AUSTHEAT AHT860 User manual

Instruction Manual

FREESTANDING ELECTRICAL HOTPLATE & TOASTER

AHT860

Version 5

2

CONTENTS

Product Features 2

Specifications 2

Parts Included 2

Safety Instructions 2

Cleaning & Maintenance 3

Installation 3

Electrical Connection 4

General Information 4

Control Layout 5

Cooking/Heating Zones 5

Operation 6

Workstation Layout 6

Safety 7

Troubleshooting 7

Thermal Cut-outs 9

Compliance 8

Spare Parts 9

Circuit Diagram 10

Exploded Views Error!

Bookmark not defined.1

Warranty 17

PRODUCT FEATURES

High Temperature Capacity

Durable Stainless Steel Elements

12mm Steel Hotplate

Adjustable Legs & Rear Castors

Easy Cleaning Grease Over-Spill Box

Digital LED Temperature Display

Independently Controlled Grill

Cook/Idle Selector Switches

SPECIFICATIONS

Model

Power

(400VAC)

Size (mm)

Kg

W

D

H

AHT860

12.5KW

590

855

1075

120

PARTS INCLUDED

Electrical Hotplate & Toaster (AHT860)

Instruction Manual

Any damage to the machine as a result of

freight must be reported to the Freight

Company and to the agent responsible for the

despatch of machine within 24 hours of receipt.

No claims will be accepted after this period.

SAFETY INSTRUCTIONS

Read all Instructions and safety warnings prior to

use. Keep user manual for future reference.

Service and repair should only be performed by

qualified technicians who have read and

understood this manual.

Personnel must be trained prior to operating

this appliance.

This product is suitable for commercial use only.

This machine should not be operated by

persons (including children) with reduced

physical, sensory or mental capabilities, or lack

of experience or knowledge, unless they have

been given supervision or instruction concerning

the safe use of the appliance by a person

responsible for their safety.

Keep out of reach from children.

Avoid contact with the exterior of this machine

as surfaces can get hot.

Do not position appliances where hot surfaces

may be accidently touched.

The machine should be disconnected from all

power and allowed to cool before cleaning or

servicing.

Regularly inspect the supply cord/plug and

discontinue use immediately if damage is found.

3

Return to manufacturer or authorised repairer

for repair prior to use.

This machine contains no user-serviceable parts.

Austheat®, one of our agents, or a similarly

qualified person(s) should carry out repairs.

Keep cord away from heated surfaces.

Do not remove any cover panels from the

machine.

Austheat® will not accept liability if:

Non-authorised personnel have tampered

with the machine

The instructions in this manual have not

been followed

Non-original spare parts are used

There is any damage to the unit

These units should NOT be left unattended

during operation.

During use, these units heat up and can cause

damage or bodily harm if not operated

correctly. Ensure proper signage is in place to

reduce the risk of any hazards.

CLEANING & MAINTENANCE

Switch off at mains switch and allow to cool

before cleaning.

CAUTION: Steel cutting processes used in the

construction of this machine can result in sharp

edges. Avoid contact with sharp edges during

cleaning and maintenance.

Do not clean with the use of a water jet or

immerse in water.

Do not use caustic or abrasive cleaning products

as they will damage the machine.

Empty/clean grease box regularly

Regular cleaning will prevent a build-up of oils

and keep the machine looking new.

No part of this machine (with the exception of

the grease box) should be immersed in water.

Wipe all surfaces of the machine with warm

soapy water using a damp non-abrasive cloth.

WARNING: Some cleaning agents can damage

stainless steel or the polycarbonates/plastics

used in switches and pilot lights. Only ever use

soapy water as a cleaning agent.

Ensure the unit is switched off before any

servicing or inspection is carried out.

Servicing and maintenance should only be

carried out by a qualified technician. It is

recommended that inspections be carried out

annually to ensure the appliance is in line with

changing standards.

INSTALLATION

Remove all packaging materials, tape, and any

protective plastic from the machine. Remove

any glue residue from the protective plastic or

tape using citrus cleaner.

Place the product on a firm, level surface in the

desired position. Do not install within 300mm of

flammable materials. The AH860 has a rear

spacer to set a minimum distance from non-

flammable walls that must never be removed or

modified.

