Aussie Pumps BB100 Hire Series Manual

Aussie Pumps

BB100 Hire Series High Pressure Blasters

OPERATION & MAINTENANCE MANUAL

June 2016

Covers:

1,200 PSI ELECTRIC COLD WATER BLASTER (BB100 EK)

2,000 PSI PETROL COLD WATER BLASTER (BB100 EX)

IMPORTANT:

TO REDUCE RISK OF INJURY, READ

OPERATING INSTRUCTIONS CAREFULLY

BEFORE USING EQUIPMENT

Aussie Pump Blasters…. Built to a Hire Spec

Aussie BB Hire Series … Operation & Maintenance Manual

2

Aussie Pumps June 2016

AUSSIE ECO CLEAN BB100 SERIES OPERATING AND MAINTENANCE INSTRUCTIONS

* * W A R N I N G * *

AUSSIE SCUD SERIES HIGH PRESSURE WATER BLASTERS ARE DESIGNED FOR PROFESSIONAL OPERATORS ONLY

IMPORTANT

INSTRUCT OPERATORS IN CARE AND USE OF THE MACHINE BEFORE USE!

Contents Page

Warranty ………………………………………………………………………………………………… 3

Safety Precautions …………………………………………………………………………………….. 3

Assembly & Use ……………………………………………………………………………………….. 5

A. Machine Preparation (initial set up) ………………………………………………………. 5

B. Hose Connections ………………………………………………………………………….. 6

C. Before Starting Machine …………………………………………………………………... 6

D. Starting Machine ……………………………………………………………………………. 6

E. Stopping Machine …………………………………………………………………………... 7

Care & Maintenance ………………………………………………………………………………….. 8

Troubleshooting ………………………………………………………………………………………. 9

Aussie Blaster Pressure Testing & Setting Instructions ………………………………...………... 11

Unloader Setting—Engine Powered Blaster ……………………………………………………….. 12

Pressure Testing & Unloader adjustment - Electric Powered Blasters …………………………. 13

