Auscision 442 Class Owner's manual

Auscision 442 Class Operating Information (v3) Page 1 of 9

Auscision Models 442 Class Operating Information.

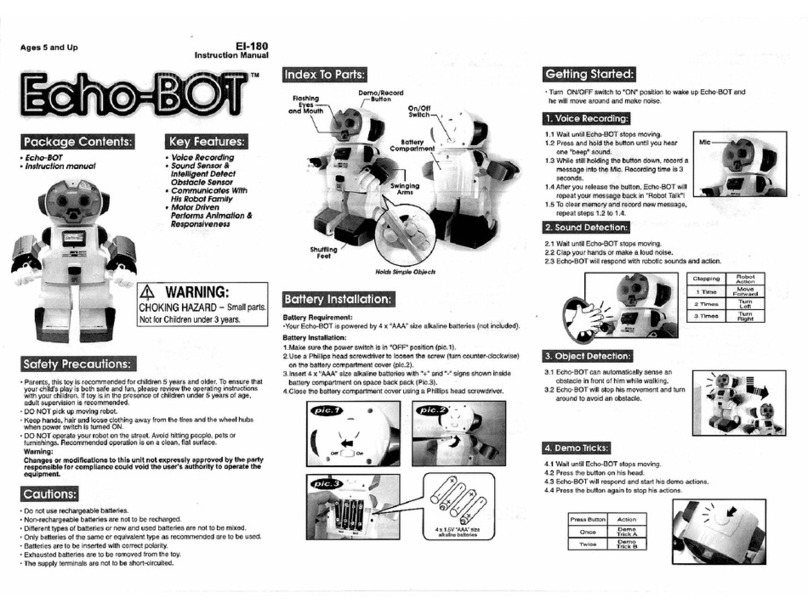

Your Auscision Mo els 442 class locomotive’s main printe circuit boar an associate lighting has been

esigne to function as a DC an DCC Sound Decoder Installed Model. In these notes reference is

ma e to the No.1 en an No.2 en of the mo el. This iagram will assist in i entifying which en

is which:

DC Model

The DC mo el is able to control the locomotives lighting via the micro switches on the bottom of the

fuel tank. The lighting is irectional. The switches are able to isolate, turn on/off:

1. The Locomotives Hea lights.

2. The Locomotives Number Boar s an White Marker Lights.

3. The Locomotives Re Marker Lights.

The lighting connection for the DC model has the Number 1 an Number 2 en white/re marker lights

connecte to the main printe circuit boar at the two plugs marke ‘DC’. The Hea lights an Number

Boar s connection is via a COMMON wiring plug that both the DC an DCC Sound Decoder Installed

versions use. (See image on page 3)

If you’re going to operate your model on a DC system controller then read no further. If you plan on

fitting an after marker decoder or your model is a DCC Sound Ready model please read on.

DCC Ready Model - fitting an aftermarket decoder

The 442 class mo els main printe circuit boar has been specifically esigne to function through the

‘NEM660 standards’ 21pin connector an integrate with the new ESU Loksound V5 decoder. Via the 21

pin connector this eco er functions with four in ivi ually powere auxiliary outputs (Hea light front,

Hea light rear, Aux 1 an Aux 2) an four in ivi ual logic outputs (Aux 3, 4, 5, 6) which the main circuit

boar has electronic components inclu e for their operation. The DCC Sound Decoder Installed

mo els lighting connects via 3 separate plugs. One COMMON connection for the Hea lights an

Number Boar s, an two plugs marke ’DCC’ for the appropriate en s marker lighting. (See image on

page 3)

Number 1, Front En .

Number 2, Rear En .

‘Ra iator Fan En ’

Auscision 442 Class Operating Information (v3) Page 2 of 9

When selecting an aftermarket eco er a few etails may nee to be consi ere first. As there are two

stan ar s of eco er 21pin connections available on the market, the NEM660 version an the NRMA

version, two lighting connection possibilities are available on the Main PCB.

