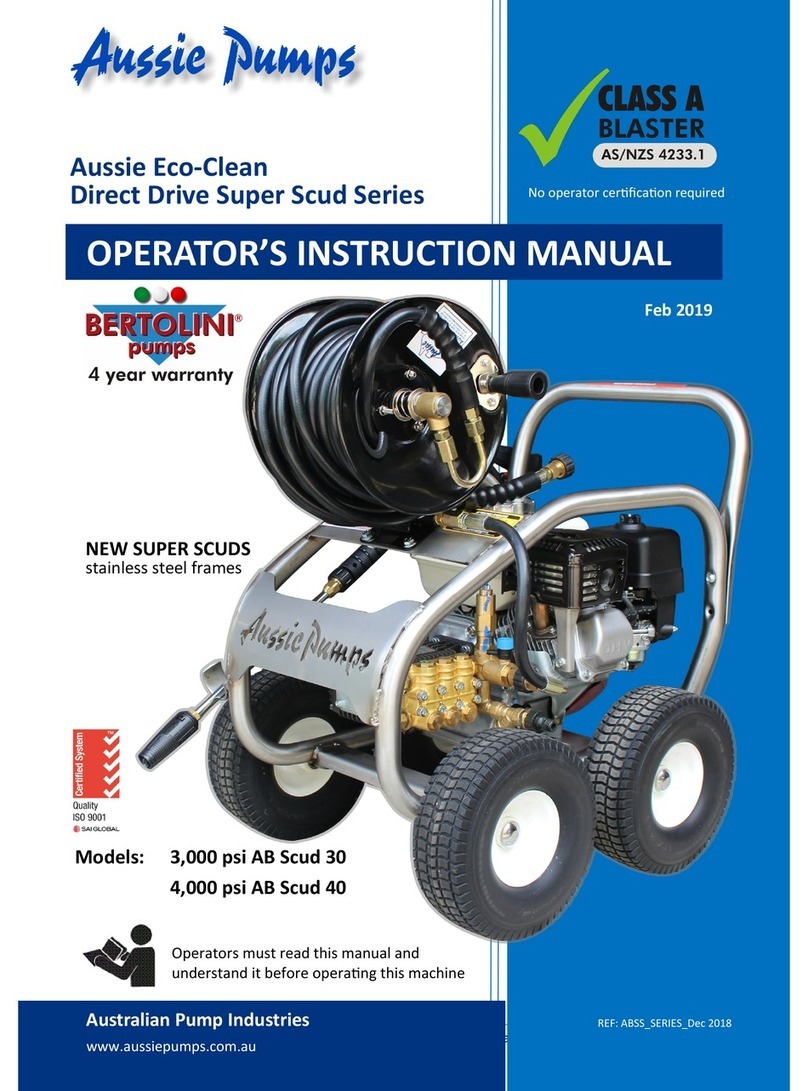

Aussie Pumps Eco-Clean Sizzler Installation and operation manual

Aussie Eco-Clean

6L]]OHU HRW :DWHU 3UHVVXUH Washer

Operating & MaintenanceInstructions

Read all instructions

carefully BEFORE

using your 6L]]OHU

pressure washer

AUSTRALIAN PUMP INDUSTRIES

2 | Aussie Eco-Clean Sizzler OperaƟng & Maintenance Manual - 2020

AUSSIE HOT WATER PRESSURE t^,Z RISK ASSESSMENT

MODELS:

In line with the Naonal Occupaon Health & Safety Commission’s

requirements the data below applies to the following Aussie Sizzler hot

water blasters:

i Sizzler

NB: Class A machine operators do not require

cerƟficaƟon under AS/NZS 4233.1

DESCRIPTION:

Electric drive hot water ƉƌĞƐƐƵƌĞǁĂƐŚĞƌƐdesigned for professional cleaning applications.

MATERIAL CONSTRUCTION:

Aussie Sizzler hot water blaster is mounted on a heavy duty trolley mounted frame. It consists of a quality 4 pole

electric motor driving a triplex style three piston high pressure pump, and a diesel fired burner/boiler system. The

machine is supplied with wheels for ease of portability and manoeuvrability.

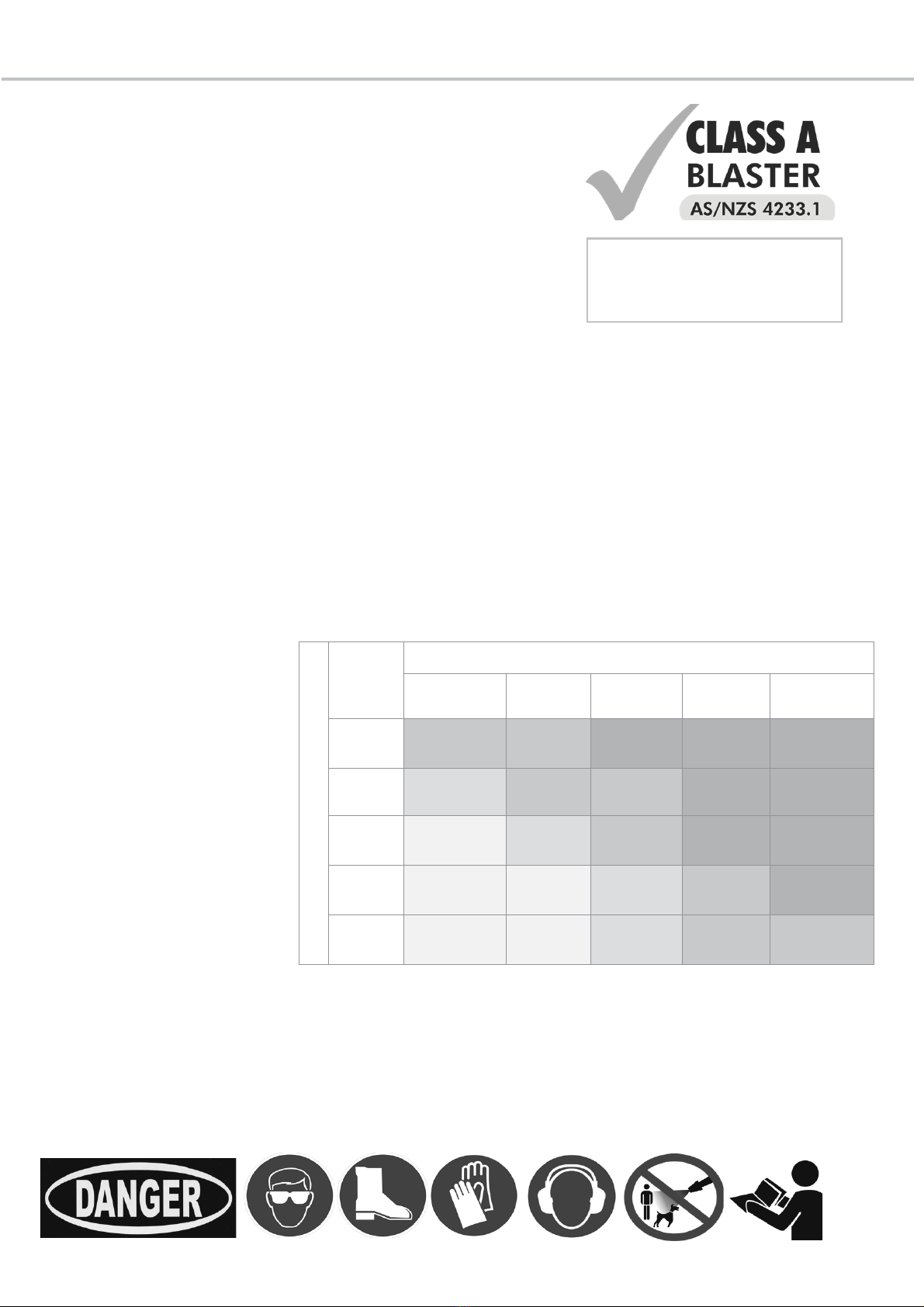

RISK RANKING METHOD:

Risk is the combinaon of the likelihood of a specific unwanted event and the potenal consequences if it should

occur.

