Auto-Chlor WaterSaver A4 User manual

Popular Water System manuals by other brands

Everpure

Everpure ScaleKleen EV9655-00 Installation and operation guide

Spectra Watermakers

Spectra Watermakers Ventura 150T MPC Installation and operating manual

ICA

ICA AQUA OCEAN AQ4000 instruction manual

GE

GE Merlin Application guide

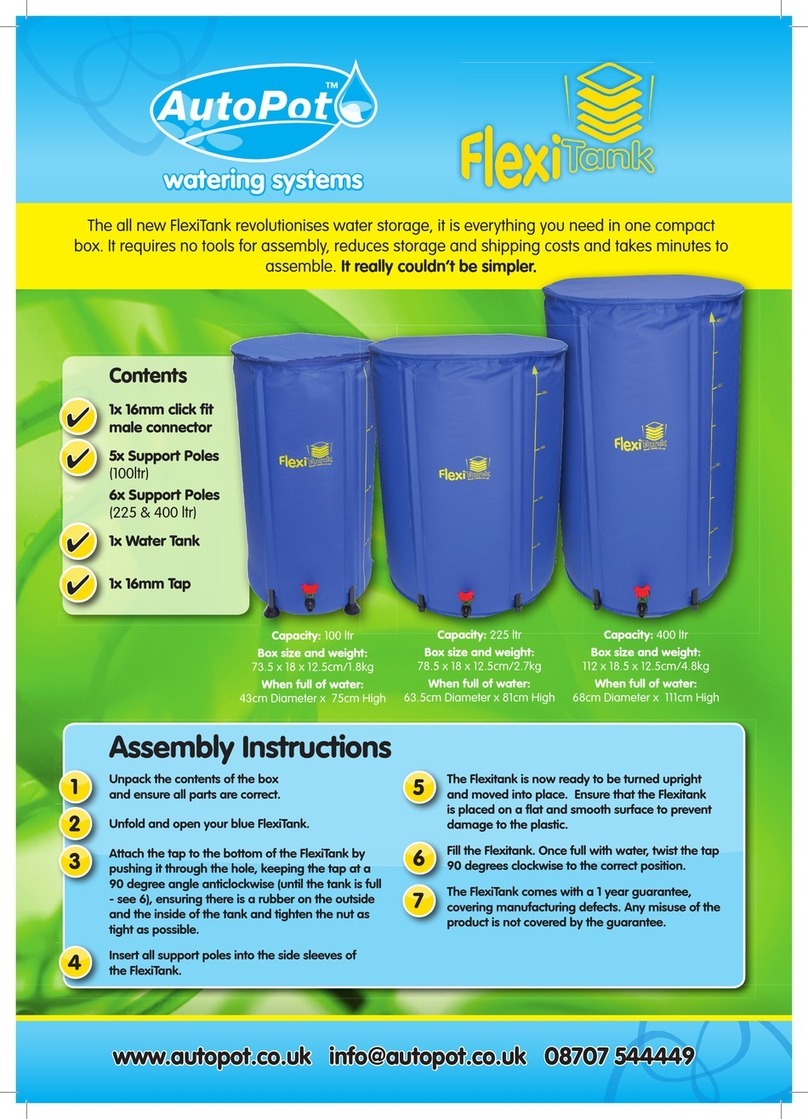

FlexiTank

FlexiTank AutoPot 100L Assembly instructions

Midea

Midea MU1649-4 instruction manual

NatureWater

NatureWater 63920 operating instructions

Ecodyne Water Systems

Ecodyne Water Systems TB-RO Installation and operation manual

BWT

