Austin AUSTINDRIVE User manual

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

1

AUSTINDRIVE PEDAL

DIY PROJECTS

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

2

QUICK START GUIDE:

(These links skip-over some of the explanation, and get right to the instructions.)

1. Tools and Preparation

2. Circuit Design

3. Drill the Enclosure (Some models only)

4. Apply the Graphics

5. Stuff and Solder the Printed Circuit Board (“PCB”)

6. Wire the Jacks and Switches

7. Wire the Enclosure

8. Create Your Tone

9. Troubleshooting Problems

This is a true DIY Pedal, designed to introduce some concepts of circuit design, and help people become

curious about building their own equipment.

Release of Liability Notification - Please Read This:

You will be soldering, using a sharp razor blade, scissors, cutting and stripping wires, and in some cases,

drilling the metal enclosure. There are dangers involved - based solely on the tools you are choosing to

use, and your experience using them. This is not a learning manual for using these tools. Avoid breathing

fumes from your solder, flux or paint, and try to use lead-free (“RoHS”) solder whenever possible.

Personal Protective Equipment (PPE) is a MUST for this project.

Do not take risks that could cause injury –especially to your eyes or hands –while building this pedal.

Your fingers can be permanently damaged from heat or sharp objects, and that’s not good for a guitar

player. Don’t “feel if this is sharp” by running your fingers around the drilled holes. You might also step-

on metal shavings from your drill or poke yourself with tiny wire leads. Cutting-off legs of the

components can shoot tiny pieces of metal across the room or into your face and eyes… or someone

else’s. Please use caution, wear safety glasses, and reduce the chance of injury wherever possible.

Doing this project by yourself is not required. It is optional.

Fully complete AUSTINDRIVE pedals are available for purchase at www.AustinMics.com/austindrive

The individual, common parts in this kit and the words in this document cannot hurt you. The parts you

have received are not hot, there are no cutting tools or solder included in the kit. As-shipped, the parts

are passive and de-energized, and pose no harm without substantial, intentional effort and energy from

you. You are choosing how to handle and use these parts in ways that I cannot predict, and do not have

any control over. Use of these parts and instructions is at your own risk.

By choosing to use these instructions and assemble the parts provided, you have just assumed all

liability and risk, releasing Austin Microphones and Rick Wilkinson from damages and/or liability.

Please contact me for details.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

3

TOOLS AND PREPARING FOR YOUR BUILD

1. You should have some soldering skills.

Like our DIY Ribbon Microphone & Preamp Kits, The AUSTINDRIVE is designed to be an easy weekend project.

However, some prior experience with solder and circuit boards really helps. If you’ve never soldered anything

before, search "soldering”videos on YouTube, and read this short comic book before you start.

2. You should have a real soldering station.

You don't need a $200 pro station, but cheap $9 irons are not

good enough. eBay and Amazon often have temperature-

controlled stations with a sponge and stand for under $40.

3. You need a few tools and safety glasses

To strip the insulation off the wires, and cut the legs off

components, you need a wire stripper tool for small wire, (22-

30 AWG) and diagonal cutters (AKA "dikes")

(Each is $5 to $25 online or at hardware stores.)

Diagonal cutters can shoot the metal legs of components across

the room when you cut them, so make sure you WEAR eye protection too.

You’ll also need sharp scissors and a Hobby Knife (AKA: “X-Acto” knife) for the graphics label.

Not required, but helpful: Needle-Nose Pliers, for bending and swapping components when designing your tone.

4. Get a $10 Multi-Meter, or better.

A multimeter is required to verify resistors if you have trouble recognizing colors or reading

the small print on components. Again, you don't need a $500 professional meter. Entry-

level, imported multimeters can be purchased for under $20 from eBay or local hardware

stores. If you cannot read component values, or need to troubleshoot your circuit, you must

use a meter.

5. Find an area to work where you won't ruin your tablecloth or counter top.

Don't start your weekend with a burned tablecloth or scratched countertop. If you have no

other choice, lay down some protection before you start. You can even use a kitchen cutting board or the

cardboard box your kit came in.

6. Magnification and The Pedal Port are highly recommended

The parts are small, so a headband magnifier works well.

The Pedal Port grips parts and PCBs during soldering.

7. This project takes 3 to 6 hours, depending on your skill level.

You do not need to do it all in one evening. You can break it up over a few nights. Follow the instructions, check-off

the boxes, and you can easily build the AUSTINDRIVE.

8. You need a “Center Negative” 9V DC Power Supply (made for pedals), or a 9V battery.

The kits include a 9V battery adapter clip that enables the use of a battery with the DC Jack. The pedal draws about

28mA when “ON” – mostly to light-up the LED indicator. Good batteries should last for 10 hours or more of playing

time.

NOTE: A “standard” 9V power supply from another product won’t work. Most supplies are usually “center

positive.” Get a power supply for guitar pedals. The circuit is diode protected when assembled correctly, but a

large, incorrect power supply could damage that diode.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

4

CIRCUIT DESIGN

This is how this circuit works: (It’s simple… really!)

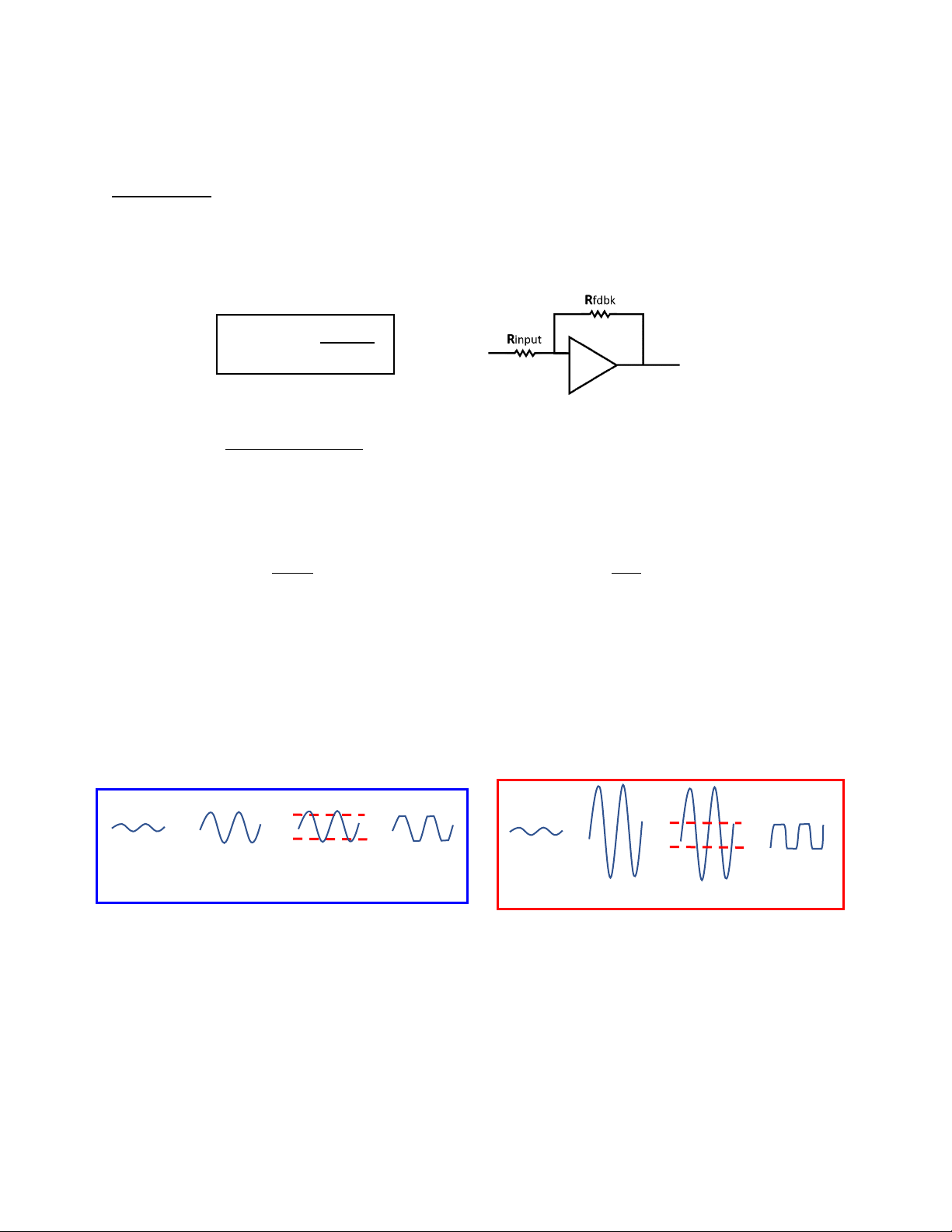

Short version: Two amplifiers amplify and clip-off the peaks of the waveforms, resulting in distortion.