Specifically, for the mo els White/Re Marker Light connection for both en s, the plugs marke ‘DC’

an ’DCC ’ are available (See image on page 3). The lighting connection will be epen ent on the bran

an version of the aftermarket eco er being use . Generally speaking any aftermarket 21 pin eco er

can be fitte .

For aftermarket eco ers with a re uce number of auxiliary lighting outputs, the Locomotives

Reversible Headlights along with Aux 1 (Front Number Boar s, Front White Marker Lights, Rear Re

Markers lights) an Aux 2 (Rear Number Boar s, Rear White Marker Lights, Front Re Markers lights)

will function as long as the Marker Lighting is connecte to the ‘DC’ PCB plug connection.

Note: Using just the 2 Auxiliary outputs the Lighting functions can also be isolate with the micro

switches on the bottom of the fuel tank. (E.g. turning the opposing en , re marker lighting off).

Alternatively refer to the link below for further eco er possibilities. This is an excellent source of

information which a resses the 21pin NEM660/NMRA stan ar s an their associate ifferences an

functionality issues, along with a chart i entifying which other bran eco ers an versions that may

also be suitable.

http://www.sbs4 cc.com/tutorialstipstricks/21mtcconnector.html

Fitting the decoder - once the mo el's bo y is remove from the chassis, taking care with the bo y’s

wiring an COMMON lighting connection plug, first remove the small 21pin DC a aptor PCB from the

main PCB’s 21 pin plug. Removal of the DC a aptor PCB also removes the components associate with

motor noise suppression for DC function. Then, an paying close attention to the pin alignment, firmly

push the eco er onto the 21 pin plug.

Note: Alter the DC DCC plug connections for Marker Lighting if required. Inadvertently plugging the

lighting into the wrong plug should pose no risk to damaging any circuitry, although care should be

taken ensuring the lighting is connected to the correct plug for the decoder that has been selected.

Speaker connection is via the supplie connector plug/wiring harness, fitte to the plug marke ‘SP’ (see

image on page 3). Keep in min matching the chosen speaker an eco er’s amplifier impe ance.

ESU Loksound V5 DCC Decoder Installed Model

Your DCC Sound Installed Model is fitte with the recently release ESU Loksound V5 Decoder. All

switches on the bottom of the fuel tank are to remain in the turne on position. The Deco er connects

to the main printe circuit boar via the 21pin connector, with the lighting wiring connecting via three

plugs at the main PCB (see image on page 3):

• The Hea lights an Number Boar s connecting from the locomotive bo y at the COMMON plug

• The white/re marker lighting via the two plugs marke ‘DCC’ for the appropriate en .

The eco ers efault settings have been a juste to ensure your mo el operates smoothly straight out

of the packaging. Please take a moment to rea through the following information as it relates to the

functionality an features along with further information as to in ivi ualising your mo el.

Auscision 442 Class Operating Information (v3) Page 3 of 9

• In or er to a just the running qualities of your mo el for your personal preference, reference to

suggeste settings in the form of a quick start gui e is available in the following notes. Alternatively

for full eco er a justment etails refer to the ESU Loksoun V5 Deco er Manual an Full Throttle

Description available at the following links:

http://www.esu.eu/en/ ownloa s/instruction-manuals/ igital- eco ers/

http://www.esu.eu/en/pro ucts/loksoun /loksoun -full-throttle- iesel-features/

A escription of the ESU 96429-LSV5.0DCC-Diesel-Auscision-Mo els-442-Class-FT-V4 an link to

ownloa the efault file can be foun here:

http://projects.esu.eu/projectoverviews/19

• If require , a justments an in ivi ual finetuning of your DCC mo el an eco er can be ma e

primarily in two ways.

1. The most simple an effective way is with an ESU Lokprogrammer interface with a Win ows

operating system PC.

