Aussie RAPTOR 12 Assembly instructions

July 2012 Raptor Electric Operator’s Manual 1

Australian Pump Industries

RAPTOR ELECTRIC

HYDRO-BLASTER

OPERATORS INSTRUCTION MANUAL

OPERATORS INSTRUCTION MANUAL

July 2012

ATTENTION: Operators must read this manual and understand it

completely before using the machine.

2 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

TABLE OF CONTENTS

Before attempting to operate your machine please read this Instruction Manual thoroughly following all

directions carefully. By doing so you will ensure safe operation of the unit and will enjoy long and trouble

free service from your heavy duty water blaster.

WARRANTY COVERAGE

The Aussie Eco-Clean Raptor has a two year warranty from date of purchase. This warranty covers any defect which occurs due to

faulty workmanship or material under normal use. Please keep your receipt as proof of purchase. This warranty specifically

excludes the following:

Damage resulting from debris or mineral deposits contained within the water supply to the machine.

Leaking hoses when the outer cover of the hose has been abraded or the hose has been kinked.

Damage to o-rings and valves, etc. caused by the use of cleaning chemicals or compounds.

Replacement of parts damaged due to fair wear and tear.

Misuse, negligence, alteration, accident or breakage.

Failure of the machine due to lack of normal maintenance services (The owner is responsible for the performance of

regular maintenance services, as specified in the Operator's Manual).

Damage and/or progressive damage caused by the failure to inform Australian Pump Industries Pty Ltd, or the closest

Authorised Australian Pump Agent or Distributor, within seven days of the defect becoming apparent.

Repair or modification by an unauthorised service person.

Australian Pump Industries Pty Ltd specifically excludes from warranty responsibility any consequential loss or damage

including on-site servicing, loss of time, loss of use of the machine, hire costs of a replacement machine or

inconvenience..

Where possible return faulty goods to the place of purchase. No products can be returned to us without prior permission.

The reason for return must be clearly stated.

N.B. Warranty is not transferable to third parties in the event of sale of the machine within the warranty period. Please

note that any parts used in warranty repairs are guaranteed for a period limited by the original warranty of the parent

product.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement

or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

The benefits under the Aussie Pump warranty are in addition to other rights under Australian Consumer Law.

Safety First Page 3

Specifications Page 3

Safety Precautions Page 5

Personal Protective Equipment Page 6

Operator’s Hand Signals Page 7

Assembly & Operating Instructions Page 8

Troubleshooting Page 11

Accident Reporting Page 12

Emergency Medical Information Page 13

Spare Parts List Page 14

Warnings Page 15

Daily Checklist Page 15

Monthly Service Page 15

Grit Blaster Head Set Up Instructions Page 10

July 2012 Raptor Electric Operator’s Manual 3

Australian Pump Industries

SAFETY FIRST

WARNING: To comply with Australian and New Zealand standards, operator’s of 5000psi machines and

larger need to complete operational and safety training courses and be duly certified in order to comply with

Occupational Health & Safety requirements.

ATTENTION OPERATOR

Please read the Operating and Safety Instructions in this manual thoroughly before using your Aussie

Raptor water blaster. Please note that safety procedures must be followed carefully. Non-compliance can

result in severe injury or even death.

SAFETY CLOTHING

Wearing protective clothing is essential for the use of B-class machines (5000psi and above). Eye

protection, gloves, body protection, steel capped boots and ear protection equipment are essential. For

details see page 7.

WATER BLASTING OPERATION

While using the Aussie Predator, take special care to ensure the gun and nozzle are never pointed at any

person or animals. Severe injury or death may result. For details and other warnings see page 5.

BACTERIA WARNING

In the event that some person or persons may be sprayed by high pressure water, it is important medical

personnel be advised as unusual infections with microaerophilic organisms can occur. For details see

Emergency Medical Information page 14.

SPECIFICATIONS

Performance Raptor 12 Raptor 16

Stock code ABRAPTOR/12EMOT ABRAPTOR/16EMOT

Pump pressure psi 7,300 (500 BAR) 7,300 (500 BAR)

EWP with turbo psi 12,000 12,000

Flow lpm 12 16

Motor Phase

Three phase Three phase

Power kW 4 pole, 12.5 4 pole, 15

Pump speed rpm 1450 1450

Pump type Penta Penta

Pump Model GHC12/50S GHC16/50S

Nozzle size 020 025

Accessories - Hose 10M 1/4” 1,000 BAR 10M 1/4” 1,000 BAR

Gun RL84 RL84

Lance RL800 RL800

Nozzle type Laser cut Laser cut

Weight kg 120 120

Boxed dimensions LxWxH (mm) 1000 x 720 x 820 1000 x 720 x 820

4 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

ACCESSORY INFORMATION

Ensure that all accessories are rated to 7,300 psi (500 bar) before using with the Aussie Raptor.