Replacement Parts …………………………………………………………………………………… 14

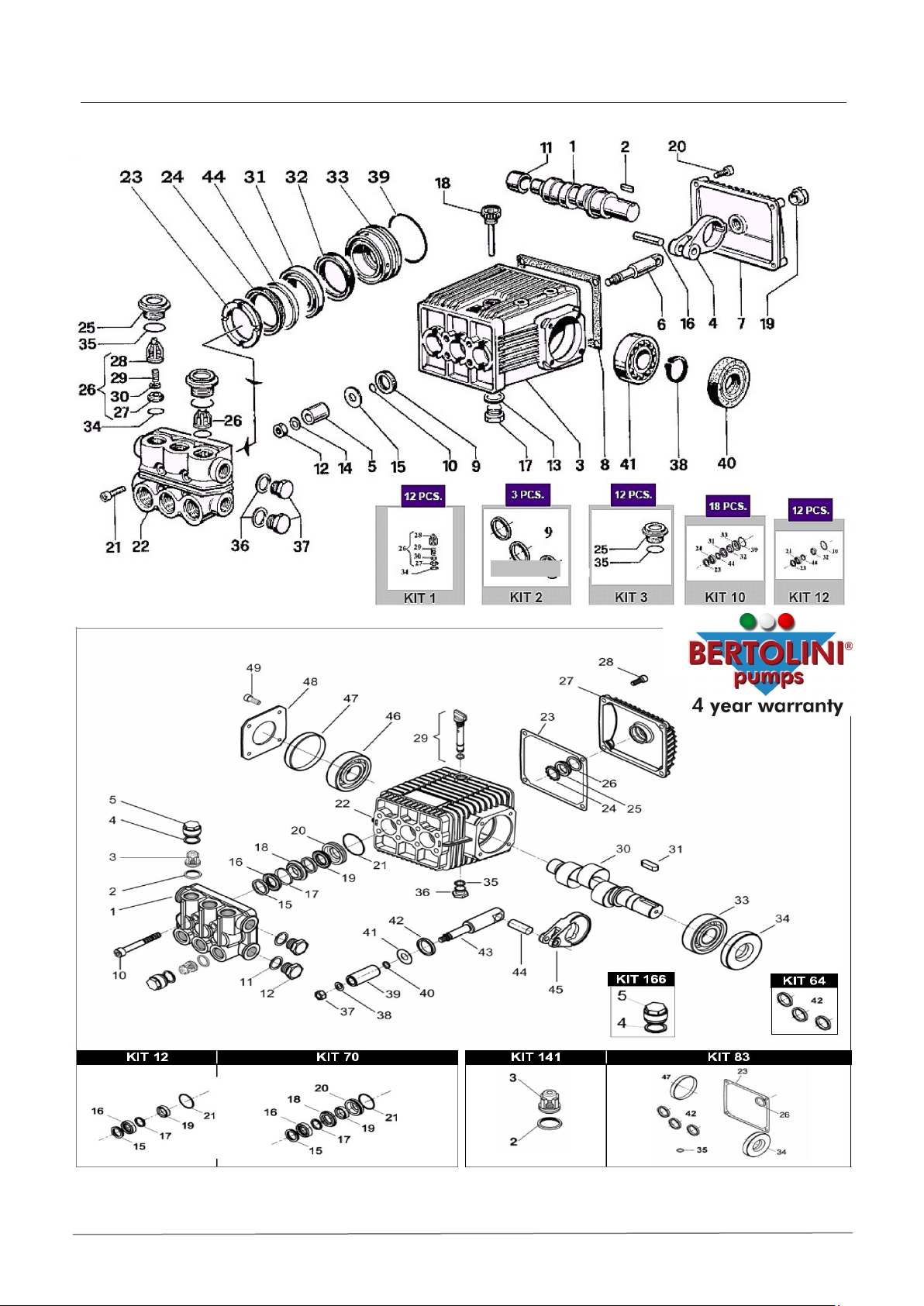

Pump Exploded View ………………………………………………………………………………... 15

Service Schedule …………………………………………………………………………………….. 16

Before attempting to operate your machine please read this Instruction Manual thoroughly following all directions

carefully. By doing so you will ensure safe operation of the unit and will enjoy long and trouble free service from

your heavy duty water blaster.

GUARANTEE … EXCLUSIVE 4 YEAR PUMP + 3 YEAR ENGINE WARRANTY

This Aussie Eco Clean product is guaranteed against faults in manufacture for two years from purchase. The

Bertolini pump has a four year warranty, but must be serviced by an authorised service agent every six months to

maintain this warranty. Keep your receipt as proof of purchase and all service receipts. This guarantee is invalid

if the product is found to have been abused in any way, or not used for the purpose for which it was intended.

Routine maintenance is the owner=s responsibility. Failure to maintain the machine in line with the services

outlined on the back page will invalidate warranty. High pressure accessories carry a 3 month warranty.

Where possible return faulty goods to the place of purchase. No products can be returned to us without our prior

permission. The reason for return must be clearly state.

N.B. Warranty is not transferrable to third parties in the event of sale of the machine within the

warranty period. Please note that any parts used in warranty repairs are guaranteed for a period

limited by the original warranty of the parent product.

Engine warranty (where applicable) is the responsibility of the engine manufacturer. Unit must be

returned to authorised engine dealer for evaluation of engine warranty. (Refer to engine handbook).

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

The benefits under the Aussie Pump warranty are in addition to other rights under Australian Consumer Law.

Aussie BB Hire Series … Operation & Maintenance Manual 3

Aussie Pumps

June 2016

SAFETY PRECAUTIONS - IMPORTANT

1. NEVER direct the spray jet at any person or animal. Keep hands and feet

clear of the cleaning nozzle at all times.

2. NEVER direct spray jet at any surface that may contain asbestos material.

3. NEVER hold a finger over the high pressure nozzle.

4. NEVER direct the spray jet at the machine itself or any electrical equipment.

5. After use release the pressure in the high pressure hose by operating the

gun trigger.

6. DO NOT attempt any mechanical repair. If you have a problem with your

machine contact your local Aussie Eco Clean Service Division, phone (02)

8865 3500.

7. NEVER supply any liquid other than water to the pump inlet.

8. DO NOT run dry. Ensure sufficient mains pressure water supply before

turning on machine.

9. Only operate this machine if all component parts are undamaged.

10. NEVER pull the high pressure hose if it has formed kinks or nooses.

11. NEVER pull the hose over sharp objects. Do not move machine by pulling

the hose.

12. DO NOT attempt to disconnect any hose or coupling with pressure still in

the hose.

13. DO NOT operate the machine whilst standing on ladders, use a platform

tower or scaffolding.

14. Operate in well ventilated areas only.

15. DO NOT fill the fuel tank while engine is running (engine drive only)

16. DO NOT try to repair a leak in the hose or connection while the system is

under pressure.

