AUSSIE ECO-CLEAN Monsoon 200 User manual

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 1

Australian Pump Industries

Aussie Eco-Clean

Monsoon Series High Pressure Blaster

(Three Phase Models)

IMPORTANT:

TO REDUCE RISK OF INJURY,

READ OPERATING INSTRUCTIONS

CAREFULLY BEFORE USING EQUIPMENT

Feb 2010

Covers:

Monsoon 200

Monsoon 300

Monsoon 300 Maxi

Monsoon 400

Monsoon 400 Maxi

Hurricane

OPERATION & MAINTENANCE MANUAL

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

2

Australian Pump Industries

Before attempting to operate your machine please read this Instruction Manual thoroughly following all

directions carefully. By doing so you will ensure safe operation of the unit and will enjoy long and

trouble free service from your heavy duty water blaster.

WARRANTY COVERAGE

This warranty covers any defect which occurs due to faulty workmanship or material under normal use.

Please keep your receipt as proof of purchase. This warranty specifically excludes the following:

1. Damage resulting from debris or mineral deposits contained within the water supply to the

machine.

2. Leaking hoses when the outer cover of the hose has been abraded or the hose has been kinked.

3. Damage to o-rings and valves, etc. caused by the use of cleaning chemicals or compounds.

4. Replacement of parts damaged due to fair wear and tear.

5. Misuse, negligence, alteration, accident or breakage.

6. Failure of the machine due to lack of normal maintenance services (The owner is responsible for

the performance of regular maintenance services, as specified in the Operator's Manual).

7. Damage and/or progressive damage caused by the failure to inform Australian Pump Industries

Pty Ltd, or the closest Authorised Australian Pump Agent or Distributor, within seven days of the

defect becoming apparent.

8. Repair or modification by an unauthorised service person.

9. Australian Pump Industries Pty Ltd specifically excludes from warranty responsibility any

consequential loss or damage including on-site servicing, loss of time, loss of use of the machine,

hire costs of a replacement machine or inconvenience.

10. Routine maintenance is the owner's responsibility. Failure to maintain the machine in line with

the services outlined on page 8 will invalidate the warranty.

11. Where possible return faulty goods to the place of purchase. No products can be returned to us

without prior permission. The reason for return must be clearly stated.

N.B. Warranty is not transferable to third parties in the event of sale of the machine within the

warranty period. Please note that any parts used in warranty repairs are guaranteed for a

period limited by the original warranty of the parent product.

STANDARD EQUIPMENT

Before proceeding with assembly of your new Aussie Eco Clean blaster, check that all parts listed

below are included.

1 Gun handle assembly and high pressure hose

1 Lance and nozzle assembly

1 Inlet hose connector assembly

HIGH PRESSURE SETTING

The high pressure pump is factory set to operate at its rated pressure. DO NOT ADJUST.

Tampering with the pressure regulator will void warranty and can be dangerous.

WARNING:

If pressure drops off, check nozzle for wear. Nozzles should be replaced on a regular basis (every

month for machines in regular use, every 3 months for machines used intermittently. Using the

machine with the incorrect nozzle size or worn nozzle will void warranty and can be dangerous to the

operator.

* * W A R N I N G * *

AUSSIE HEAVY DUTY WATER BLASTERS ARE DESIGNED

FOR PROFESSIONAL OPERATORS ONLY

IMPORTANT

INSTRUCT OPERATORS IN CARE AND USE OF THE MACHINE BEFORE USE!

AUSSIE ECO CLEAN BLASTER OPERATING AND MAINTENANCE INSTRUCTIONS

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 3

Australian Pump Industries

High pressure

hose connection

Supply hose

SAFETY PRECAUTIONS - IMPORTANT

1. NEVER direct the spray jet at any person or animal.

2. NEVER direct spray jet at any surface that may contain asbestos material.

3. NEVER hold a finger over the high pressure nozzle.

4. NEVER direct the spray jet at the machine itself or any electrical equipment.

5. After use release the pressure in the high pressure hose by operating the pistol

trigger.

6. DO NOT attempt any mechanical repair. If you have a problem with your machine

contact your local Aussie Eco Clean Service Division, phone (02) 9894 4144.

7. NEVER supply any liquid other than water to the water inlet.

8. NEVER pull the high pressure hose if it has formed kinks or nooses.

9. NEVER pull the hose over sharp objects.

10. DO NOT attempt to disconnect any hose or coupling with pressure still in the hose.

11. DO NOT operate the machine whilst standing on ladders, use a platform tower or

scaffolding.

12. Children should NOT be allowed to use the machine.

13. We recommend the use of safety goggles when using the machine, particularly

with the sand blasting attachment (optional accessory) or any application where

loose particles of stone or ``grit, etc. may be blown around by the pressure spray.

ASSEMBLY AND PREPARATION FOR USE

1. Check the oil in the pump . Note separate reservoirs. With the

machine on a level surface the oil level should cover the red spot

in the oil level sight glass on the side of the machine. If

necessary, top up with SAE 30w 50 oil (non foaming type). Do

not mix different grades of oil as this may affect the machine=s

performance. If alternative oil is used, first empty out oil by

unscrewing drain plug in bottom of machine.

