AUTO GYRO RotorSport CALIDUS User manual

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 1 of 101 Page issue 4, dated 01.07.13

Pilots Handbook

Gyroplane Type CALIDUS (UK spec only)

RotorSport UK Ltd

Poplar Farm

Prolley Moor

Wentnor

Bishops Castle

SY9 5EJ

Company Reg No 5486550

Phone: +44 (0) 1588 650769

Fax: +44 (0) 1588 650769

Email: [email protected]

Approval number DAI/9917/06

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 2 of 101 Page issue 6, dated 12.04.16

Applicability

Aircraft Registration: G-

Aircraft serial no. RSUK/CALS/

Engine type: Rotax 912ULS or 914UL

Engine serial No:

Rotor blade type & diameter: Autogyro 8.4m rotor system,

(orange end-caps only)

or

Autogyro 8.4m RotorSystemII

(red caps only) when modified

under SB-039

or

Autogyro 8.4m Rotor System II

TOPP (blue end caps only)

NB: all types have silver spacers

(clamp profiles)

Propeller type: HTC 1,73m ground adjustable

propeller

or

IVO-prop DL3-68 in-flight variable

pitch propeller

NOTE!

This autogyro may be operated only under adherence to the

operation limits and the information contained in this

manual. The manual should be carried on board the aircraft.

The manual is not a replacement for theoretical and

practical training as to how to operate this machine. Failure

to adhere to its provisions or to take proper instruction can

have fatal consequences

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 3 of 101 Page issue 6, dated 12.04.16

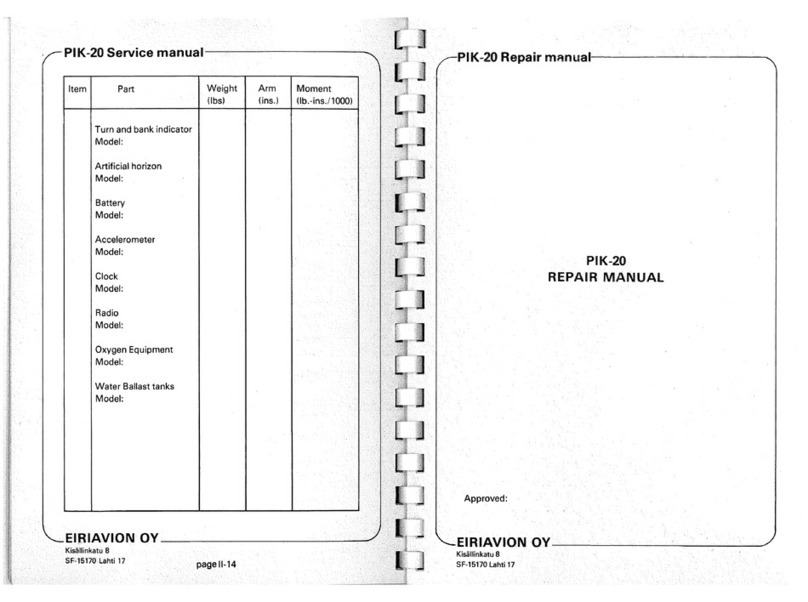

Table of contents Page

1. GENERAL

1.1 Introduction 7

1.2 UK Authority for flight 7

1.3 Explanations and sensible safety measures 7

1.4 Aircraft description 9

1.5 Pictorial views 10

2. OPERATIONAL LIMITS

2.1 Introduction 14

2.2 Airspeed 15

2.3 Airspeed indicator marking 15

2.4 Rotor 15

2.5 Engine 16

2.6 Engine instruments 16

2.7 Weight and balance 16

2.8 Fuel 18

2.9 General placards 18

3. EMERGENCY PROCEDURE

3.1 Introduction 24

3.2 Engine failure 24

3.3 Engine start in the flight 25

3.4 Abandoning the aircraft 25

3.5 Smoke and fire 25

3.6 Gliding flight & forced landings 26

3.7 Precautionary landings 26

3.8 Loss of control 27

3.9 Engine shutdown 27

3.10 PIO/reduced rotor rpm 27

3.11 Vibration 28

3.12 Other equipment failure 29

3.13 Canopy open in flight 30

3.14 Loss of vision 30

3.15 Further Information (914 UL) 30

4. NORMAL OPERATIONAL PROCEDURES

4.1 Introduction 31

4.2 Rotor rigging 31

4.3 Daily inspection 39

4.4 Flight Operation 41

4.5 Normal procedures and check list 41

5. PERFORMANCE

5.1 Performance data 47

5.2 Further data 48

5.3 Height distance diagram 49

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 4 of 101 Page issue 6, dated 12.04.16

