AUTEC Dynamic Series User manual

Original instructions

DYNAMIC SERIES

Receiving unit PCR

INDEX

1 Description ............................................................................................................ 2

2 Technical data ....................................................................................................... 3

3 Technical data sheet ............................................................................................. 3

4 Plates ..................................................................................................................... 4

5 Light signals .......................................................................................................... 4

5.1 POWER LED (green) ....................................................................................... 4

5.2 ALARM LED (red) ............................................................................................ 5

5.3 STATUS LED (blue) ......................................................................................... 5

5.4 LED RUN (green) e LED ERR (red) ................................................................. 5

5.5 SETUP LED (yellow) ........................................................................................ 5

6 Malfunction signalled by the receiving unit ........................................................ 6

AUTEC

LIPCRE00-00

2

LIPCRE00-00

Description

AUTEC - Dynamic Series

1 Description

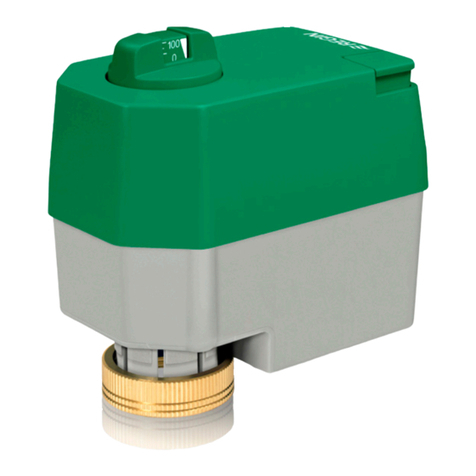

Aplugs

Bmounting holes

CAntenna

DLED

ETechnical data plate

FRadio remote control identication

plate

The receiving unit is interfaced with the machine through the outputs and their wiring and/or

through a CAN network (of which it is a master node).

The STOP (STP_1 and STP_2) and SAFETY (SAF_1 and SAF_2) outputs are some of the

receiving unit's outputs.

AUTEC - Dynamic Series

Technical data 3

LIPCRE00-00

2 Technical data

Power supply ........................................................................................................ 8-30V

Antenna .............................................................................................................. dedicated

Rated current of STP_1 and STP_2 outputs .................................................... 2A (30V )

Rated current of the SAF_1 output .................................................................. 2A (30V )

Rated current of the SAF_2 output .................................................................. 2A (30V )

Rated current of digital outputs ........................................................................ 2A (30V )

Rated current of analogue outputs (PWM) ....................................................... 2A (30V )

Rated current of analogue outputs (voltage) ............................................... 10mA (28V )

Protection of power supply (resettable fuse) ............................................................... 1.3A

Protection of outputs (fuse F1) ....................................................... 10A (32V , autofuse)

Protection of the SAF_1 output (fuse F2) .......................................... 3A (32V , autofuse)

Protection of the STP_2 output (fuse F3) .......................................... 3A (32V , autofuse)

Protection of the SAF_2 output (fuse F5) .......................................... 3A (32V , autofuse)

Protection of the STP_1 output (fuse F4) .......................................... 3A (32V , autofuse)

Housing material ................................................................................................ aluminum

Protection degree ....................................................................................... IP65 (NEMA 4)

Dimensions .................................................................... 260x160x70mm (10.2x6.3x2.7In)

Weight ............................................................................................................. 2kg (4.4Lb)

3 Technical data sheet

The technical data sheet contains the wiring diagram showing the connection between the

receiving unit and the machine. It also contains the transmitting unit conguration and shows

the matching between commands sent and machine functions/movements.

Each technical data sheet must be lled in, checked and signed by the installer, who is

responsible for a correct wiring.

A technical data sheet must always be kept toghether with this manual (always keep a copy

of the technical data sheet when it is used for administrative purposes).

The wiring of the receiving unit outputs must always reect the wiring

indicated in the technical data sheet.