17. DO NOT substitute any component part on this machine. Use of incorrect

parts could cause serious personal injury. Only carry out maintenance or

repairs described in this manual. ALL other work should be performed by

your local authorised Aussie Pumps Service Agent.

18. DO NOT allow minors to operate this machine.

19. DO NOT lend this machine without this instruction manual.

20. DO NOT operate if under the influence of any substance which may impair

vision, dexterity or judgement.

Aussie BB Hire Series … Operation & Maintenance Manual

4

Aussie Pumps June 2016

21. DO NOT operate this machine when you are fatigued.

22. Never modify your machine in any way.

23. Have a thorough knowledge of machine's controls. Ensure you know how to

stop machine and release pressure quickly.

24. Always hold spray gun and lance firmly with both hands so you maintain full

control.

25. We recommend the use of safety goggles and steel cap boots when using

the machine.

Electric drive machines only ...

26. The electrical power voltage must agree with the voltage specified on label

on base of machine. [Note: Improper connection will damage machine and

void warranty.]

27. The machine must be grounded. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

28. Do not modify the plug provided with the machine. If plug does not fit your

outlet have a proper outlet installed by a qualified electrician.

29. Electric cables should not be left in a position where water can come into

contact with the electric cable. Always keep electrical connections dry and

off the ground

30. Do not use any type of double adaptor or multiple socket power board with

this product.

31. Use only extension cords having an electrical rating not less than the rating

of the product. An improper gauged extension cord will cause drop in wire

voltage resulting in loss of power and overheating. Use only extension

cords that are intended for outdoor use. These are identified by a marking

"Acceptable for use with outdoor appliances.”

32. Do not touch plug with wet hands.

33. Disconnect the plug from power supply and relieve pressure to hose before

attempting any work on the machine.

34. To avoid damage to power cable do not roll, crush or pull it.

35. The power cable may only be repaired or replaced by a qualified

electrician.

Aussie BB Hire Series … Operation & Maintenance Manual 5

Aussie Pumps

June 2016

A

BC

ASSEMBLY & USE

Before proceeding with assembly of your new Aussie Eco Clean high pressure blaster, check that all

parts listed below are included.

1 Gun handle assembly (A)

1 High pressure hose with pigtail wrap

1 Lance and nozzle assembly (B & C)

A. Machine Preparation (initial start-up)

1. Check the oil in the pump

With the machine on a level surface the oil level should

cover the red spot in the oil level sight glass on the side

of the machine. If necessary, top up with SAE 75W-90.

Do not mix different grades of oil as this may affect the

machines performance. If alternative oil is used, first

empty out oil by unscrewing drain plug in bottom of

machine.

2. Ensure breather plug is fitted to pump.

WARNING: Before operation ensure top mounted

travel plug is replaced by breather plug. Failure to fit breather and keep clean can result in over

pressuring of oil chamber (crank case) and can blow oil seals. This will void warranty.

Additional checks on engine drive BB100

1. Check oil level in gearbox. Note this is a separate chamber to that of the pump. Fill with SAE

75W-90 if required.

2. Check oil level in engine and fill with proper grade oil if necessary. (Automotive detergent oil

e.g. SAE 10W-30)

3. Check fuel level and fill if necessary. (unleaded petrol)

Aussie Safety Protection Kit

Unloader - factory set,

DO NOT adjust

Thermal dump

Safety valve

HP hose connection

Supply hose

connection

Unloader - factory set,

DO NOT adjust

Thermal dump

HP hose

connection

Supply hose connection

Inlet filter

Inlet filter

Engine drive Electric drive

Breather plug & dip stick

Pump oil level sight glass

Gearbox oil filler cap

(engine drive only)

Aussie BB Hire Series … Operation & Maintenance Manual

6

Aussie Pumps June 2016

B. Hose Connections

1. Connect high pressure hose to machine outlet.

2. Connect gun/lance assembly to high pressure hose.

3. Check inlet water filter is clean then connect water supply hose to machine.

Incoming water supply must deliver double the flow of the machine. If questionable, check

supply at machine. If supply is insufficient, do not operate from this outlet. For residential use,

the outlet closest to the meter will usually deliver the highest flow rate. Connect only to clean

town water supply.

Warning: Do not operate from tank or pond. Doing so will cavitate the pump causing damage.

Cavitation or pump starvation is not covered by warranty. Cavitation is a phenomenon causing

vacuum pockets to form within the pump that eventually implode under pressure pitting the

internal pump surfaces.