A minimum distance of 500mm above the

cooking plate must be kept clear of any

obstruction. Do not obstruct or in any way close

off the front of the machine.

Install at least 100mm from materials and have a

100mm air gap at the front & rear of the unit. If

the unit is used near combustible material,

common sense should be applied to deem

sufficient distancing.

Consult national standards that outline the

positioning, spacing and ventilation before

installation.

4

If this appliance is located in a row of appliances

(e.g. Austheat® Fryer), ensure that adjacent

machines do not restrict air flow. Failure to

provide adequate air flow could result in the

tripping of the thermal protective circuits within

the unit.

Consideration should be given to securing the

unit or limiting mobility if the unit is hard-wired.

Consult appropriate standards to ensure

compliance with all requirements.

We recommend the use of an RCD (Residual

Current Device) rated at no less than 30mA for

circuit protection. If an RCD is used to protect

multiple appliances, ensure the RDC is

appropriately rated so as to allow up to 30mA

leakage current for this unit.

CAUTION: Do not attach any other items,

machines or brackets to these units as any such

alterations may change the thermal properties

or safety aspects of these machines and will void

any warranty.

CAUTION: In order to avoid inadvertent re-

setting of the internal thermal cut-outs, ensure

the appliance is not wired through an external

switching devices (such as a timer), or any device

that is regularly switched on and off by the

utility.

ELECTRICAL CONNECTION

Before connecting the machine to the power

supply, ensure that all switches are in the OFF

position.

A licensed electrician must install this unit to

comply with national installation codes and

regulations. Means for disconnection from

supply must be incorporated in the fixed wiring

in accordance with the wiring rules.

WARNING: UNIT MUST BE EARTHED

We also advise that this unit, and any other

stationary appliances, be connected to a

equipotential bonding grid to eliminate any

differences in electrical potential within the

kitchen,

WARNING: If the electrical mains supply cabling

is damaged, the machine must not be used until

a qualified person has replaced the cabling and

deemed the machine to be functioning properly.

There are two main supply connection points in

the unit. The first is through the lower back

panel at the rear of the unit. The second

connection point is through the base of the

machine at the rear. Both connection points

have three choices of holes for the cable to pass

through. Protection must be given to the mains

cables if they are positioned such that they can

contact the hot surfaces of the unit. A suitable

cable gland is required for the cable to pass

through.

Each hotplate must be connected to an

adequately protected power supply and an

isolation switch mounted adjacent to, but not

behind the Hotplate. This switch must be clearly

marked and readily accessible in case of fire.

GENERAL INFORMATION

This appliance is designed as a floor mounted

unit. The controls are located along the front

display panel with the primary ON/OFF switch

located on the lower control panel.

These units generate an extreme amount of

heat, which has the capacity to adversely affect

some components within the machine. To

prevent any damage, and to provide an air

curtain along the grease box guide assembly

and upper display panel, these units are fitted

with internal fans.

In the event of a failure of an internal fan, a

safety thermostat will operate and cut power to

the machine, the result being a sudden loss of

power (pilot lights will no longer be lit).

If such a shutdown occurs, leave the unit to cool

for 30 minutes and turn the unit off and back on.

5

This electrical reset will allow the unit to begin

operating again. If the unit shuts down a

second time this is confirmation that the unit is

overheating and you should call Austheat®or

your local electrician for service.

A strong Pest-Eradication program should be in

place in any kitchen before installing this or any

similar machines.

WARNING: Pouring cold water onto a hot plate

will cause spitting and may result in damage to

the plate.

If required, the unit can be moved by lifting

from underneath the front, just above the door,

and pulling it along on the rear castors.

CONTROL LAYOUT

WARNING: THE ON/OFF SWITCH DOES NOT PROVIDE COMPLETE ISOLATION –REFER TO

“ELECTRICAL CONNECTION”.

CONTROL DESCRIPTION

Both the hotplate and toaster have an idle/cook function, meaning you are able to have 2 pre-set

temperatures to switch between. Simply set the thermostats on the lower control panel to your desired

cooking or idle (non-peak cooking period) temperatures and switch between the two during busy

periods (or quiet periods) to save energy.