RISK RANKING TABLE:

The consequences (loss

outcomes) are combined with the

likelihood (of those outcomes) in

the risk ranking table to idenfy

the risk rank of each loss event

(e.g. a consequence of

‘Moderate’ with a likelihood of

‘Likely’ yields a risk rank of 17).

The table yields a risk rank from 1

to 25 for each set of probabilies

and consequences. A rank of 25 is

the highest magnitude of risk that

is a highly likely, very serious event.

A rank of 1 represents the lowest magnitude of risk, an almost impossible very low consequence event.

Likelihood

Consequences

Use the

matrix to

determine

the risk Insignificant Minor Moderate Major Catastrophic

Almost

certain

High

11

High

16

Extreme

20 Extreme 23 Extreme

25

Likely Moderate

7

High

12

High

17 Extreme 21 Extreme

24

Possible Low

4

Moderate

8

High

13 Extreme 18 Extreme

22

Unlikely Low

2

Low

5

Moderate

9

High

14

Extreme

19

Rare Low

1

Low

3

Moderate

6

High

10

High

15

Aussie Pumps provides training

for all Class A machine operators

FREE of charge

Controls must be taken to either eliminate or minimise the risk.

| 3

Aussie Eco-Clean Super Sizzler OperaƟng & Maintenance Manual - 2020

Hazard Risk Risk

RaƟng Controls

Entanglement

with hose

(tripping, falling)

Personal injury of

the operator or

bystanders

13 i Warning sckers

i hose reel opon

i Ensure firm foong before operang machine

Injury from high

pressure water

Personal injury of

the operator or

bystanders

13 i Warning noce on blaster

i Wear eye protecon & PPE

i Use high pressure resistant gloves

i Always point spray jet at area to be cleaned

i Use barriers to keep bystanders away from work

area

i Stop jeng if persons enter working area

i Never leave machine unaended

i Never point hose at any person or animal

i Never put your hand over the spray nozzle when

operang

i Stop operang if a malfuncon occurs

Ergonomic liing

or movement on

site,

Personal injury 18 i Operator’s Manual

i Stafftraining

Electrocuon Personal injury 14

i Warning scker

i Disconnect from power before servicing machine

Burns from hot

water

Personal injury 14 i Warning in Operang Instrucons & decals on

machine

Unsecured

machine, moves

unaended

Cause of accidents

and/or injury

8 i Use of chocks behind wheels or ute mounng kit

Dislodged

parcles in

atmosphere

Sight damage 20 i Never clean asbestos with high pressure water

i Use of eye protecon

Slipping on wet

surface

Personal injury 17 i Use of proper footwear

Contact with

chemical cleaners

used to clean

surfaces

Skin contact could

result in burns,

skin irritaon etc.

Fumes from some

chemicals may

lead to respiratory

problems

22 i Chemical cleaners to only be used as a last resort

when other methods have failed.

i Areas to be kept well venlated.

i Staffto follow manufacturers’ instrucons at all

mes for use, storage & disposal.

i Staffto wear the appropriate PPE

i Respiratory protecon when required

Risks associated with operaƟng a high pressure cleaner … for use in daily SAFE WORK METHOD STATEMENT

NB: Class A machine operators do not require cerƟficaƟon under AS/NZS 4233.1

4 | Aussie Eco-Clean Sizzler OperaƟng & Maintenance Manual - 2020

Contents

Risk Assessment................................................................................... 2

Preparaon ......................................................................................... 5

Descripon of symbols ........................................................................ 6

General Safety Rules for the use of high pressure cleaners................ 7

Intended use ..................................................................................... 10

Preliminary operaons ..................................................................... 10

Using the Cleaner ............................................................................. 12

Maintenance ..................................................................................... 13

Periods of inacvity .......................................................................... 15

Scrapping .......................................................................................... 15

Trouble-shoong .............................................................................. 16

Technical data ................................................................................... 18

/ŶƚƌŽĚƵĐƚŝŽŶŽĨƵƐƐŝĞ^ƵƉĞƌ/ŶĚLJΘĚmiralƌĂnŐĞ......................... 19

Roune Check Lists ........................................................................... 20

Use hot water for a faster, chemical free, hygienic clean

--

CongratulationsWKDQN\RX

for buying this $XVVLH6L]]OHUKRWZDWHUSUHVVXUHZDVKHU. You have shown that you do not accept compromises

We have prepared this manual to enable to fully appreciate the qualities and high performance that this cleaner can offer you.

Please read it completely before using the machine.

The CE mark on your cleaner shows that it has been constructed in compliance with the European Standards on safety.

We can also offer you a wide range of cleaning machines such as:

VACUUM CLEANERS, FLOOR CLEANERS, FLOOR SWEEPERS and a complete range of ACCESSORIES, CHEMICALS

and DETERGENTS suitable for cleaning all kinds of surfaces.

Ask your Dealer for the complete catalogue of our products.

PREPARING THE CLEANER

Continue reading this manual without connecting the cleaner to the power mains and the water supply.

TRANSLATION OF ORIGINAL INSTRUCTIONS

The text has been carefully checked, however any misprints should be notified to the manufacturer.

The manufacturer also reserves the right to alter and update this publication without prior notice for the sake of

product improvement.

All reproductions of this manual, in whole or in part, are forbidden without the manufacturer's authorization.