The etails of which can be foun here:

Note: An updated software version to function with the V5 decoder will be required.

Product Information... http://www.esu.eu/en/pro ucts/lokprogrammer/

Instructions................ http://www.esu.eu/en/ ownloa s/instruction-manuals/lokprogrammer/

Updated Software...... http://www.esu.eu/en/ ownloa s/software/lokprogrammer/

2. Alternatively a justments can be ma e via your DCC operating system controller or with other PC

base software such as JRMI. Refer to your operating system manual an the ESU V5 eco er

manual.

#2 En Marker Light

DCC‘ Soun Installe

Version Connection

#1 En Marker Lights

DCC Soun Installe

Version Connection Plug

#1 En Marker Lights

DC Version Connection

Plug

#2 En Marker Lights

DC Version Connection

Plug

Common Hea light an Number

Boar Co

nnection Plug

Speaker Plug

‘SP’

21 Pin Plug

Auscision 442 Class Operating Information (v3) Page 4 of 9

Quick Start Guide

Care has been taken in order for your model to perform straight out of the packaging. In general it

has been programmed to ESU Loksound’s V5 Decoder default values. As modellers we all have

different ideas and preferences as to how our models perform. Should you wish to further adjust how

your model performs, the following is a quick start guide to some of the primary settings required to

do so.

Excerpts from the ESU Loksound V5 and Lokprogrammer references are included in the description

and are as follows. (Refer to the V5 Decoder Manual, the Lokprogrammer Manual or your DCC

systems programming section for full programming details)

• The Default Locomotive A ress for your 442 class mo el is 3.

In or er to change the locomotive a ress, refer to chapter 9.1, 9.2 ‘A ress Settings’ of the ESU

V5 Deco er Manual. In ivi ual DCC controller systems may also have a programme track output

an function available for this purpose.

• Deco ers operating within a DC operating system will function as per ESU’s efault DC settings.

For further etail also refer to the DC notes containe within our 48 class operating information

ocument foun here:

http://www.auscisionmo els.com.au/PDFs/Auscision%20HO%20Scale%2048-

830%20class%20DCC%20Operating%20Information%20v4.p f

Motor Auto Tune Procedure

Should you encounter any running performance issues the following Auto Motor Tune procedure may

help resolve the problem.

This feature will automatically a just the Motors Back-EMF in most cases. This is not meant to be a

“cure all” solution. In most cases this will be all that is require , however there still may be the nee to

perform some manual a justments.

In or er to use this automatic a justment you will first nee to place your locomotive on a section of

track paying attention to the set irection of travel. Set CV 54 to a value of 0. Activate function F1. (Be

sure to have plenty of clear space ahead of your locomotive. Allow 2 metres of available track) Your

locomotive will quickly take off at full spee an then stop while rea ing the motor responses. This will

automatically set the motor values require in CVs 52, CV 53, CV 54, an CV 55. From here you can

make any other manual a justments if nee e .

Refer Loksoun V5 manual, chapter 11 for full motor a justment etails.

Minimum and Maximum Speeds

As efault, the eco er will automatically etect the user’s controller spee step settings, with the

controller using 14, 28 or 128 steps (28 being common).