“Clipping” is literally cutting-off the tops and bottoms of a signal.

In this circuit, the gain or “drive” of each stage is defined by the builder changing the GAIN 1 and GAIN 2 resistors.

The simple math for defining voltage gain in each stage of an Operational Amplifier (“Op-Amp”) is:

Where Rinput is the input or “GAIN” resistor, and Rfdbk is the “feedback” resistor.

In this circuit, the Rfdbk is fixed at 100k, but the builder chooses the values for the Rinput: The “GAIN” resistors.

•When a 10k resistor is chosen as the GAIN resistor, the voltage gain is 100k ÷ 10k - a 10x gain (amplification)

•If a 5k resistor is chosen, the gain is 100k ÷ 5k –a 20x gain (amplifies 20x).

In other words, for every millivolt that goes in, 10mv (or 20mv) comes out. Your choice.

However, we are here to distort the signal. We don’t want clean gain, we want dirty gain. That is where the

“clipping diodes” come in. The amplified signal goes into the clipping diodes which distorts it like this:

A diode allows voltage to pass in one direction but blocks it in the other direction. That blocking happens at

different voltages in each of the 3 types of diodes included in this kit. With 2 diodes facing the opposite direction in

the feedback circuit, the voltage peaks are literally “clipped-off,” resulting in distortion of the signal.

•When you amplify the signal just a little (low gain), just the very tips of the peaks are clipped-off.

•When you amplify the signal a lot (high gain), a lot of the peaks get clipped and it is more distorted.

•The more the peaks are “squared-off” the more “distorted”the signal sounds:

We are also limited by the 9-Volt power supply, or 4.5v on each side of the waveform. If the diodes do not clip-off

enough signal, then the Op-Amp will clip the signal as well.

This circuit generates distortion at 4 different points in this circuit: 2 sets of clipping diodes, plus 2 Op-Amps. The

distortion from Gain Stage 1 passes into Gain Stage 2, so if you clip the signal heavily in Gain stage 1, Gain stage 2

will clip it even more. Different Op-Amps can also sound different when they clip, based on their internal circuitry.

GAIN =

Rfdbk

Rinput

Input Signal

After low gain

Diode Clipping

Input Signal

After High gain

Diode Clipping

Slightly

distorted

(“clipped”)

signal

Heavily

distorted

(“clipped”)

signal

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

5

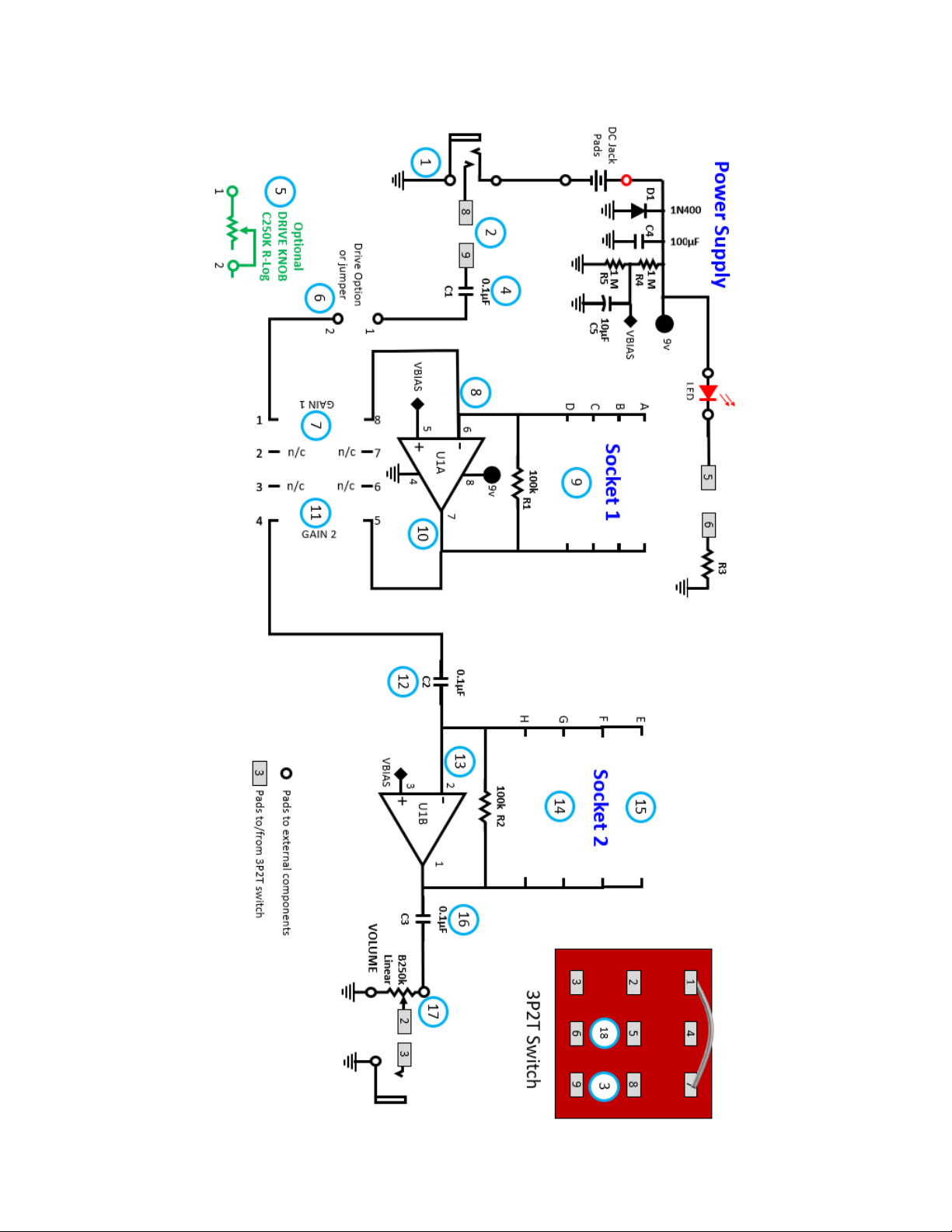

THEORY OF OPERATION (Numbered on the next page)

1. The 9V power circuit is completed (powered-on) when you insert a guitar cable into the input

2. The signal from the guitar goes through two poles of the 3-Pole, Double-Throw (3PDT) switch

3. The switch either jumpers the signal directly to the output (“True Bypass”), or to the drive circuit

4. Through the drive circuit, the signal passes through a DC-blocking capacitor, C1

5. If a drive knob is installed, signal is reduced by a C250k, reverse-logarithmic potentiometer

6. If a drive knob is not installed, a jumper is installed instead.

7. The signal passes through the GAIN 1 resistor, which defines the gain for Op-Amp #1 (previous page)

8. It enters Stage 1 of the op-Amp, U1 on Pin 6.

oThis is the “inverting input” of this Op-Amp, and it flips the phase 180°

9. The feedback loop contains the feedback resistor R1, and clipping diodes which clip the peaks of the signal

oIf there is high gain in the circuit, more clipping happens = more distortion in Gain Stage 1

oAlso, different diodes clip the signal differently. (“Hard” or “Soft” clipping here.)

10. The distorted signal comes out of the first Op-Amp on Pin 7

11. The signal goes to the GAIN 2 resistor, which defines the gain for Op-Amp #2 (previous page)

12. Before going into the next Op-Amp, the signal passes through another DC-blocking capacitor, C2

13. Like Gain Stage 1, the signal enters Gain Stage 2 of Op-Amp, U1 on Pin 2

oThis is also an “inverting input”- so the phase flips 180° again, restoring the correct phase

14. The Gain Stage 2 feedback loop contains a feedback Resistor R2, and clipping diodes

oMore gain here distorts the signal more, especially if it was heavily distorted by Gain Stage 1

oAlso, different diodes clip the signal differently. (“Hard” or “Soft” clipping here.)

15. The second gain stage socket also has room for a filter capacitor, which will reduce high-frequencies

oWith no capacitor here, all frequencies are allowed to pass through to the output

oAs this capacitor value gets larger, more high-frequencies are removed.

oA capacitor tends to “smooth” the sound of the distortion, making it less “harsh”

16. Out of the second op-amp on Pin 1, the signal passes through a final DC-blocking capacitor, C3

17. The signal then enters a B250k linear potentiometer

oWhen turned “up,” the signal passes through without any resistance, for the loudest volume.

oWhen turned “down,” more and more of the signal is shorted to ground, reducing the output

volume of the pedal.

oThis knob helps match the distorted volume to the clean (“True-Bypass”) volume.

oThe volume knob does not increase or decrease the distortion… only the output level.

