AUSTRAMAC FLASHCUT 1400 RM User manual

1

OPERATORS MANUAL:

Diamond Rock Saw

Excavator Attachment

AUSTRAMAC FLASHCUT 1400 RM

WARNING!

Inappropriate use of rock saw may cause

serious injury or death. Operators must read this manual

before use and follow all instructions.

If ever in doubt please call AUSTRAMAC Australia on (02) 9099 9774 for

assistance. Keep this operation manual for future reference.

©

Copyright June 2016

AUSTRAMAC PTY LTD

The information in this document is copyright. No part may be reproduced by any process

without written permission from the Directors of AUSTRAMAC PTY LTD.

2

Table of Contents

MACHINE INFORMATION:.....................................................................................................3

FLASHCUT 1400RM

Machine Components

...........................................................3

Identification of Symbols:

...............................................................................................3

SAFETY PRECAUTIONS:..........................................................................................................4

Essential Safety Information:

........................................................................................4

Transport Handling and Storage:

...............................................................................5

Installation and Commissioning.....................................................................................6

Use

..............................................................................................................................................8

•

Secure work site

...........................................................................................................8

•

Plan for cut

......................................................................................................................8

•

Position excavator

......................................................................................................9

•

Operate saw

...................................................................................................................9

•

Clean saw

...................................................................................................................... 10

•

Post use inspection

.................................................................................................. 10

MAINTENANCE AND SERVICING..................................................................................... 11

SUGGESTED PRE-START CHECK...................................................................................... 13

3

MACHINE INFORMATION:

The AUSTRAMAC FLASHCUT Series Rock Saws have been specifically

designed for the use on excavators to cut through concrete, brick walls and rock.

AUSTRAMAC is a leading designer, manufacturer, supplier and service

provider of hydraulic diamond tipped rock saw attachments. Through innovative

design and high safety standards. AUSTRAMAC has developed a rock saw that

minimizes noise, vibration and dust. The FLASHCUT series is specifically

designed to be used on excavators and places very little pressure on them due to

its high speed and low power requirements. Some of the innovative features of

the

FLASHCUT 1400 RM

includes the rotating guard, rotating stand and the

elimination of the need for case drains.

The rock saw is not designed to cut

through metal that isnot encased in concrete.

FLASHCUT 1400RM

Machine Components

Identification of Symbols:

WARNING!

Inappropriate use of rock saw may cause serious injury

or death. Operators must read this manual before use and follow all

instructions.

4

SAFETY PRECAUTIONS:

WARNING!

Inappropriate use of rock saw may cause serious injury or death. It

is essential that operators read and follow all instructions in this manual. Operators

must complete an induction with approved AUSTRAMAC technician and prove they

arecompetent in use prior to handover. Pre start checks must be completed and the

machine maintained to ensure the safety of operators and others.

Essential Safety Information:

1.

Prior to use the

pre start check

must be completed on the saw and

attachment points including the following:

a.

Ensure the pickup and the quick hitch (or pins) are securely

attachedto the rock saw.

b.

Ensure the hydraulic hoses are secured and in good condition.

c.

Ensure the water is attached and that there is adequate flow.

d.

Ensure the guard is in the correct position and that it is secure.

e.

Check the saw blade has no more than two segments in a row

missing and no more than 4 in total missing.

f.

Ensure adequate cutting time is left on blade (minimum 3 mm).

g.

Ensure blade bolts are tightened to 120Nm and flange bolts to140Nm.

h.

Ensure that there is no play in excavator arm.

2.

Operator must complete a test run prior to cutting.

3.

Ensure that the work area is secure and that all persons are moved to a safe

distance.

4.

Complete a survey of the site including all

underground services,

overhead wires

or other structures that may cause a hazard prior to operating

saw.

5.

Ensure excavator is in stable secure position prior to operating saw.

6.

Operator and others in immediate work area to wear appropriate face,

hearing and head protection at all times.

5

7.

Ensure guard and mud flap are in position and in good condition.

8.

Operator to work inside appropriately screened excavator, never

stand or operate saw in the same plane as the blade and always

stand at a safe distance from the saw (minimum 30m).

9.

Rock saw to be checked every hour and after use for damage or lose

bolts.

10.

Only use approved AUSTRAMAC blade designed for material being

cutand the correct size for the rock saw (do not cut metal unless it is

imbedded in concrete).

11.

Operator to observe blade at all times while cutting, if circular

scratches are observed on boundary wall, or blade begins to wobble

cease cutting immediately and check bolts.

12.

Never use a blade that is out of tension.

13.

Keep saw well clear of excavator and other persons.

14.