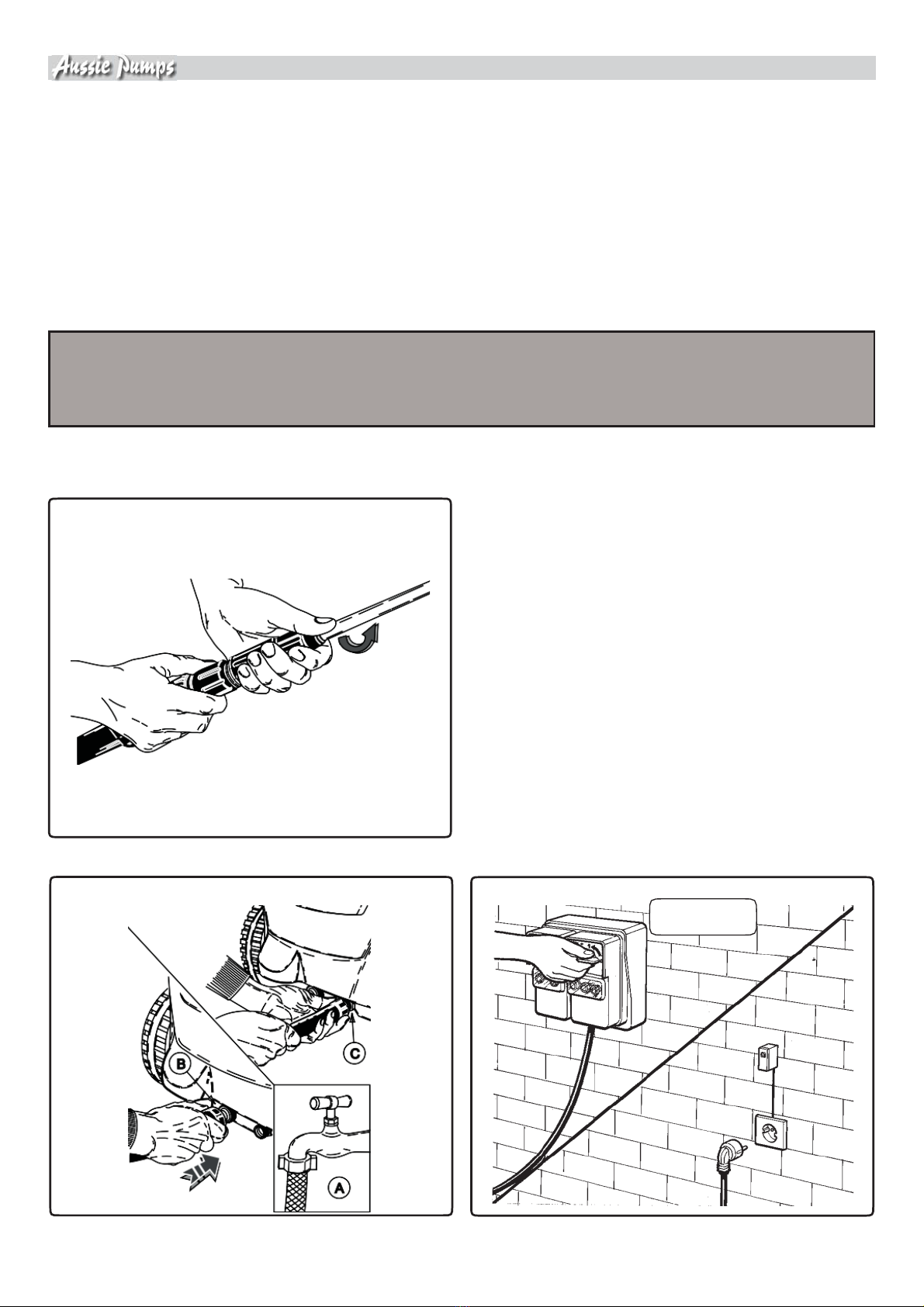

Fitting the lance.

A

C

B

Water circuit connection.

Electrical connection.

--

DESCRIPTION OF SYMBOLS ON THE CLEANER

ATTENTION:

RISK OF BURNS.

ATTENTION: RISK OF

ELECTRIC SHOCK.

EARTH.

WATER INPUT.

WATER OUTPUT.

SWITCHING OF THE PUMP

MOTOR.

DO NOT DIRECT THE

JET AGAINSTPEOPLE,

ANIMALS, POWER

SOCKETS OR THE

MACHINE IT SELF.

LIGHTING THE BURNER.

FUEL (DIESEL).

CHEMICHALS

(DETERGENT).

DO NOT &211(&772

DRINKING WATER7$3

:,7+287$%$&.)/2:

35(9(17(5

USE AN EN 12729 TYPE BA

SYSTEM SEPARATOR.

--

Danger

Identifies an imminent risk which could lead to serious or fatal

injury.

Warning

Identifies a risk situation which could lead to serious injury.

Information

Identifies a risk situation which could lead to minor injury or

damage to things.

Warning

You must read this manual before installing, starting up and

using the high pressure washer.

This manual is an integral part of the product.

Read the warnings and instructions contained in the manual

carefully as they provide important information on USER SA-

FETY and MAINTENANCE, paying particular attention to the

general safety regulations.

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE

REFERENCE.

Warning

Those operating and servicing the high pressure washer must

be aware of the contents of this manual.

The user must observe the conditions of use of the applian-

ce prescribed by the Rules, and particularly he must respect

the following classification:

As for the protection against electric shock, the H.P.cleaner

belongs to CLASS I.

The H.P. cleaner is factory set and all its safety devices are

sealed. It is forbidden to alter their adjustment values.

In the Hot water cleaner the water is heated by a burner feed

with Diesel fuel.

The H.P. cleaner must be always used on a firm and flat

ground, furthermore it must not be moved while it is working or

connected to the electric supply.

Failure to observe this prescription may cause danger for the

user.

The H.P.cleaner must not be used in the presence of corrosive

or potentially explosive atmospheres. (vapours orgas)

Warning

- The electric connection must be performed

by qualified technicians who are able to

work in observance of the governing rules

(in compliance with the provisions of the IEC

60364-1standard)andofthemanufacturer’s

instructions.

A wrong electric connection may cause

damage to persons, animals or things, and

the manufacturer cannot be considered

responsible for these.

- The H.P. cleaners with power lower than 3

kW are equipped with a plug for connection

to the electric supply.

In this case please check if the electric

power system and the electric sockets are

compatible with the max. power of the ap-

pliance indicated on the plate. (kW). In case

ofdoubt,pleaseapplytoqualifiedpersonnel.

If the socket and the plug of the machine are

not compatible, have the plug replaced with

a suitable type by qualified personnel.

- Before connecting the machine make sure

that the data indicated on the plate corre-

spond to those of the electric supply.

- Do not use extensions to power the high

pressure washer.

If you use an extension, the plug and socket

must be watertight. Unsuitable extensions

may be dangerous.

- The electric safety of this machine may be

assuredonlywhenitisproperlyconnectedto

an efficient groundingsystem in accordance

withthegoverninglawsforelectricsafety.(In

compliance with the provisions of the IEC

60364-1 standard)

CLASSIFICATION OF RISKS:

!

!

PREFACE

!

!

CLASSIFICATION

GENERAL SAFETY RULES FOR

THE USE OF HIGH PRESSURE

CLEANERS

!

--

-Itisnecessarytocheckthisessentialsafety

requisite. In case of doubt, ask for accurate

control of the power system by qualified

personnel.

The manufacturer may not be considered

responsible for damages occurred because

of the lack of the grounding system.

- The H.P.cleaner must be connected to the

electric supply by means of an omnipolar

switch with opening contacts of at least 3

mm. This switch must have electric features

which are consistent with the appliance.

(This requisite does not apply to H.P. cle-

aners with plug and electric power lower

than 3 kW).

It is recommended that the electric supply

to this machine should include a residual

current device that will interrupt the supply

if the leakage current to earth exceeds 30

mA for 30 ms or a device that will prove the

earth circuit.

- The appliance is disconnected from the

electric supply only by pulling out the plug or

switching off the omnipolar switch.

- Failure to respect the above absolves the

manufacturer of all liability and represents

negligent use of the product.

The water cleaner is considered as a fixed

device.

- Water cleaners with the “Total Stop” device

should be considered as off when the omni-

polar switch is in the “O” position or the plug

is unplugged from the socket.

- The appliance must be attended during

operation.

- The high pressure washer is not intended

for use by children, adolescents or persons

with reduced physical, sensory or mental

capabilities, under the influence of alcohol

or lacking experience and knowledge.

Operators must be made aware of the

instructions for using the appliance by a

person responsible for their safety.

Children must be supervised to ensure

they

do not play with the high pressure washer.

-Useonlyoriginalaccessoriesthatcanallow

safe working of the appliance.

- The flexible hose connecting the lance to

the H.P. cleaner must not be damaged.