18. The red LED is turned on/off with the pedal by passing voltage through the 3rd pole of the 3PDT switch

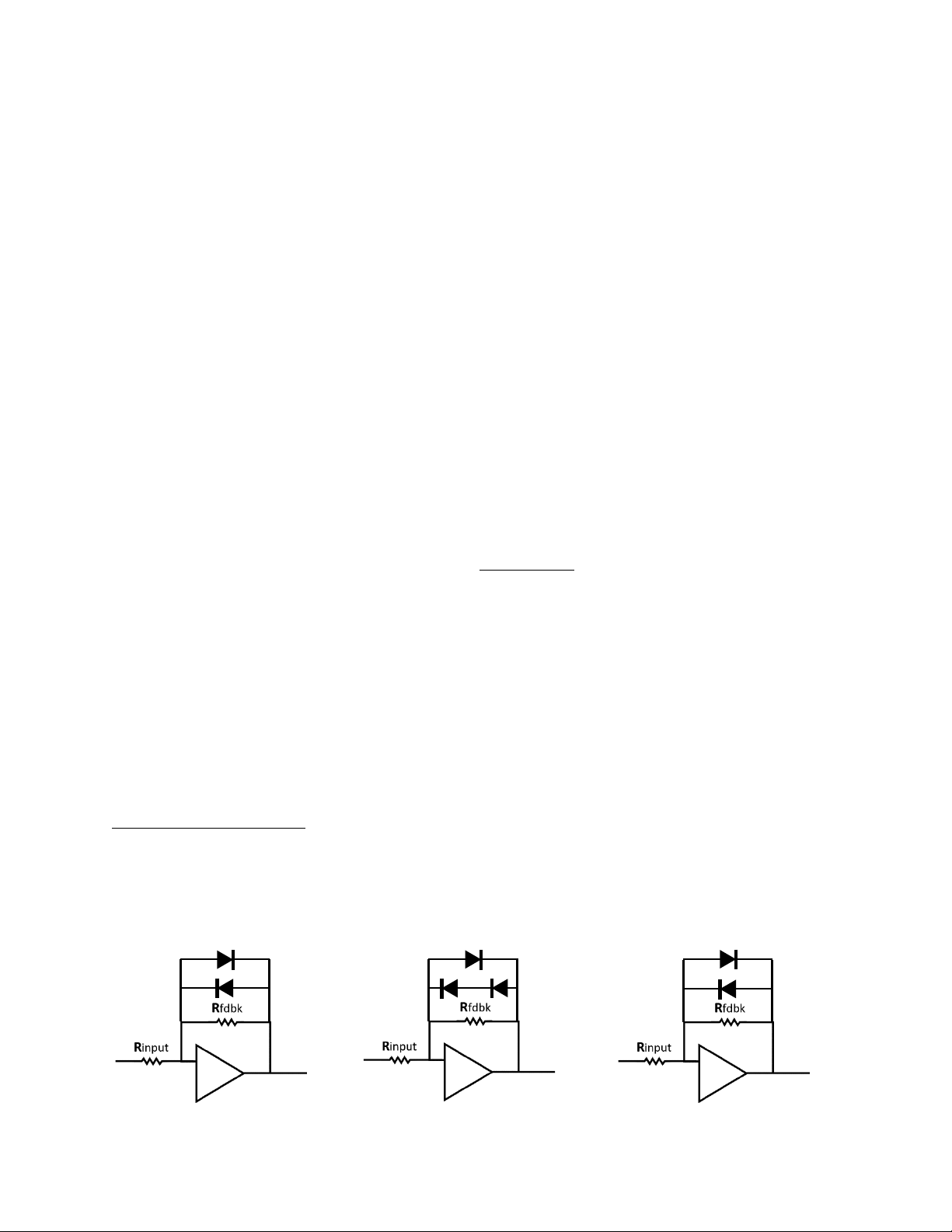

Notes to create a unique tone:

•Try a high-gain setup, then use a filter capacitor to reduce harsh high frequencies for a smoother tone

•Try different-value GAIN resistors, diodes, and capacitors with each of the 4 different Op-Amps

•You can mix/match diodes, or point 2 in one direction and one in the other, in parallel or in series.

•Two diodes in series clip the signal less than a single diode, also known as “uneven clipping”

•Some vintage pedals use these tricks. Here are some typical diode setups:

1N914

1N400x

Standard, “Even” clipping with

matching diodes

“Uneven” clipping with 2 pointing in one

direction, and one pointing the other

“Uneven” clipping with 2

different diodes

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

6

Theory of Operation

4

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

7

DRILL THE ENCLOSURE (Before any graphics are applied)

NOTE: Most kits come with pre-drilled enclosures, but a few “budget-friendly”kits do not.

I have drawn templates for marking the holes below. Print this page onto regular paper and cut

them out around the outside edges.

I also have .stl files for 3D printing punch templates. Customers can email me for the link.

NOTE: IF YOU ARE DRILLING YOUR OWN YOUR HOLES WITH THESE PAPER TEMPLATES:

LOCATIONS MAY NOT BE “ABSOLUTELY PERFECTLY”ALIGNED.

There are variations between printers and programs, so if you are

creating your own graphics: I strongly advise creating graphics that

are not aligned to the holes.

The top graphic (with 4 crosshairs) is intentionally smaller than the

actual face of the enclosure, and must be centered by eyeball. Once

centered, tape it down and center-punch the marks. I recommend

using a spring-loaded center-punch.

Carefully remove the top template. Align the short edge near the

switch crosshair (on the left below, in RED) with the end-face edge of

the enclosure to mark the DC Jack

Use the INPUT/OUTPUT template to mark the input/output JACK

locations, one on each side, at the correct end: Near the switch.

If my descriptions seem confusing, look at the photos to confirm.

+

+

Open Side

INPUT/OUTPUT JACKS

(1 per side)

Use the red crosshair to

mark the DC jack

location on this end face.

+

+

+

+

Mark this center hole ONLY if

you have a DRIVE knob!!

TOP TEMPLATE

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

8

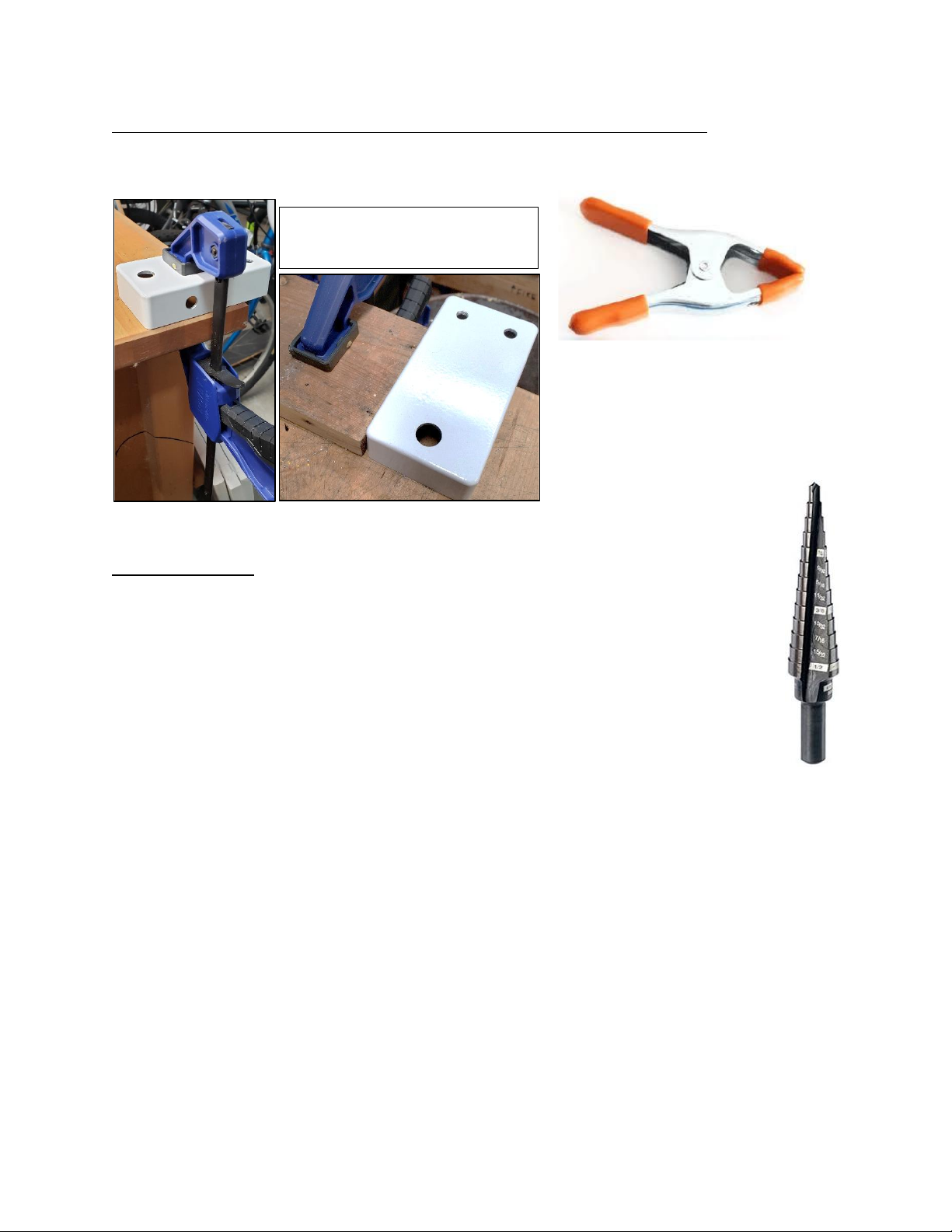

While drilling the enclosure, block or clamp the enclosure so it does not spin.