Once the cut is complete slowly raise the saw so that only

approximately 100mm of blade is in the cut. Turn off oil and allow

blade to stop in cut. Remove saw from cut and place on stand.

15.

Always turn off machine and remove key when getting out

ofthe excavator or performing any maintenance or inspection.

16.

Never apply lubricants or anti cease to bolts.

Transport Handling and Storage:

It is essential that the rock saw is transported in a safe manner to ensure

the safety of other and that the machine is not damaged.

AUSTRAMAC supplied a stand and strap for the purpose of

transportation. The rock saw has a tag indicating the weight of the rock

saw and blade. The tag also indicates the weight of the saw, blade and

stand combined. Operators are responsible for ensuring that they safely

transport the rocksaw. The rock saw is delivered fully assembled and

ready for use.Operators should consult AUSTRAMAC for guidance on

any repairs or maintenance.

6

Transportation Guidelines:

1.

Only approved AUSTRAMAC stand to be used to store rock saw.

2.

Use lifting equipment to load rock saw. Ensure lifting equipment is

capable of taking the load of the machine as indicated on rock saw

identification stamp.

3.

Strap rock saw to stand with approved strap supplied by

AUSTRAMAC or another strap capable of taking the load.

4.

Ensure quick hitch is secure when lifting with excavator and pin

inserted where appropriate.

5.

Lift rock saw and position with lifting equipment or excavator on to

transport vehicle.

6.

Ensure rock saw is carefully placed on stand and does not contact

ground etc. take care with blade.

7.

Attach rock saw with chains or straps capable of holding the load.

8.

Ensure that transport vehicle is capable of taking load of rock saw

and stand an indicated-on rock saw identification badge.

9.

Unlock rock saw and stand following above procedures in reverse.

10.

Carefully place rock saw and stand on secure level ground.

Installation and Commissioning

The rock saw comes with all parts assembled ready for use.

Operators

should consult AUSTRAMAC prior to completing any service,

repair ormodifications.

It is essential that the rock saw is securely

attached to the excavator at all times to prevent serious injury to operators

or others and damage to the machine. Operators must attach the rock saw

as indicated below and perform a “

Prestart Check

” on the machine prior

to use (a sample prestart check has been provided at the end of this

manual).

7

Installation and commissioning guidelines:

1.

Connect rock saw to excavator with quick hitch or manually secure

pin. Operator to ensure that:

a.

Quick hitch (or pins) matches the rock saw pick up.

b.

Pin is always securely inserted in quick hitch.

c.

All debris is removed from attachment points.

d.

The pickup devices are securely attached to the saw.

e.

All operators must be educated on connection procedure at

handover.

f.

Head bracket bolts are tight.

2.

Connect Hydraulic hoses. Operators to ensure:

a.

All operators must be educated on connection procedure at

handover.

b.

Connections are tight and are not cross threaded.

c.

Appropriate hose and connectors are used.

d.

Pressure limiting device is installed.

e.

Maximum pressure and flow rates do not exceed levels

indicated on identification badge.

f.

Hoses are kept clear of blade at all times.

3.

Connect water hose. Operators to:

a.

Ensure water hose is connected for every cut.

b.

Ensure that flow rate is appropriate to control dust and cool

blade.

c.

Cease cutting if water stops.

4.

Pre start check list of rock saw (sample attached at end of manual)

to be completed prior to every operation. Pre start check should

include but not be limited to:

a.

Operator to check connection to excavator is secure.

b.

Hoses are connected appropriately.

c.

Head bracket is tight.

d.

Rock saw guard is in the correct position and secure.

8

e.

No more than two segments in a row missing on the blade and

no more than 4 in total are missing.

f.

Adequate cutting time left on blade (minimum 3mm).

g.

Blade bolts are tightened to

120Nm and flange bolts to140Nm

.

5.

Operator to warm up hydraulic fluid,

ensure hydraulic fluid in

excavator is free of contamination and complete test run prior

to cutting.

Use

Inappropriate use of the rock saw may cause serious injury or death. It is

essential that operators follow the instructions for use and that they follow

the instructions provided at the handover of the machine. Operators

should also consult the operator’s manual for the excavator license. The

following job steps and safety precautions outline the requirements for

safe suit of the rock saw.

•

Secure work site

1.

Ensure worksite is secure and signposted at all times.

2.

No persons to enter 30m exclusion zone.

3.

Persons to never stand in the same plane as the cutting blade.

4.

Ensure guard is in appropriate position at all times.

5.

Operators must hold appropriate license for excavator.

6.

Induction to be completed with all operators prior to

commencement.

•

Plan for cut

1.

Site controller to discuss cut with operator and plan procedure.

2.

Services inspection to be completed prior to cut (Dial before you

dig).