Suitable accessories available from Australian Pump Industries;

1) Aussie CTN500-020 (12 LPM version) or CTN500-025 (16 LPM version) 500 bar rated Turbo Master

turbo head. (1/4”M to 1/2” M nipple required to fit to lance.) Also available as a complete kit with lance,

gun, nozzle & nipple to allow quick coupling to hose (CTN500-_ _ _GLK)

2) Aussie Grit blast Kit

TPS450 500 bar grit blast head, 1/4” F BSP (C4700.18)

Probe 580mm, 20mm hose barb (C4604.01)

Note: Available as a complete kit with lance, gun, nozzle & nipple

to allow quick coupling to hose (TPS450/_ _ _GLK).

3) Aussie 500 bar gun, lance & shoulder rest.

RL84 500 bar spray gun, 1/2” F BSP (MPA30540000)

RL800 500 bar s/s 800mm single lance, 1/2”M (MPA30500080)

RL1250 500 bar s/s 1250mm single lance, 1/2”M (MPA30500092)

Shoulder rest, 300mm (MPA30501921)

HIGH PRESSURE WASH DOWN

The Aussie Raptor can be used for any high pressure water blasting application in construction, mining,

ship cleaning, dry docks, graffiti removal or for any other difficult task.

HIGH PRESSURE PISTON PUMPS

Your high pressure Udor pumping system is the heart of your water jetter. The pump has been specially

designed to be used with cold water (max 60ºC) for high pressure wash down applications. Your high

pressure Udor piston pump is designed to move a certain amount of water per revolution by its three solid

ceramic pistons.

High pressure is created once the pump outlet is restricted with a nozzle. All high pressure outlet

connections, hosing and equipment is rated over and above the maximum operating pressures of the

pump.

Please do not alter any valving on your pump; altering will void all warranty. For any malfunction of the

high pressure pumping system, please contact Australian Pump Industries or the Distributor you purchased

the unit from.

Because of safety/danger hazards with high pressure systems, only use approved high pressure hosing

and components when replacing or repairing your Raptor. For guidance on this, please contact Australian

Pump Industries or the Distributor you purchased the unit from.

Once wash down nozzles have worn, pressure loss will occur. Replacement of nozzles is necessary to

maintain constant and maximum efficiency of your Raptor. Using worn nozzles will reduce unloader valve

service life.

July 2012 Raptor Electric Operator’s Manual 5

Australian Pump Industries

WARNING… Do Not Alter Pressure Setting

Altering the high pressure unloader device and safety valve may result in severe injury or death. Warranty

will be void if any high pressure valve equipment has been altered by non-qualified staff. Over-speeding or

over-pressurizing of the pump system is dangerous and can severely reduce the operating life of the

machine. It may also result in injury or death!

SAFETY PRECAUTIONS - IMPORTANT

1. Never direct the spray jet at any person or animal.

2. Never direct spray jet at any surface that may contain asbestos material.

3. Never hold a finger over the high pressure nozzle.

4. Never direct the spray jet at the machine itself or any electrical equipment.

5. After use release the pressure in the high pressure hose by operating the pistol

trigger.

6. Electric cables should not be left in a position where water can come into contact

with the electric cable. Always keep electrical connections dry and off the ground

7. When not in use always switch off the engine and disconnect from water supply.

8. Certain components become very hot when in use. Switch off the blaster and

ALLOW TO COOL before touching.

9. Do not attempt any mechanical repair. If you have a problem with your machine

contact your local dealer or Aussie Pumps service division, phone 02 8865 3500

10. Never supply any liquid other than clean water to the water inlet.

11. Never pull the high pressure hose if it has formed kinks or nooses. Never pull the

hose over sharp objects.

12. Use only chemical cleaning agents (detergents) approved for power washing when

using the chemical injection facility.

13. Never use the chemical injection facility to introduce solvents, e.g. paint thinners,

petrol, oil, etc.

14. Do not attempt to disconnect any hose or coupling with pressure still in the hose.

15. Do not operate the machine whilst standing on ladders, use a platform tower or

scaffolding.

16. Children should not be allowed to use the machine.

17. We recommend the use of safety goggles when using the machine, particularly with

the sand blasting attachment, or any application where loose particles of stone or grit,

etc, may be blown around by the high pressure spray.

18. The electrical power voltage must agree with the voltage specified on label on base of

machine. [Note: Improper connection will damage machine and void warranty.]

19. The machine must be grounded. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with all local codes and

ordinances.

20. Do not modify the plug provided with the machine. If plug does not fit your outlet

have a proper outlet installed by a qualified electrician.

21. Do not use any type of double adaptor or multiple socket power board with this

product.

22. Do not touch plug with wet hands.

23. To avoid damage to cable do not roll, crush or pull it. The power cable may only be

repaired or replaced by an trained electrician.

24. Disconnect the plug from power supply and relieve pressure to hose before

attempting any work on the machine.

6 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

PERSONAL

PROTECTIVE

EQUIPMENT

‘Wear protective clothing’’

General

Appropriate personal protective equipment should be worn where:

1. hazards cannot be otherwise prevented or suitably controlled, e.g. by

engineering or administration controls, total enclosure or substitution;

and/or

2. complete protection is essential, e.g. in some occupational environments

with uncertain levels of hazards.