4

LIPCRE00-00

Plates

AUTEC - Dynamic Series

4 Plates

The receiving unit has the following plates:

Plate Position Content

radio remote control

identication plate On the casing of the receiving unit

Radio remote control

serial number (S/N), bar

code and manufacturing

year.

technical data plate On the casing of the receiving unit

MODEL, TYPE and main

receiving unit technical

data, marking and

possible radio remote

control marks.

5 Light signals

The receiving unit PCR has six LEDs:

-POWER is green

-ALARM is red

-STATUS is blue

-RUN is green

-ERR is red

-SETUP is yellow

5.1 POWER LED (green)

The POWER LED indicates the status of the receiving unit and of the radio link.

The POWER LED... Meaning

…is o The receiving unit is not powered.

...is on The receiving unit is powered and radio link is missing.

… blinks The receiving unit is powered and radio link has been

established.

AUTEC - Dynamic Series

Plates 5

LIPCRE00-00

5.2 ALARM LED (red)

The ALARM LED warns about anomalies in the receiving unit.

The ALARM LED... Meaning

…is o The receiving unit works correctly.

... blinks once Error on the STOP outputs.

... blinks twice Error on the SAFETY outputs.

... blinks three times Error on the outputs corresponding to direction

commands.

... is on The receiving unit does not work correctly.

5.3 STATUS LED (blue)

The STATUS LED warns about anomalies on the outputs or on the power supply and indicates

the reception of data from the transmitting unit.

The STATUS LED... Meaning

…is o No radio link.

... blinks slowly Over-voltage on power supply.

... blinks fast The receiving unit receives data from the transmitting unit.

... is on Over-current in one of the PWM analogue outputs.

5.4 LED RUN (green) e LED ERR (red)

RUN and ERR LED signals are congurable during the maschine installation: it is recommended

to respect the guidelines of the CANopen® standard, CiA recommendation 303-3.

5.5 SETUP LED (yellow)

SETUP LED signals are congurable during the machine installation.

6

LIPCRE00-00

Malfunction signalled by the receiving unit

AUTEC - Dynamic Series

6 Malfunction signalled by the receiving unit

Use the light signals on the receiving unit to identify the radio remote control malfunction.

If the problem persists after the suggested solution has been carried out, contact the support

service of the machine manufacturer.

Signals Possible reason Solutions

The POWER LED is o. The receiving unit is not

powered.

Disconnect the power supply

and restore it after 5 minutes

to make sure that a restorable

thermal fuse integrated in the

receiving unit has not been

activated.

Correctly plug in the

connecting plug and power on

the receiving unit.

The POWER LED is on. No radio link. Bring the transmitting unit

closer to the receiving unit.

The ALARM LED blinks

once. Error on the STOP outputs.

Make sure that fuses F3 and

F4 are intact.

Correctly plug in the

connecting plug.

Make sure that the STOP

outputs are wired correctly.

The ALARM LED blinks

twice. Error on the SAFETY outputs.

Make sure that fuses F2 and

F5 are intact.

Correctly plug in the

connecting plug.

Make sure that the SAFETY

outputs are wired correctly.

The ALARM LED blinks three

times.

Error on the outputs

corresponding to direction

commands.

Contact the support service of

the machine manufacturer.

Make sure that the outputs of

direction commands are wired

correctly.

The ALARM LED is on. The receiving unit does not

work correctly.

Contact the support service of

the machine manufacturer.

AUTEC - Dynamic Series

Malfunction signalled by the receiving unit 7

LIPCRE00-00

Signals Possible reason Solutions

The STATUS LED blinks

slowly. Over-voltage on power supply.

Make sure that the receiving

unit power supply is within the

voltage limits provided in the

technical data.

The STATUS LED blinks fast

and irregularly.

The receiving unit loses some

data sent by the transmitting

unit.

Bring the transmitting unit

closer to the receiving unit.

If this signal persists, contact

the support service of the

machine manufacturer.

The STATUS LED is on. Over-current in one of the

PWM analogue outputs.

Contact the support service of

the machine manufacturer.

Other manuals for Dynamic Series

6

Table of contents

Other AUTEC Controllers manuals