2. Ensure breather plug is fitted to pump (yellow).

WARNING: Before operation ensure top mounted oil filler plug is

replaced by breather. Failure to fit breather and keep clean can

result in over pressuring of oil chamber (crank case) and can blow oil seals. This will void

warranty..

HEAVY DUTY LANCE: To assemble the lance, insert Section B into Section A and screw together and

check nozzles have been fitted to end of lance (C & D).

HIGH PRESSURE HOSE

Connect the high pressure hose to the threaded water outlet on

the side of the machine via a screw coupling. No spanners are

necessary.

C

D

B

A

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

4

Australian Pump Industries

WATER SUPPLY HOSE:

Use a good quality hose (not supplied) of 25mm diameter minimum.

Fasten the one end of the hose to the inlet hose connector securing using a worm drive clip. This

connection MUST be tight to avoid leaks.

Water supply can be by means of either:

$ Mains Supply

Secure the free end of the hose to your tap using a suitable tap adaptor (not supplied - available

through all good hardware and garden supply stores).

$ Syphon Fed Supply

Place the free end of the hose into a water tank or container and the pump will draw water itself.

Use a larger diameter suction hose, at least 1" diameter and no more than 2 metres long.

Water supply must be above or level with pump.

NOTE: To prevent the ingress of foreign bodies into the pump we recommend that a gauze filter (not

supplied) be fitted to the free end of the hose, before connection to pump.

HOT WATER APPLICATION

Aussie Eco-clean Monsoon & Hurricane water blasters can be used in their standard configuration with

cold or hot water up to 60 C. Using optional Hot Shot seals and valves the pumps can be modified to

operate with water temperatures up to 80 C.

DETERGENT FUNCTION

This machine is designed to handle non-caustic cleaning agents to improve cleaning efficiency.

1. Push clear plastic chemical injection hose with filter assembly onto the injector nipple.

2. Submerge the end of the hose with filter into your chemical container.

3. Reduce pressure of machine to enable venturi system to activate: on double lance

machine adjust by control handle

4. Allow some time for the chemical to work into the grime.

5. Set the lance to high pressure and blast detergent and dirt from the job.

6. Remove pick up hose from detergent bottle.

7. Rinse detergent valve with clean water by running at low pressure.

Warning: leaving detergent in the valve can cause it to stick and malfunction.

OPERATION:

Turn on water supply. Note: Tap should be full on.

Pull the trigger to expel air from the system. Water will trickle from the end of the lance when air is

expelled.

Start the engine. (Refer to engine manual for details)

Check that there are no leaks in the line connections, pistol or power lance. Pressure begins

when the pistol trigger is squeezed. SAFETY … IMPORTANT

EXCESS ATOMISED MOISTURE CAN ENTER SWITCHES &

MOTOR CONNECTIONS AND OVER TIME MAY CAUSE FAILURE

KEEP THE MACHINE OUT OF MOISTURE LADEN ATMOSPHERES

ACCESSORIES: (Consult Selection Guide)

Your Aussie water blaster can be used with a wide variety of optional extras to enhance performance.

To use the accessories you must first disassemble the lance. Unscrew quick coupler to unlock the

lance. The accessories can then be connected to the end of the lance assembly. If quick coupler is

not supplied it can be purchased from your local Aussie Eco-Clean Distributor.

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 5

Australian Pump Industries

A

B

TURBO LANCE - A correctly selected heavy duty turbo lance can cut pressure cleaning time in

half and is a very important accessory.

SANDBLAST HEAD - Wet sandblasting is safe and tremendously effective. Ideal for rust

removal, paint stripping and graffiti removal.

OPTIONAL LANCES - A range of optional lances in stainless steel or zinc plated steel are

available in lengths of up to 2 metres.

ROTARY CLEANER - The Aussie Eco-Clean rotary cleaner allows flat surfaces to be cleaned in

a fraction of the time normally taken. Ideal for contractors and professional users.

LONG LENGTH HOSES - HOSE REELS, COUPLINGS - A wide range of optional long length

hose assemblies, rapid reel hose reels and quick couplers and fittings are available to enhance

your machine=s performance. Consult your Aussie Eco-Clean Distributor for details.

Q STYLE COUPLERS - Colour coded quick couplers make nozzle change over a matter of

seconds. Change from zero degrees for direct impact to 15 or 25 degrees in seconds.

Personal protection apparel recommended.

CARE AND MAINTENANCE:

AFTER EACH USE.....

If cleaning agents have been mixed with the incoming water, it is particularly important to flush the

machine with clean water after use.

If there is a danger of freezing anti-freeze should be mixed with the flush water or the machine must be

completely drained. After the final flush stop the machine. DO NOT allow the machine to idle for more

than 15 seconds. This is particularly important when there is a danger of freezing. Do not run for

longer without water supply.

