7

Maintenance

Timer 3: ‘Reset Delay Timer’

• Timer 3 controls how long the pump must run

before resetting the ‘Lockout Timer’ (Timer 1).

This allows the pump to run long enough to re-

pressurize the system if there is pressure loss

when not in use. Timer 3 is factory set to 15

seconds.

To change to the parameters of the internal timers in

the Smart Relay complete the following steps:

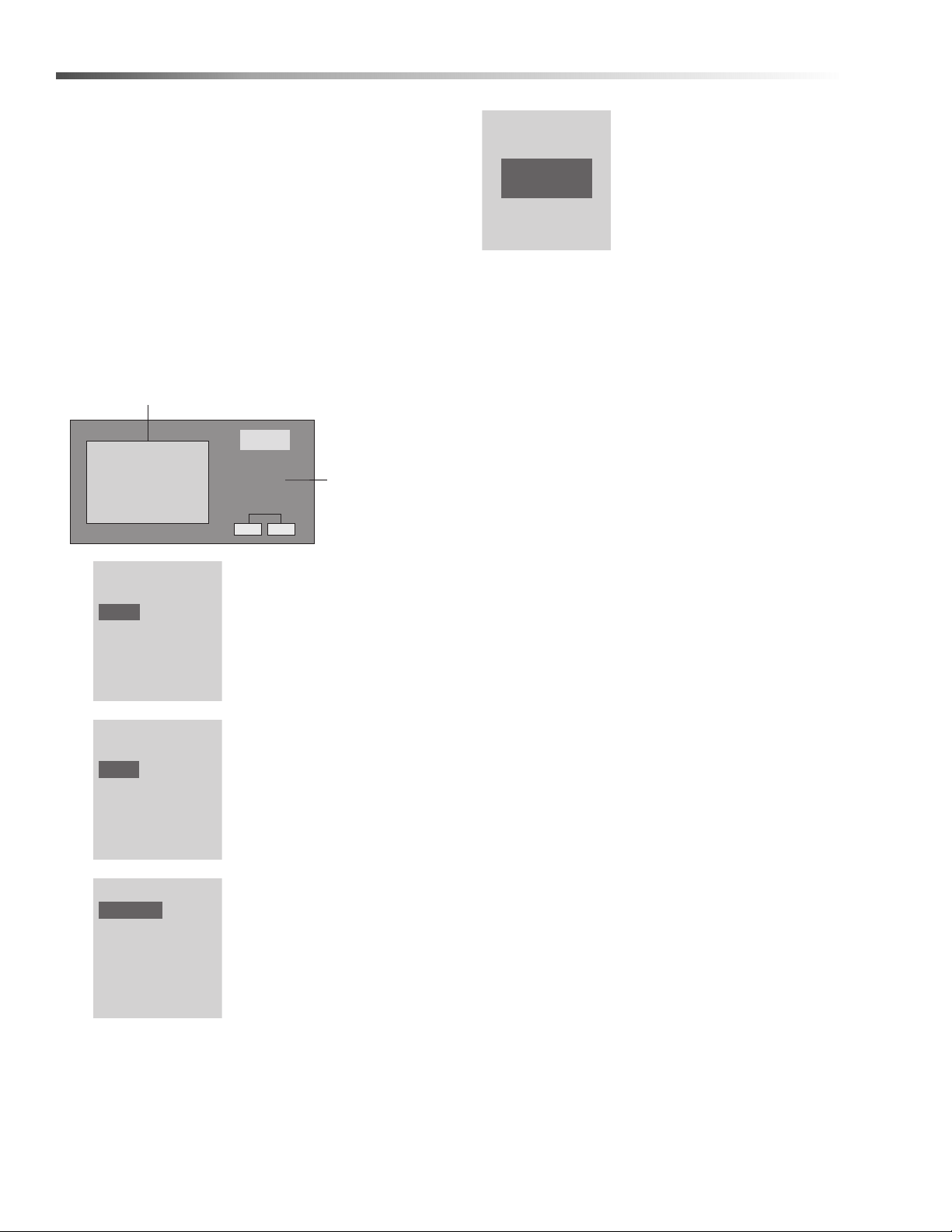

1. Turn on the power to the machine but do not press

the start switch. Remove the front panel and then

the control panel cover. NOTE: Use extreme

CAUTION when reaching into the control box,

the machine has live power. Once powered the

Smart Relay window will display the following

screen, see figure 1 (if screen does not appear

press the left/right arrow keys or until correct

screen appears).

2. Press the ESC key located next to the display

window and under the arrow key pad to access the

Menu.

3.Using the up/down arrow

key ▲ or ▼, move the

cursor to highlight ‘Program’

and press OK to confirm.

4.Using the up/down arrow

key ▲ or ▼, move the

cursor to highlight ‘Set

Parameter’ and press OK to

confirm.