C. Before starting the machine

1. Ensure machine is level

2. Turn on water supply.

3. Pull gun trigger until water starts to flow in a steady stream then release trigger.

D. Starting the machine

Engine Drive: OPERATE IN WELL VENTILATED AREAS ONLY.

1. Ensure fuel valve is open

2. Move the choke on the engine to the closed position If engine is warm, move choke half-way.

3. Turn engine ON/OFF switch to ON

4. Hold the gun trigger on.

5. Start engine, pull the recoil starter grip lightly until resistance is felt, then pull briskly.

6. After engine starts, release the gun trigger and slowly open the choke.

7. Warm up engine for 3 minutes without load.

8. Adjust speed control lever at to the required engine speed.

Electric Drive:

1. Ensure unit is plugged in to a suitable power supply.

2. Hold the gun trigger on and turn on start switch.

KEEP THE MACHINE OUT OF MOISTURE LADEN ATMOSPHERES

WEAR PROPER FACE PROTECTION WHEN OPERATING PRESSURE WASHER!

NOTE: Check the system for water leaks, fuel leaks, oil leaks, hose kinks, etc. Correct any problems before

proceeding.

HIGH PRESSURE SPRAY CAN PENETRATE THE SKIN AND CAUSE SERIOUS INJURY!

NEVER POINT THE SPRAY GUN AT YOURSELF, OTHER PEOPLE OR ANIMALS.

SHOULD SPRAY PENETRATE THE SKIN, SEEK MEDICAL ATTENTION IMMEDIATELY!

Aussie BB Hire Series … Operation & Maintenance Manual 7

Aussie Pumps

June 2016

UNLOADER SETTING … DO NOT ADJUST

The high pressure unloader on the machine is factory set to operate the pump at it’s rated pressure.

DO NOT ADJUST. Tampering with the unloader will void warranty and can be dangerous.

WARNING: CHECK HP NOZZLES & REPLACE REGULARLY

If pressure drops off, check nozzle for wear. Nozzles should be replaced on a regular basis (every

month for machines in regular use, every 3 months for machines used intermittently. Using the

machine with the incorrect nozzle size or worn nozzle will void warranty and can be dangerous to the

operator.

F. Stopping the machine

Engine Drive:

1. Set the engine speed control lever to low speed position. Allow machine to run for 1 minute

without load to cool before stopping.

2. Turn engine ON/OFF switch to OFF

3. If your machine has a recoil start, pull recoil start until compression resistance is felt. Store the

machine in this position to help prevent valve warping or sticking.

4. Close fuel valve.

FAILURE TO CLOSE THE FUEL VALVE ON THE ENGINE CAN CAUSE FUEL LEAKAGE

WHEN THE MACHINE IS BEING TRANSPORTED!

5. Pull the starter handle slowly and return the handle to its original position when resistance is felt.

This operation is necessary to prevent outside moist air from entering the combustion chamber.

Electric Drive:

1. Turn off switch

Both Options:

1. Turn off water supply.

2. Pull gun trigger to release all pressure in the system, then LOCK THE TRIGGER.

3. Hoses may now be disconnected from the machine.

Failure to release pressure before disconnecting the hose quick coupler will result in the quick coupler

o-ring seal blowing out. This o-ring must be replaced before operating machine.

WARNING .... DO NOT RUN ON EXCESSIVE BY-PASS

SWITCH MACHINE OFF WITHIN TWO MINUTES OF CEASING OPERATION AS

EXCESSIVE BY-PASS CAN CAUSE HEAT BUILD UP IN PUMP AND SUBSEQUENT DAMAGE.

EXCESSIVE BY PASS RUNNING VOIDS WARRANTY!!

Aussie BB Hire Series … Operation & Maintenance Manual

8

Aussie Pumps June 2016

CARE & MAINTENANCE:

AFTER EACH USE

If there is a danger of freezing anti-freeze should be mixed with the flush water or the machine must

be completely drained.

After the final flush stop the machine. DO NOT allow the machine to idle for more than 15 seconds.

This is particularly important when there is a danger of freezing. Do not run for longer without water

supply.

STORAGE

Store the washer in an upright position, preferably drained of water if there is a danger of freezing (or

fill with anti-freeze).

PUMP CRANKCASE LUBRICATION

Proper pressure washer pump crankcase lubrication will help extend the working life of the machine.

Follow these important guidelines. We recommend keeping a simple service log book.