3.

Operator to inspect site for all hazards including overhead wires,

structures, hazards slopes, trenches or slippery surfaces.

4.

Warn all other workers in vicinity of works being completed.

9

•

Position excavator

1.

Operator to ensure excavator is on stable level footings and secure.

2.

Operator to follow excavator operating instructions.

3.

Never attempt to move or stop the excavator using the saw as a

lever.

4.

Operator to complete “two-point test” at start and of cut to

check alignment

•

Operate saw

1.

Operator and others in immediate work area to wear hearing

protection

2.

Operator and others in immediate work area to wear eye protection

at all times.

3.

Operator to ensure guard and mud flap are in position and in good

condition.

4.

Operator to work inside appropriately screened excavator.

5.

Operator not to work in same plane as saw.

6.

Ensure operator is at least 800mm outside plane of saw.

7.

Never place pressure on blade, do not pull through cut.

8.

Operator to cut in download motion using weight of saw, complete

cut then raise the saw and move to next cut.

9.

Ensure saw is lined up with previous cut and aligned correctly.

10.

Do not exceed maximum hydraulic pressure or flow rate of saw (as

indicated on identification label).

11.

Keep blade well clear of excavator at all times.

12.

Do not remove guards or mud flap.

13.

Ensure metal part of blade is touching ground on side mud is being

ejected.

14.

If parts of guard are removed for detailed cuts operator to ensure

that appropriate screen is in place to protect operator from being hit

by flying objects. All other persons must be moved to a distance of

30m from saw.

10

15.

Removal of guard is not recommended.

16.

Operator to check all equipment as listed in pre start check (above)

after completing a test cut.

17.

Equipment to be checked every hour for damage or lose bolts.

18.

Operator to only use approved AUSTRAMAC blades designed for

material being cut and the correct size for the rock saw (see

identification label).

19.

Operator to observe blade at all times while cutting, if circular

scratches are observed on boundary wall, or blade begins to wobble

cease cutting immediately and check bolts.

20.

Never use blade that is out of tension.

21.

Ensure that excavator is operated as per manufactures instructions

and appropriate warning lights and signals are operating.

22.

Once the cut is complete, slowly raise the saw so that only

approximately 100mm of blade in still in the cut. Turn off oil and

allow blade to stop in cut. Remove saw from cut and place on stand.

•

Clean saw

At completion of work operator to wash down rock saw to assist with

inspection and clean parts.

•

Post use inspection

1.

Operator to inspect the saw at completion of cutting and at regular

intervals.

2.

Operator to check connection to excavator secure, hoses are

connected appropriately, head bracket is tight, the guard is in the

correct position and secure, no more than two segments in a row

missing and no more than a total of four missing on the blade,

adequate cutting time left on blade (minimum 3mm), bolts to blade

are tightened to

120Nm and flange bolts to140Nm

, all components and

bearings are tight.

3.

Operator to wear leather gloves and never place hand over hydraulic

leaks.

11

4.

Operator to ensure that they have the excavator key with them when

completing inspections to avoid unexpected start up.

MAINTENANCE AND SERVICING

The rock saw is a precision instrument and must be handled with care. The

blade and other components are designed for high-speed low torque cutting

and do not require excessive force to perform their operations. Operators

should always take care with the machine and only use it for the processes it

is designed to perform. If the rock saw is maintained and used correctly the

rock saw will have a long life and will perform exceptionally well. It is also

important that the excavator is maintained as this will impact on the rock saw.

The excavator oil should be free from contamination, the pickup should

be tight and the bushes in the excavator arm should not be worn.

The following maintenance and servicing are recommended:

1.

Equipment to be inspected before and after every use as outlined in the

pre start checklist.

2.

The rock saw must be serviced by qualified persons (Approved by

AUSTRAMAC) every 500 hours of operation or as necessary.

3.

Rock saw motor lubrication to be changed every 500 hours or as

necessary.

4.

Blade to be serviced if more than two segments in a row are missing,

more than a total of 4 segments missing, if the metal is less than 5 mm

thick or if segments are worn out (less than 3mm).

5.

Blade to be serviced if it has lost tension.

6.

Blade replacement and repair should be undertaken by approved

AUSTRAMAC technicians.

7.

Never apply anti cease or lubrication to bolts.

8.

If replacing blade, ensure blade bolts are tightened to

120Nm and flange

bolts to140Nm

.

12

The maintenance manual supplied should be filled in at all maintenance

and kept with the machine along with the operator’s manual and the pre

start checks.