Keep the enclosure from spinning while drilling by pressing it against a piece of wood that is

clamped to the table with clamps or heavy spring clips.

Don’t drill into your table! - The space under the enclosure must clear the table!!

The hole sizes are:

•LED ¼inch (6.2mm)

•Volume/Drive Pot 9/32 inch (7mm)

•Input/Output Jacks ⅜Inch (9.5mm)

•Switch + DC Jack ½Inch (12.7mm)

If you buy a step-drill as shown here, make sure it has all these hole sizes, or

be prepared to use a round file to enlarge small holes.

Clamped or Blocked to prevent

movement while drilling.

Heavy-Duty spring

clamp with rubber tips

Milwaukee Step Drill

P/N 48-89-9201

⅛

to ½Inch (~$25)

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

9

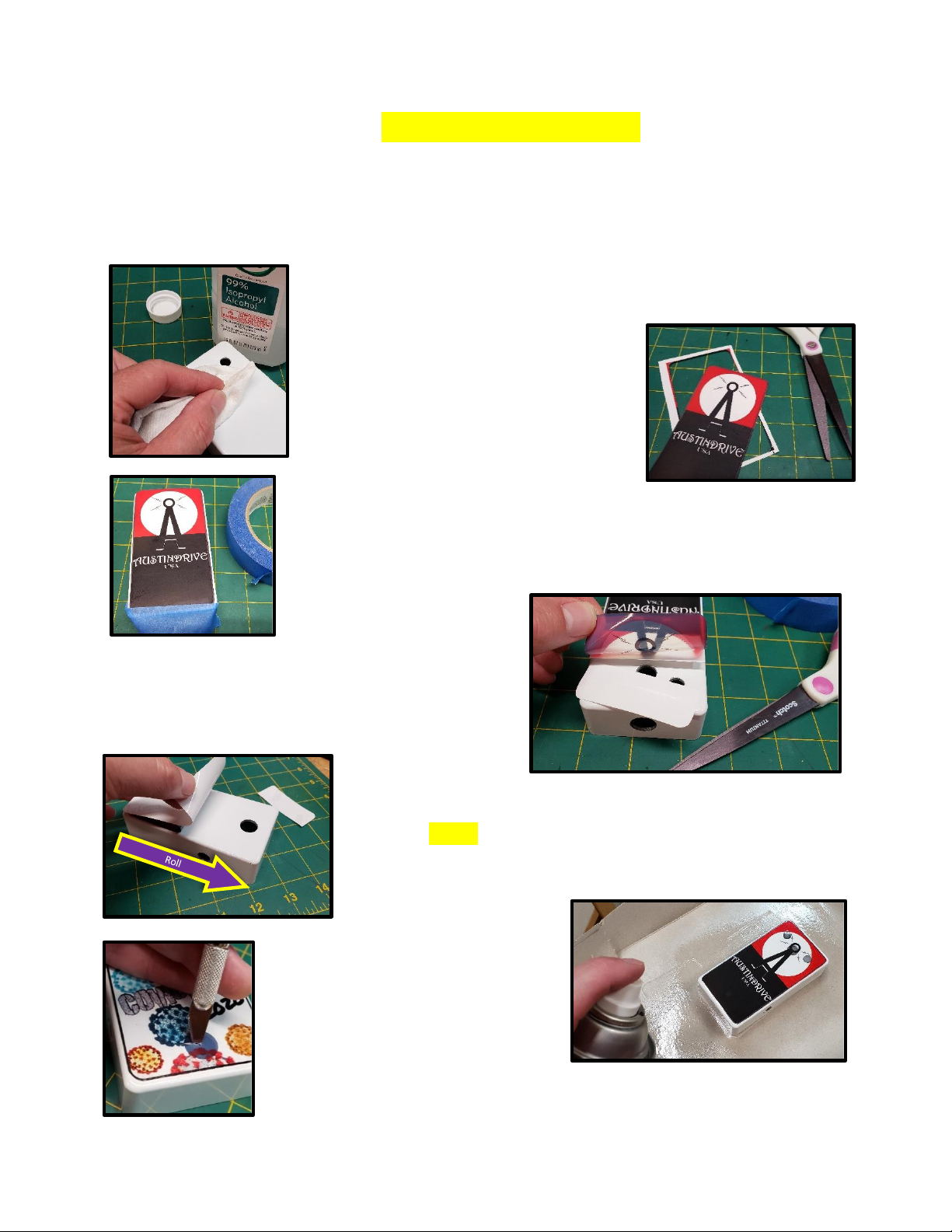

APPLY THE GRAPHICS (Drill first, Label second!)

For workshops and customers designing their own graphics, use the AUSTINDRIVE Graphics

Creator on Google Slides. Labels will be printed from your artwork.

All other kits have a graphics label included, or search YouTube to learn how to make your own

graphic labels without me!

Clean the face of the pedal with Isopropyl Alcohol and let it dry.

However, do not wet the label or clean it with cleaners. The graphic

may rub-off.

Use sharp scissors to carefully trim the

edge of the included label around the

outside, leaving the black line as the edge.

Before you remove the label backing, center the label on the enclosure

and lightly tape it down across one side with painter’s tape.

Leaving the painter’s tape on one end, peel the

backing on the opposite end, cut off a small section

of the backing, and press that end of the label onto

the enclosure.

Remove the painter’s tape, then continue to peel the backing of

the label, “rolling”the label onto the enclosure.

Spray the newly labeled enclosure

with several coats of clear paint to

seal the edges, and set aside to dry

for at least 2 hours, preferably

overnight.

Cut out the holes with an X-Acto knife or razor blade, cutting with

downward motions to avoid peeling-up the label.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