STORAGE:

Store the washer in an upright position, preferably drained of water if there is a danger of freezing (or fill

with anti-freeze WARNING .... DO NOT RUN EXCESSIVE BY-PASS

SWITCH MACHINE OFF WITHIN TWO MINUTES OF CEASING OPERATION AS EXCESSIVE BY-PASS CAN

CAUSE HEAT BUILD UP IN PUMP & SUBSEQUENT DAMAGE.

EXCESSIVE BY PASS RUNNING VOIDS WARRANTY!!

ASP SYSTEM..... AUSSIE SAFETY PROTECTOR SYSTEM

THERMAL DUMP (A): All Aussie Eco-clean machines are fitted with

this valve as of June 2000 production. This device protects the pump

by dumping water to ground if the machine is left on bypass running.

AUSSIE SAFETY VALVE (B) OPTIONAL EXTRA: This device

“blows off”excess pressure if unloader has been tampered with thus

protecting the pump. Do not tamper with pre-set unloader and safety

valve. (This will void your warranty.)

AUSSIE FLOW SHUTDOWN DEVICE OPTIONAL EXTRA: a low flow

shutdown device protects the machine from inadequate water supply.

It also has the function of providing a “Total Stop” function be turning

the machine on and off when the operator shuts off the trigger

mechanism.

When the operator turns the gun on again he MUST first switch the double lance back to low pressure,

momentarily, before moving back to the high pressure side of the lance.

The machine will start automatically when the operator presses the gun trigger when the machine is on

low pressure lance adjustment.

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

6

Australian Pump Industries

FAULT

CAUSE

REMEDY

Pump running normally

but pressure low on

installation

Pump sucking air

Valves sticking

Unloader valve seat faulty

Nozzle incorrectly sized

Worn piston packing

Check water supply and possibility of air

ingress.

Check and clean or replace if necessary

Check and replace

Check and replace

Check and replace

Fluctuating Pressure

Valves worn

Valves blocked

Pump sucking air

Worn piston packing

Check and replace

Check and replace

Check water supply and air ingress at

joints in suction line

Check and replace

Pressure low after period

of normal use

Nozzle worn

Check valves worn

Check valves blocked

Unloader valve seat worn

Worn piston packing

Check and replace

Check and replace

Check and clean

Check and replace

Check and replace

Pump Noisy

Air in suction

Broken or weak suction or delivery

valve spring

Foreign matter in valves

Worn bearing

Excessive temperature of liquid

Check water supply and connections on

suction line

Check and replace

Check and clean

Check and replace

Reduce temperature

Presence of water in oil

Oil seal worn

High humidity in air

Piston packing worn

Check and replace

Check and change oil twice as often

Check and replace

Water dripping below

pump

Piston packing worn

O.R plunger retainer worn

Check and replace

Check and replace

Oil Dripping

Oil seal worn

Check and replace if necessary

Valves switches

repeatedly when gun is off

Leaking gun and/or pressure pipe.

Leaky sleeve

Worn out kick-back valve body

Leaky seals

Renew gun, seal pressure pipe

Renew sleeve

Check and renew as necessary kick-

back valve plate and seat

Renew seals

Leaky piston rod

Defective O-Ring/Support Ring

Renew piston rod seals and examine

surfaces in guide case

Leaky by-pass at nominal

pressure

Nozzle too small, too much water.

Worn out by-pass valve

Install larger nozzle

Examine and renew as necessary,

poppet (16 for APR-11 for VD valves -

10 for ADV-8 for Unifit valves), valve set

(14 or APR-12 for VD valves - 11for

AVD valves - 7 for Unifit) and by-pass

valve body.

Pressure gauge shows

high pressure fluctuations

when shutting off gun

Valve set too high above operating

pressure

Dirty valve

Adjust the unloader at the operating

pressure.

Clean valve (removing lime deposits

etc). Grease parts before installing.