The provision and use of personal protective equipment does not reduce or

replace the need for proper Occupational Health and Safety prevention

measures, such as engineering or administrative controls to be undertaken.

Recommendations of such preventative measures should always be fully

explored before considering issue of personal protective equipment. Where

personal protective equipment is issued, instruction and training should be

provided regarding its correct use and maintenance.

Head Protection. Where appropriate suitable

head protection complying with AS/NZS 1808

should be worn.

Eye Protection. Eye protection complying with

AS/NZS 1337 (adequate for the purpose and of

adequate fit on the person) should be worn at all

times when in the vicinity of water blasting

operations. Where liquid is liable to cause eye

damage, full visor and goggles are recommended.

Body Protection. All persons should wear

suitable waterproof clothing complying with AS

3765.1 or AS 3765.2 as appropriate, having

regard to the type of work being undertaken.

Liquid or chemical-resistant suits should be worn

where there is an assessed risk to health or of

injury that can be prevented by such equipment.

Hand Protection. Adequate hand protection

complying with the recommendation/s of AS/NZS

2161.2, AS/NZS 2161.3 or AS/NZS 2161.5 should

be worn when there is an assessed risk of injury

that can be prevented by such equipment.

Foot Protection. All persons should wear

appropriate occupational protective footwear

complying with AS/NZS 2210.2. A metatarsal and

lower leg guard should be used by water blasting

operators where it is assessed that the risk of foot

injury can be prevented by such equipment. AS/

NZS 2210.1 provides guidance for the selection of

footwear.

Hearing Protection. Suitable hearing protection

complying with AS 1270 should be worn at all

times when the noise levels exceed limits set by

regulatory authorities. All personnel and operators

should receive instruction in the correct use and

maintenance of hearing protectors so that noise

exposure lies within the limits as recommended by

the regulatory authority.