Change oil in pump after initial 50 hour run-in period. (SAE 75W-90)

Change pump oil every 3 months, use high quality oil. (SAE 75W-90)

Pump oil level can be checked with the dip stick under the breather cap or by viewing the oil

sight gauge where fitted. The oil level is correct if level is in the centre of the gauge. If oil level is

low, fill to correct level with recommended oil (SAE 75W-90). DO NOT OVERFILL

CRANKCASE!

Replace oil in gearbox (separate chamber) with SAE 90 gear oil every three months.

PREVENTATIVE MAINTENANCE

Keep filter in supply hose connection clean, rinse regularly.

Use correct size nozzles for machine and replace when worn, check serial tag for correct size.

Drain water from pressure hoses, gun/lance assembly and accessories after use.

Protect pump from freezing. Failure to remove water from the pump in freezing temperatures will

result in damaged pump manifold.

Use ONLY injector of the size and type designed for this model.

DO NOT tamper with unloader valve adjustment or alter engine or motor speed.

DO NOT siphon chemicals through the pump, it is designed for water only.

Incoming water supply must not exceed 60ºC, otherwise pumps seal damage could result

Follow engine manufactures guidelines for engine maintenance. (see engine manual)

Look after your machine &

it will look after you!

Aussie BB Hire Series … Operation & Maintenance Manual 9

Aussie Pumps

June 2016

TROUBLE SHOOTING GUIDE

Symptoms Cause Action

No pressure Unloader jammed

Worn unloader valve

Debris in pump valves

Replace unloader valve

Replace unloader valve

Wash out pump , flush manifold and install inlet water

filter, clean valves

Pump runs normally but

pressure is low

Pump is sucking air

Valves worn, dirty or stuck

Unloader seat worn or damaged

Nozzle worn, missing or incorrect

Worn piston packing

Insufficient water supply

Relief valve jammed, plugged or improperly

adjusted

Cracked pistons caused by dry running

Check that hoses and fittings are tight

Replace valves

Replace unloader

Check user manual for correct nozzle size, Check size is

correct, replace if worn

Replace packing

Check supply, clean or replace water filter

Clean, adjust relief valve

Replace pistons

Pressure fluctuates Valves are worn, dirty or stuck

Pump sucking air

Worn piston packings

Replace valves

Check that hoses and fittings are tight

Replace piston packings

Back pressure in supply

hose when on by-pass

Low pressure valves dirty or worn Clean or replace valves

Pulsation Faulty pulsation dampener Check pre-charge, if low recharge or replace

High pressure hose

vibrates

Pump is sucking air from empty detergent

tank

Pump sucking air from hoses or fittings

Air in water circuit

Valves dirty or stuck

Insufficient water supply

Refill the detergent tank

Tighten detergent valve

Check for leaks. Tighten all fittings. Disconnect high

pressure hose and let machine run until water is flowing

constantly without air

Replace valves

Check supply, clean or replace water filter

Machine is noisy Pump sucking air

Valves worn, dirty or stuck

Worn bearings

Water too hot

Check hoses and fittings are tight

Replace valves

Replace bearings

Reduce temperature to below 60ºC

Pump oil is milky

(water in oil)

Worn packings and oil seals

High humidity in air

Sand or dirt entering system

Replace or contact distributor for service

Check and change oil more frequently

Check supply, use only clean water and fit water filter if

required

Water dripping from pump Worn piston packings

O-rings of piston guide or retainer worn

Replace or contact distributor for service

Replace or contact distributor for service

Oil leak

Travel plug in use on pump

Worn oil seals

Oil level too high

Loose drain plug

Replace with breather plug

Replace seals or contact distributor for service

Drain excess oil

Check drain plug fitted correctly

Unloader valve is

‘knocking’ during

operation

Water nozzle partially blocked

Water filter dirty

Clean water nozzle

Clean water filter

Unloader valve is

‘knocking’ when gun is

closed

Gun is leaking

Air in water circuit

Damaged high pressure hose

Faulty unloader valve

Clean inside gun removing any deposits or build-up

See ‘High pressure hose vibrates’, above

Check and replace

Contact Distributor for service

Pressure gauge shows

high pressure fluctuations

when shutting off gun

Valve set too high above operating pressure

Dirty valve

Adjust the unloader to achieve the correct operating

pressure.

Clean valve (removing lime deposits etc, Grease parts

before installing.

Leaky by-pass at nominal

pressure

Nozzle too small, too much water.