BWT STARDECK INEO Installation and maintenance instructions

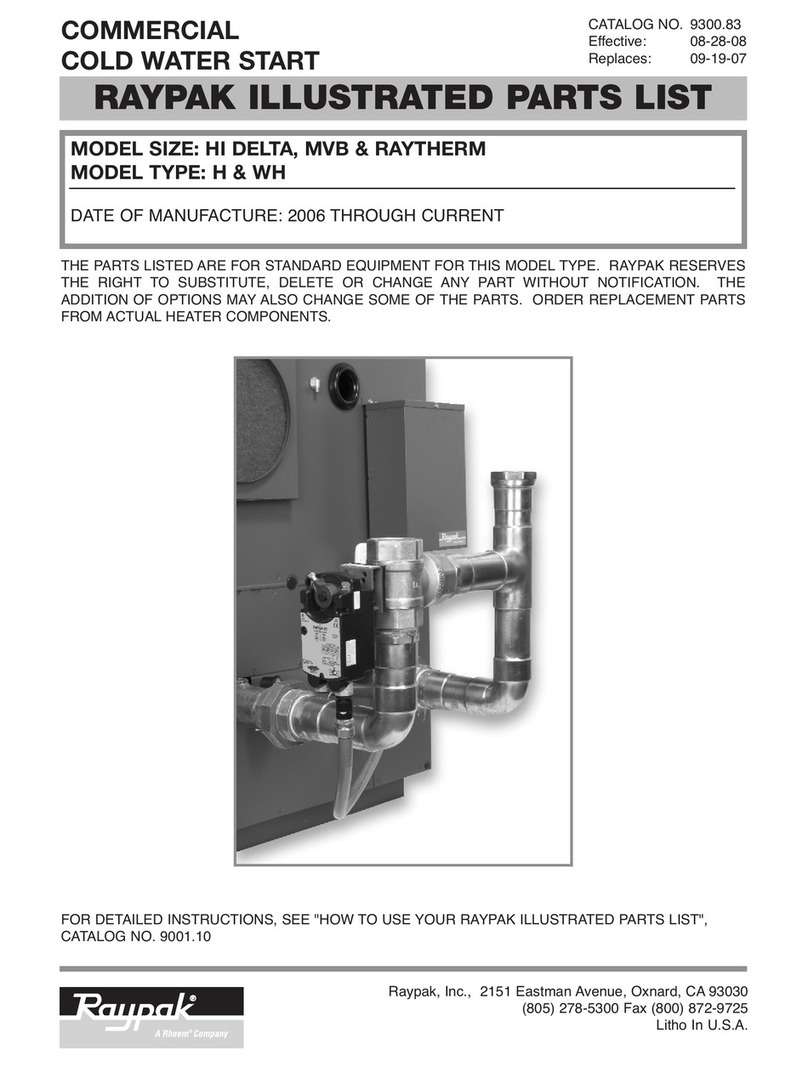

Raypak

Raypak RAYTHERM Illustrated parts list

Addie Water Systems

Addie Water Systems OXIDIZER PLUS owner's manual

SMARDY

SMARDY YR100-A Quickstart & Video Guide

Elkay

Elkay ERS1-2F Installation, care & use manual

Everpure

Everpure Insurice Triple PF-i40002 Specification sheet

Trane

Trane Axiom GEH006 manual

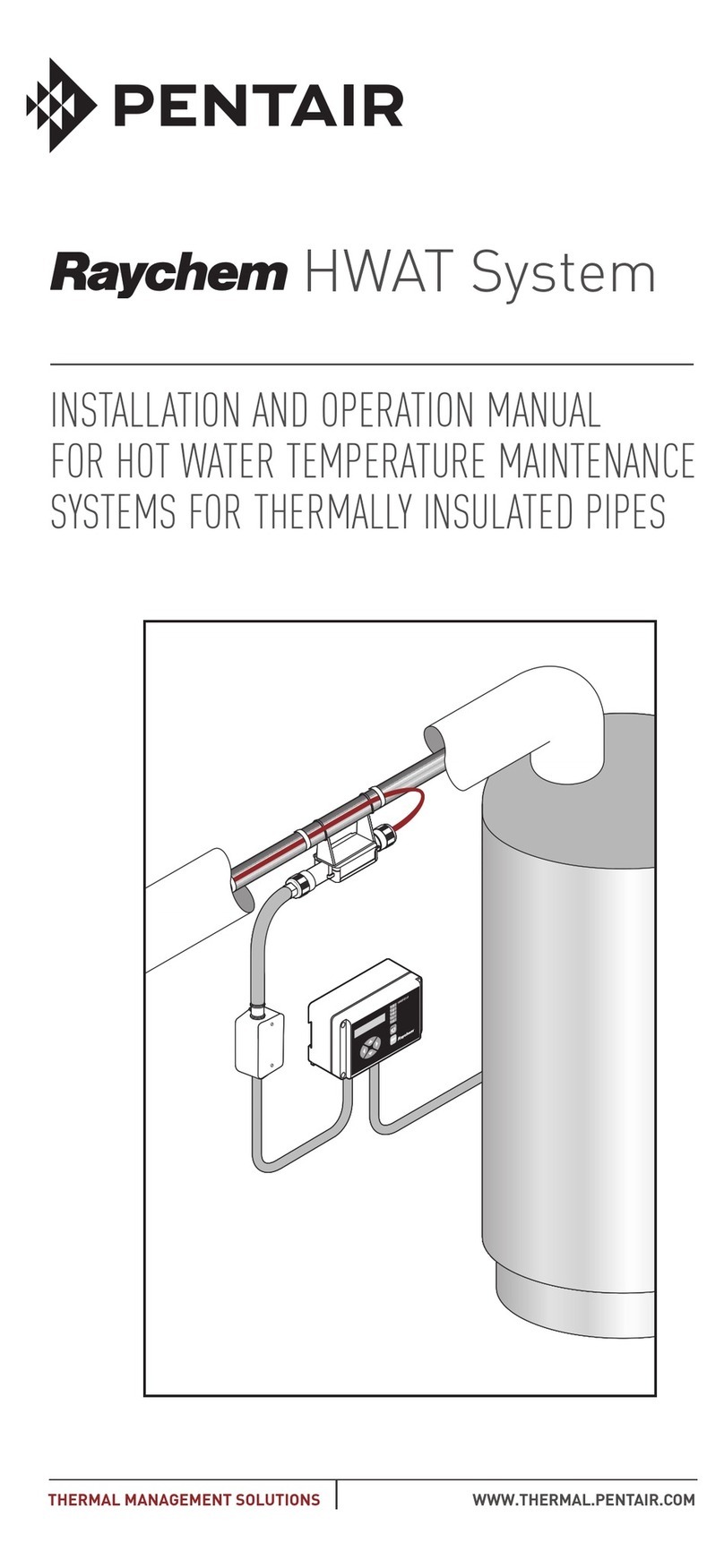

Pentair

Pentair Raychem HWAT System Installation and operation manual

POBEL

POBEL DESA 0041 using manual

Beko

Beko BEKOMAT 16i CO Translation of original installation and operation manual