10

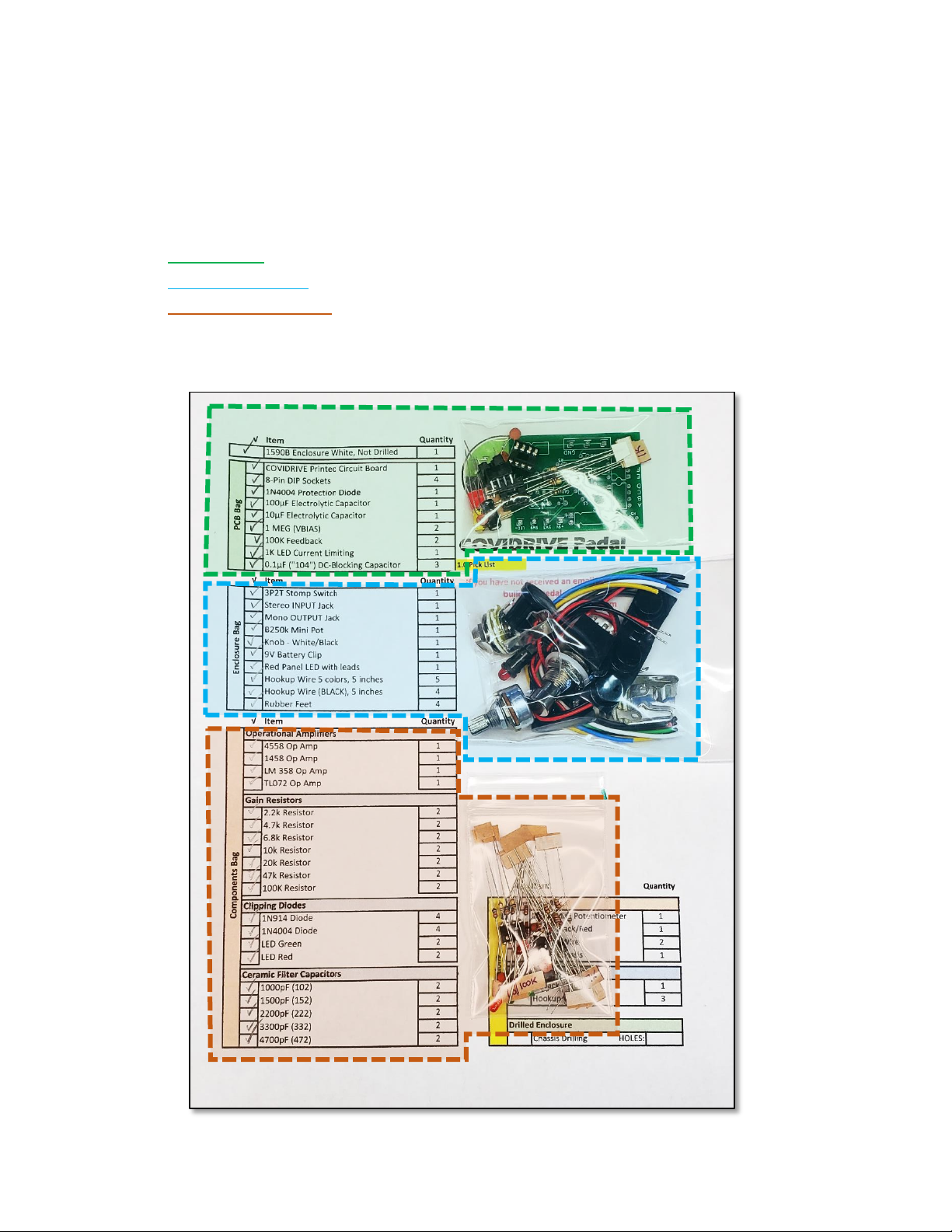

PREPARE YOUR PARTS AND WORKSPACE

Clean off your bench or prepare a nice workspace where you won’t burn a kitchen tabletop or

tablecloth. Having a nice area ahead of time really does help.

NOTE: There are 3 bags in this kit, plus the enclosure. (+ 1 bag if you ordered a Drive Knob)

•The PCB Bag has the green printed circuit board, sockets, and a few other parts in it.

•The Enclosure Bag has the jacks, switches, pots, and multi-colored wires in it.

•The Components Bag has ~40 resistors, capacitors, diodes, op-amps and LED’s in it.

Because there are MANY different resistors included. You will need a meter to measure the

resistors before soldering. I highly recommend a magnifying glass to verify your soldering, too.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

11

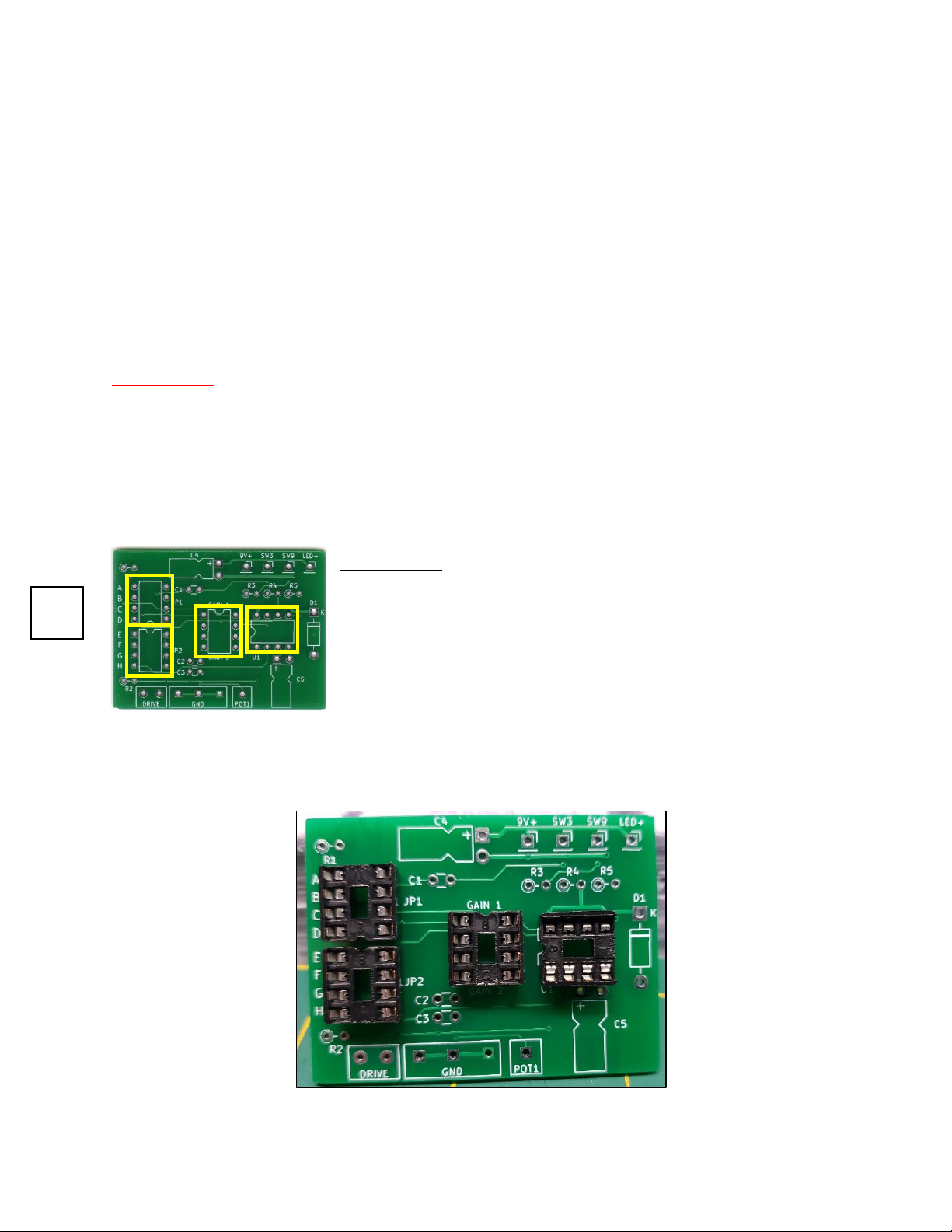

STUFF THE CIRCUIT BOARD

Find the PCB Bag. It has the following components:

4) 8-pin Sockets

3) “104” (0.1µF) Caps

2) 1MEG resistors

2) 100k resistors

1) 1k resistor

1) 100µF Electrolytic cap

1) 10µF Electrolytic cap

1) 1N400xDiode (x= 1, 4 or 7)

1) Printed Circuit Board

Check-off each step in the check box at left

IMPORTANT:

Do not stuff all the components into the board, then try to solder them all at once.

Trust me on this: Too many legs make it extremely easy to miss soldering one!

Maybe do 2 or 3 at a time, solder, cut-off, and repeat. But not everything all-at-once.

8-Pin Sockets

Install a socket into each location, one at a time.

NOTE: Legs can get bent during shipping. Just bend them back.

Each socket has a small “u-shaped” notch on one edge. Match

that cutout with the notch printed on the board. On the back-side

of the board, bend- the legs outward so that the sockets don’t

fall-out when you turn-over the board.

Solder all 32 legs now. It’s great practice for everything else!

Check-Off

4 Sockets

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

12

D1 (1N400x) Diode

Bend the 1N400x diode with your fingers so it fits in the holes.

A diode is “polarized” and current only flows one way.

Put the diode through the holes so that the stripe on the diode

matches the stripe on the board. Spread the leads slightly so that the

diode stays in the board. Solder the leads from the back side, and cut-

off the legs. This diode protects the circuit from reversed 9V leads or a

bad Power Supply.

Save the two cut leads from this diode. Or from another component.

You will need them later.

NOTE: Resistors are NOT “polarized.” They can be installed and bent either way.

The bodies of the resistors may be tan, brown, or blue, depending on the manufacturer.

R1 & R2 (100k) Resistors

Bend one lead of each resistor back-over on

itself, so that both legs point the same direction.

Install the resistors upright.

These are fixed feedback resistors in the

gain stages.

R3 (1k Ohm) Resistor

Bend one lead of the resistor back-over on itself, so that both legs

point the same direction. Install the resistor upright.

This 1K resistor keeps the LED from burning-out.

1k:

Brown Black Red

Check-Off

R3

100k:

Brown Black Yellow

Check-Off

R1 & R2

Check-Off

D1

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

13

R4 & R5 (1 MEG) Resistors

Bend one lead of each resistor back-over on itself, so that both

legs point the same direction. Install resistors upright.

These resistors divide the 9V equally into

+/- 4.5v, to “center-bias” the Op-Amps.

C1, C2 and C3 (0.1µF, “104”) Ceramic Capacitors

Line-up the three 0.1µF (104) capacitors in the column near the

center of the board. These capacitors block DC voltage from the

audio stages. DC offset would alter the waveform in the next gain

stage.