Motor hums when

switched on but does not

start

Main voltage too low

Spray gun not activated

Cross section of extension lead too

small

Check electrical connection

Activate spray gun when switching on

Use correct dimension extension lead

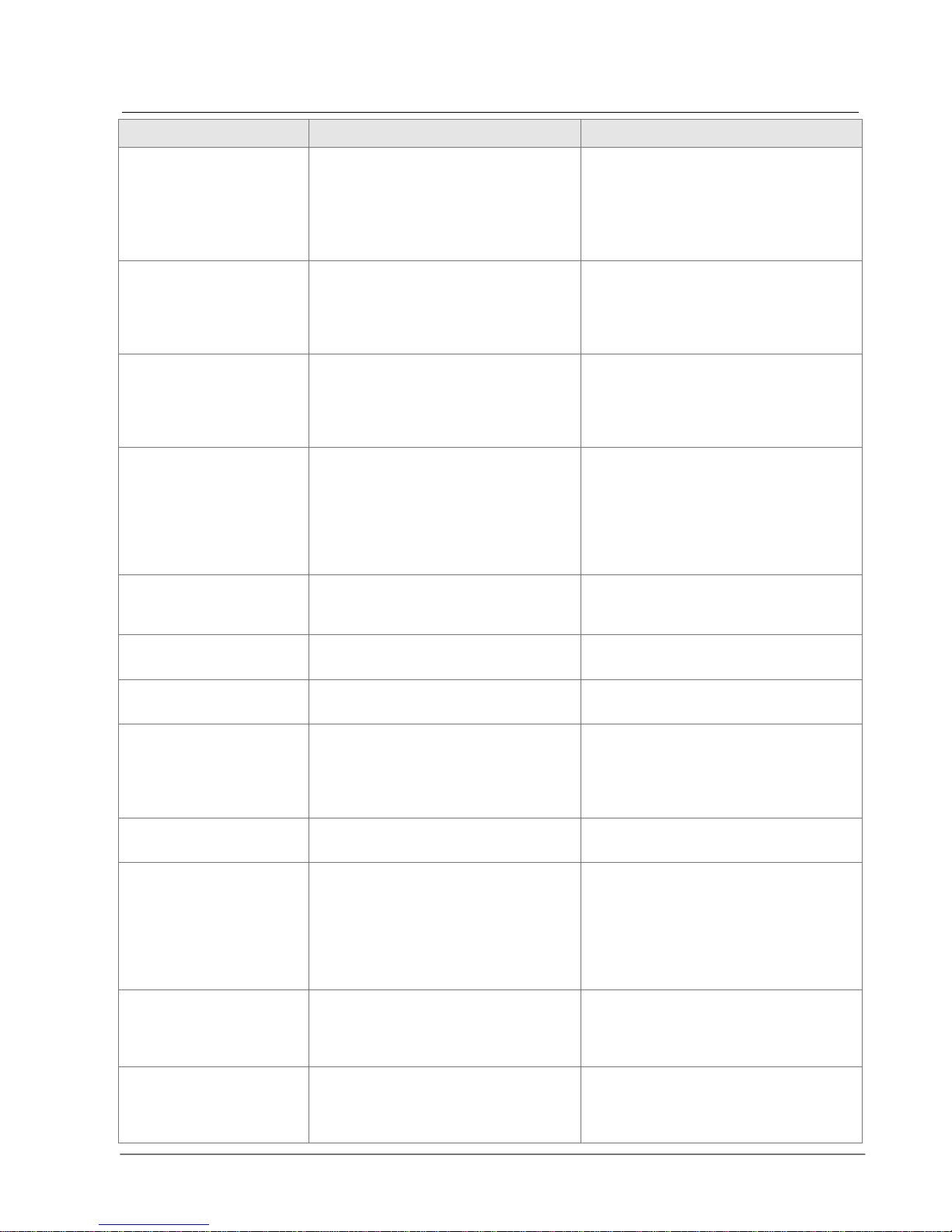

TROUBLE SHOOTING GUIDE

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 7

Australian Pump Industries

PARTS IDENTIFICATION

Model Motor Pump Model Pump Pressure

(psi) EWP Flow rate

(lpm) Pump

rpm

Monsoon 200 7.5HP, 5.5kW, IP56 TTV2015 3000 4785 15 1450

Monsoon 300 10HP, 7.5 kW, IP56 TTV2021 3000 4785 21 1450

Monsoon 300 Maxi 15HP, 10 kW, IP56 KKV2028 3000 4785 28 1450

Monsoon 400 10HP, 7.5 kW, IP56 KTV3015 4000 6400 15 1450

Monsoon 400 Maxi 15HP, 10 kW, IP56 KTV3021 4000 6400 21 1450

Hurricane 17HP,12.5kW, IP56 HDS5057 5000 8500 18 1725

A

B

C

D E

F

G

H

I

J K

L

N

M

Monsoon

Position Part No Description 200 300 300m 400 400m Hurricane

Nozzles

A

C915065M HP NOZZLE (15º ANGLE, TIP SIZE 65) x

C915085M HP NOZZLE (15º ANGLE, TIP SIZE 85) x

C915035M HP NOZZLE (15º ANGLE, TIP SIZE 35) x

C915055M HP NOZZLE (15º ANGLE, TIP SIZE 55) x

C915040M HP NOZZLE (15º ANGLE, TIP SIZE 40) x

B C915500MSS LP DETERGENT NOZZLE x x x x x

Lance & Gun

C C3924.01 684MM SS DUAL LANCE x x x x x

C3905.15 900 MM SS SINGLE LANCE x

D C4326.23 AL5 GUN WITH MELTED HANDLE & QC x x x x x

C4344.12 5000 PSI RATED AL35 GUN & QC x

Hose

E R206K2214MB6X10 10 MTR HP HOSE (R2, 4500 PSI) x x x x x

HW06FB6FB6X10 10 MTR HP HOSE (R2, 5800 PSI) x

Unloader

F C4910.10 UNLOADER VALVE (3600 PSI) x

BVB80/280 UNLOADER VALVE (4000 PSI) x x

BVB350 UNLOADER VALVE (5100 PSI) x x x

Thermal Dump Valves

G MPA60063070 THERMAL DUMP VALVE 1/2" x x x x x x

Inlet Strainer

H AYSTRAINER3/4” 3/4” Y STRAINER x x x x x x

Gauge

I AGCDR0102 6,000 PSI PRESSURE GAUGE x x x x x x

Chemical Injector

J MTM00029143 CHEMICAL INJECTOR x x x x x

Switch

K ASWITCH25A ON/OFF SWITCH (25 AMP) x x x x x x

Electric Motor

M

A140060T001 7.5HP MOTOR (5.5 KW) 24MM x

A140060T002 10HP MOTOR (7.5 KW) 24MM x x

A140060T003 15HP MOTOR (11 KW) 30MM x x

A140060T009 17HP MOTOR (12.5 KW) x

Wheel

N A400016 13" WHEEL x x x x x x

Use motor size & pump model to identify your machine:

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

8

Australian Pump Industries

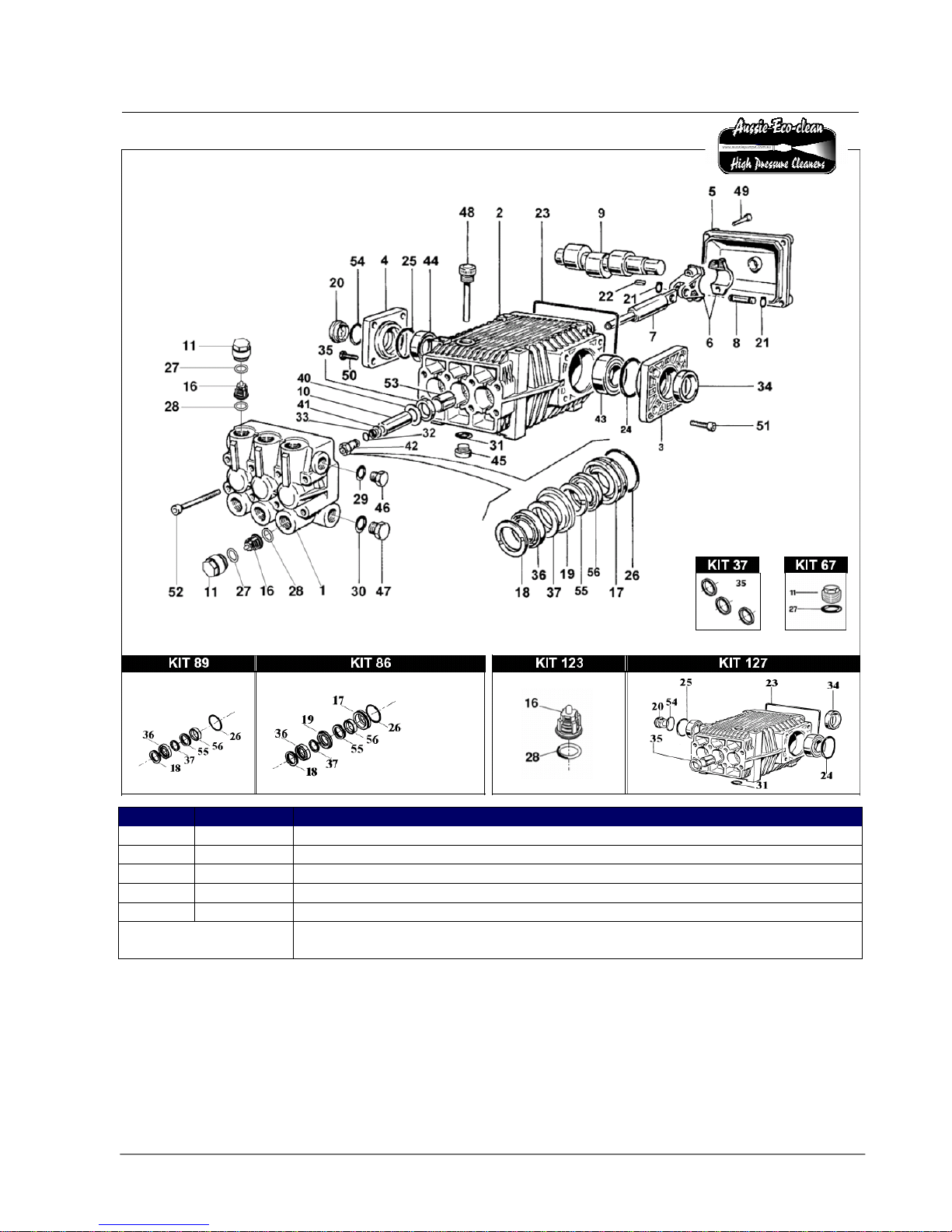

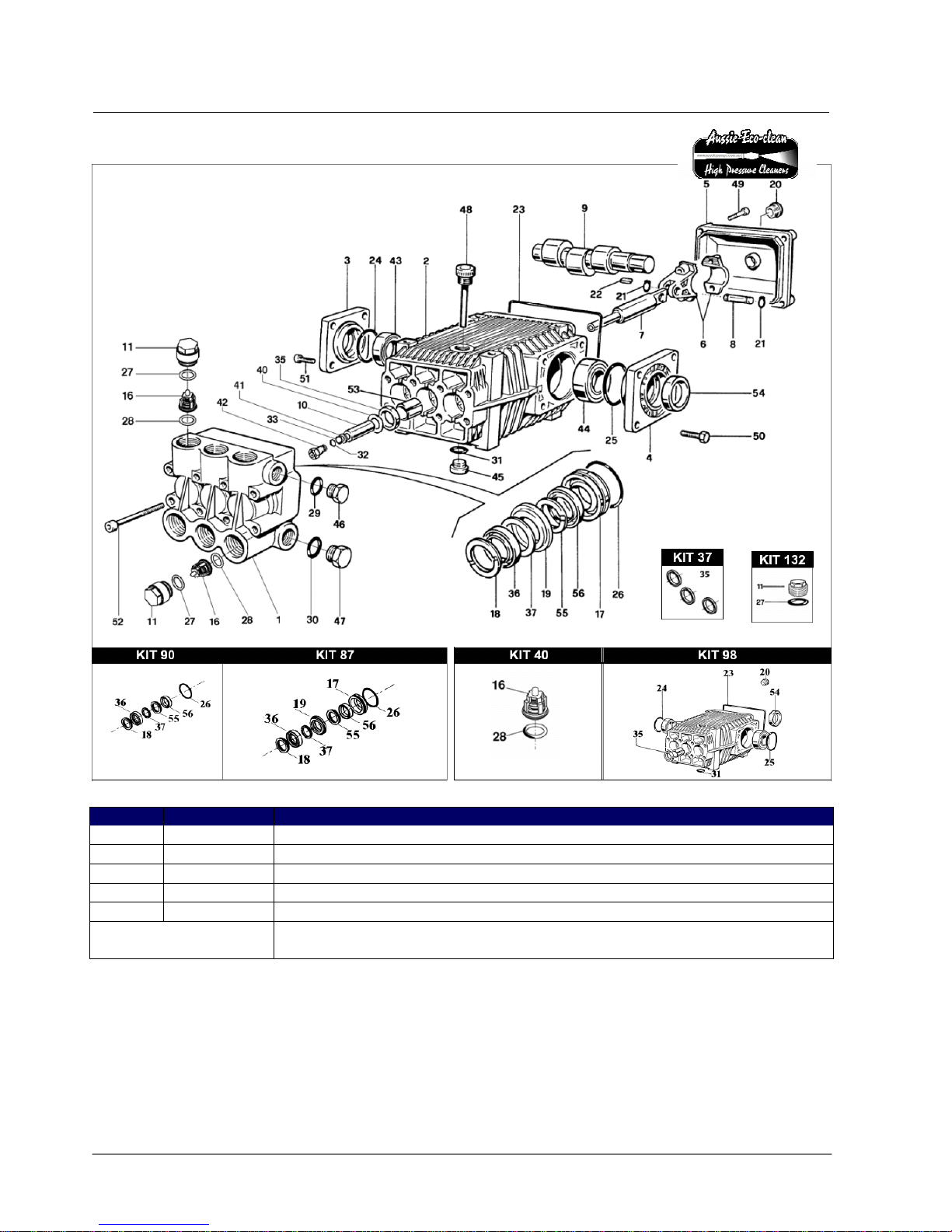

Kit No. Part No. Description

127 B069872973 Oil Seal & Sight Glass Kit

123 B069867973 Valve Kit

89 B069839973 Seal Kit Minor

86 B069836973 Seal Kit Major

37 B069814973 Oil Seal Kit

Aussie pressure test Aussie pressure test set includes gauge and fitting for testing pump output

PUMP PARTS TTV 2015 2021 (Monsoon 200, 300)