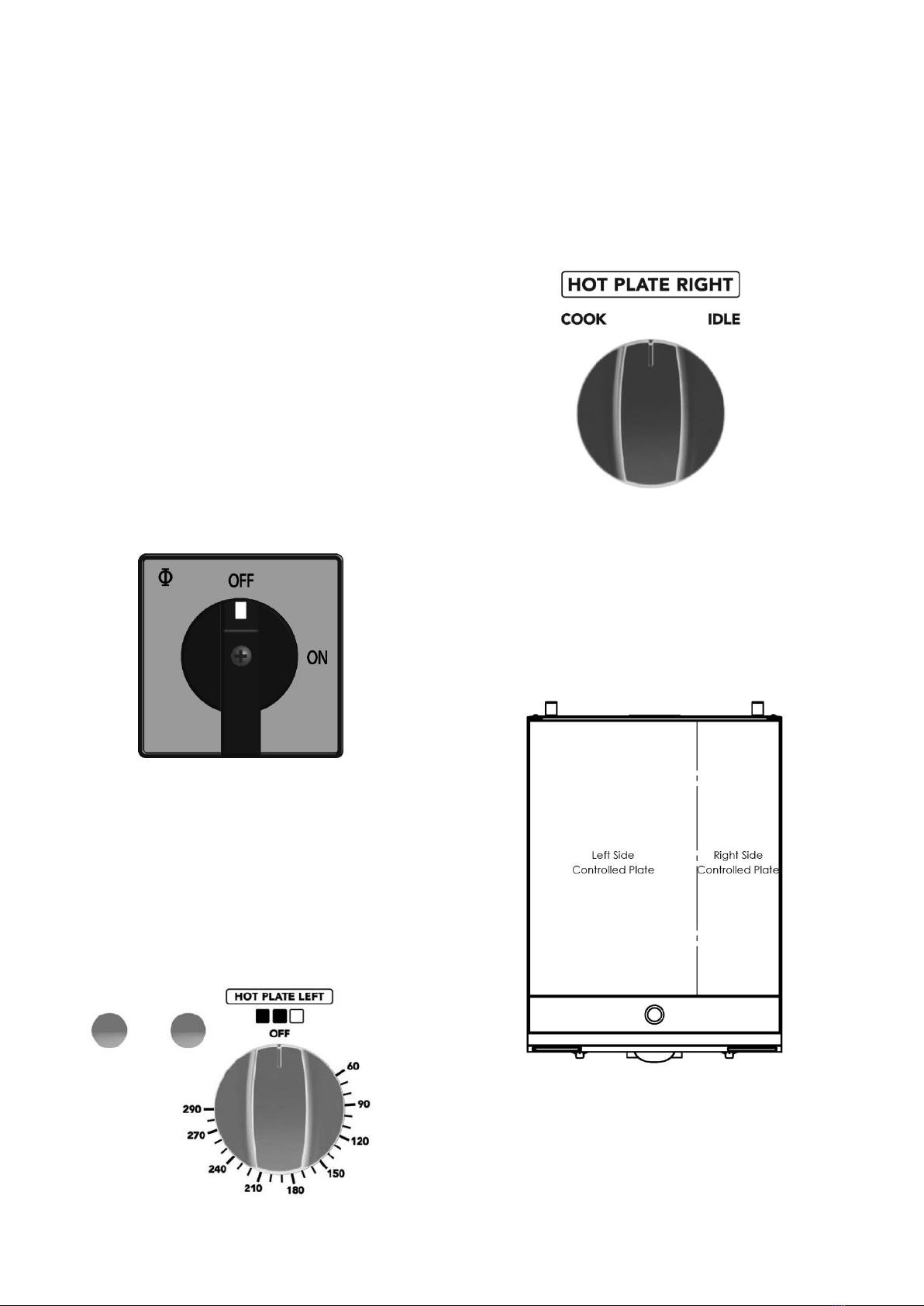

TOP DISPLAY PANEL CONTROLS

Cook/Idle

switch –Left

Heating Zone

Cook/Idle

switch –Right

Heating Zone

Cook/Idle

switch –

Toaster

Thermometer

Displays

Lower Control Panel

Left Zone

Thermostats

Right Zone

Thermostats

On/Off

Switch

Toaster Controls

Grease Tray

6

CONTROL DESCRIPTION