6. DESCRIPTION

6.1 Structure 50

6.2 Controls 50

6.3 Instrument panel 56

6.4 Wheels and Tyres 64

6.5 Seats and belts 64

6.6 Engine 65

6.7 Fuel system 70

6.8 Electrical system 73

6.9 Pitot and static pressure 76

6.10 Avionics 76

6.11 Navigation lights 77

6.12 Options and Modifications 77

7. HANDLING, SERVICE AND MAINTENANCE

7.1 Introduction 87

7.2 Regular maintenance requirements 87

7.3 Repairs 88

7.4 Ground handling & road transport 88

7.5 Cleaning and care 90

7.6 Winter operation 90

8. EQUIPMENT

8.1 Minimum equipment 92

8.2 Additional equipment 92

9. IVO-PROP IN-FLIGHT VARIABLE PITCH PROPELLER (OPTION) 93

9.1 Introduction 93

9.2 Function 93

9.3 Control 93

9.4 Manifold Absolute Pressure Indications 94

9.5 Circuit Protection 94

9.6 Pilot Training & Experience 94

9.7 Normal Procedures 95

9.8 Pre-Flight Inspection 96

9.9 Coping With Malfunctions 97

APPENDIX

I Change of ownership form 99

II Incident reporting form 100

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 5 of 101 Page issue 6, dated 12.04.16

Amendments Control Page

1. Where & when necessary RotorSport UK Ltd (hereafter referred to as RSUK) will issue

updates to this manual, and will notify known owners to review the changes via the RSUK

website with changes appropriately identified by a strike in the margin.

2. Aircraft operators are responsible for ensuring that amendments to their publication are

carried out immediately and in accordance with instructions contained in amendment

transmittal letters (where issued).

ISSUE

NUMBER

DATE

INSERTED

BY

ISSUE

NUMBER

DATE

INSERTED

BY

Initial

_______

________

11

1 14.01.11 12

2 12.09.11 13

3 02.04.12 14

4 01.07.13 Superceded –

Not Published 15

5.1 10.06.14 16

612.04.16 17

7 18

8 19

9 20

10 21

Issue Change summary

4 Warning on Binx nuts (p38), different rpm gauges (p62), nitrogen-

filled tyres (p64) and pressures clarified in Checklist. 5hr greasing

added (p39-40), ATR833 audio socket (p76), AI option (p62).

Improved pre-rotator gearbox (p44), cooler unblanking highlighted

(p91), turbo cooling note (p46), UL91 and Mogas E10 (p18), rotor

brake technique (p46), Section 3.15 introduced (p30), Clutch Brake

MC260 (p44)

5.1 Section 9 IVO-prop added (p93-98), info on MC-258 cabin heater on

P74 and 84 added.

6 TOPP rotor option added p2,p5,p6,p9,p14,p15,p19,p31,p32,p36,

p46,p48

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 6 of 101 Page issue 6, dated 12.04.16