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 9

Australian Pump Industries

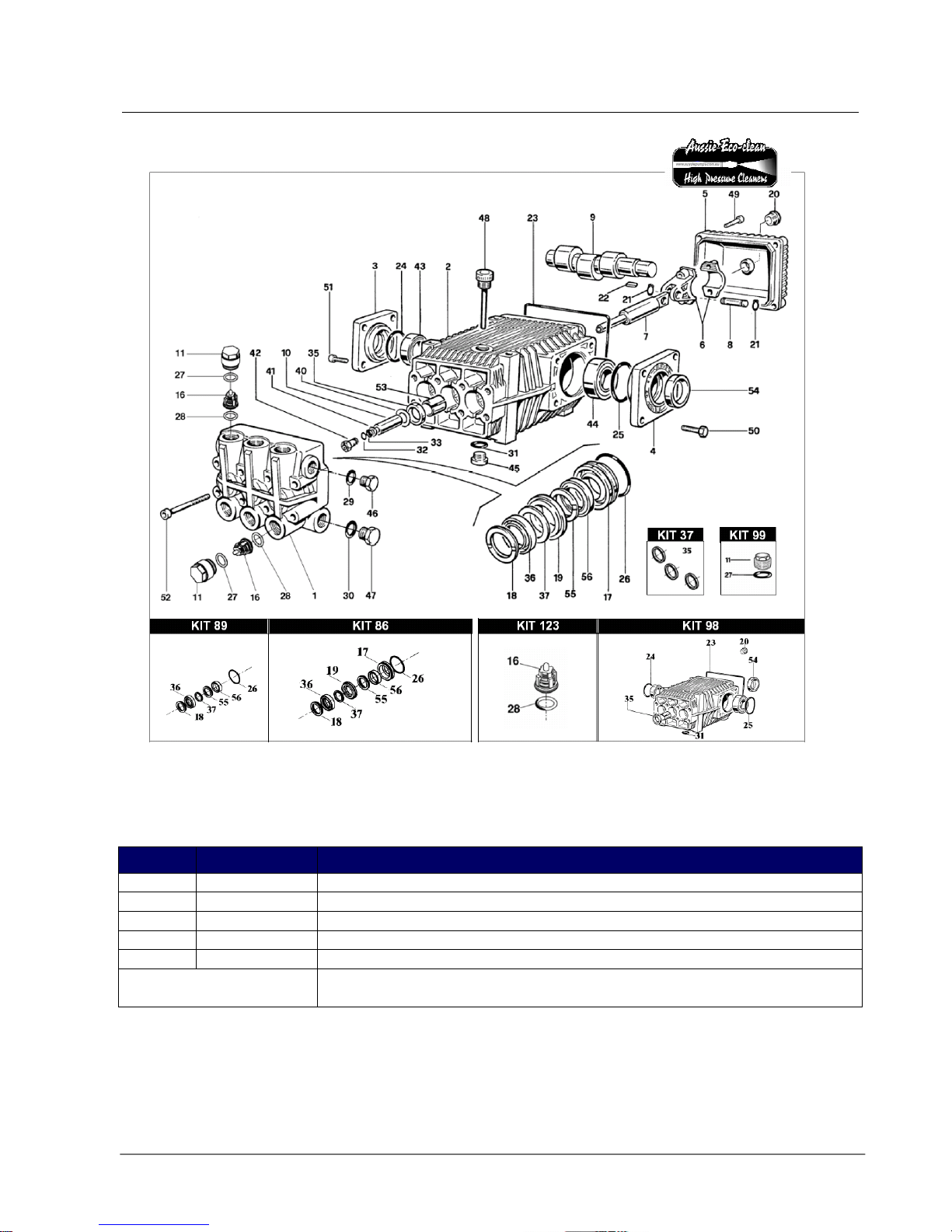

Kit No. Part No. Description

98 B069842973 Oil seal & Sight Glass kit

40 B069817973 Valve Kit

90 B069840973 Seal Kit Minor

87 B069837973 Seal Kit Major

37 B069813973 Oil Seal Kit

Aussie pressure test Aussie pressure test set includes gauge and fitting for testing pump output

PUMP PARTS KKV 2028 (Monsoon 300 Maxi)