These capacitors are not polarized. They can be installed either way,

but I like to have the “104” number facing the same way on all of

them.

C4 & C5 (100µF and 10µF) Electrolytic capacitors

Holding each capacitor in your right hand, with the stripe towards you, bend the legs of the

100µF and 10µF capacitors 90° UP.

NOTE: The colors of the capacitors in your kit may vary from these images.

1 MEG:

Brown Black Green

Check-Off

R4 & R5

Check-Off

C1, C2 & C3

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

14

Both electrolytic capacitors lay flat on the board. They must be installed correctly.

These capacitors ARE polarized. The longer leg goes into the square “+” pad.

C4 is the 100µF capacitor at the top, that lines-up horizontal.

C5 is the 10µF capacitor at the bottom, that lines-up vertical.

These capacitors filter-out leftover AC voltage from a power

supply, and store energy for use during short, quick transient

bursts when the pedal is being asked to deliver 100% of its design

capability.

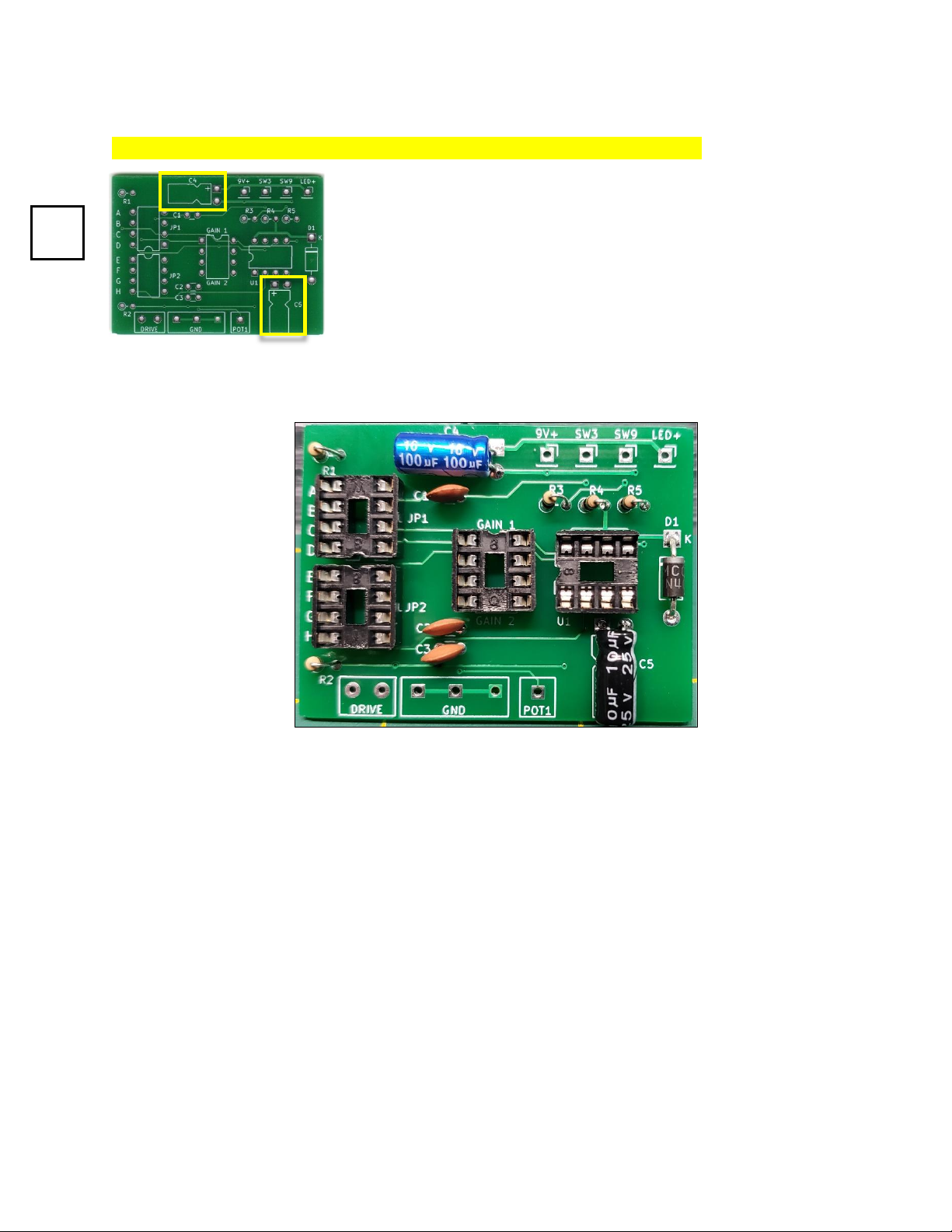

Your board should look a lot like this now:

Please double-check your components with this image.

Again, your 10 µF and 100µF capacitor colors may differ from those in this image, and the

bodies of the resistors may be tan, brown, or blue, depending on the manufacturer.

Check-Off

C4 & C5

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

15

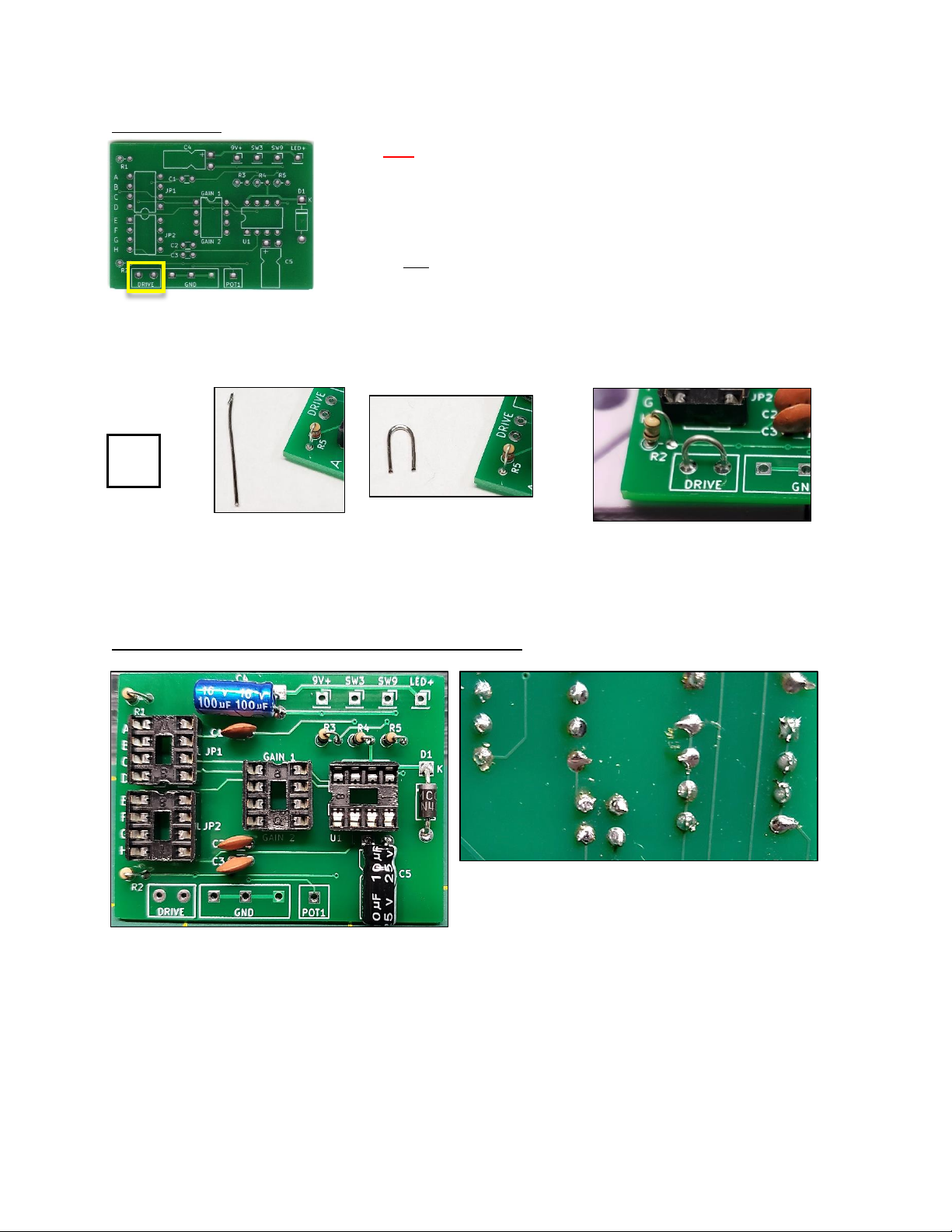

DRIVE Jumper

IF YOU ARE INSTALLING THE OPTIONAL DRIVE KNOB:

Leave these pads empty for now.