LIST OF EFFECTIVE PAGES

Page

Issue

Date

Page

Issue

Date

Page 1 4 01.07.13 Page 51 2 12.9.11

Page 2 612.04.16 Page 52 2 12.9.11

Page 3 6 12.04.16 Page 53 2 12.9.11

Page 4 6 12.04.16 Page 54 2 12.9.11

Page 5 6 12.04.16 Page 55 2 12.9.11

Page 6 6 12.04.16 Page 56 5.1 10.06.14

Page 7 1 14.01.11 Page 57 3 02.04.12

Page 8 1 14.01.11 Page 58 2 12.9.11

Page 9 6 12.04.16 Page 59 2 12.9.11

Page 10 1 14.01.14 Page 60 3 02.04.12

Page 11 1 14.01.11 Page 61 3 02.04.12

Page 12 1 14.01.11 Page 62 4 01.07.13

Page 13 2 12.9.11 Page 63 2 12.9.11

Page 14 6 12.04.16 Page 64 4 01.07.13

Page 15 6 12.04.16 Page 65 2 12.9.11

Page 16 5.1 10.06.14 Page 66 2 12.9.11

Page 17 2 12.9.11 Page 67 2 12.9.11

Page 18 4 01.07.13 Page 68 2 12.9.11

Page 19 6 12.04.16 Page 69 2 12.9.11

Page 20 6 12.04.16 Page 70 2 12.9.11

Page 21 3 02.04.12 Page 71 2 12.9.11

Page 22 2 12.9.11 Page 72 2 12.9.11

Page 23 5 10.06.14 Page 73 2 12.9.11

Page 24 2 12.9.11 Page 74 5.1 10.06.14

Page 25 2 12.9.11 Page 75 5.1 10.06.14

Page 26 2 12.9.11 Page 76 4 01.07.13

Page 27 2 12.9.11 Page 77 4 01.07.13

Page 28 2 12.9.11 Page 78 2 12.9.11

Page 29 2 12.9.11 Page 79 2 12.9.11

Page 30 6 12.04.16 Page 80 2 12.9.11

Page 31 6 12.04.16 Page 81 2 12.9.11

Page 32 6 12.04.16 Page 82 2 12.9.11

Page 33 6 12.04.16 Page 83 2 12.9.11

Page 34 6 12.04.16 Page 84 5.1 10.06.14

Page 35 6 12.04.16 Page 85 2 12.9.11

Page 36 6 12.04.16 Page 86 2 12.9.11

Page 37 6 12.04.16 Page 87 3 02.04.12

Page 38 6 12.04.16 Page 88 3 02.04.12

Page 39 6 12.04.16 Page 89 3 02.04.12

Page 40 6 12.04.16 Page 90 2 12.9.11

Page 41 2 12.9.11 Page 91 4 01.07.13

Page 42 5.1 10.06.14 Page 92 2 12.9.11

Page 43 2 12.09.11 Page 93 5.1 10.06.14

Page 44 4 01.07.13 Page 94 5.1 10.06.14

Page 45 6 12.04.16 Page 95 5.1 10.06.14

Page 46 6 12.04.16 Page 96 5.1 10.06.14

Page 47 6 12.04.16 Page 97 5.1 10.06.14

Page 48 6 12.04.16 Page 98 5.1 10.06.14

Page 49 2 12.9.11 Page 99 5.1 10.06.14

Page 50 2 12.9.11 Page 100 5.1 10.06.14

RotorSport UK Ltd approval signatures for this Pilot Handbook

Signature:

Position: Test Pilot

Signature:

Position: Engineering Manager

Signature:

Position: Head of

Airworthiness

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 7 of 101 Page issue 1, dated 14.01.11

GENERAL INFORMATION

1.1 INTRODUCTION

This manual is provided to give pilots and instructors information which contributes to the

safe and efficient operation of this autogyro.

It also contains basic information from the aircraft manufacturer, as well as the legal basis

for flight.

Pilots of this aircraft must hold an appropriate type licence, with type conversion training

by an authorised instructor.

Pilots must make themselves familiar before flight with the special characteristics of this

autogyro. Pilots are obliged to read both this pilots manual and the maintenance manual

to ensure you are familiar with all equipment and aircraft structure/engine.

1.2 AUTHORITY FOR FLIGHT WITHIN THE UK

The legal basis for the operation of this CALIDUS autogyro is regulated in the

Airworthiness Approval Notification (AAN29266), issued by the Civil Aviation Authority

(CAA). It has been shown to comply with the requirements of BCAR Section T issue 3,

and is considered as a factory built aircraft.

It is supplied by RotorSport UK Ltd.

The aircraft is equipped and permitted for daytime VFR flight only.

1.3 EXPLANATIONS AND SENSIBLE SAFETY MEASURES

The manual is not a replacement for theoretical and practical training on the operation of

this machine. Failure to take proper instruction can have fatal consequences.

The following definitions are used in this manual with warnings, precautionary measures

and remarks. Their sense and their meaning are described as follows.

WARNING: means that the neglect of the appropriate procedure will result in a direct or

critical reduction of flight safety.

NOTE: means that the neglect of the appropriate procedure will lead, on a longer time

base, to a reduction of flight safety.

REMARK: stresses the attention for a special circumstance, which does not affect safety

directly, but is still important.

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 8 of 101 Page issue 1, dated 14.01.11

PRECAUTIONARY & SENSIBLE SAFETY MEASURES

Before flight pilots should familiarise themselves with the appropriate navigational,

weather and safety information pertinent to their planned route.

Flight in severe turbulence is prohibited.

Flight near thunderstorms is prohibited

Aerobatics and manoeuvres resulting in reduced “g” are prohibited

Reason: manoeuvres where “g” is reduced results in a loss of rotor speed. Gyroplanes

rely on the centripetal load induced on the blade by rotor rpm to maintain blade

straightness, and counteract the bending moment induced on the blade during normal

flight manoeuvres. Allowing rotor rpm to decay, and then inducing high manoeuvring loads

may cause blade bending and cracking, and ultimately, blade failure. As an example, (but

not limited to), slowing the aircraft down at the top of a climb to zero airspeed (which will

reduce rotor rpm), tipping it into a stick and pedal turn such that the rotor is unloaded

further, then allowing the aircraft to drop to build momentum and then pulling-up hard

whilst still at low rotor rpm.

Smoking in the aircraft is prohibited

The choice, selection and use of this particular aircraft for the purpose chosen is at the

sole discretion and responsibility of the owner/pilot. RotorSport UK Ltd take no

responsibility for your decision to fly.