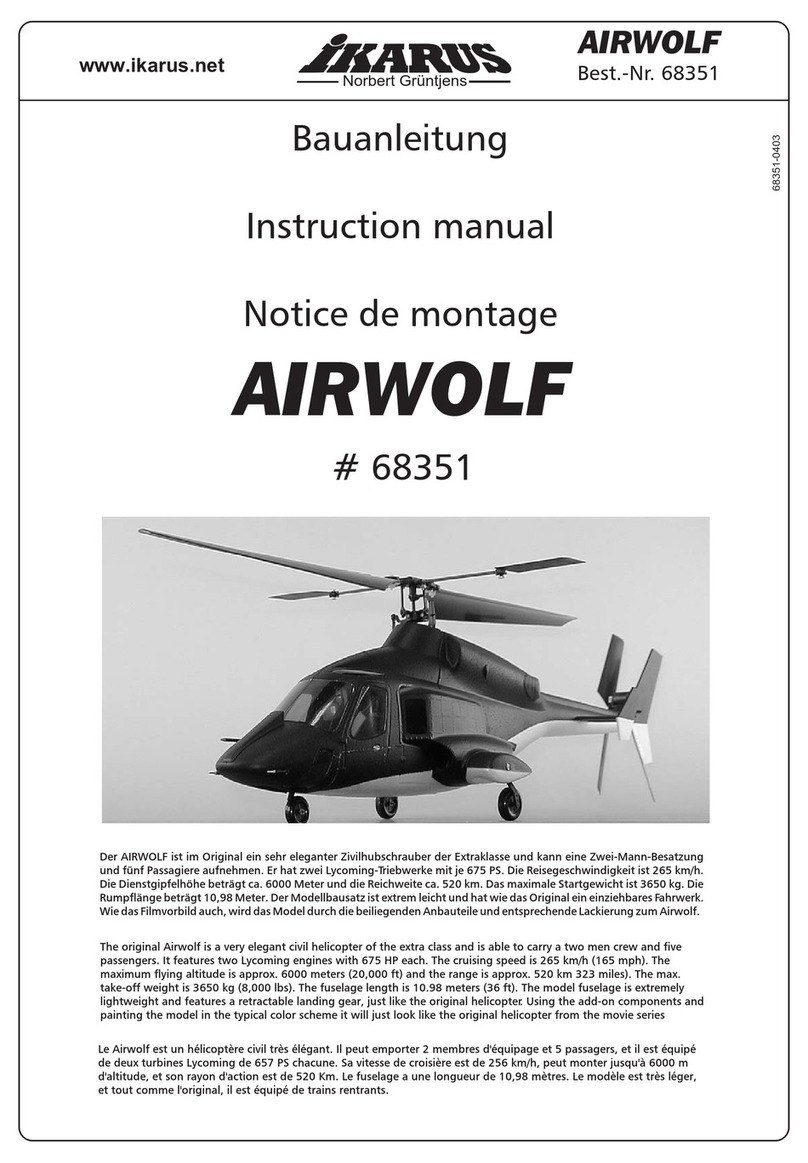

• Default is the Exponential 1 28 step spee table as per the graph below utilising minimum an

maximum spee settings.

• Defaults are CV2 =3 (minimum spee value) an CV5 = 255 (maximum spee value).

Auscision 442 Class Operating Information (v3) Page 5 of 9

• These two values efine the compression of the curve while automatically a justing the 28

in ivi ual spee steps in between that make up the curve. Alternatively an using Lokprogrammer

there are several other spee preset tables available, as well as being able to a just each of the 28

in ivi ual spee steps by changing the values at CV67 through to CV94 with values in the range

between 1 an 255. Full etails can be foun in Chapter 10 ‘a aptive riving behaviour’ of the

Loksoun V5 instruction manual.

Acceleration Momentum and Deceleration Momentum

The mo els acceleration momentum time an eceleration momentum time can be a juste

in ivi ually.

The time for accelerating from 0 to maximum spee is a juste in CV 3 ( efault value = 22, which

equates to 19.71 secon s) while eceleration is set in CV 4 ( efault value = 22, which equates to 19.71

secon s). Value Range is from 1 to 255 or from 0.9 to 228.48 secon s. (Approximately 0.89 secon s

for each increment of value)

The times set in these CVs work spee epen ant. Therefore, the acceleration istance an the brake

istance are longer at higher spee s. In other wor s, the faster the locomotive moves, the longer the

istance until it stops.