In case of damage, replace it immediately.

The hose must be marked with the admis-

sible pressure value, production date and

manufacturer’s name.

- Hoses, connections and fittings for high

pressure systems are very important to

guarantee the safety of the H.P. cleaner.

Use only original spare parts which have the

manufacturer’s approval.

- Do not use the H.P. cleaner whenpersons

or animals are in its of action field.

- High pressure jets may be dangerous if not

properly used.

The jet must never be directed at persons

or animals, electric appliances or at the

appliance itself.

- The high pressure water jet causes a re-

action power on the lance. Hold the lance

grip vigorously.

- The use of the H.P. cleaner must be con-

sidered according to the kind of washing

which must be performed.

Protect yourself against the ejection of solid

--

materials or corrosive substances by means

of adequate protective clothing.

- The use of the H.P. cleaner must be con-

sidered according to the place where the

washing is performed (for example: food

plants, pharmaceutical plants, etc.)

Pertinent rules and safety conditions must

be followed.

-Donotdirectwater jetsatyourownorother

people’s body in order to clean clothes or

shoes.

-Whileworkingitisforbidden,tostopthetrig-

ger (lever) of the lance in deliveryposition.

- In the hot water H.P. cleaners a Diesel fuel

burner is used for water heating. The use

of other fuels is dangerous.

- Before starting any cleaning or maintenan-

ce operation, disconnect the machine from

the electric and water supply networks.

- Periodically, at least once a year, have the

safetydevicescheckedbyoneofourservice

centres.

-The machine is for outdoor use. If the ap-

pliance is to be used in an enclosed space

(not advisable), install a flue gas extraction

systemandguaranteeadequateventilation.

- Do not clog the openings or the ventilation

grilles and the heat and smoke extraction

systems in the hot water cleaners.

- Do not use the machine if the supply cable

is damaged.

For the replacement of the damaged cable

apply exclusively to one of our technical

service centres.

The supply cable of this appliance must not

be replaced by the user.

- The electric power cable must never be

under mechanical tension and must be pro-

tected against accidental crushing.

- The use of any electric appliance requires

the respect of some basic rules:

•Do not touch the appliance with wet or

damp hands or feet.

•Do not use the appliance bare-footed or

with unsuitable clothing.

•Do not pull the supply cable or the applian-

ce itself in order to disconnect the plug from

the electric supply.

(For water cleaners rated at less than 3 kW

fitted with plug).

- In case of damage or malfunction, switch

off the appliance (disconnecting it from the

water main and from the electricity main via

the omnipolar switch or by unplugging the

plug in the case of water cleaners rated at

less than 3 kW) without tampering with it.

- In the event of accidents, seek medical

advice or emergency treatment.

As for the protection against electric shock,

the H.P.cleaner belongs to CLASS I.

Apply to one of our technical service

centres.

Failure to observe the above warning

frees the manufacturer from all respon-

sibility and constitutes negligent use of

the product.

--

!

This appliance is intended exclusively for cleaning machines,

vehicles, buildings and general surfaces suitable for treatment

with a high pressure jet of detergent solution between 25 and

250 bar (360 - 3600 PSI).

This appliance has been designed for use with the detergents

supplied or recommended by the manufacturer. The use of

other detergents or chemicals may influence the safety of the

appliance.

This appliance must be used only for the purpose for which it

was specifically designed.

All other uses are to be considered incorrect and therefore

unreasonable.

Examples of unreasonable use:

- Washing surfaces not suitable for cleaning with a high

pressure jet.

- Washingpeople,animals,electricequipmentorthemachi-

ne itself.

- Using unsuitable detergents or chemicals.

- Blocking the trigger (lever) of the lance in delivery posi-

tion.

The manufacturer cannot be held responsible for any damage

due toimproper, incorrect or unreasonable use.As far as safety

rules are concerned, the cleaners are manufactured according

to the European Standard.

UNPACKING

After unpacking, ensure that the cleaner is undamaged.

If in doubt, do not use the machine.

Contact your dealer.

Packaging(bags,boxes,nails,etc)ispotentiallydangerousand

should be kept out of reach of children. It should be disposed of

or retained in respect of national environmentallegislation.

FITTING THE SEPARATE PARTS OF THE MACHINE

All the fundamental parts and safety devices ofthe machine are

assembled by the manufacturer.

For reasons of packing and transport, some secondary cleaner

parts are supplied separately.

The user must fit these parts as explained in the instructions

supplied in each assembly kit.

DATA PLATE:

Thedataplatebearingthemaintechnicalcharacteristicsofyour

cleaner is located on the trolley and is always visible.

When buying your cleaner, ensure that it has an

identification plate. If there is no plate, inform the manu-

facturer and/or the dealer immediately. Machines without

a plate must not be used and the manufacturer declines all

responsibility for them. Products without a plate must be

considered anonymous and potentially dangerous.

FILLING THE FUEL TANK

Fill the tank with fuel for Diesel

motors (fig. 1).

Warning

Do not use different fuel from that indicated on the

identification plate.

Check the fuel level from time to time while the

cleaner is operating.

Attempting to use the cleaner without fuel may cause

damage to the fuel pump.

INTENDED USE

PRELIMINARY OPERATIONS

FIG. 1

!