This aircraft is operated under a Permit to Fly, not a certificate of airworthiness. This

means that it is only allowed to be used for recreation, or flight training (where allowed). It

also means that the aircraft has not been certified to any international standard, and that

the components used in the aircraft are not necessarily certified parts. Whilst the

manufacturer takes great care to ensure the parts are of appropriate quality, the level of

guaranteed service is less than that with a certified aircraft, and pilot operators must

consider this in their flight planning

In common with other aircraft of this type the Calidus utilises a non-certified engine. This

means that there may be a higher risk of engine failure than in a certified aircraft, with the

associated risks of damage or injury as the result of an unplanned landing. Therefore

strict compliance with the engine manufacturer’s maintenance schedules, operational

procedures and any additional instructions which may be given to you by RotorSport UK

Ltd, on behalf of the engine supplier, is essential. The aircraft must always be flown with

the risk of engine failure in mind, and must not be flown over any areas where a forced

landing cannot be safely executed.

Similarly the aircraft instruments (and other equipment) are non-certified. Gauges may fail

completely, or part fail such that a gauge may under or over-read, or fluctuate. Good

judgement must be used in monitoring instruments, and timely action taken should a

reading be in doubt.

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 9 of 101 Page issue 6, dated 12.04.16

1.4 AIRCRAFT DESCRIPTION

Characteristics:

Autogyro

Airframe manufactured from inert gas welded stainless steel tube

Front aircraft structure is a GRP/CRP monocoque bolted to the airframe.

Two-seat tandem configuration (monocoque design)

GRP spring spar mainwheel undercarriage, and sprung nosewheel

Main wheels fitted with hydraulic disc brakes (front seat operation)

Extruded aluminium rotor

Rotor head controlled with push pull cables

Rudder controlled via cable

GRP or optional carbon fibre fin, rudder, horizontal stabilizer, engine cowlings and

body.

Engine four-stroke flat-four Rotax 912 ULS or optional Rotax 914 UL

Three-blade ground-adjustable 1.73m diameter HTC, or

Three-blade variable-pitch propeller 68inch diameter IVO-prop

TECHNICAL DATA (see also fig. 1)

Rotor diameter: 8.4. Rotorsystem II, either standard variant (red end caps) or

TOPP variant (blue end caps)

Length: 4.77m

Height: 2.74m

Width: 1.72m

Rotor blade profile: NACA 8H12

Empty weight: 270 kg nominal (see individual aircraft load sheet for specific

version weight, as the 914UL engine will add 8Kg and the IVO-prop 4Kg.

Instrument panels weights with & without GPS options vary significantly)

Payload: 230 kg nominal (see individual aircraft load sheet for specific version

weight)

Take-off mass (max.): 500 kg.

Fuel tank capacity: 39ltrs or 75ltrs with optional second tank fitted

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 10 of 101 Page issue 1, dated 14.01.11

1.5 PICTORIAL VIEWS OF THE CALIDUS (figure 1, dimensions in mm)

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 11 of 101 Page issue 1, dated 14.01.11