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

10

Australian Pump Industries

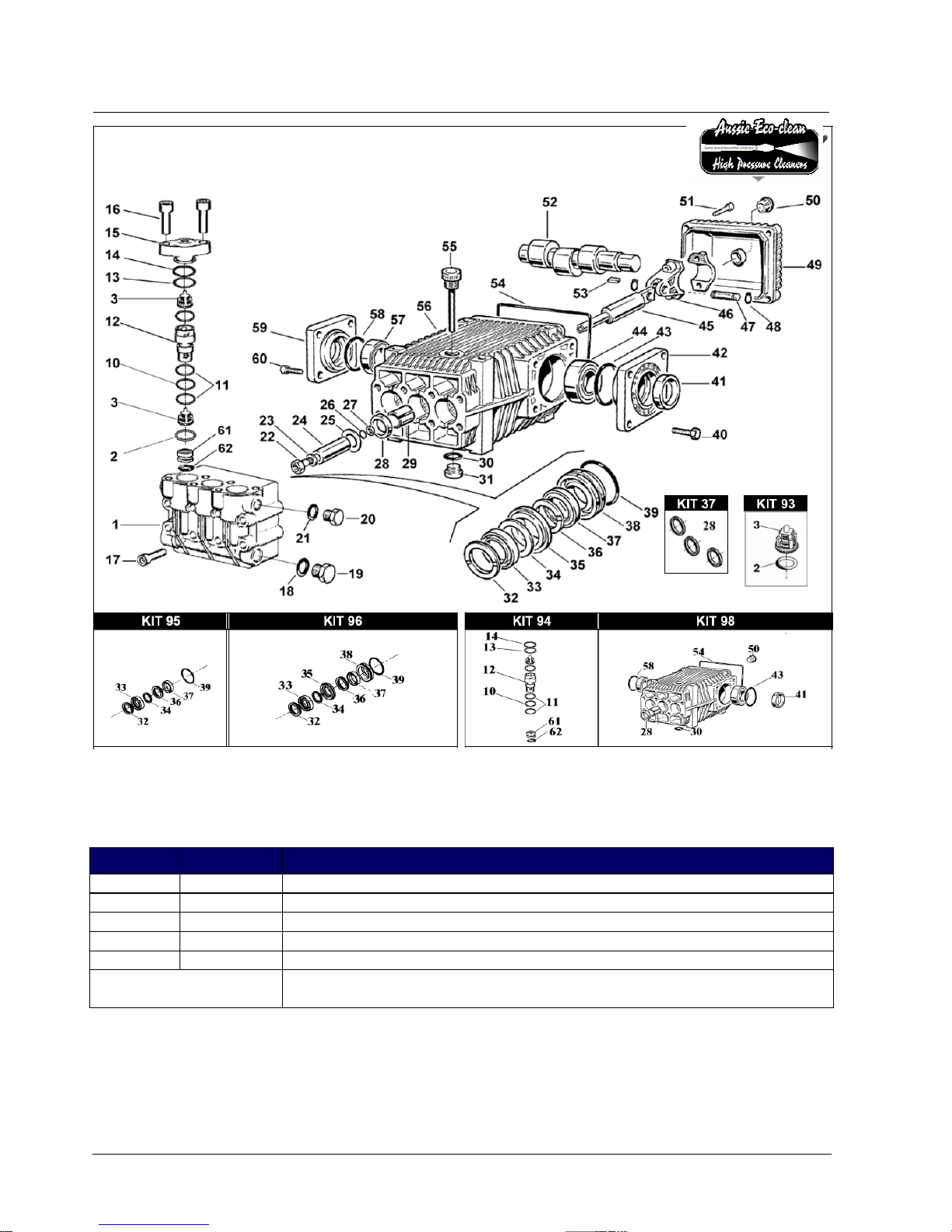

PUMP PARTS KTV 3015, 3021 (Monsoon 400, 400 Maxi )

Kit No. Part No. Description

98 B069842973 Oil seal & Sight Glass kit

123 B069867973 Valve Kit

89 B069839973 Seal Kit Minor

86 B069836973 Seal Kit Major

37 B069814973 Oil Seal Kit

Aussie pressure test set Aussie pressure test set includes gauge and fitting for testing pump output

pressure and Bertolini Pump Selection Guide

Aussie Monsoon & Hurricane … Operation & Maintenance Manual 11

Australian Pump Industries

PUMP PARTS HDS 5057 (Hurricane)

Kit No. Part No. Description

98 B069842973 Oil seal & Sight Glass kit

95 B069833973 Seal Kit Minor

96 B069834973 Seal Kit Major

37 B069813973 Oil Seal Kit

93 B069829973 Valve Kit

Aussie pressure test set Aussie pressure test set includes gauge and fitting for testing pump output

pressure and Bertolini Pump Selection Guide

Aussie Monsoon & Hurricane … Operation & Maintenance Manual

12

Australian Pump Industries

WARNING

OVERSPEEDING

Do not operate machine at over maximum pump rpm. Over speeding can cause serious

pump damage.

EXCESSIVE BYPASS

Do not run on excessive by-pass. Switch machine off within five minutes of ceasing

operation as excessive by-pass can cause heat build up in pump and subsequent

damage. Excessive bypass running voids warranty.

HIGH PRESSURE SETTING

The high pressure pump is factory set to operate at its rated pressure. DO NOT

ADJUST. Tampering with the pressure regulator will void warranty and can be

DANGEROUS.

CHECK NOZZLE MONTHLY

If pressure drops off check nozzle for wear. Nozzles should be replaced on a regular

basis (every month for machines in regular use, every three months for machines used

intermittently). Using the machine with the incorrect nozzle size or worn nozzle will void

warranty and can be DANGEROUS to the operator.

" Check pump oil level

" Check engine oil level

" Check nozzle for wear

" Check all high pressure components for leaks:

" gun/lance

" HP hose

" all fittings

" Check water filter and clean if necessary

" Check unloader, safety valve and thermal dump for leaks

All professional machines need to be thoroughly serviced every three months. The service

involved should include the engine manufacturer's recommendations (see separate Engine

Manual) and the following;

" Change pump oil

" Change gearbox oil (if applicable)

" Check filter for foreign debris

" Check unloader, safety valve and thermal dump for leaks

" Check all HP components for leaks: Gun/lance, HP hose and all fittings

" Replace nozzles

" Check gearbox to engine key for wear, if key is worn see your local Aussie Eco Clean

Service Department

NB Damage generated by worn keys is not covered by warranty!

PRESSURE CLEANER DAILY CHECK LIST

THREE MONTHLY REGULAR SERVICE

Australian Pump Industries Pty Ltd

7 Gladstone Road, Castle Hill NSW 2154

Ph: (02) 9894 4144 Fax: (02) 9894 4240

WEAR PROTECTIVE GOGGLES

AND CLOTHING!

This manual suits for next models

5

Table of contents