July 2012 Raptor Electric Operator’s Manual 7

Australian Pump Industries

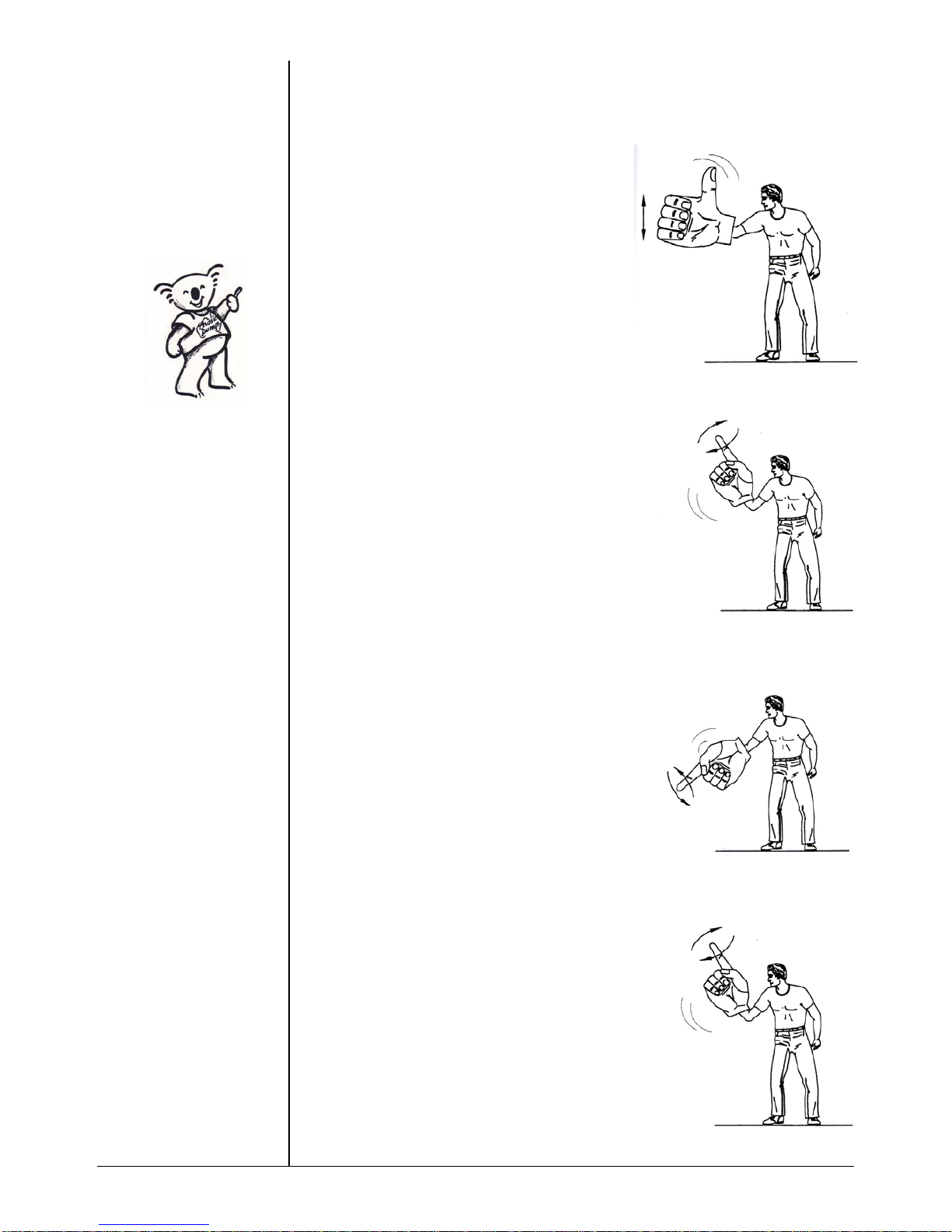

OPERATOR’S

HAND

SIGNALS

‘Aussie Eco-Clean …

Safety First!’

This section provides a set of hand signals for communication when carrying

out water blasting operations.

Pressurise System.

Thumb pointing upwards, the rest of the

hand closed. From the shoulder height

the arm moves up and down.

Raise Pressure. First finger pointing up,

the rest of the hand closed. The hand is

moved in a circular motion.

Lower Pressure. First finger pointing

down, the rest of the hand closed. The

hand is moved in a circular motion.

Depressure System. Form a fist. Move

the arm back and forth at shoulder height.

8 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

STANDARD EQUIPMENT

Before proceeding with assembly of your new Aussie Eco Clean blaster, check that all parts listed below

are included.

1 Gun handle assembly and high pressure hose

1 Lance and nozzle assembly

1 Inlet hose connector assembly

HIGH PRESSURE SETTING

The high pressure pump is factory set to operate at its rated pressure. DO NOT ADJUST.

Tampering with the pressure regulator will void warranty and can be dangerous.

WARNING:

If pressure drops off, check nozzle for wear. Nozzles should be replaced on a regular basis (every month

for machines in regular use, every 3 months for machines used intermittently. Using the machine with the

incorrect nozzle size or worn nozzle will void warranty and can be dangerous to the operator.

ASSEMBLY AND PREPARATION FOR USE

Check the oil in the (A) pump

With the machine on a level surface the oil level should be level

with middle of side oil plug or sight glass. Do not overfill. If

necessary top up with SAE30W pump oil.

Do not mix different grades of oil as this may affect the

machine's performance.

If alternative oil is used first empty out existing oil by unscrewing

drain plug in bottom of machine.

NOTE: Read this handbook thoroughly and follow all directions carefully before you begin using the

machine

Power lance

To assemble the lance, insert section 'B'

into section 'A' and screw together.

High pressure hose

Connect the high pressure hose to the threaded water outlet on the side of the

machine.

Water supply hose

Use a good quality hose (not supplied) of 13mm diameter and secure one end to the inlet hose connector

securely using worm drive clip. This connection must be tight to avoid leaks.

Water supply is by means of mains supply. Secure the free end of the hose to your tap using a suitable

tap adaptor (not supplied, available through all good hardware and garden supplies stores).

NOTE: A pump filter has been fitted to prevent the ingress of grit to the pump, ensure filter is clean before

using machine. This hydro-blaster can be used with cold or hot water up to 60ºC

A

A

B

July 2012 Raptor Electric Operator’s Manual 9

Australian Pump Industries

OPERATING INSTRUCTIONS

The power washer is supplied with an amperage cut-out switch. Do not adjust. Adjusting amperage cut-out

switch voids warranty.

SWITCHING ON MACHINE

1. Plug power cable into suitable power supply.

2. Turn on water supply. NOTE: Tap should be fully open.

2. Pull the trigger to expel air from the system. Water will trickle from the end of the lance when air is

expelled.

3. Start motor at amperage protection switch.

4. Check that there are no leaks in the line connections, pistol or power lance. Pressure begins when

the pistol trigger is squeezed.

SWITCHING OFF MACHINE

1. Turn switch to OFF position.

2. Turn off water.

3. Release pressure in spray gun by pressing trigger until water only drips from the spray head.

4. Release trigger on gun.

5. Press safety latch on gun. This locks gun trigger and prevents accidental triggering.

6. Unplug machine from power point.

7. Disconnect water supply hose from machine.

CARE AND MAINTENANCE

AFTER EACH USE

If there is a danger of freezing anti-freeze should be mixed with the flush water or the machine must be

completely drained. After the final flush stop the machine. DO NOT allow the machine to idle for more than

15 seconds. This is particularly important when there is a danger of freezing. Do not run for longer without

water supply.

STORAGE

Store the washer in an upright position, preferably drained of water if there is a danger of freezing (or fill

with anti-freeze).

SAFETY … IMPORTANT

EXCESS ATOMISED MOISTURE CAN ENTER SWITCHES & MOTOR CONNECTIONS AND OVER

TIME MAY CAUSE FAILURE

KEEP THE MACHINE OUT OF MOISTURE LADEN ATMOSPHERES

WARNING .... DO NOT RUN EXCESSIVE BY-PASS

SWITCH MACHINE OFF WITHIN TWO MINUTES OF CEASING OPERATION AS EXCESSIVE BY-

PASS CAN CAUSE HEAT BUILD UP IN PUMP & SUBSEQUENT DAMAGE. EXCESSIVE BY PASS

RUNNING VOIDS WARRANTY!!