Auscision 442 Class Operating Information (v3) Page 6 of 9

DCC Function Table

F0 Directional Headlights

F1 Not in use. For future applications

F2 Playable Air horn

F3 Drive Hold (Full throttle feature)

F4 Dynamic Brake

F5 Locomotive Brake (Full throttle feature)

F6 Headlight Dimmer Control

F7 Front Number 1 End. Marker Light and Number Board Logic (See notes below)

F8 Prime Mover Locomotive Sound (Start Stop)

F9 Rear Number 2 End. Marker Light and Number Board logic (See notes below)

F10 Manual Coupler sounds

F11 Coast (Full throttle feature)

F12 Run 8 (Full throttle feature)

F13 Manual Cooling Fan on off

F14 Acceleration Shunting mode (Turns off any momentum settings. Runs at half speed)

F15 Volume Fade Control (set at 50% normal volume level - ideal for loud multiple unit

consists)

F16 Manual Sanding Valve on off

F17 Manual Compressor on off

F18 Brake Set Brake Release (Default is on. Automatically Brake Valve Sound plays when

moving off or stopping)

F19 Not in use

F20 Not in use

F21 Headlight, #1 Front End (not directional)

F22 Headlight, #2 Rear End (not directional)

F23 Number Boards #1 Front End

F24 Number Boards #2 Rear End

F25 White Marker Lights #1 Front End

F26 White Marker Lights #2 Rear End

F27 Red Marker Lights #1 Front End

F28 Red Marker Lights #2 Rear End

Auscision 442 Class Operating Information (v3) Page 7 of 9

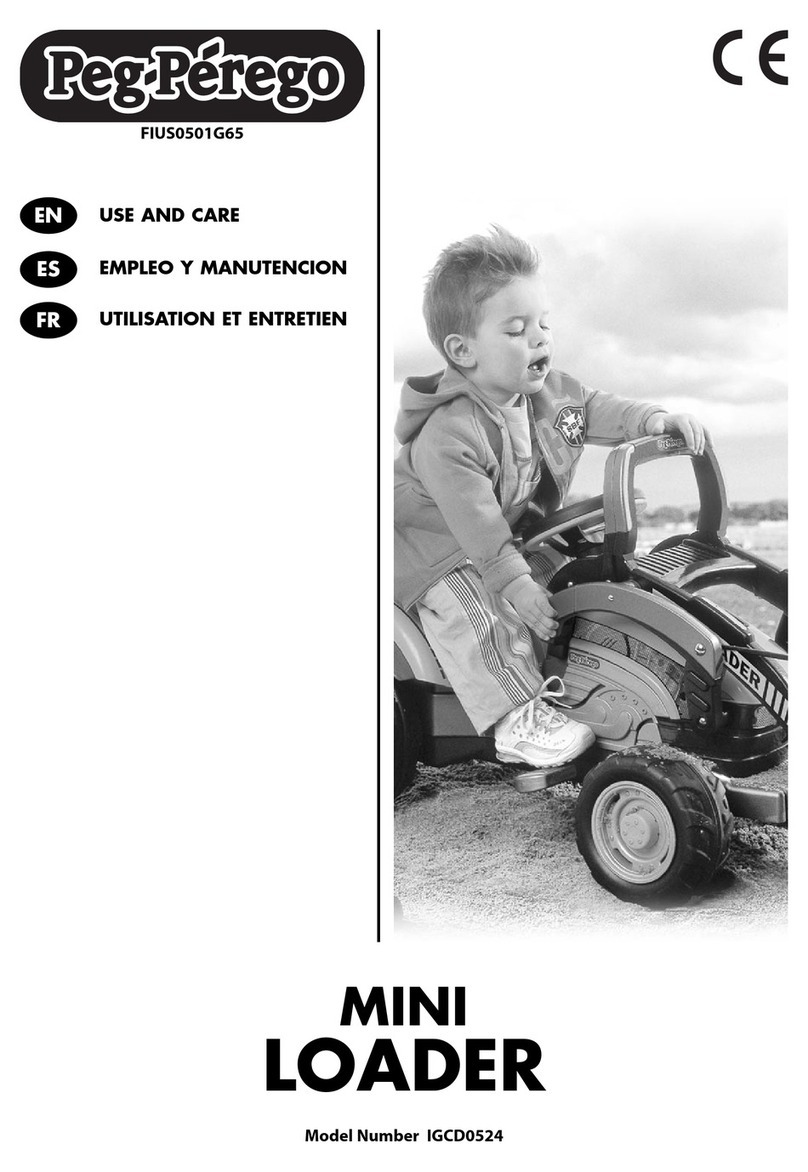

Random Sounds

With previous Loksoun Select an V4 eco ers Ran om Soun s such as ‘Compressor’ were turne on

as efault an woul start an stop automatically. The parameters within the soun flow in most cases

ma e it ifficult to alter their con ition.

The V5 eco er along with the up ate Lokprogrammer software allows more flexibility to control

ran om soun s. The default 442 class sound file has NO ‘Random Sounds’ turned on. The following is

an overview on how to activate an a just these soun s using Lokprogrammer. With reference to the

below screenshot the following settings can be a juste to your personal preferences if require . The

ran om compressor soun will be use as the example, although any soun containe in the efault file

can be use . The V5 eco er also has the flexibility of importing further soun s into the mo els efault

file from ESU’s template soun files.

Refer to the 442 class efault function table: Compressor being mappe to Function 17.

Un er the Decoder – Function Settings – Random functions tab in Lokprogrammer, select position

‘Ran om 1’ an select triggere function F17, along with the Stop an Only Play When Driving Sound Is