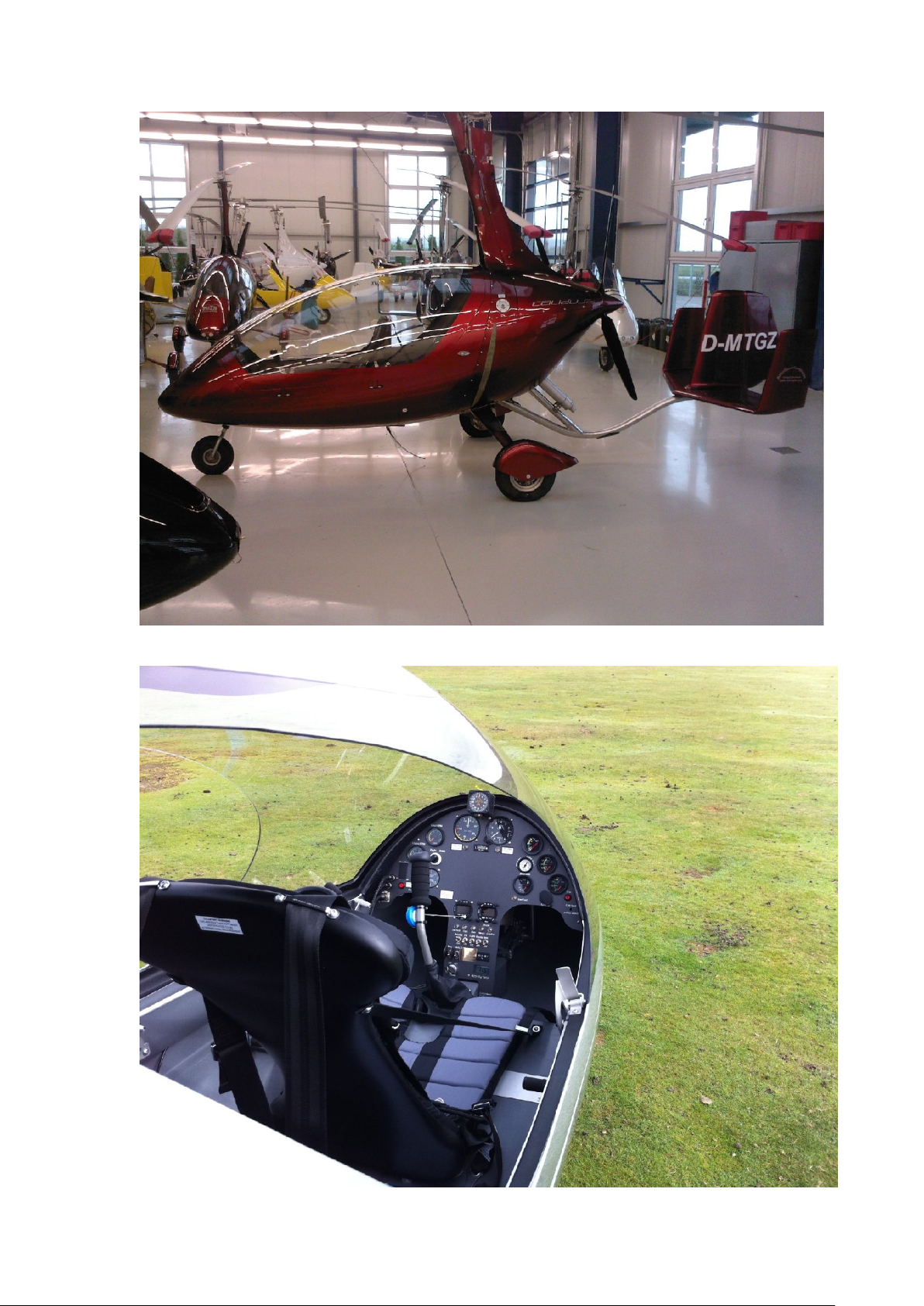

Front quarter view

Rear quarter view

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 12 of 101 Page issue 1, dated 14.01.11

View from the side

Example cockpit view (Centre blank panel for customer GPS fitment)

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 13 of 101 Page issue 2, dated 12.9.11

Intentionally blank

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 14 of 101 Page issue 6, dated 12.04.16

2. OPERATIONAL LIMITS

2.1 INTRODUCTION

This section defines the limit values for safe operation of the Calidus autogyro. It contains

the operation limits established during flight testing, as well as limit values established by

test or computation. The existing instrument placards are described.

Recommended aircraft operational temperature limits -25 degC to +50degC.

SPECIFIC LIMITATIONS AS PER THE CAA AIRWORTHINESS AUTHORISATION

NOTICE

These limitations are mandatory, and are directly copied out below.

6. Conditions Affecting This Approval

6.1 Aerobatic Limitations

Aerobatic manoeuvres are prohibited

Manoeuvres involving a deliberate reduction in normal ‘g’ shall be avoided

6.2 Loading Limitations

Maximum Total Weight Authorised: 500kg

Maximum Empty Weight 311.6 kg (914UL) 309Kg (912ULS)

Maximum Pilot Weight front seat 125 kg

Minimum Pilot Weight front seat 65 kg

Maximum Occupant Weight rear seat 120 kg

Front seat occupants under 65 kg in weight must carry suitable ballast

6.3 Engine Limitations

Maximum take-off (max. 5 minutes) 5800 rpm

Max. continuous 5500 rpm

Max. CHT 135ºC

Min. oil temp. 50ºC

Max. oil temp. 130ºC

Min. oil pressure 0.8 bar

Normal operating range 2-5bar

Max. oil pressure 7 bar

6.4 Air Speed Limitations

Maximum indicated air speed (IAS) 90 mph,or 120mph if SB-039

incorporated, or 120mph if SB-039 incorporated and Rotor System II TOPP rotor

variant fitted (blue end caps)

6.5 Other Limitations

The aircraft shall be flown by day in visual meteorological conditions only.

Flight in icing conditions is prohibited (not placarded)

Flight in strong gusty winds or wind velocities of more than 45mph (40 kts) is

prohibited. (not placarded)

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 15 of 101 Page issue 6, dated 12.04.16

Manoeuvre Limitations

Aerobatic manoeuvres are prohibited.

Manoeuvres involving a deliberate reduction in normal ‘g’ shall be avoided.

Maximum bank angle 60 degrees from vertical

This aircraft shall be flown by day and under Visual Flight Rules only

CROSS-WIND

The maximum cross-wind component for takeoff is 22kts.