10 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

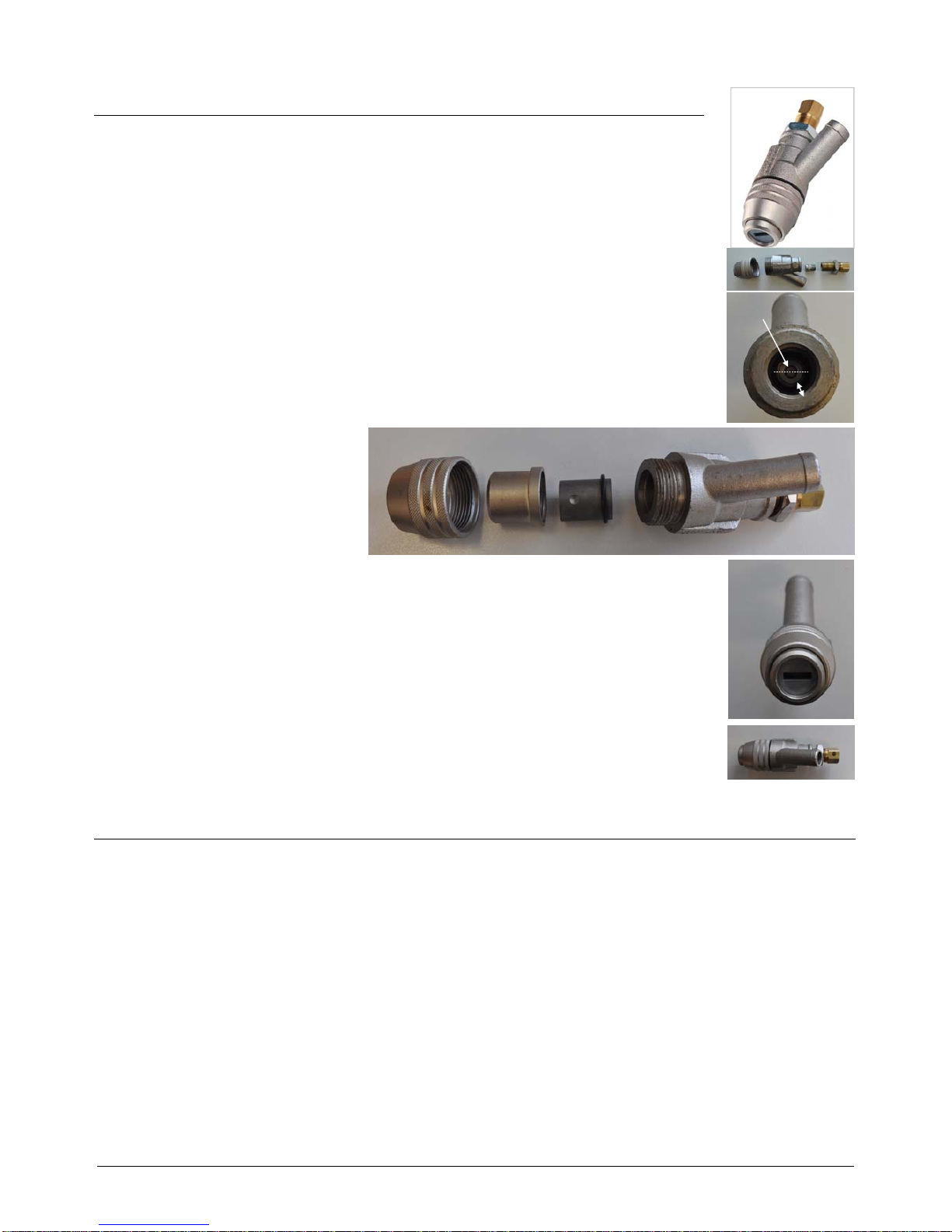

AUSSIE GRIT BLAST HEAD SET UP INSTRUCTIONS

(optional accessory)

Note: the Aussie Grit Blast head does not come with a nozzle. You will need a 15º

Aussie Laser Cut ’M’ series nozzle that suits the high pressure blaster the kit

will be used with.

1. Unwind the tail coupling and remove top of the blast head. Screw in the

nozzle to the tail.

2. Replace the tail and ensure that the tip of the nozzle is a minimum of 28mm

from leading edge of body and a maximum of 36mm. The fan spray from the

nozzle should be perpendicular to the sand intake tail. Mark the top side of

the hexagonal coupling for reference.

3. Line up the dimple in the ceramic nozzle perfectly with the sand intake tail

and hold in place with the holder. Screw down the head locking nut.

4. The fan produced by the two

nozzles must be aligned.

5. Connect grit blast head to hp

gun/lance and activate the gun

with the high pressure blaster

running. Check the fan jet leaving the nozzle is the full width of the slot.