Enabled check box’s. If the ‘Drive’ check box is ticke the ran om compressor soun will also function

when the locomotive is moving. Active Minimum an Active Maximum is the variable length of time

the ran om soun will occur, while Passive Minimum an Passive Maximum is the variable time frame

in which the ran om soun will turn on an function. These values once selecte will then require

writing to the eco er in or er for them to function.

For further information refer to Chapter 13 ‘Soun A aptation’ in the Loksoun V5 instruction manual.

Lokprogrammer - Decoder – Function Settings - Random Functions

Auscision 442 Class Operating Information (v3) Page 8 of 9

Function button 7 (Number 1 End Auxiliary Lighting Logic)

Function button 9 (Number 2 End Auxiliary Lighting Logic)

The lighting for each en of the locomotive has been ivi e into four separate lighting states. By

pressing the function key repetitively the following applies:

State 1. All Lighting Off.

State 2. Number Boar s On. White Marker Lights On. (As in lea ing en mainline running)

State 3. Number Boar s On. Re Marker Lights On. (As in yar shunting. Both en s)

State 4. Re Marker Lights On. (As in the trailing en of a light engine movement)

(State 4 is followe by State 1)

If require , the in ivi ual light brightness can be controlle / a juste separately. Refer to the ESU V5

Deco er Manual, with reference to the auxiliary outputs 1 through 6.

Number 1 end Auxiliary Lighting

Aux 1 - Number Boar s, Aux 3 - White Marker Lights, Aux 5 - Re Marker Lights

Number 2 end Auxiliary Lighting

Aux 2 - Number Boar s, Aux 4 - White Marker Lights, Aux 6 - Re Marker Lights

PLEASE N TE:

The following notes are relevant for the previously used Loksound Select Series

Decoder as used in the Auscision 48 class model which had the following

possible issue. The new Loksound V5 decoder utilises an extra 2 sound

processing channels, (now 10 in total) and, following thorough testing, the

problem appears to no longer exist in the V5. However if the issue should

reoccur the following details can be followed in order to remedy the problem.

.........................................................................................................

In order for the Function 7 and Function 9 auxiliary lighting feature to work, ESU

Loksound had to create a lighting logic template. This template is N T built into the

decoders function logic, however utilises two of the eight available sound processing

flow channels.

