GE PGP953 User manual

Other GE Cooktop manuals

GE

GE Monogram ZEW145 User manual

GE

GE PGP989 Operating instructions

GE

GE JDP39BWBB User manual

GE

GE Profile PHP900 User manual

GE

GE JGP628 How to use

GE

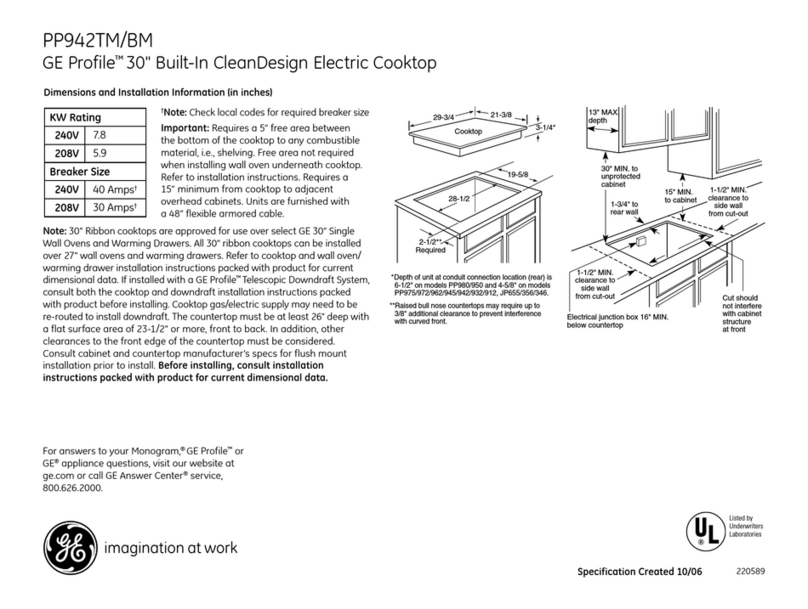

GE Profile PP942 Manual

GE

GE Eterna EGR3001EPSS User manual

GE

GE Monogram ZHU30RBM User manual

GE

GE Monogram ZGU375NS User manual

GE

GE PGP9830 Original instructions

Popular Cooktop manuals by other brands

Bonnet

Bonnet OPTIMUM 700 Technical instructions

Jenn-Air

Jenn-Air JGCP430 installation instructions

Frigidaire

Frigidaire FES367FCC Wiring diagram

Ztove

Ztove EZ2 DUO instruction manual

Kleenmaid

Kleenmaid cooking GCTK9011 Instructions for use and warranty details

Jenn-Air

Jenn-Air JGC2536EB00 Use & care guide