Landing should always be made into wind where practical. The maximum landing

crosswind 15kts.

Ensure you read your CAA Operational Limitations (part of the Permit to Fly) for exact

limitations of your aircraft.

2.2 AIRSPEED

The values below are indicated speeds (IAS) measured via the ASI metering hole,

centrally located in the fuselage nose.

VNE Maximum speed 90 mph, or

120mph if SB-039 incorporated

Vclimb Best climb speed 70mph

VAManoeuvre speed 80mph

VApproach Approach speed. 70mph (1st stage) 55mph (final)

VTMax speed in turbulence 70mph

Best glide speed (for maximum range) 60mph

Min rate of descent speed (min height loss) 40mph

WARNING! The maximum speed VNE must be never exceeded! Operating in excess

of this is dangerous, as this area is the safety margin to the maximum design

speed!

2.3 AIRSPEED INDICATOR MARKS

Green range (normal range) from 30-80mph

Yellow range (caution, especially nearing Vne) from 0 to 30mph, and from

80 to 90 mph

Red line (VNE) at 90 mph, or 120mph if SB-039 incorporated, or 120mph if SB-039

incorporated and Rotor System II TOPP rotor variant fitted (blue end caps)

2.4 ROTOR

Once airborne, the rotor will maintain and manage its rotational speed to match the load

exerted on it. An rpm gauge is provided to enable the pilot to easily see the rpm whilst pre

rotating and making ready for take-off, and as an in-flight monitor.

Gauge markings:

0 to 200, amber. Take care in this range, keep the stick into the wind. Allowing the wind to

get under the rotor at low rotor rpm, or leaving the stick free in windy conditions may allow

blade flap. This may damage your aircraft!

200 to 550rpm, green. Full power can be applied in take-off from 200rpm. Normal flight

range depends on loading, see 5.1, performance data.

550 to 610rpm, amber. In this range the aircraft is pulling in excess of 3G. Do not

increase G load further, reduce power and return to normal flight conditions and rotor rpm

610 rpm red line. Do not exceed. Estimated in excess of 3G loading.

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 16 of 101 Page issue 5.1, dated 10.06.14

2.5 ENGINE

Manufacturer: Bombardier Rotax, Gunskirchen/A

Type: Rotax 912 ULS or Rotax 914UL

Take-off power: 100 HP/5800 rpm (for 5 minutes max operation), 115HP/5800

for the 914UL (for 5 minutes max operation)

Continuous duty: 90 HP/5500 rpm 912ULS, 100 HP/5500rpm 914UL

Cylinder head temperature: max. 135 °C

Oil temperature: max. 130 °C

Propellers: HTC 3 blade. Pitch angle: 20.5deg 912ULS, 22deg 914UL (ground

adjustable to suit engine and working environment). Take account of the propeller

concave face whilst measuring (see maint. Manual RSUK0061). Propeller is pitched for

max ground rpm of 5500.

IVO-prop DL3-68 in-flight variable pitch propeller – see section 9

For further data refer to the engine manual and parts catalogue.

WARNING! The engine must not be run without the propeller fitted – doing so may

result in severe engine damage.

2.6 ENGINE INSTRUMENTS

The following engine values are placarded on the instruments:

Note that, other than the engine rpm, the gauges are marked with these values internally.

Range

Maximum value

Unit of

measurement

Engine RPM

Green 1600 - 5500 Amber 5500 - 5800/5min,

red line 5800.

rpm

Oil temperature

50 - 130 130 max °C

Cylinder head

temperature

to 135 135 max °C

Oil pressure

0.8bar min to 3,500

rpm, 1.5bar min

above 3,500rpm.

Normal range 2-5bar

7 (cold weather starting) Bar

2.7 WEIGHT & BALANCE

The maximum take-off weight (MTOW) of the Calidus is 500kg. Marked on the aircraft,

and on the aircraft AWC, is the actual aircraft empty weight with unusable fuel. The

Payload is the MTOW minus the empty weight, and represents the allowance available for

occupants, fuel and luggage.

If any accessories are fitted which increase the empty weight of the aircraft then the

aircraft’s maximum payload must be reduced accordingly.

The pilot is responsible for ensuring the aircraft is not flown overweight.

NOTE! Flying the aircraft overweight invalidates your Permit to Fly.

The maximum permissible positions of the centre of gravity may not be exceeded.

The centre of gravity of the aircraft type was determined during Section T Compliance

evaluation. The envelope operational extremes were evaluated and shown to be

satisfactory. However operation outside of these evaluated points is not permitted!

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 17 of 101 Page issue 2, dated 12.09.11

Evaluation recorded that the approved envelope extremes (with maximum 10kg baggage

in the rear passenger footwell) are:

Most Forward limit - 125pilot, 74Kg pass, min fuel – 485mm forward of mainwheel axle.