Adjust by rotating hexagonal tail coupling, ensuring that the marked side of

the tail always finishes on top.

6. With the high pressure washer turned off, connect the sand hose to the sand

intake tail and secure with hose clips. Secure sand blast probe to other end

of the hose in the same way. The probe should be lodged into the sand bag.

WARNING: To reduce the risk of injury, always protect eyes and face with

goggles and mask, and hands and arms with heavy work gloves when

spraying abrasive materials.

GRIT BLAST INSTRUCTIONS

1. Connect and open the water supply line before starting the pressure washer.

2. Squeeze the gun trigger to bleed air as normal.

3. Turn on the pressure washer and squeeze the gun trigger to activate the spray.

CAUTION: Always test spray on a scrap of similar material first! The high pressure spray could

damage the surface if the grit blaster is held too close.

4. To determine best distance for grit blasting, start with the spray nozzle a metre away from the

surface and gradually move closer, frequently checking the surface for damage.

6. Always point the nozzle downward when not spraying. This prevents water from entering the sand

supply. If water does get into the sand supply hose, remove the probe from the sand, hold the gun

trigger open, and let the hose air dry. Always be sure the sand hose is dry before using.

7. Keep the sand covered to prevent the overspray from wetting the sand. Do not allow small pieces

of the sand bag to fall into the sand supply. A smaller piece could prevent the flow of sand.

Min 28mm

Max 36mm

Check angle of jet from

nozzle

Head locking nut holder ceramic piston with dimple

Sand intake tail

7,300 psi grit blast

head (C4700.18)

July 2012 Raptor Electric Operator’s Manual 11

Australian Pump Industries

MAINTENANCE, SERVICE AND SPARES

Your Aussie Raptor has been designed to give you long and trouble free service. If, however, having

carefully followed the instructions in this booklet, you have a problem which cannot be resolved by referring

to the Troubleshooting Guide below, or if you require spare parts or servicing, contact your local dealer or

Australian Pump Industries on Telephone No.: (02) 8865 3500.

FAULT CAUSE REMEDY

Pump running normally but

pressure low on installation Pump sucking air

Valves sticking, dirt in valves

Unloader valve seat faulty

Nozzle incorrectly sized

Worn piston packing

Check water supply and possibility

of air ingress

Check and clean or replace if

necessary

Check and replace

Check and replace

Check and replace

Fluctuating pressure Valves worn

Valves blocked

Pump sucking air

Worn piston packing

Check and replace

Check and clean out if necessary

Check water supply and air ingress

at joints in suction line

Check and replace

Pressure low after period of normal

use Nozzle worn

Suction or delivery

valves worn

Suction or delivery valves

blocked

Unloader valve seat worn

Worn piston packing

Cracked pistons as a result of

dry running

Check and replace

Check and replace

Check and clean if necessary

Check and replace if necessary

Check and replace if necessary

Replace pistons

Pump noisy Air in suction

Broken or weak suction or

delivery valve spring

Foreign matter in valves

Worn bearings

Excessive temperature of

liquid

Check water supply and

connections on suction line

Check and replace if necessary

Check and clean if necessary

Check and replace if necessary

Reduce temperature

Presence of water in oil Oil seal worn

High humidity in air

Piston packing worn

Check and replace

Check and change oil twice as

often

Check and replace if necessary

Water dripping from under pump Piston packing worn

Plunger retainer worn Check and replace

Check and replace

Oil dripping Travel plug in use on pump

Oil seal worn Replace with breather plug

Check and replace

TROUBLESHOOTING GUIDE

WARNING: CHECK OIL LEVEL IN PUMP REGULARLY

DO NOT OVERFILL

12 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

ACCIDENT

REPORTING

FOR

INDUSTRIAL

APPLICATIONS

Reporting. All accidents or injuries, whether resulting in “lost time” or

“no lost time” injuries, should be recorded in accordance with the

recommendations of AS 1885.1.

Incidents that result in “near misses” should also be recorded as a

means of providing a record of significant incidents that have the

potential to result in serious injury at the workplace, so appropriate

measures can be implemented to minimise or eliminate these potential

hazards.

Personal Injuries. In the event that a person is injured by the impact

of a water jet, the injury caused may appear insignificant and give little

indication of the extent of the injury beneath the skin and the damage

to deeper tissues. Although only a small hole may be present,

quantities of water may have penetrated the skin and entered the flesh

and organs causing serious injury.

Medical Recommendation. If an accident occurs where pressurised

water penetrates or appears to have penetrated the skin, medical

assistance should be sought immediately.

Immediate First Aid. Where medical examination is not immediately

possible (e.g. in remote situations), appropriate basic first aid

measures should be applied and the patient observed closely until

medical treatment is available.