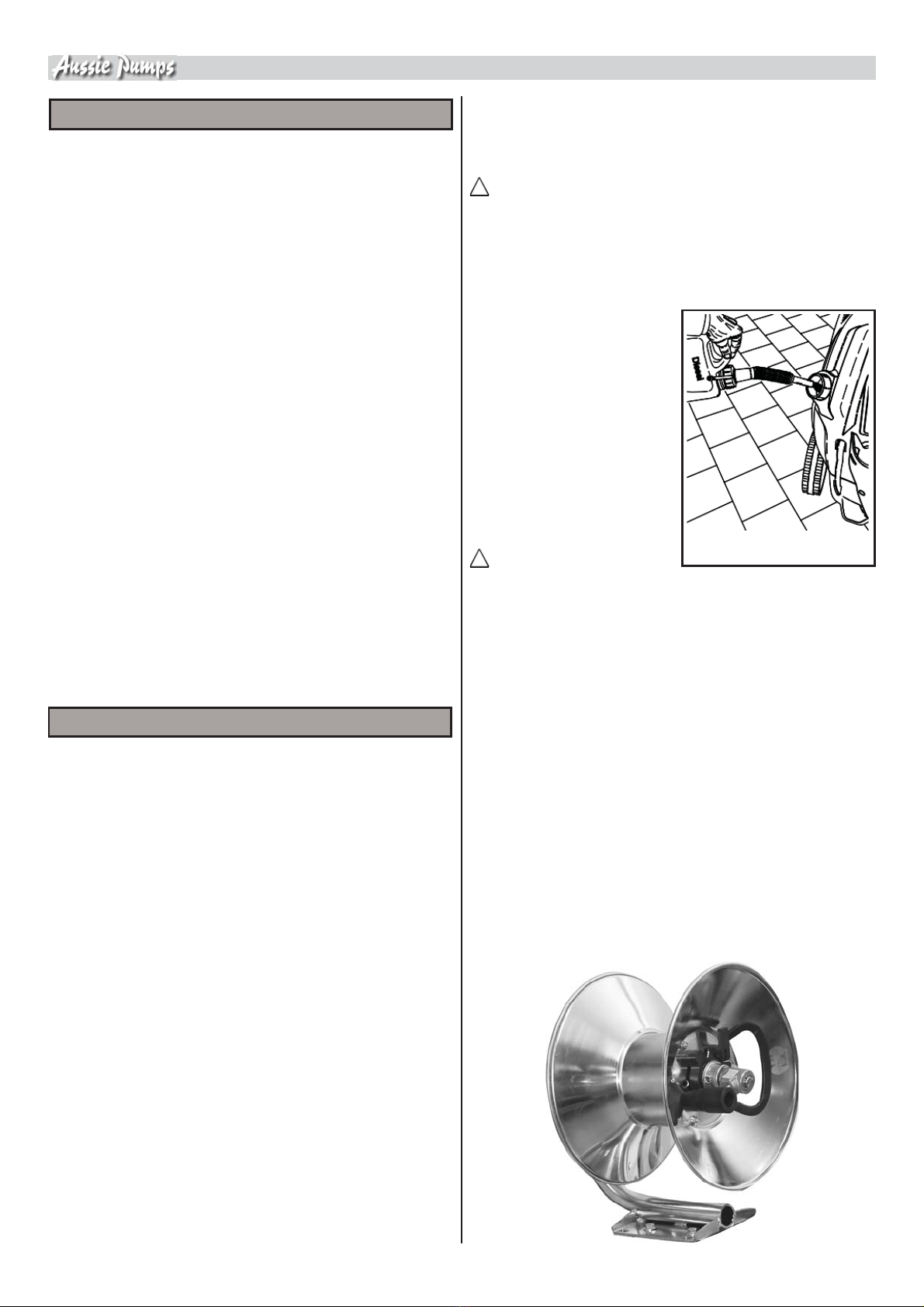

$XVVLHVWDLQOHVVVWHHOKRVHUHHOVFDQEHZDOO

PRXQWHGKROGXSWRPRIKRVH

--

A

FIG. 5

C

B

TRANSPORTING

To move the machine,

disconnect it from the

mains electricity and water

supplies, release the parking

brake on the side of the

machine and push it by the

handle.

COMMAND AND CONTROL DEVICES

Warning

Before connecting the machine to the water supply and to the

power mains, it is essential to know the function of the cleaner's

command and control devices.

SAFETY DEVICES

The safety devices protect the user and the appliance. They

must not be tampered with or used for other than their desi-

gnated purpose.

Safety valve: protects the high pressure hydraulic circuit in

the event of a by-pass valve malfunction or if the hydraulic

circuit is blocked.

The safety valve is calibrated by the Manufacturer and sealed.

Operations involving thesafe-

tyvalve must be performed by

atechnicalservicecentreonly.

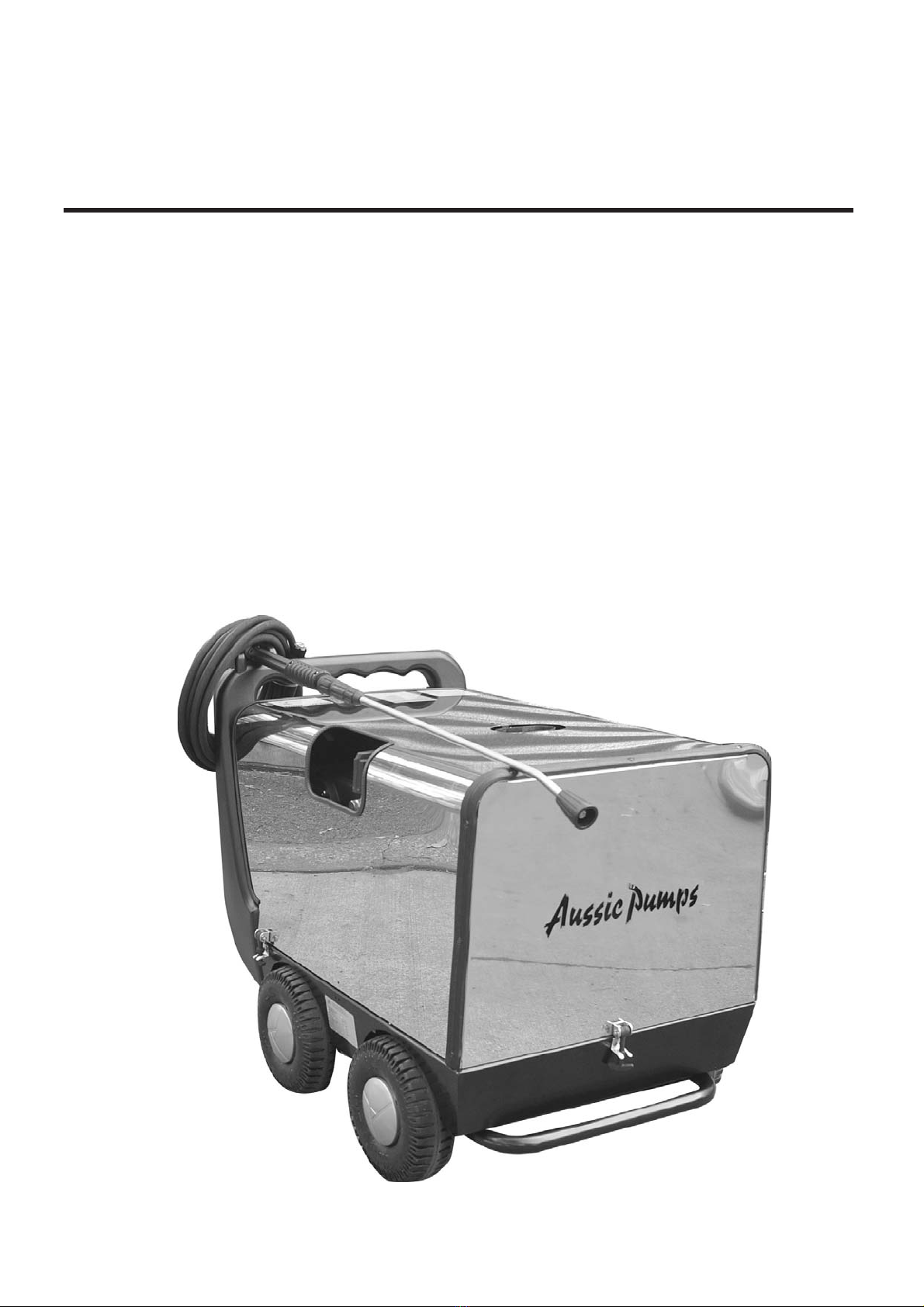

Safety device on lance

handgrip: Prevents the trig-

geronthehandgripfrombeing

operated accidentally.

Thermal cutout: stops the

high pressure washer if the

electric motor overheats.