Most Rearwards limit - 65Kg pilot, 82Kg passenger, max fuel – 255mm forward of

mainwheel axle.

Most Highest limit - 60Kg pilot min fuel – 895mm above mainwheel axle.

Most Lowest limit - 125Kg pilot, 74Kg passenger, 15Kg fuel - 795mm above mainwheel

axle.

Vertical CG position (z) is relative to the wheel axle plane drawn between the main and

nose wheel. Longitudinal CG position (x) is fore or aft of the mainwheel axle plane

(positive forwards).

The weight and balance report (AWC) supplied with the aircraft shows the Empty Weight

and CG envelope calculated for that specific aircraft, with options supplied as new. Empty

weight means aircraft containing minimum flight accessories and minimum fuel.

The report also shows, for reference, the thrust line offset.

WARNING! Care must always be taken when flying at extremes of the operational

envelope.

Maximum occupant weight in the front seat = 125 kg

Maximum occupant weight in the rear seat (with a 65kg front seat occupant) = 120kg

Minimum occupant weight in the front seat = 65 kg

Front seat occupants under 65kg body weight must carry ballast.

Remember - Fuel loading permissible is 500kg minus occupant weight, minus aircraft

empty weight, minus any baggage or items added to the aircraft since weighed. Aircraft

empty weight is placarded. Mogas nominal density is 0.72kg/ltr (check for the type of fuel

used).

Example: 500Kg – 275Kg (empty wt) – 90Kg (rear seat occupant) – 90Kg (pilot) – 10Kg

(rear seat luggage) = 35Kg. Useful fuel load (assuming both fuel tanks fitted) is 35/0.72 =

48.6ltrs.

Maximum possible fuel load (assuming both fuel tanks fitted) is 75ltrs, 54Kg

If ballast is required to meet the minimum front seat loading condition of 65Kg, then it

should be in the form of thin lead sheet placed behind and under the pilot seat cushion.

Carrying of bags or other items inside the aircraft is possible, due to the design of the

inside construction covering the control cables and linkages.

WARNING! If carried, ensure there is no control obstruction! Bags fitted into the rear seat

must be securely attached to the seat harness, and included in the weight/balance

calculation.

This is especially important with an open canopy, take care that items inside the cockpit

do not get blown out!

WARNING! The rear seat harness must be fastened correctly around the seat in single

seat operation. DO NOT leave loose on the seat, it may entangle with the controls and

prevent correct function!

A small detachable bag may be fitted inside the aircraft. Its purpose is to carry the rotor tie

down strap and basic aircraft documents only.

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 18 of 101 Page issue 4, dated 01.07.13

2.8 FUEL

The engine manufacturer recommends unleaded gas station premium fuel (EN228

MOGAS, as allowed under GC No 3 of CAP747, accessible via the CAA website). AVGAS

100LL can be used, although not recommended for long term operation, as the lead in the

fuel causes excess plug fouling and problems with the slipper clutch – refer to the engine

manual for further information. Alternatively, unleaded aviation gasoline Avgas UL91 is

now available at some airfields and is approved for use with Rotax engines.

MOGAS should not be used if the fuel temperature exceeds 20°C or at altitudes above

6000ft due to the increased risk of vapour bubble formation in fuel lines. In these

conditions AVGAS 100LL should be used. Note: MOGAS E10 (unleaded gasoline

blended with 10% ethanol) is not approved or recommended.

Whilst refuelling:

1. Ensure that the fuel is clean and water-free.

2. Always use a filter when refuelling, preferably with a water trap

3. Ensure the aircraft keyswitch is OFF before commencing refuelling

4. Ensure filler cap properly closed (latch flush to surface) after refuelling.

5. Ensure that an earthing cable is connected, where one is available.

Before flight, use the water drain point under the keel to ensure the fuel is water free.

2.9 GENERAL PLACARDS AND MARKINGS:

In conformity with BCAR Section T the following placards and markings are installed:

- All emergency controls are coloured red.

- All cockpit controls are clearly marked as to their function and method of operation.

- Fuel and oil filler openings are clearly marked, together with the grade or type required.

- Fuel tank capacity is clearly marked.