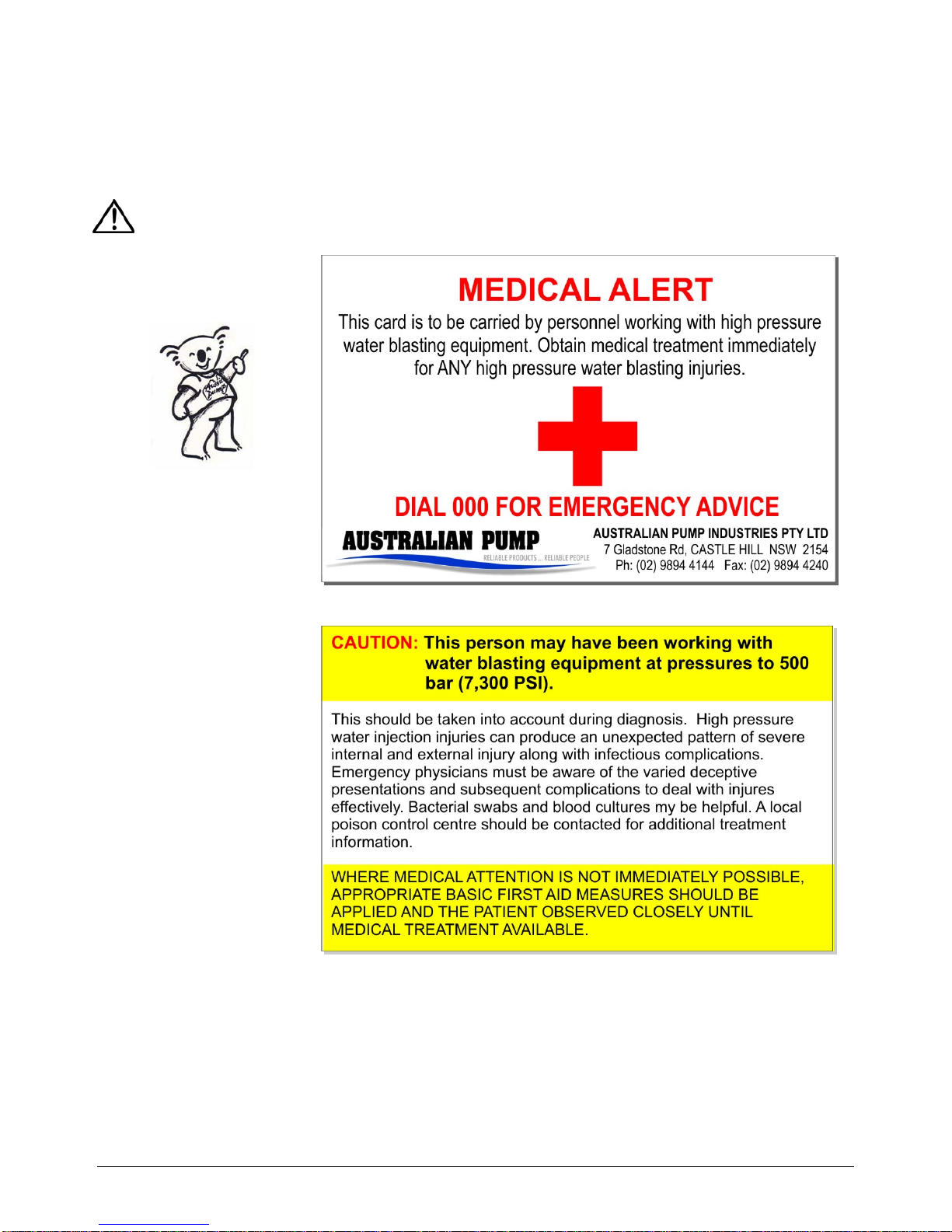

Medical Alert Card. All operators engaged in commercial and

industrial water blasting operations should carry out an immediately

accessible, waterproof medical alert card. This card should:

outline the possible nature of injuries and post-accident

infections that can be caused by high pressure water

blasting;

provide details of immediate first-aid treatment until

medical treatment can be arranged; and

provide the name or names of medicos (and contact phone

numbers) who should be contacted for expert medical

advice for the treatment of high pressure water blasting

injuries.

In addition, the card may also:

identify the worker; and

outline medical information about the worker; e.g. blood

type, allergies and conditions, such as asthma.

July 2012 Raptor Electric Operator’s Manual 13

Australian Pump Industries

EMERGENCY

MEDICAL

INFORMATION

IMPORTANT

‘Aussie Eco-Clean …

Safety First!’

Immediate hospital attention should be given to personnel who sustain

equipment related injuries while operating the system. In such cases, it is

vital that medical personnel be apprised of all facts relevant to such injuries.