5.The display window will

display the Timers.

Highlight the Timer desired

to change and press OK.

NOTE: Ta is the

accumulator timer and T is

the adjustable timer (the

variable that changes).

6.Highlight the T field and

press OK to edit the value.

Use the left/right arrow keys

or , move the cursor to

the used the up/down arrow

keys ▲ or ▼ to change this

value. Each timer has

optional units of time in

seconds (s), minutes (m),

and hours (h). To change

the unit of time using the arrows up/down keys ▲

or ▼. Once all values have been set press, OK to

accept and ESC to back up to the Timer selection

menu.

Repeat steps 5 and 6 for the other times if needed.

When finished press ESC three times to go to the main

menu.

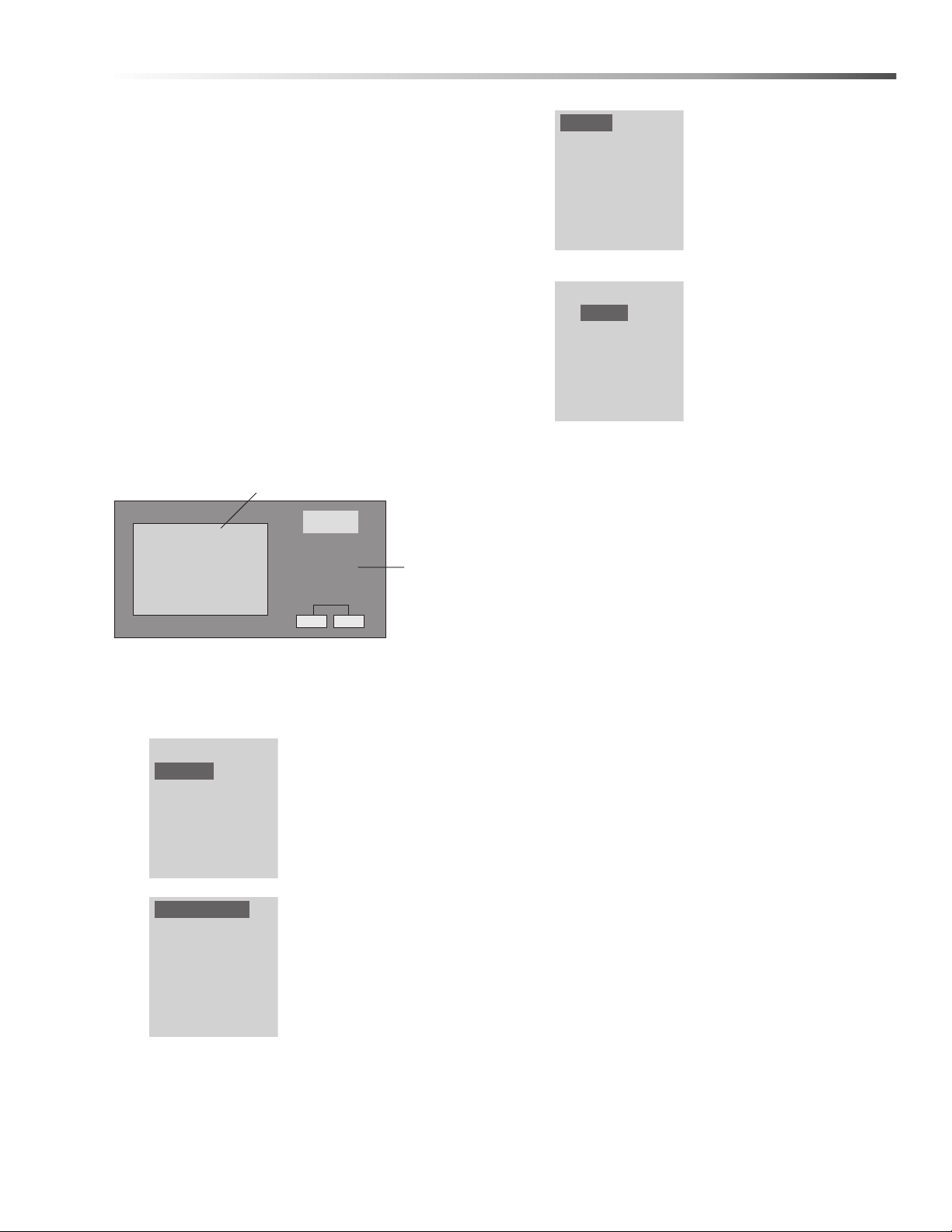

Stop

Program

Setup

Network

Diagnostics

Timer-1 1/1

T= 04:00h

Ta= 00:00

HOTSY 1800 GAS FIRED SERIES 8.916-993.0 - AL

S

WX

T

ESC OK

1:

0.. 123456789

1..0123456789

2..01234

Fig. 1

Display Screen