13

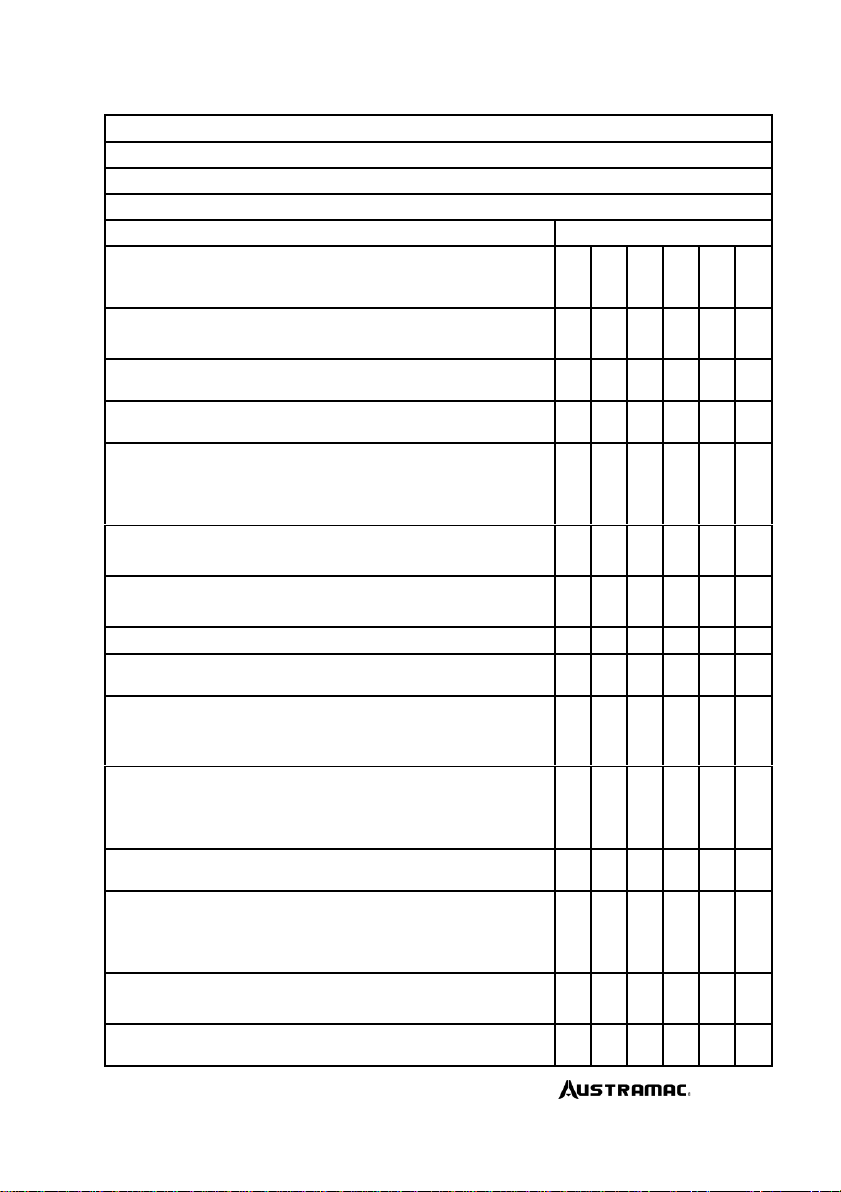

SUGGESTED PRE-START CHECK

Rock Saw Number:

Operator:

Date:

Inspection Item:

Check

Are pick up and the quick hitch (or pins) securely

attached to the rock saw?

Are hydraulic hoses appropriately secured and in

good condition?

Is the water attached and is flow rate adequate?

Is the guard in the correct position and secure?

Are there no more than (2) two segments in a row

missing and no more than (4) four in total missing

on the saw blade?

Is there adequate cutting time left on blade

(Minimum 3mm)?

Are the blade bolts tightened to

120Nm and

flange bolts to140Nm

?

Is the blade still in tension?

Is there no play in excavator arm?

Is the work area secure and all persons are moved

to a safe distance?

Has a survey of the site been completed including

all

underground services

, overhead wires or

other structures that may cause hazard?

Is the excavator in a stable secure position?

Are the operators and others in immediate work

area wearing appropriate face, hearing and head

protection?

Is the guard and mud flap in position and in good

condition?

Is the excavator oil free from contaminants?

14

Table of contents

Popular Saw manuals by other brands

Evolution

Evolution R185SMS-Li Original instructions

EINHELL

EINHELL TC-SB 245 L operating instructions

Anova

Anova MB300 Instruction and user's manual

Scheppach

Scheppach HM100T Original operating manual

METAWOOD

METAWOOD MTSB250-6 manual

Parkside

Parkside PSSAP 20-Li B2 Operation and safety notes translation of the original instructions