Therefore, all operating personnel should be provided with waterproof

emergency medical tags or cards describing the nature of their work and

the possibility of injury inherent in the use of a water blasting device. The

tag or card should also bear the following standard notice:

14 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

ITEM NO. DESCRIPTION RAPTOR 12 RAPTOR 16

A 700 BAR GAUGE AGAUGE700BAR AGAUGE700BAR

B UNLOADER VALVE (VB53) MPA60147000 MPA60147000

C SAFETY VALVE BVS500 BVS500

D Y STRAINER AYSTRAINER AYSTRAINER

E THERMAL DUMP VALVE MPA60063070 MPA60063070

F ON/OFF SWITCH ASWITCHASSY25A ASWITCHASSY36A

G 13” WHEEL A400016 A400016

H MOTOR A140060T025 A140060T026

I FRAME AFRAMESCERAPTOR AFRAMESCERAPTOR

J 8100 PSI GUN (RL84) MPA30540000 MPA30540000

K SS SINGLE LANCE (RL800) MPA30500080 MPA30500080

L HP NOZZLE C1915020M C1915025M

N 10MTR HP HOSE BLUE ¼”500BARHOSE ¼”500BARHOSE

O UDOR PISTON PUMP 7,300 PSI GHC 12/50S GHC 16/50S

PUMP ASSEMBLY DIAGRAM – (GHC 12/50 & GHC 16/50)

Replacement Parts

Kit No. Part Number Description

BKIT 85 606185 Piston kit

BKIT 152 606186 Valve kit

BKIT 87 606187 Brass ring kit

BKIT 88 606188 Water seal kit

1205.45 Piston (3 required per pump) price each

Breathers & Sight Glass

GHC & GHD series 162505 Breather

1603B8 Sight glass

A

H

E D

C

B

O

G

F

July 2012 Raptor Electric Operator’s Manual 15

Australian Pump Industries

WARNING

OVERSPEEDING

Do not operate machine at over 1450rpm.

Over speeding can cause serious pump damage.

EXCESSIVE BYPASS

Do not run on excessive bypass. Switch machine off within five minutes of ceasing operation as

excessive bypass can cause heat build-up in pump and subsequent damage. Excessive bypass

running voids warranty.

HIGH PRESSURE SETTING

The high pressure pump is factory set to operate at its rated pressure. DO NOT ADJUST. Tampering

with the pressure regulator will void warranty and can be DANGEROUS.

CHECK NOZZLE MONTHLY

If pressure drops off, check nozzle for wear. Nozzles should be replaced on a regular basis (every

month for machines in regular use, every three months for machines used intermittently). Using the

machine with the incorrect nozzle size or worn nozzle will void warranty and can be DANGEROUS to

the operator.

PRESSURE CLEANER DAILY CHECK LIST

IMPORTANT:

Check pump oil level (A)..

NB. Pump oil level should be level with the middle of the side oil plug or

sight glass. Do not overfill. If necessary, top up with SAE30W oil.

Do not mix different grades of oil as this may affect the machine’s

performance. If alternative oil is used, first empty out existing oil by

unscrewing drain plug in bottom of machine.

Check nozzle for wear.

Check all high pressure components for leaks:

(a) Gun/Lance. (b) HP hose. (c) All fittings.

Check water filter and clean if necessary.

Check unloader, safety valve and thermal dump for leaks.

Warning: Ensure top mounted breather plug is kept clean. Blocked breather can result in pressurisation

of the oil chamber and blown seals.

THREE MONTHLY REGULAR SERVICE

All professional machines need to be thoroughly serviced every three months. The service

involved should include the motor manufacturer’s recommendations (see separate Manual) and

the following:

Change pump oil

Check filter for foreign debris.

Check unloader, safety valve and thermal dump for leaks.

Check all HP components for leaks: Gun/Lance, HP hose and all fittings.

Replace nozzles.

16 Raptor Electric Operator’s Manual July 2012

Australian Pump Industries

WEAR PROTECTIVE GOGGLES AND CLOTHING!

RELIABLE PRODUCTS … RELIABLE PEOPLE

AUSTRALIAN PUMP INDUSTRIES

7 Gladstone Road, Castle Hill NSW 2154 PO Box 6164, BHBC NSW 2153

Ph (02) 8865 3500 Fx (02) 9894 4240

Aussie Pumps runs

Safety Awareness Training for operators

of Aussie Class B Hydro-Blasters.

Call Aussie for details & get your operators

certified!

Comfort, Function and Safety - Pro-Operator Personal Protective Clothing

Available from Aussie Pumps … comfort combined with high pressure protection (up to 7,500 psi)

This manual suits for next models

1

Table of contents

Other Aussie Pressure Washer manuals

Popular Pressure Washer manuals by other brands

LIFAN Power USA

LIFAN Power USA Pressure Storm 2100 operating instructions

Annovi Reverberi

Annovi Reverberi BLUE CLEAN 1003 Original instructions

Craftsman

Craftsman 580.76201 owner's manual

Kärcher

Kärcher K 2000M manual

Hotsy

Hotsy 1260SS Operator's manual

STEELE PRODUCTS

STEELE PRODUCTS SP-WG250V owner's manual

Kärcher

Kärcher K 5.86 M Operating instruction

Craftsman

Craftsman 580.752271 Operator's manual

Campbell Hausfeld

Campbell Hausfeld PW1345 Assembly instructions and parts list

AR Blue Clean

AR Blue Clean AR120 Assembly, care and use instructions

Mac Afric

Mac Afric HCLEAN150 Operator's manual

Worx

Worx WG607 manual