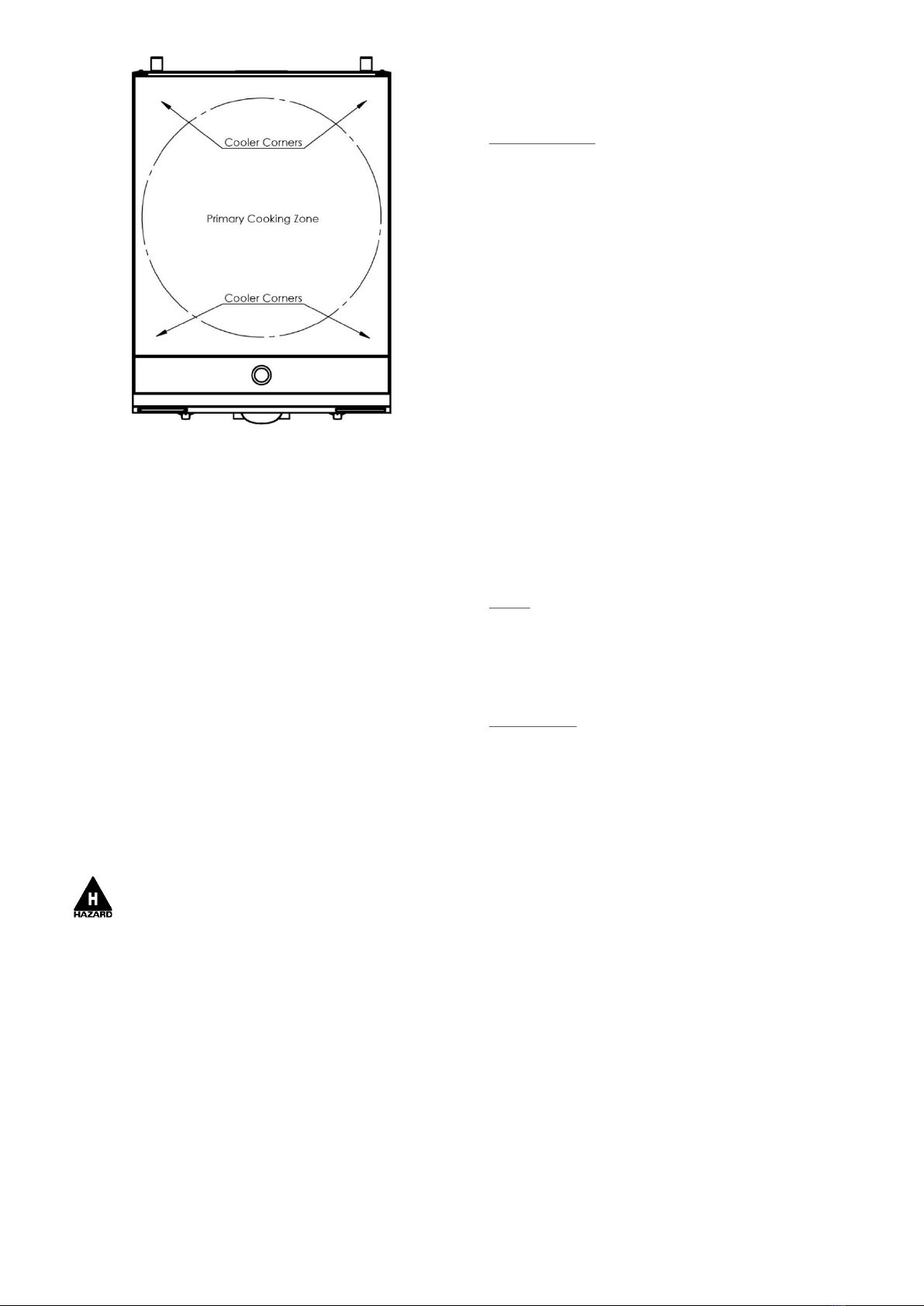

This appliance utilises a hotplate that is able to

heat either the left side, right side or both sides

during operation. The three elements heating

the hotplate are split so that the left thermostat

controls the 2 left elements, and the right

thermostat controls the element on the right

hand side.