Therefore, under certain circumstances and especially when B TH ends of the model’s

F7/F9 auxiliary lighting are turned on, then some of the secondary sounds may not

function. (For example brake squeal when stopping ) This is due to the non

availability of spare sound channels at that particular moment in time, and is not a

fault with your decoder.

If any activated secondary sound function (including the F7 and F9 lighting) appears

erratic/frozen turn off the locomotive prime mover (F8). This will then allow the

processes selected and queued the available space to function and complete. nce

complete the prime mover (F8) can be turned back on as normal.

If this type of sound response becomes an operating issue, then to free up sound

channels the auxiliary lighting has also been mapped to be individually controlled

with the Logic Functions F21 through to F28. (See function table )

Auscision 442 Class Operating Information (v3) Page 9 of 9

Locomotive Horn Sounds

Your 442 class mo el has been fitte with 2 Brass Castings of the RVB Hurricane 5 chime horn as

originally fitte to the prototype.

For the Loksound V5 decoder the CV for horn selection is 163 with has a efault value of 8. The

efault horn soun for your mo el has two slightly ifferent soun ing RVB Hurricane 5 Chime horns

at each en of the mo el epen ing on the irection of travel. Version 1 of the RVB is on the No.1

en an the Version 2 RVB is on the No.2 en .

At one time or another some in ivi ual units within the 442 class fleet have use Nathan Airchime

P5 an M5 horns at various times. These soun files are also available to in ivi ualise your mo el if

require .

To alter the horn soun to the applicable type, refer to the list below an for further reference the

ESU Loksoun V5 Deco er Manual.

Please Note: To complete the change in CV value, it is recommended that power to the decoder

be interruption after writing.

CV163 Horn type

0 Airchime P5

2 RVB Hurricane 5 Chime (Version 1)

7 RVB Hurricane 5 Chime (Version 2)

8 Directional 2 x RVB Hurricane 5 Chime

14 Airchime M5

Decoder Reset

If at any point your model’s decoder becomes unresponsive, it may simply require a reset in

order to regain normal function. You can reset the decoder to the current memory default

settings at any time.

In most cases POM (Programming on the Main) will not work to reset a decoder. Please use a

separate programming track.

To reset the decoder:

• Refer to the ESU V5 Decoder manual for full details.

• Enter the value 8 into CV8.

• To complete the reset, power to the decoder must be interrupted.

For ease of connection to the web links attache within this ocument, an online version of

the 442 class Operating Information can be foun on the Auscision website at the below link:

http://www.auscisionmo els.com.au/442%20Class%20Locomotive.htm

Table of contents

Popular Toy manuals by other brands

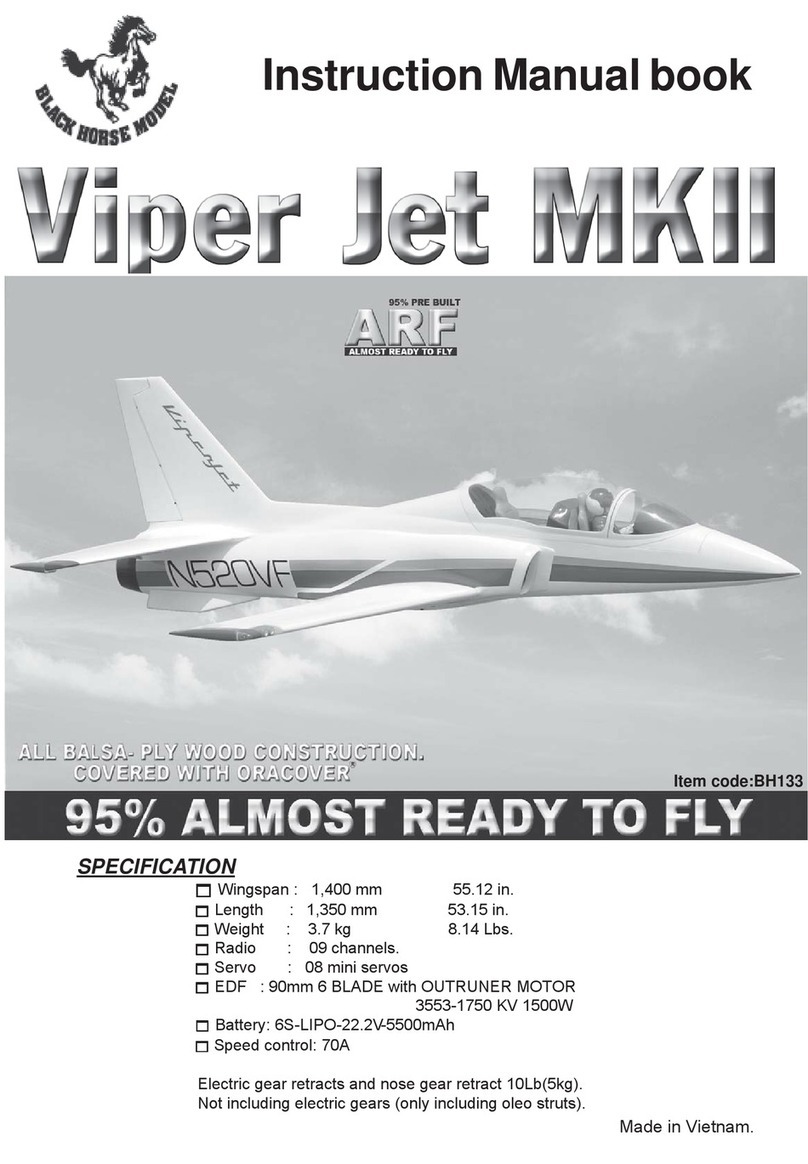

Black Horse Model

Black Horse Model MKII Instruction manual book

Enabling Devices

Enabling Devices Holly Jolly Express 9346 user guide

NORDIC PLAY

NORDIC PLAY 805-433 manual

Hongda USA

Hongda USA Coloured Glaze Time instruction manual

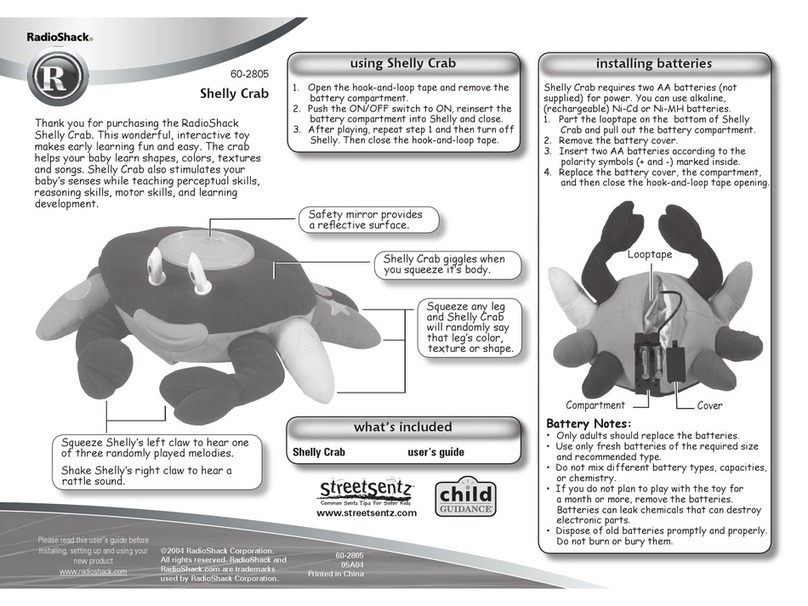

Radio Shack

Radio Shack 60-2805 user manual

Fisher-Price

Fisher-Price CDG07 instructions