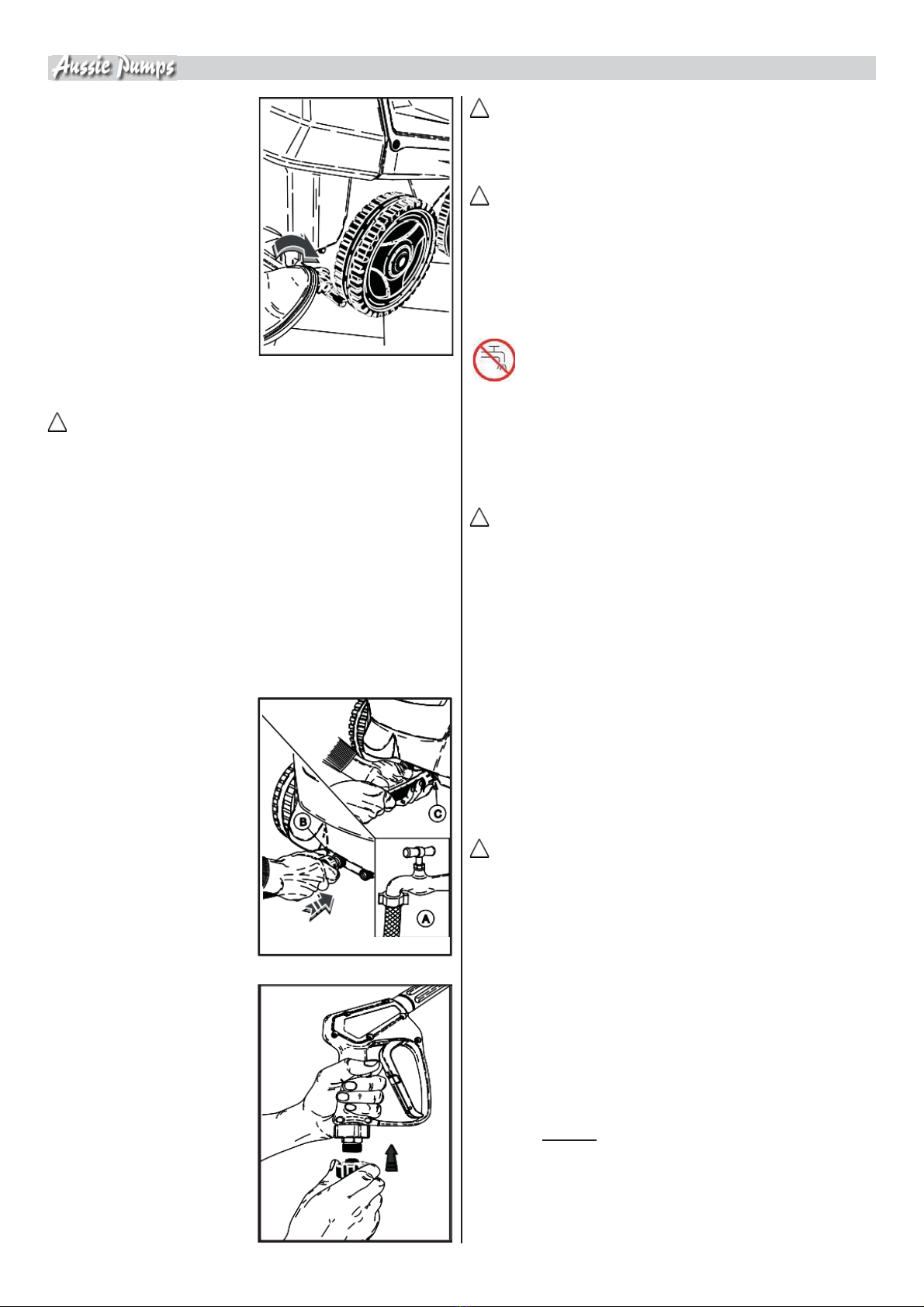

WATER CIRCUIT CONNEC-

TION

Connect the feed hose to the

mains (fig. 5A) and to the ho-

setail on the cleaner (fig. 5B).

Check that the pressure and

quantity of the water supplied

by the mains are sufficient for

the cleaner to work properly:

200to800kPa(29to116PSI).

Maximum temperature of

feeding water 50°C (122°F).

Connect the high pressure

hose to the cleaner (fig. 5C)

and to the lance (fig. 6).

Danger

The cleaner must operate with clean water. Dirty or sandy

water, corrosive chemicals and solvents can cause severe

damage to the cleaner.

Danger

Never suck up liquids containing solvents or acids in the pure

state,forexamplepetrol,paintsolventsordiesel.Thespraymist

fromthe lanceishighlyinflammable,explosive andpoisonous.

Failure to respect the above absolves the manufacturer

of all liability and represents negligent use of the product.

Information

Respect the instructions provided by the water utility

company.

Current regulations specify that the appliance may not be con-

nected to the drinking water supply unless a suitable system

separator is fitted.

Use a suitable EN 12729 type BA system separator.

Water passing through a system separator is no longer classi-

fied as drinking water.

Warning

Do not connect the machine to a drinking water container.

ELECTRICAL CONNECTION

The water cleaner must be connected to a mains electricity

supply conforming to current legislation and standards.

Ensure that the mains voltage available is the same as the vol-

tage at which the cleaner is supposed to work; this is indicated

on the identification plate.

Danger

-Theelectriccablemustbeprotectedfromaccidental crushing.

- Do not use the machine if the supply cable is damaged.

- The use of any electric appliance requires the respect of

some basic rules:

•Do not touch the appliance with wet or damp hands orfeet.

•Do not use the appliance bare-footed or with unsuitable

clothing.

•Do not pull the supply cable or the appliance itself in order

to disconnect the plug from the electric supply.

(For water cleaners rated at less than 3 kW fitted with plug).

As for the protection against electric shock, the H.P.cleaner

belongs to CLASS I.

Failure to observe the above warning frees the manufac-

turer from all responsibility and constitutes negligent use

of the product.

FIG. 4

!

FIG. 6

!

!

!

!

--

CONTROL PANEL

A- On/off switch

B- Temperature regulator

STARTING THE CLEANER

1) Turn on the water supply tap (fig. 5A).

2) Connect the water cleaner to the mains electricity supply by

plugging the plug into the socket.

3) Start the cleaner by turning the selector switch to pos. I

(fig. 7A).

Warning

The high pressure water jet generates a reaction force in the

lance. Keep a firm grip on the lance handle.

4) Press the trigger on the gun and begin washing.

5) Tooperate the water cleaner with hot water, turn the tempe-

rature regulator to the recommended washing values. (fig. 7B).

Warning

In water cleaners with the “Total Stop” system, the motor starts

and stops when the lever on the lance handle is actioned or

released.

Danger

Do not block the handle lever in the delivery position.

IMPORTANT!

To eliminate any impurities

or air bubbles from the wa-

tercircuit we advisestarting

the cleaner for the first time

withoutthelanceandletting

the water run out for a few

seconds.

Impurities could block the

nozzle and cause malfun-

ction (Fig. 8).

USING THE ACCESSORIES.

The high pressure washer has a nozzle with a flat angle jet for

cleaning large surfaces.

ROTARY HEAD (optional accessory)

The high pressure washer can be fitted with a head with rotary

nozzle to clean the most stubborn dirt.

Danger:

Aim the jet from a certain distance to avoid damage caused by

the high pressure.

Do not aim the jet at people, animals or electrical sockets.

STOPPING THE CLEANER

1) Switch off the burner by turning the pressure regulator to

pos. "0" (fig. 7B).

2)Letthecleanerrunwithcoldwateronly foratleast30seconds

to cool down the boiler.

3) Stop the cleaner by turning the selector switch to pos. "0"

(fig. 7A).

4) Discharge the pressure from the H.P.hose by pressing the

trigger on the gun.

5) Disconnect the water cleaner from the mains electricity

supply via the Solenoid switch or by unplugging the plug from

the socket.

6) Turn off the water supply tap (fig. 5A).

Warning

- If the water cleaner is left, even temporarily, turn it off by using

the Solenoid switch or by unplugging the plug from the socket.

- Water cleaners with the "Total Stop” device should be consid-

ered as off when the Solenoid switch is in the “O” position or

the plug is unplugged from the socket.