Both thermostats have a maximum temperature

of 290C as seen below.

The primary ON/OFF switch is located on the

lower control panel which, when turned in the

“ON” position, will illuminate the green pilot

light located on the upper display panel and

signal that the unit is operational.

While the green pilot light will be constantly

illuminated during operation of this appliance,

the 2 orange pilot lights connected to either the

left or right hand side controls will cycle on/off

as the thermostat supplies power to the

elements to maintain the predetermined

temperature.

The Cook/Idle Switch allows you to quickly

switch between 2 predetermined temperatures

set by the lower thermostat.

Each thermostat clearly labels which operating

“zone” it controls, and matches up with the

relevant Cook/Idle Switch.

COOKING/HEATING ZONES

As previously mentioned, the hotplate is not

split evenly, with the left hand side elements

heating 2/3rd of the hotplate and the right hand

side elements heating the remaining 1/3rd (as

seen in the pictorial below).

The hotplate is designed in such a way that heat

pools in the centre of the hotplate, with the

front and rear corners being comparatively

cooler. This allows the user to balance the

cooking times of multiple products/foods that

require different temperatures or times to cook.

7

TOASTING CONTROLS

The toaster element is controlled by the two

energy regulators on the lower control panel on

the right hand side. These are wired to a

“Cook/Idle” switch on the upper display panel

which allows switching between the two energy

regulators.

It is suggested that the “Cook” energy regulator

be set between 4-HIGH, and that the “Idle”

energy regulator be set to 2. This will allow the

elements to stay warm while using minimal

power and will speed up the recovery time

when the “Cook” setting is later selected. This is

only a guide and only personal use will dictate

the best settings for your particular bread.

Always use gloves when handling the

toast rack during operation.

TEMPERATURE DISPLAY

The temperature displays can be seen on the

display panel, located on the front of the

hotplate on the right hand side. It displays the

current approximate temperature if the

appropriate hotplate “heating zone”.

In the event of an overheating situation, the

temperature displays will also be shut down and

will not re-illuminate until the machine is turned

off and back on again (after cooling down).

OPERATION

SEASONING

Before cooking for the

first time

the hotplate

need to be seasoned as follows.

Remove the paper from the plate and wipe

off excess fat.

Brush the plate liberally with frying oil and

cover the surface with a layer of salt.

Set the thermostat to a temperature of

around 180and heat for 25 minutes.

Allow the oil and salt to cool, and then

remove it carefully without scratching the

surface.

Brush the plate with oil again and re-heat

until the oil is burnt in. This will form a skin

on the surface of the plate.

Re-oil the surface once again.

Your Hot Plate is now ready for use. Be sure to

never clean the hotplate using cleaning agents

(only soapy water) as this can strip back the

seasoning layer that has formed and can

damage the plate.

COOKING

1. Rotate the main switch to the “ON” position,

the green pilot light will illuminate, indicating

power is on.

2. Rotate thermostats to desired cooking/idle

temperature. Once set, the amber pilot light

associated with each side will illuminate until the

temperature is reached and will turn off.

3. Once the amber pilot light switches off,

cooking may commence (temperature has been

reached). Notice the amber pilot light will cycle

on/off in sync with when the thermostat

energises the elements.

4. When finished with the appliance, ensure

both thermostats are set at “OFF” and primary

switch is in the “OFF” position.

8

TOASTING

WORKSATION LAYOUT

These units are likely to be installed next to

similar sized machines (e.g. Fryers) that will

perform complimentary roles. In most cases,

operators will be using this machine in

conjunction with a bench or suitable surface on

which burgers and other food products can be

assembled or prepared.

For this reason, we recommend that areas

between this unit and other machines and work-

surfaces be kept clear of any potential obstacle

or trip hazard. Work areas should also be

cleaned and floors should be oil-free to reduce

the likelihood of slipping.