Worn out by-pass valve

Replace with correctly sized nozzle

Replace valve

Frequent or premature

failure of packing

Scored, damaged or worn pistons

Overpressure to inlet manifold

Abrasive material in fluid being pumped

Excessive pressure and/or temperature of

fluid being pumped

Over pressure of pump

Running dry … results in cavitation &

cracked pistons

Replace pistons

Reduce inlet pressure

Install proper filtration on pump inlet plumbing

Check pressure & fluid inlet temperature, ensure that are

within specified range

Reduce pressure

Replace pistons, do not run machine without water

These instructions are for trained service technicians, alternatively contact your nearest Aussie service centre.

Aussie BB Hire Series … Operation & Maintenance Manual

10

Aussie Pumps June 2016

Symptoms Cause Action

Machine does not start Power not connected

Wrong voltage

Power cable damaged

Check plug, cable and switch

Check main voltage

Electrician to replace

Motor hums but does not

run

Voltage supply is too low

Pump is stuck

Spray gun not activated

Extension lead too small

Check power supply for correct voltage

Manually turn motor

Activate spray gun when switching on

Use correct dimension extension lead

Motor stops suddenly Cut out switch activated due to

overheating

Check power supply is correct.

Disconnect machine & allow to cool off

Motor trips out Unit run on long extension lead

Power lead or plug damaged

Excessive pressure build up

Motor earthed e.g. water ingress

Suction amperage cut-out set too

low

Remove lead

Fix or replace

Check pressure, nozzle size, unloader setting

Electrician to reset, fix or replace

Reset to correct setting

Symptoms Cause Action

Machine does not start Battery dead

Battery cables disconnected

Engine, pump or gearbox is seized

Low oil shutdown is activated

Low on fuel

Recharge or replace battery

Clean connections and reconnect cables

Replace or repair seized part

Add oil to engine, consult user guide

Add fuel

Engine slows down under

load, whenever gun trigger

is pressed

Engine needs service

Consult engine manufacturers handbook

Engine drive

Electric drive

TROUBLE SHOOTING GUIDE CONTINUED

Further troubleshooting information relating to the engine can be found in the engine operators manual

FREE BERTOLINI TRIPLEX

PUMP MAINTENANCE GUIDE

…. Call for your copy or download from

the Aussie Pumps website

www.aussiepumps.com.au

Check out the customer service & spares

page for ….

Aussie Blasters Service Fundamentals

FREE HIRE OH&S stickers available …

call if yours need replacing.

Aussie BB Hire Series … Operation & Maintenance Manual 11

Aussie Pumps

June 2016

PRESSURE TESTING INSTRUCTIONS …. 2,000 PSI PETROL ENGINE BLASTERS

1. Connect machine to mains pressure water supply,

ensuring that water is passing freely through the

pump at the correct flow rate for specified pump by

holding the gun trigger open.

2. Ensure that nozzle fitted in lance is the correct size

(BB100 nozzle should be 035). Replace nozzle if

worn or damaged. Check there are no leaks in the

hose or high pressure connections.

3. Check oil level in pump, gearbox and engine before further

testing.

4. Fit pressure gauge kit between high pressure outlet of pump

and high pressure hose.

5. Turn on engine with the trigger on the gun pressed. Check

the engine rpm is set to 3200. Adjust if necessary. Let the

engine run for a few minutes to warm up.

6. Check the pressure on the gauge (BB100 should read 2,000

psi) when blaster is operating. If adjustment is required refer

to next instructions .

AUSSIE PRESSURE CLEANER TEST SET

Everybody knows that professional pressure cleaners

occasionally need to have their pressure tested and sometimes

reset. Doing this efficiently, and in line with our professional

recommendations is not easy unless you have the right

equipment.

Checking pressure regularly will tell you if nozzles are worn, if the

pressure regulator is worn, if there are leaks in the system, if the

valves are sticking and signal other problems that can manifest

themselves in low pressure operation.

The Aussie Test Set (Part number ATESTSET) will solve those

problems. Consisting of a convenient brass T with M22 quick

coupler and 6,000 psi pressure gauge you can check to make

sure everything is operating as it should. Detailed instructions are

included with each kit.

AUSSIE BLASTER PRESSURE TESTING & SETTING

Pressure gauge kit fitted between pump high

pressure outlet and high pressure hose

Aussie BB Hire Series … Operation & Maintenance Manual

12

Aussie Pumps June 2016

UNLOADER SETTING …. ENGINE POWERED AUSSIE BLASTER

The following steps should be taken to set the water pressures, with the unit running.