- When the water cleaner is not used, close the safety device

on the handle.(fig. 9).

- Dry use of the water cleaner causes serious damage to pump

gaskets.

00°°

USING

THE CLEANER

B

A

6565°°CC

140°°FF

MAX

250°°FF

120°°CC

FIG. 7

!

!

!

FIG. 8

!

!

FIG. 9

--

REGULATING PRESSURE.

This chapter concerns only

those models provided with

the “pressure regulating” de-

vice. The pressure regulator,

fig. 10, allows the operator to

adjust the working pressure.

When knob C is turned in

an anti-clockwise direction

(B) (minimum), the working

pressure is reduced.

Use the steam nozzle (supplied as an accessory).

Turn the thermostat knob “B” (fig. 8) to steam position to obtain

an increase in the temperature of the water at delivery.

At work temperatures higher than 95°C (203°F), the work

pressure must be < 32 bar (460 PSI).

Danger

During use with boiling water, "Steam Phase", keep away

from the openings for fumes discharge (risk of burning).

Whenyou have finished using the "Steam Phase",turn the

thermostat knob "B" to position "0" (fig. 8) and let the ma-

chinecooldownforabout 3minuteswiththegunturnedon.

Danger

Formaintenanceoftheboiler,highpressurepump,theelectrical

parts and all parts with a safety function, you must apply to our

Technical service centre.

Themanufacturerisnotliableincaseoftampering,changes,in-

correct repairs or maintenance carried out on the machine bya

thirdpersonnotprovidedwiththemanufacturer’sauthorization.

All documents pertaining to the repair and planned service

interventions, as well as any certificates concerning the device

installationaccordingtothelawsinforce(incompliancewiththe

provisions of the IEC 60364-1 standard) must be kept carefully

by the user, together with the Instructions Manual.

Periodically, at least once a year, have the safety devices and

theratedvaluescheckedatoneofourtechnicalservicecentres.

Particularly, as for the hotwater high pressure cleaner, which is

factory set, the exhaust system must be checked.

Theratingdonebythemanufacturerdetermines a productionof

exhaustgaseswithaCOcontentlowerthan0,04%anda smoke

content corresponding to a smoke point nr.2 Shell-Bacharach

according to the laws in force.

Danger

Disconnect the water cleaner from the mains electricity supply

via the omnipolar switch or by unplugging the plug from the

socketand closethe watersupply tap(seechapterson connec-

ting to the electricity and water mains) before carrying out any

maintenance jobs. Once maintenance has been completed,

ensurethattheclosingpanelshavebeencorrectlyreassembled

andanchored withthescrewsprovided before reconnecting the

cleaner to the mains.

Failure to do so may cause a risk of electric shock.

ONLY THE OPERATIONS AUTHORIZED IN THIS

INSTRUCTION MANUAL MAY BE CARRIED OUT BY

THE USER.

ALL OTHER OPERATIONS ARE FORBIDDEN.

MAINTENANCE

FIG. 10

!

!

!

$XVVLH)RDPHURSWLRQDODFFHVVRU\

8VHDQ$XVVLHIRDPHUDWWDFKHGWRWKH

JXQIRUDSSO\LQJGHWHUJHQW

--

PRECAUTIONS AGAINST FROST

The cleaner must not be exposed to frost.

If the cleaner is left in premises where it is exposed to frost,

when work is over or for storage, antifreeze must be used to

prevent serious damage to the hydraulic circuit.

OPERATIONS FOR USING

ANTIFREEZE (fig. 12).

1)

Turn off the water supply

(tap), disconnect the hose

and run the cleaner until it is

completely empty.

2)

Stop the water cleaner with

the ON/OFF switch in the “O”

position.

3)

Prepareacontainerwiththe

solution of antifreeze.

4)

Immerse the tube in the

container with the anti-freeze

solution.

5)

Start the water cleaner with the ON/OFF switch in the “I”

position.

6)

Start the cleaner and let it run until antifreeze comes out

through the lance.

7)

Suck up antifreeze with the detergent intake systemtoo.

8)

Disconnect the water cleaner from the mains electricity

supply via the omnipolar switch or by unplugging the plug from

the socket.

9)

For high pressure cleaners provided with water tank, the

detergent solution prepared as described in the point 3, must

be poured directly into the tank.

Warning

Anti-freeze may cause environmental pollution. Always follow

the instructions given on the pack. (Dispose of carefully.)

CHECKING PUMP OIL

LEVEL AND OIL CHANGE

From time to time check the

oil level in the high pressure

pump by means of the sight

glass (fig. 13A) or the dipstick

(fig. 13B).

Iftheoilhas amilky appearan-

ce, call the technical service

centre immediately.

Change the oil after the first

50 hours' work and subse-

quently every 500 hours or

once a year.

Proceed as follows:

1) Unscrew the drain cap

situated under the pump (fig.

13C).

2) Unscrew the cap with the

dipstick (fig. 13).

3) Let all the oil drain off into

a container and deliver it to an

authorized oil collection and

disposal centre.

4) Replace the drain screw

and pour fresh oil in through

the filling cap on top (fig.

14A) until it reaches the level

indicated on the sight glass

(fig. 14B).

For water cleaners without

oil drain bung, contact our

technical service centre for

replacement.

Use only SAE 15W 40 oil.

CLEANING THE FUEL

FILTER AND TANK.

Remove and replace the in-

line fuel filter (fig. 15).

Change it from time to time.

Empty the fuel tank.

Open the drain cap (fig. 16) (if

available) and let any impuri-

ties drain out into a container.

Flushoutthetankwithclean

fuel and close the drain cap.

CLEANING THE WATER

FILTER

Clean the water intake filter

regularly and free it from any

impurities (fig. 17).

FIG.12

!

FIG.13

FIG.14

FIG.15

FIG.16

FIG.17

--

CHANGING THE NOZZLE

The high pressure nozzle fitted on the lance must be chan-

ged from time to time, as this component is subject to

normal wear during use. Wear may generally be detected

byadropintheworkingpressureofthecleaner. Toreplace

it, consult your supplier and/or dealer for instructions.

TABLE OF ROUTINE MAINTENANCE TO BE PER-

FORMED BY THE USER

DESCALING

Descaling must be carried out from time to time because the

scale present in the water partially deposits inside the hydraulic

circuit and the coil which with time becomes clogged.

Apply to our technical service centre to have the machine

descaled from time to time; this will save you money and

increase the efficiency of the cleaner.

TABLE OF EXTRAORDINARY MAINTENANCE TO

BE PERFORMED BY THE TECHNICAL SERVICE

CENTRE

Description of operations:

Check power cable - pipes - highpressure

connectors

Ist oil change in H.P. pump

Subsequent changes in H.P. pump

Change and clean fuel filters

Clean fuel tank

Clean water filter

Each use

After 50 hours

Every 500 hours

Every 100 hours

Every 100 hours

Every 50 hours

Description of operations:

Boiler:

Clean Coil

Descale coil

Clean fuel pump

Change fuel nozzle

Regulade electrodes

Change electrodes

Change seals on H.P. pump

Change lanze nozzle

Calibrate and check the safety devices

Every 200 hours

Every 300 hours

Every 200 hours

Every 200 hours

Every 200 hours

Every 500 hours

Every 500 hours

Every 200 hours

Once a year

If the machine is to remain inactive for a long period, disconnect the supply sources, drain the tank(s) of all the operating fluids

and protect any parts that could be damaged by the accumulation of dust.