It is anticipated that these machines will be

operating beneath a suitable exhaust/extraction

unit to reduce the ambient temperatures around

the operator.

SAFETY

GENERAL SAFETY

This machine contains no user-serviceable parts.

Austheat®Australia, one of our agents, or a

similarly qualified person(s) should carry out all

repairs. Any repair person(s) should be

instructed to read the safety warnings within this

manual before commencing work on these

units.

Steel cutting processes such as those

used in the construction of this machine

result in sharp edges. Whilst any such edges are

removed to the best of our ability it is always

wise to take care when contacting any edge.

Do not remove any cover panels that may

be on the machine (with the exception of

the circuit breaker cover.

This unit can get very hot, ensure everyone is

aware that the machine is operating and take

care to avoid contact with hot surfaces. (Refer to

installation for guide to ventilation)

Always ensure the power cable is not in contact

with hot parts of the machine when in use, and

ensure that if the cable is damaged in any way

that it is replaced immediately

Always use original spare parts. Genuine

Austheat®parts have been checked for

compliance and reliability and the use of non-

original spare parts may compromise the

function or safety of these units.

As part of the normal operation of this unit, hot

air is expelled out the front of the unit. Never

block or interfere with this air flow as the internal

temperatures may rise and component damage

can occur.

GENERAL FIRE SAFETY

Before using any hotplate adequate safety

measures should be in place. Such measures

should include, but not be limited to, having an

appropriate fire extinguisher or fire blanket

located nearby in case cooking oils on the plate

ignite. Refer to the appropriate regulations

pertaining to your operating environment for

details of the correct fire prevention measures

required.

SAFETY OF SERVICEPERSONS

Before servicing this machine it is necessary to

disconnect all power. These units are NOT

fitted with a mains isolating switch –as detailed

in the installation section of this manual, an all-

pole disconnection isolating switch should be

mounted and wired

external

to this machine. A

cooling circuit will remain “live” within these

units even when turned “off” at the control

panel. Please consider this before allowing

qualified servicepersons to gain access to the

machine.

9

TROUBLESHOOTING

If the Hotplate does not function check the

following points before calling for service.

The power is switched “on”, both on the

unit and at any other point that supplies

power to the machine (e.g. an isolating

switch on the wall).

The mains power is not faulty.

The temperature has been set correctly and

the thermal cut-out has not tripped. Refer to

the “Thermal Cut-Out” section previous for

more information on this control.

The thermostat knobs are not loose or

broken, rendering the thermostats

inoperable.

The circuit breakers located inside the lower

section of the unit are all in the “on”

position”. These are located behind a cover

panel.

Typical issues that can be easily identified can

be listed below:

1.1 Symptom –All power shut off

1.2 Check –Is air still flowing through the grease

box guide?

1.3 Probable Cause –(If Yes) –Overtemp has

cut out. Let machine cool for 30 minutes before

switching back on. (If no) –Possible failure of

primary fan or ON/OFF switch

2.1 Symptom –Plate takes too long to

heat/cook

2.2 Check –All circuit breakers are in the “ON’

position

2.3 Probable Cause –If tripped, there could be

possible element failure. Reset circuit breakers

and operate as normal. Call for service if they

trip again.

3.1 Symptom –Grinding noise coming from

inside the unit

3.2 Check –Does it sound like a fan turning but

being noisy?

3.3 Probable Cause –Internal fan bearing may

be failing. Call for servicing before the fan fails,

as such a failure will cause the machine to

overheat and shut down.

THERMAL CUTOUTS

These units are fitted with an internal safety

thermostat designed to cut power if the internal

temperatures reach a point where other

components may be damaged. There are a

number of possible situations that may cause

the safety thermostat to cut out, such as a

thermostat failure or the failure of an internal

fan. You may follow the procedure below as a

first step to rectifying the problem.

1. Switch the Hotplate OFF using the main

On/Off switch and allow it to cool for

approximately 30 minutes.

2. Switch the unit back on –operation can

now continue as normal.

3. Repeat steps 1 and 2.

4. If the unit again trips out it may be the

result of a failure in an internal fan -

phone for service.