1. Before setting the pressure, the lock nut (C) on the safety valve should be undone and the adjusting

bolt (D), should be screwed in all the way.

2. Using an allen key, loosen the lock nut on the unloader (B) and wind the unloader knob (A) in

gradually until the required pressure is obtained (4,000 psi for a BB400, 2,000 psi for a BB100

engine drive) whilst the trigger is pulled and water is running through the pump. The lock nut (B)

should then be wound down until it grounds out at the bottom (do not over tighten as this will further

adjust the pressure) and locked with use of the allen key. Paint mark across the nut and knob to

identify any tampering with the setting.

3. With the pump running at the required pressure, the adjusting bolt (D) on the safety valve should be

wound out until there is a slight drip. Screw it in one quarter of a turn, or until the drip stops, this will

set the safety valve 10% over the required pressure. The lock nut (C) should then be locked off.

Paint mark to identify any tampering.

4. Repeat running with the trigger open and then closed two or three times to ensure safety valve

doesn’t blow off pressure.

C

D

A

B

Aussie BB Hire Series … Operation & Maintenance Manual 13

Aussie Pumps

June 2016

PRESSURE TESTING & UNLOADER ADJUSTING …. ELECTRIC POWERED BLASTERS

1,200 PSI ELECTRIC MOTOR COLD WATER BLASTERS

1. Connect machine to mains pressure water supply, ensuring

that water is passing freely through the pump at the correct

flow rate for specified pump by holding the gun trigger open.

2. Ensure that nozzle fitted in lance is the correct size (BB100

nozzle should be 035). Replace nozzle if worn or damaged.

3. Ensure machine is unplugged and check inside the on/off

switch to ensure contactor inside is set to 13 amps.

4. Fit pressure gauge kit between high pressure outlet of pump

and high pressure hose.

5. Plug in blaster and turn on with the trigger on the gun

pressed.

6. With the unit running and the trigger on the gun pressed,

measure amps on power supply cable to make sure amps

are running at acceptable levels. (No more than 12.5 amps,

ideally set at 12.2 amps). Amp meter must be connected to

the active (brown) wire.

7. The BB100 should achieve 1200- 1250 psi when set to 12.2

amps. To change the pressure or the amperage drawn,

adjust the unloader using the allen key while the gun trigger

is pulled.

It is more important to set the machine to the correct

amperage rather than pressure. Check amp meter to ensure

electrical characteristics are within acceptable parameters.

Apply Loctite 243 Super Thread to grub screw of unloader

and mark with paint.

For further information on maintenance of Bertolini high pressure piston

pumps refer to our Aussie Blasters Service Fundamentals booklet.

Call Aussie for a copy or download from the customer service page of

our website …. www.aussiepumps.com.au

Aussie BB Hire Series … Operation & Maintenance Manual

14

Aussie Pumps June 2016

REPLACEMENT PARTS

* pump produced before 6/2002, ** pump produced after 6/2002

PUMP KITS: WBL1111 & WB1114 (post 2011 production)

KIT 141 B019826973 Valve Kit (12 pieces) xx

KIT 12 B049813973 Seal Kit Minor (15 pieces) xx

KIT 70 B049841973 Seal Kit Major (21 pieces) xx

KIT 83 B049847973 Oil Seal Kit (8 pieces) xx

ATESTSET See below xx

PUMP KITS: WEL744 (pre 2011 production)

KIT 1 B059880973 Valve Kit xx

KIT 12 B049813973 Seal Kit Minor xx

KIT 10 B049812973 Seal Kit Major xx

B050010182 Piston 18mm xx

B853505002 Sight Glass 3/8 xx

B852570002 * 3/8 Breather Yellow xx

B049832973 ** 1/4 Breather Orange xx

Aussie Pressure test set includes gauge and fitting for

testing pump output pressure (includes Bertolini

Pressure Pump Maintenance Guide)