Grease the parts that could be damaged by drying out, such as the supply hoses. When bringing back into use, ensure that

there are no cracks or cuts in the water supply hoses.

Oil and chemical products must be disposed of according to current legislation.

If you no longer wish to use the water cleaner, you should render it unusable by removing the power cable.

Youshould alsomake surethat all potentially hazardousparts of the appliance aremade safe, particularly for children who could

play with the unused water cleaner.

This product is classified as WEEE type special waste and is covered by the requisites of the new environmental protection

regulations. It must be disposed of separately from ordinary waste in compliance with current legislation and standards.

Do not use parts dismantled for scrap as spare parts.

IMPORTANT:

These intervals refer to normal working conditions. For heavy duty use decrease the interval for each job.

For maintenance and/or repairs, use only original spare parts which offer the greatest characteristics of quality and

reliability. Failure to use original spare parts absolves the manufacturer from all liability and transfers it to the person

carrying out the operation.

PERIODS OF INACTIVITY

SCRAPPING

--

TROUBLE-SHOOTING

Before carrying out any operations, disconnect the water cleaner from the mains electricity supply via the omni-

polar switch or by unplugging the plug from the socket.

When the switch is turned the cleaner

does not start.

No jet or leakage from high pressure

water circuit. After 30 seconds, the

water cleaner stops. (DS Vers.).

The pump functions but does not reach

rated pressure.

When the lance is open, the pressure

drops and rises.

Inby-passor totalstop phase,the water

cleaner shuts down. (DS Vers.).

When thetemperature regulator isbrou-

ght to the required position, the boiler

does not come on.

Water notenough.

Excessive smoke from exhaust.

Inadequate detergent suction.

Water leakage from head.

Water in the oil.

Faulty electric connection.

Thermal protection has tripped.

Water supply filter clogged.

Faulty connection to the mains water

supply.

Mains water supply tap closed.

Leakage from high pressure circuit.

Water supply filter clogged.

Faulty connection to the mains water

supply.

Pressure regulation valve is set at

minimum.

Lance nozzle worn.

Valves dirty or worn.

Detergent tap open.

Pressure adjustment devices on lance

open (if present).

Nozzle clogged or deformed.

Inadequate water supply.

Detergent tap open.

Micro-leaks of water from the high

pressure circuit.

No diesel.

Motor rotation direction incorrect on

three-phase models.

Temperature regulator position.

Filters clogged.

Boiler element coated with scale.

Incorrect combustion.

Fuel contaminated with impurities or

water.

Tap closed.

No detergent.

Element or tube clogged.

Gaskets worn.

Excessive humidity in

atmosphere

Check the mains voltage.

Reset (if it trips again, apply to the tech-

nical service centre).

Clean.

Check.

Open.

Contact Service Centre.

Clean.

Check.

Regulate it.

Contact Service Centre.

Contact Service Centre.

Close.

Close.

Clean or contact Service Centre.

Check.

Close.

Contact Service Centre.

Check the level of diesel in the tank and

make sure the fuel supply circuit is free

of water.

Contact Service Centre.

Check.

Clean or replace.

Contact ServiceCentre.

Clean or replace diesel filters.

Contact Service Centre.

Empty the tank and clean thoroughly.

Clean diesel filters.

Open.

Fill the detergent tank.

Contact Service Centre.

Contact Service Centre.

Replace oil

FAULTS

CAUSES REMEDIES

--

We declare on our own responsibility that the product to which

this declaration refers is in accordance with the following Eu-

ropean Community Directives:

:

2006/42/CE - 2014/30/UE - 2000/14/CE - 2014/68/UE - 2011/65/UE

“CE” CONFORMITY DECLARATION

IMPORTANT:

For maintenance and/or repairs, use only original spare parts which offer the greatest characteristics of quality and

reliability. Failure to use original spare parts frees the manufacturer from all responsibility.

6L]]OHUILWWHGZLWKRSWLRQDOSURWHFWLYHIUDPH

Technical data

Model Mod.

D1310P4

xPower supply ~

v

Hz

1

230 / 240

50

xAbsorbed power

kW

W

2,8

2800

xPressure

bar

40 ÷ 130

psi

580÷1800

xFlow rate

l/h

280 ÷ 600

gph

74 ÷ 160

xFuel consumption

xThermal capacity

kg/h

gph

kW

3,2

0,85

37,8

xWaterout-put

temperature

°C

°F

30 ÷ 130

86 ÷ 266

xFuel tank l

gal

18

4,8

xDetergent tank l

gal

-

xDescaling tank l

gal

-

x

High pressure hose

m

ft

8

26,3

xPower cable m

ft

5,5

18

xLance thrust N 27

.m/s

2< 2,5

xNoise Lp dB (A)

78

Lw dB

(A)

94

(kp. 2dB)

xWeight

kg

lb

80

176,4

xDimension

cm

82x69x87

Aussie Eco-Clean Super Indy OperaƟng & Maintenance Manual - 2020

Aussie Steam Cleaners | Super Indy & Admiral series

Designed for Aussie CondiƟons

Single & three phase opons

Pressuresto 4,000 psi

Steam to 120 °C

Slow speed four poleheavy duty

motors

Triplex pumps with brass head

& ceramic pistons

Mild steel or stainless steel coil

opons

18 litre diesel fuel tank

High pressure detergent

injecon

Stainless steel cover & steel

chassis with bumper

Low water cut-out

Low fuel sensor

Timed Total stop—auto shut

down

Safety thermostat

Micro-leak detecon

Class A … no operator RTO

cerficaon required

Oponal protecve cage

Use steam for a faster, more hygienic clean!

Cod. PLDC88056

RELIABLE PRODUCTS . . . RELIABLE PEOPLE

AUSTRALIAN PUMP

Australian Pump Industries Pty Ltd ACN 061 619 234 ABN 79 061 619 234

7 Gladstone Rd, Castle Hill NSW 2154 PO Box 6164, BHBC NSW 2153

Ph 02 8865 3500 Fx 02 9894 4240 www.aussiepumps.com.au

Look after your machine . . .

and it will look after you!

AND REMEMBER . . .

Always wear protective clothing,

including boots and goggles!

IMPORTANT INFORMATION

ROUTINE CHECK LIST - IMPORTANT

- DAILY:

1. Check pump oil level. If oil is milky contact your Aussie Eco-Clean Distributor for service.

2. Check all high pressure components for leaks:

a) gun/lance; b) high pressure hose; c) all fittings.

3. Check power supply cable and plug for damage.

4. Check water inlet filter - clean if necessary.

- MONTHLY:

1. Check high pressure nozzle for wear. If pressure has dropped off, replace nozzle. If you machine is

used regularly the nozzle may need replacing monthly to maintain performance.

2. Clean detergent suction filter.

3. Change lance nozzle tip.

4. Change oil

5. Check fuel filter

- 6 MONTHLY/250 HOURS: - Contact your Aussie Eco-Clean Distributor for recommended service.

- ANNUALLY/ 500 HOURS: - Contact your Aussie Eco-Clean Distributor for recommended service.

WARNING

HIGH PRESSURE SETTING - The high pressure pump is factory set and

sealed to operate at its rated pressure. DO NOT ADJUST.

Tampering with the pressure regulator will void warranty and can be DANGEROUS

This manual suits for next models

1

Table of contents

Other Aussie Pumps Pressure Washer manuals