If the Hotplate continues to perform without any

further tripping of the thermal cut-out after step

3, then there is a strong possibility that the

thermostat in use at the time is faulty, or that

one of the internal cooling fans is no longer

functioning. This should be attended to by

qualified electrical personnel.

If the machines have tripped the thermal cut-out

two or three times switch the unit off and refrain

from further use until the unit has been repaired.

Continuing to use the machine may cause

premature failure of other components if

repeatedly exposed to over-temperature

situations.

10

COMPLIANCE

RCM:

Austheat®products have been designed and

manufactured to comply with any and all

specifications set out by the Australian

Communications and Media Authority (ACMA)

in regards to Electromagnetic Compatibility. As

testament to such compliance these units bear

the RCM symbol.

For further information contact the Australian

Communications Authority, PO Box 13112, Law

Courts, Melbourne VIC 8010.

ACSS (Advance Control Safety System)

The ACSS framework is a stringent and specific

set of voluntary requirements aimed at the

electrical safety, reliability and longevity of

equipment used in the foodservice industry.

The ACSS framework has been developed as

both a guide to the engineering and

development of products as well as a guarantee

to consumers that Austheat®equipment bearing

this mark not only meets the requirements of the

Australian Standards, they exceed them.

A unit bearing the ACSS mark is your guarantee

that you are purchasing a machine built to far

exceed the Australian standards. The unit has

been designed to be safer, particularly from an

electrical aspect, and last longer than similar

units on the market today.

SPARE PARTS

EC0225 Circuit Breaker –32A

ES0232 Mains Rotary Switch –4 Pole

EC0245 Rail Mounted Terminal Block Red

EC0246 Rail Mounted Terminal Block

Blue

EC0247 Rail Mounted Terminal Block

Earth

EC0249 Bridging Link

EC0347 Circuit Breaker –13A

EC0348 Contactor –2 Pole –25A

EC0361 Contactor –1 Pole –25A

EC0471 Fan –Tangential –18W

ES0264 Amber Pilot Light Assembly

ES0265 Green Pilot Light Assembly

HC0141 Element –125W 230VAC

HC0174 Element –3500W 230VAC

MC0093 Clamp - Cable

MC0609 Adjustable Leg

MC0610 Castor

MC0649 Toasting Rack

PC0276 Bush –1 3/8” Nylon 6/6

PC0287 3/4” Plastic Knockout Plug

PC0288 1” Plastic Knockout Plug

PC0379 Bush –1 3/8” Nylon 6/6 –

Slotted Face

SS2204 Crumb Tray/Reflector

SS2219 Circuit Breaker Cover

TC0033 Thermal Cutout - 60C –N/O

TC0035 Thermal Cutout - 70C –N/C

TS0030 Thermostat 290C Pan Assembly

VS0374 Grease Box & Handle Complete

CIRCUIT DIAGRAM

12

WARRANTY

© Copyright 2021 –Roband® Australia Pty Ltd

All rights reserved. No part of this work may be reproduced or copied in any form or by any means,

electronic or mechanical, including photocopying or posting to a website, without the written permission of

the publisher. The material contained within this document is intended entirely for instructional purposes.

Roband®Australia is a wholly Australian owned company and has been manufacturing quality commercial

catering equipment for the food service industry for more than 60 years.

This manual suits for next models

1

Table of contents

Popular Cooktop manuals by other brands

Miele

Miele KM 611 Series Operating and installation instructions

LG

LG MFL62725501 installation instructions

Jenn-Air

Jenn-Air JED8130ADB Use & care guide

Thor Kitchen

Thor Kitchen TGC Series manual

Monogram

Monogram 36 Ceramic Cooktop installation instructions

Jenn-Air

Jenn-Air CCE3401 installation instructions

Aarow

Aarow BK061 Operating & installation manual

Fisher & Paykel

Fisher & Paykel CG363MLNGB1 instructions

True Induction

True Induction TI-2B user manual

AIRLUX

AIRLUX TV267MC RECOMMANDATIONS DE MONTAGE ET MODE D’EMPLOI

Gaggenau

Gaggenau VI 414 613 use and care manual

Linea 2000

Linea 2000 DOMO DO-309KP Instruction booklet