We will wire them in the final step: Wiring the Enclosure.

If you are not installing a DRIVE knob, you must place a jumper

between these two pads:

Use one of the legs you previously cut-off from a resistor, diode or capacitor, and bend it into a

U shape. Install that jumper into the DRIVE pads and solder it. Cut the legs off the back like the

other components, leaving a small “horseshoe” or “rainbow” loop here.

RECOMMENDATION: Leave the jumper a little higher than the board, not pressed down flat.

Later, if you want to upgrade and install a drive knob, the jumper will be easier to cut, and it will

provide two short “pins” to wrap the DRIVE pot wires to before soldering.

Double-check your soldering with a magnifying glass.

Review your check boxes from the pages above.

Use magnification to look for pads that you missed soldering, and solder bridges where solder

has connected 2 pads, especially at the resistors. Some pads are very close together.

The two rows of pads on the top and bottom edges of the board are where the wires from the

jacks and switches are soldered in the final step: Wire the Enclosure.

If you don’t have a

drive knob

Check-Off

DRIVE Jumper

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

16

PREPARE YOUR PARTS AND WORKSPACE

Clean off your bench or prepare a nice workspace where you won’t scratch a kitchen tabletop

or tablecloth. Having a nice area ahead of time really does help.

Inside your enclosure, use a sharpie to write the names of the holes from the inside.

MARKING THE INSIDE REALLY HELPS. Trust me.

You will spend several hours building the pedal “upside-down.”This can be confusing when you

go to use it “right-side up.”I spent many minutes wondering why my prototype pedals didn’t

work…because I had the guitar plugged-into the OUTPUT, or I thought my Drive knob was all

the way down, when it was my Volume knob that was all the way down!

Twisting Wires

Some wires go to almost the same point on the board, so twisting a pair of wires helps

assembly. Use a slow drill, pinch the wires with your fingers, and slowly twist wire pairs if you

need to. Not more than 2 turns per inch, or about 1 turn per cm.

NOTE: AUSTINDRIVE Kits have pre-twisted wire pairs for certain connections.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

17

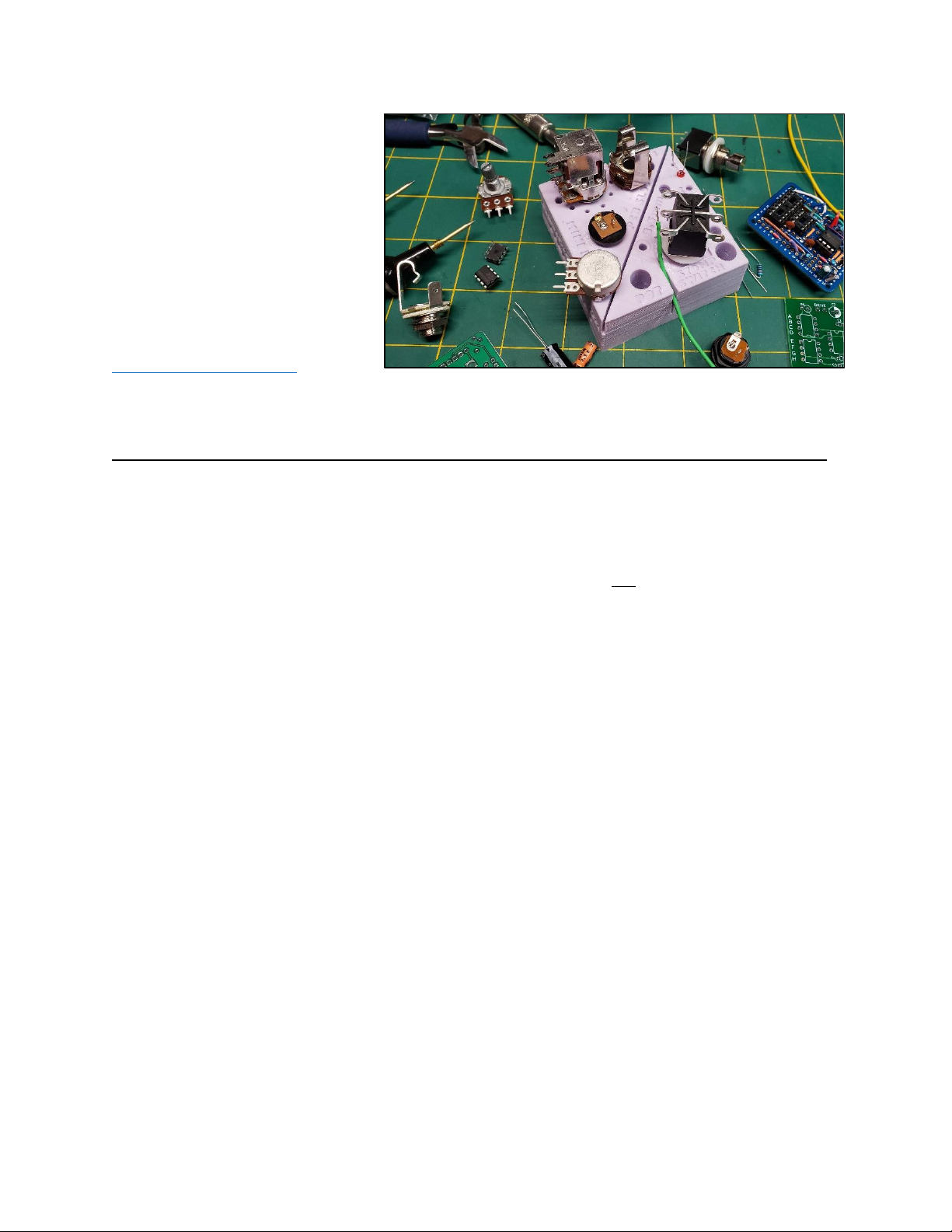

THE PEDAL PORT

Throughout this tutorial, I use

The Pedal Port, a silicone parts

holer molded exclusively for

pedal-building. It grips parts tight

without scratching, and it doesn’t

suck-out the heat of soldering.

The Pedal Port is available from

www.ThePedalPort.com

Why aren’t these parts soldered onto the Circuit Board?

One answer: Reliability.

Circuit boards, metal enclosures, solder lugs, input jacks and guitar cable plugs don’t bend.

When you constantly plug & unplug rigid components into a circuit board, tweak knobs, and stomp on

switches, those soldered connections on a printed circuit board (“PCB”) will fail. It may take years, but

when rigid components move, solder joints on PCBs crack - and electronic things stop working. This is a

major reason why modern electronics and appliances only last a few years, but a 1960’s Tube Amp is still

running.

When rigid connections are “insulated” from the circuit board by a flexible wire, those connections to

the PCB last longer. Maybe forever.

Yes. There are guitar pedal circuit boards where everything is neatly soldered to a circuit board, and it all

fits nicely into an enclosure. That takes all the fun out of it for me. I like wires and colors.