xx

ATESTSET

Part No BB100EH

Electric drive BB100K/EY20

Engine drive

Description

Nozzles

C915035M HP NOZZLE (15º ANGLE, TIP SIZE 35) xx

C915035M-P1 5 PACK OF NOZZLES xx

Lance & Gun

AHIREGUNKIT-1AUSSIE HIRE SPEC COLD WATER GUN/LANCE/

NOZZLE KIT xx

M200019050 AL12 GUN ONLY xx

C3930.00 400MM STAINLESS STEEL LANCE ONLY (NOZZLE

SOLD SEPARATELY) xx

Hose

AHIREHOSEKIT1 10M HIRE SPEC HOSE WITH PIGTAIL WRAP xx

Unloader

APRI-20 UNLOADER VALVE (2000 PSI) xx

Thermal Dump Valves

MPA60063050 THERMAL DUMP VALVE 3/8” xx

Inlet Strainer

AYSTRAINER1/2” 1/2” Y STRAINER xx

Switch

ASWITCHASSYHIRE HIRE SPEC SWITCH ASSY x

Pumps

BWEL744 BIG BERTY PUMP (1500 PSI, 11.3 LPM) xx

BWBL1111 BIG BERTY PUMP (1500 PSI, 11.3 LPM)

Production after Jan 2011 x

BWBL1114 BIG BERTY PUMP (2000 PSI, 11.3 LPM)

Production after Jan 2011 x

Electric Motor

A140060M001 3HP MOTOR 2.2KW (240 VOLT, 4 POLE) x

Wheel

AWHEELBB100K WHEEL FOR BB100 BLASTER xx

Gearboxes

B318699973 G'BOX RTI-126 FOR WEL744/WBL1114 PUMP x

1,200 PSI ELECTRIC MOTOR &

2,000 PSI PETROL MOTOR

COLD WATER BLASTERS

MODEL: BB100K/EX17

BB100H/EX17

MODEL: BB100EH

BB100EK

AHIREHOSEKIT1

AHIREGUNKIT-1

M212003540

C1500.24

Couplings between gun & hose

Note: Coupling required to join

two hoses is M212003660

Viton o-ring found in all couplers

is C0601.40

Aussie BB Hire Series … Operation & Maintenance Manual 15

Aussie Pumps

June 2016

KIT 64

WEL 744

WBL 1111 & 1114

PUMP EXPLODED VIEW

Full pump exploded view information available online …. www.aussiepumps.com.au

(check our the Customer Service & Spares page)

Aussie HP Accessories … making light work of cleaning chores

WARNING

OVER SPEEDING

Do not operate machine at over 3200rpm (engine speed). Over speeding can cause serious pump

damage.

EXCESSIVE BYPASS

Do not run on excessive by-pass. Switch machine off within two minutes of ceasing operation as

excessive by-pass can cause heat build up in pump and subsequent damage. Excessive bypass running

voids warranty.

HIGH PRESSURE SETTING

The high pressure pump is factory set to operate at its rated pressure. DO NOT ADJUST. Tampering

with the pressure regulator will void warranty and can be DANGEROUS.

CHECK NOZZLE MONTHLY

If pressure drops off check nozzle for wear. Nozzles should be replaced on a regular basis (every month

for machines in regular use, every three months for machines used intermittently). Using the machine

with the incorrect nozzle size or worn nozzle will void warranty and can be DANGEROUS to the operator.

PRESSURE CLEANER DAILY CHECK LIST

Check pump oil level

Check engine oil level

Check nozzle for wear

Check all high pressure components for leaks:

gun/lance

HP hose

all fittings

Check water filter and clean if necessary

Check unloader, safety valve and thermal dump for leaks

THREE MONTHLY REGULAR SERVICE

All professional machines need to be thoroughly serviced every three months. The service involved should

include the engine manufacturer's recommendations (see separate Engine Manual) and the following;

Change pump oil

Change gearbox oil (if applicable)

Check filter for foreign debris

Check unloader, safety valve and thermal dump for leaks

Check all HP components for leaks: Gun/lance, HP hose and all fittings

Replace nozzles

Check gearbox to engine key for wear, if key is worn see your local Aussie Eco Clean Service

Department. NB Damage generated by worn keys is not covered by warranty.

SIX MONTHLY REGULAR SERVICE

To maintain the Bertolini pump warranty (three years from date of purchase), the pump must be serviced by an

authorised service agent every six months. Contact Aussie for your nearest agent.

LOOK AFTER YOUR MACHINE AND IT WILL LOOK AFTER YOU!

Australian Pump Industries Pty Ltd

7 Gladstone Road, Castle Hill NSW 2154

Ph: (02) 8865 3500 Fax: (02) 9894 4240

www.aussiepumps.com.au [email protected]

WEAR PROTECTIVE GOGGLES & CLOTHING!

Table of contents

Other Aussie Pumps Pressure Washer manuals