10 SYSTEM PERFORMANCE

Rev C

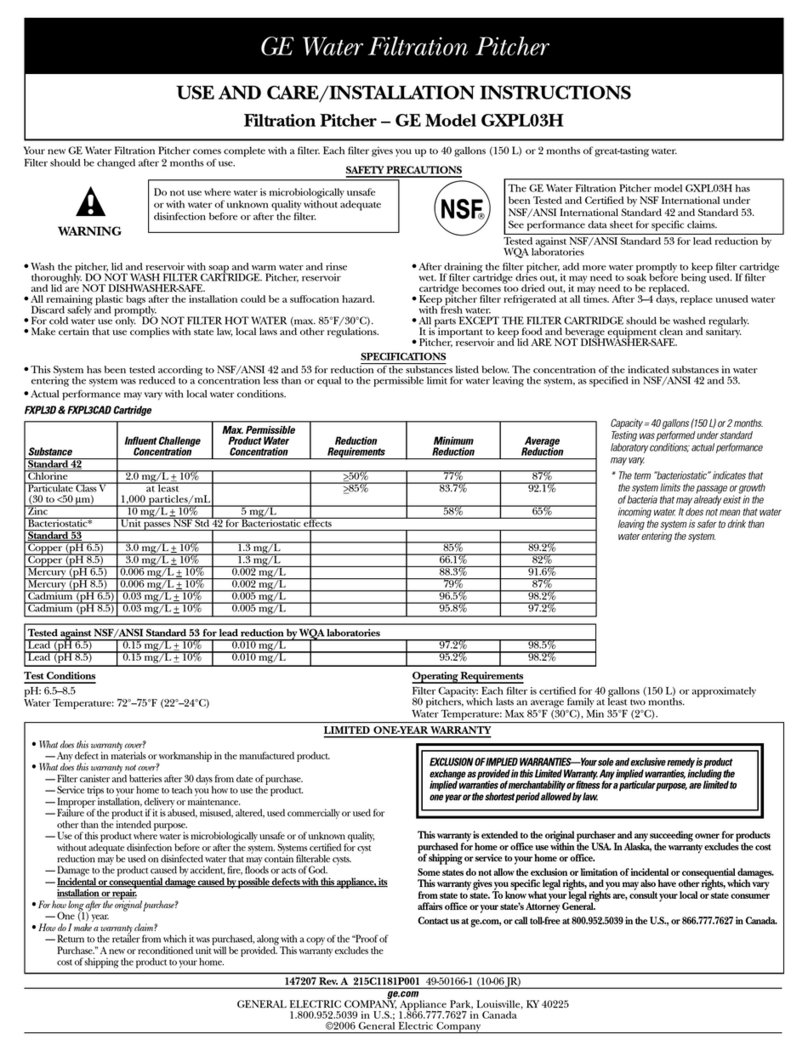

Pressure Drop Through Post Filter

The Merlin post filter is custom designed to reduce the amount of pressure

drop as much as possible. The Merlin post filter is designed to provide no

more than a 3 psi (0.21 bar) drop when brand new. Using other post filter/

post treatment methods may cause significantly higher drops in pressure.

Figure 7

The Merlin post filter uses Granular Activation Carbon (GAC). Like all other

RO systems, the post filter is critical for providing the best tasting

permeate water.

Pressure Drop Through Faucet

To estimate pressure drop through the Merlin faucet follow the steps

below:

1. Estimate flow rate into the faucet using Table 1.

Use inlet pressure into the Merlin minus the total pressure drop

caused by tubing, elevation, post filter, and obstructions as the Net

Driving Pressure for the purposes of this estimation.

2. Using the estimated flow rate found in step 1 above, find the pressure

drop through the tubing with Figure 8.

EXAMPLE:

Q: A Merlin will be installed with 8 feet (2.4 m) elevation difference

between the Merlin and the faucet. Find the elevation pressure

drop.

A: The elevation pressure drop is found as follows:

8 feet X 0.43 psi/foot = 3.5 psi elevation pressure drop

2.4 m X 0.1 bar/m = .24 bar elevation pressure drop

weuro

iefosqwe

ruqweri

uiro

weurio

wier

weuro

iefosqwe

ruqweri

uiro

weurio

wier

weuro

iefosqwe

ruqweri

uiro

weurio

wier

EXAMPLE:

Q: A Merlin will be installed with one post filter. Find the post filter

pressure drop.

A: The post filter pressure drop is found as follows:

1 post filter X 3 psi = 3 psi post filter pressure drop

1 post filter X 0.21 bar = 2.1 bar elevation pressure drop

weuro

iefosqwe

ruqweri

uiro

weurio

wier

weuro

iefosqwe

ruqweri

uiro

weurio

wier

weuro

iefosqwe

ruqweri

uiro

weurio

wier