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

18

PRE-WIRE THE JACKS POTS AND SWITCHES

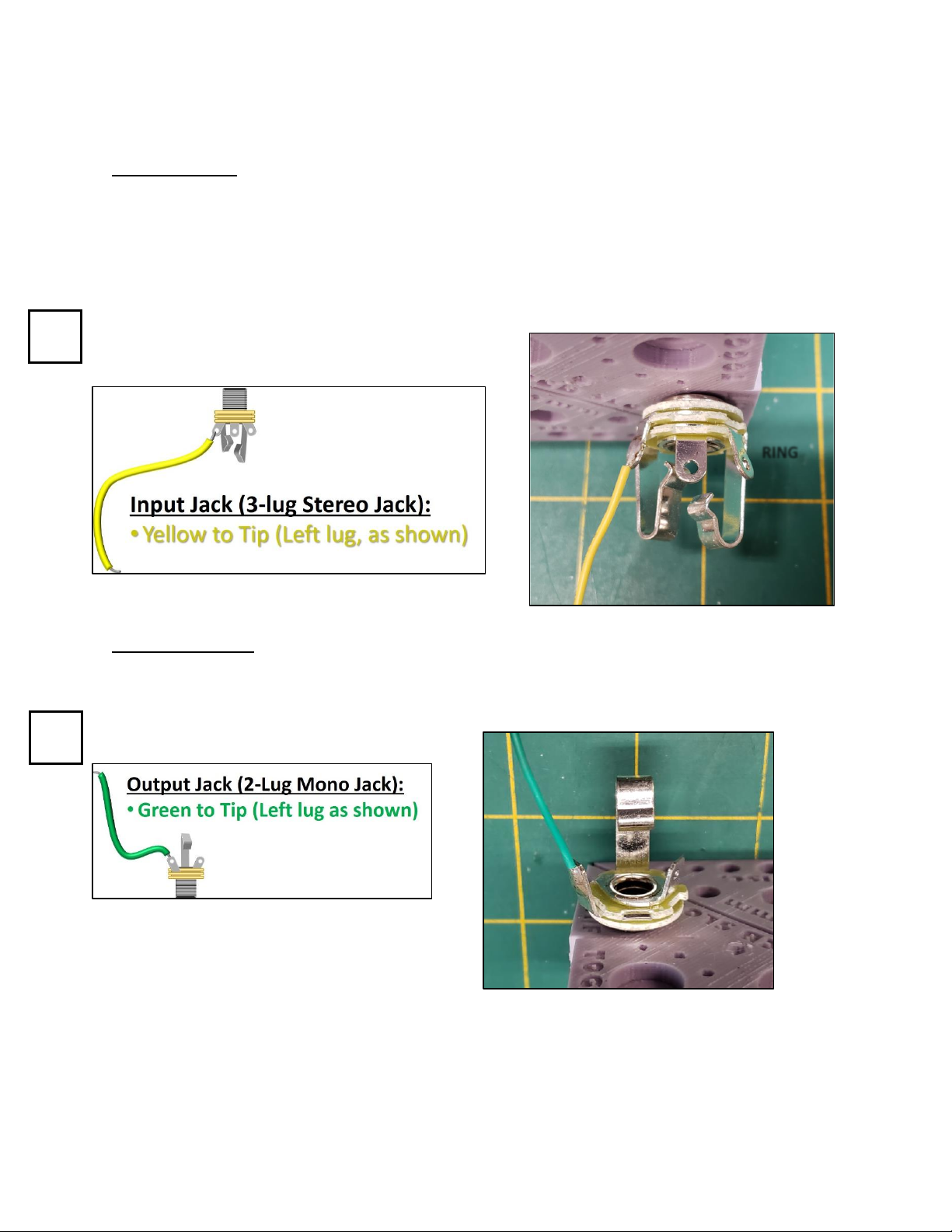

THE INPUT JACK has 3 connections, commonly called a “Tip/Ring/Sleeve”(TRS) or “Stereo” jack.

When a guitar cable is plugged-in, the ring makes contact with ground, connecting the DC

Power Jack for as long as a cable is plugged-in. Unplug to de-energize the circuit or save battery

if you’re using the 9V battery adapter cable.

The diagram here shows the installed position in the enclosure: Solder lugs UP.

•Yellow to Tip (Left lug)

•

THE OUTPUT JACK has 2 connections, commonly called a “Tip/Sleeve” (TS) or “Mono” jack.

The diagram here shows the installed position in the enclosure: Solder lugs UP.

•Green to Tip (Left lug)

TIP

SLEEVE

RING

Check-Off

Check-Off

TIP

SLEEVE

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

19

THE VOLUME POT is a B250k Pot with 3 connections. The outside two are the ends of a “C-

shaped” resistor, and the center connection is a moveable point (“wiper”) along that resistor.

Turning the knob changes the resistance between the center terminal and each end. The

Volume Pot literally shorts more of the signal to ground, as you turn it down.

With wires pointing LEFT:

•RED to Center

It really helps to write a “V” on this potentiometer

if you have more than one knob on your pedal.

Use a leftover leg from one of the PCB components to make a jumper between Pins 1 and 7.

THE FOOT SWITCH has 9 connections. It is a single button that controls 3 switches at one time.

•Switch 1 is on pins 1, 2, and 3 (This will be the input Switch)

•Switch 2 is on pins 4, 5, and 6 (This will be the LED on/off Switch)

•Switch 3 is on pins 7, 8, and 9 (This will be the output Switch)

It is a “3-Pole”(3 switches in one), “Double-Throw”(2-position) switch, AKA: a “3PDT Switch.”

If you want more information about this type of switch (I know you do!), Google: “3PDT Switch”

Jumper between pins 1 and 7

Cut-off the ends of the jumper

Check-Off

Check-Off

AUSTINDRIVE Assembly Tutorial Rev 3.02 December, 2020

20

Otherwise, the things you need to know to continue are:

1. The orientation matters. The pins are rectangles: Longer in one direction than the

other. In the diagrams above and below, the pins are taller than they are wide. If the

switch is oriented like this diagram in your enclosure, the pin numbers will be correct.

2. The switch can be turned 180° and still be wired correctly.

3. View the images above and see photos of the complete build if you are unsure.

4. Don’t forget to put a jumper between pins 1 and 7. Use a cut-off leg from one of your

resistors or capacitors from the PCB soldering section.

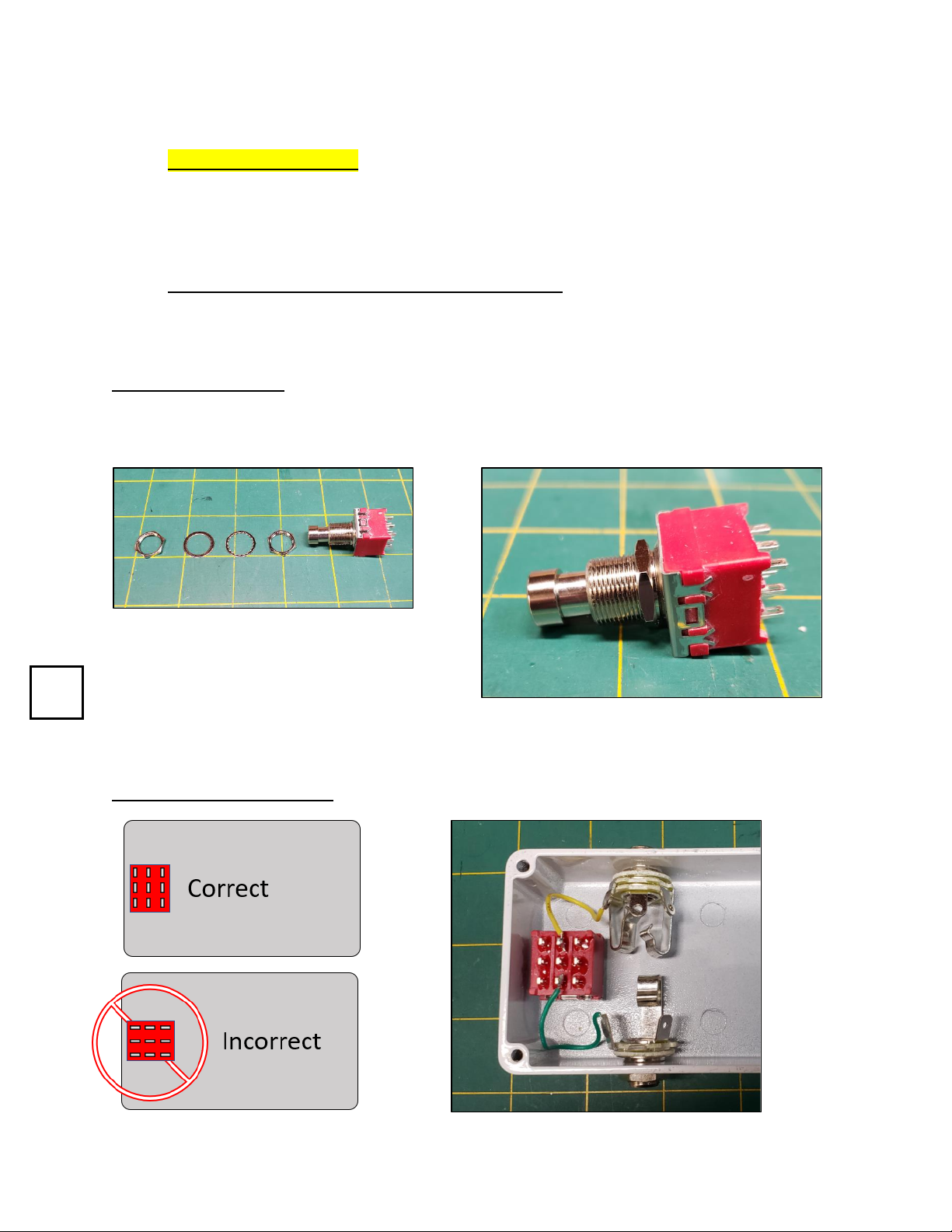

Install the Foot Switch

The foot switch has 2 lock nuts, a tooth washer and a flat metal washer. Remove everything

then thread one nut on the switch so that goes all the way to the bottom of the shaft:

Install the tooth washer on top of that first

nut, and put the switch through the enclosure

from the inside. With the lock nut and the

tooth washer inside the enclosure, the flat

metal washer and the remaining nut are installed from the outside. Be sure the rectangle lugs

are oriented vertically as shown. Your switch may vary in color from these images.

Installation in the enclosure:

Check-Off

Table of contents