditioner manuals

Popular Air Conditioner manuals by other brands

Carrier

Carrier 48TFD008-014 Installation and service instructions

Coleman

Coleman ECHELON AC21 Series Technical guide

Vertiv

Vertiv Liebert AHU user manual

KITANO

KITANO Roka II Series Operation and installation manual

Carrier

Carrier 42QHC007D8S Series installation manual

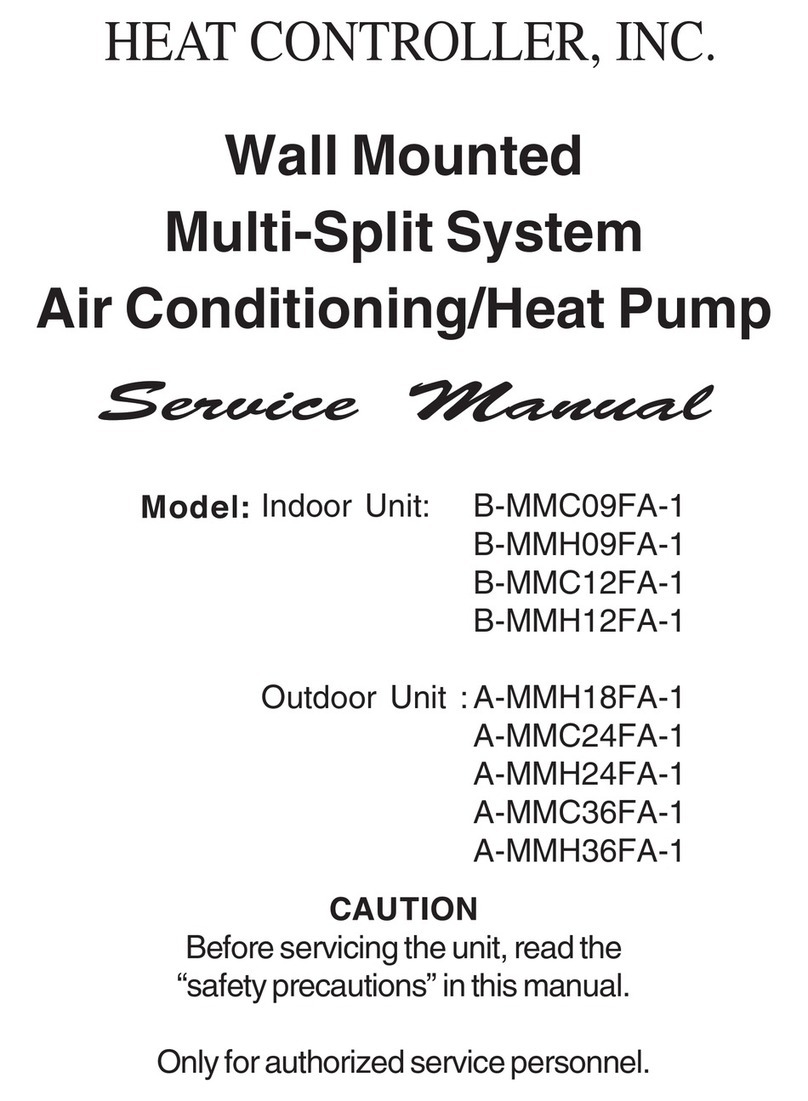

Heat Controller

Heat Controller B-MMC09FA-1 Service manual