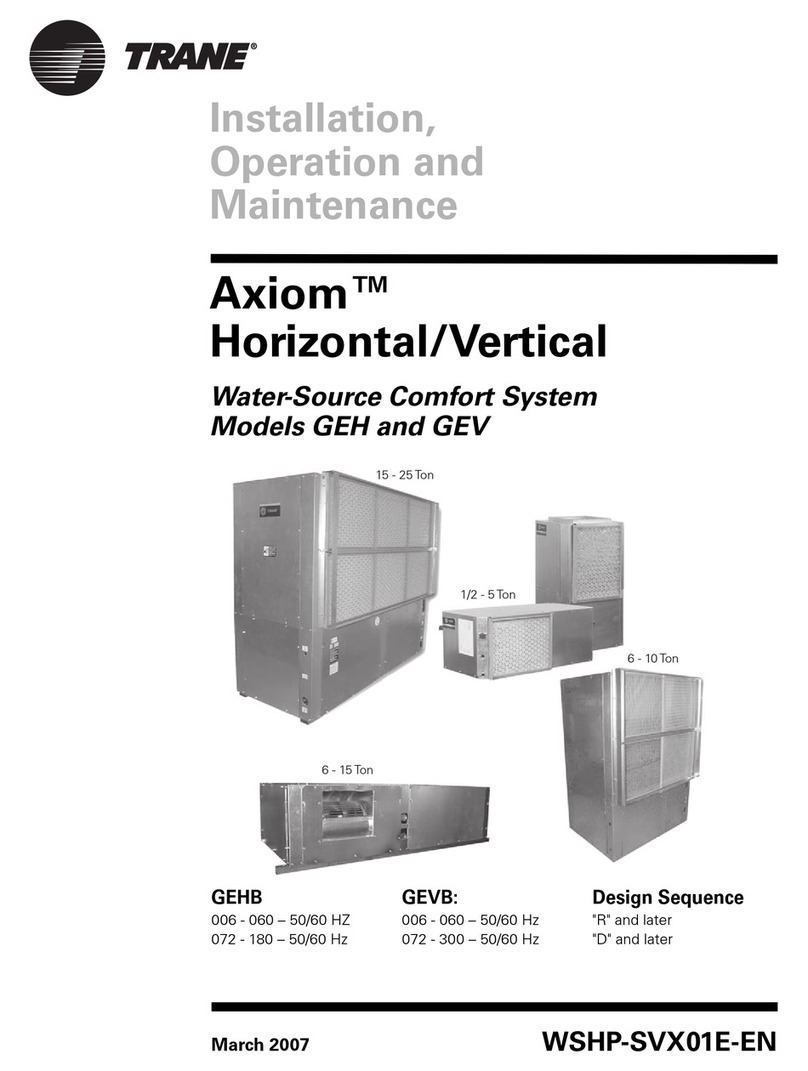

10 WSHP-PRC001-EN

Reversing Valve

A system reversing valve (4-way

valve) is included with all heating/

cooling units. This valve is piped to be

energized in the cooling mode to al-

low the system to provide heat if valve

failureweretooccur.Oncethevalveis

energized for cooling, it will remain

energized until the control system is

turned to the OFF position, or a heat-

ing cycle is initiated.

Units with the cooling only option will

not receive a reversing valve. (See

Figure 15 for reversing valve).

Blower Motor

The 1/2 through 5-ton supply-air

(blower) motor is a multi-speed motor

with internal thermal overload protec-

tion. The motor bearings are perma-

nentlylubricatedandsealed.Standard

motors are rated from .20 ESP.Option-

alhighstatic motorsareratedfrom .40

to 1.40 ESP. All motors are factory

wired to the option selected. A high,

medium, and low speed tap is provid-

ed for field customization on all volt-

ages. The speed tap modification can

be made in the control box of the unit.

(See Figure 16 for blower motor).

Note: The 380, 415, 460 and 575

volt designs are provided in a dual

or three-speed version only. See

fan performance section for factory

ratings (Page 91).

The 12 1/2 through 25 ton GEV models

incorporate a belt driven motor selec-

tion into the design. The 12 1/2 and 15

ton units include a single fan assem-

bly, while the 20 and 25-ton units in-

clude dual fan assemblies. Because

the motor sheave and the motor base

are adjustable in the field, a greater

variation in external static pressures

are available. The large tonnage units

are capable of providing 0 ESP to 3.0

ESP allowing a higher static ductwork

to be applied on the mechanical sys-

tem when the application requires

extensive ductwork design. This is a

low cost alternative to purchasing, in-

stalling, and maintaining multiple

smaller tonnage units to meet the re-

quired air flow demand for the space.

Serviceability to the motor is made

through either of the two air-side ac-

cess doors for the horizontal configu-

ration, and through one air-side

access door for the 1/2 through 5-ton

vertical configuration. The motor and

blower wheel are removable by an or-

ifice ring mounted to the fan hous-

ing.

Access to the 12 1/2 through 25 ton

units is made through the back of unit

by way of two panels, and/or through

a side access panel if adjustment to

the motor belt or motor base are need-

ed. (See Figure 17 for motor

accessibility).

Blower Housing

The blower housing is constructed of

non-corrosive galvanized steel. A fac-

tory-mountedorifice ring isprovided

for ease of motor serviceability on the

1/2 through 5-ton direct drive units.

Allair-sidepanelsareinterchangeable

with one another for ease of field con-

vertibility of the supply-air on the GEH

model.

Air-Side Filter

Theair-sidefilter incorporates a 1-inch

thick (nominal) or 2-inch thick (nomi-

nal) disposable fiberglass option.

These filters include an average syn-

thetic dust weight arrestance of ap-

proximately 75%. This dust holding

capability includes a colorless, odor-

less adhesive to retain dirt particles

within the filter media after fiber con-

tact. (See Figure 18 for filter media)

Features and

Benefits

Figure 15: Reversing valve

Figure 16: Blower motor (direct drive)

Figure 17: Motor accessibility

Figure 18: Filter media