- Loading conditions are clearly marked as follows:

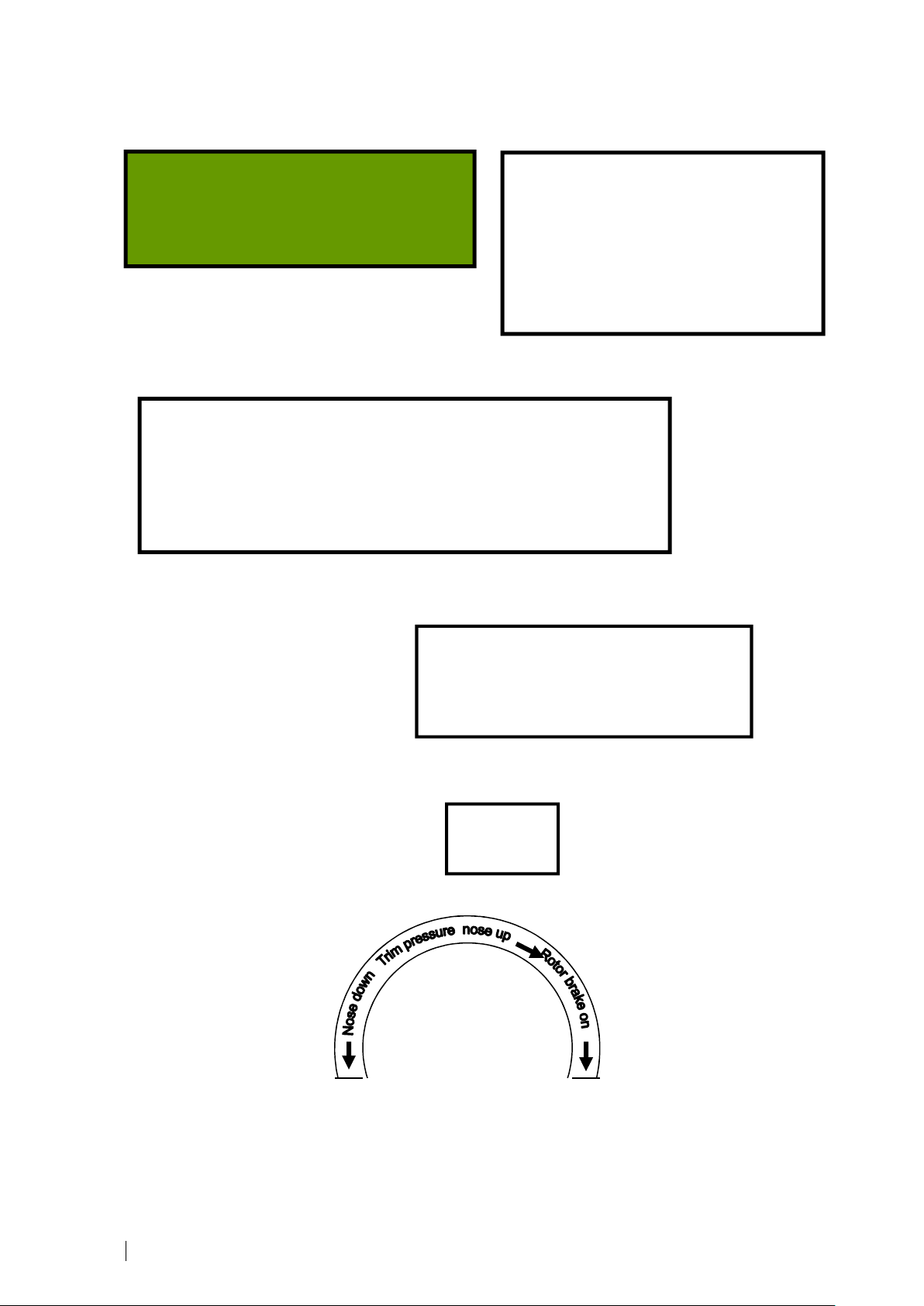

- Standard placards

Loading conditions

Primary control marking

Aircraft Payload Specification

Front seat pilot: 125Kg max,

65Kg min

Pilot must carry ballast to

meet 65Kg min.

Rear seat passenger 120Kg

max

Empty weight (as measured)

Kg

MTOW 500Kg

Aircraft must only be flown

solo from the front seat.

MAX

↑

THROTTLE

CHOKE

↓

ON

BRAKE

↓

ENGAGE

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 19 of 101 Page issue 6, dated 12.04.16

Limitations if fitted with orange end-cap rotor system

Limitations if fitted with red end-cap RotorSystemII under SB-039, or SB-039 is embodied

and Rotorsystem II TOPP variant is fitted (blue end caps)

Occupant warning (both seats) Fitted beside front seat

and back of front seat

Auxiliary socket (where fitted,

marked ‘12v 5A on the panel) Roll trim indicator (where fitted)

OPERATING LIMITATIONS

Aerobatic Limitations

Aerobatic manoeuvres are prohibited.

Manoeuvres involving a deliberate reduction in normal ‘g’ shall be avoided.

CG Range Limits (Gyroplane) – refer to Pilots Handbook data.

Airspeed Limitations

Maximum Indicated Airspeed (Vne): 90mph

Other Limitations

This aircraft shall be flown by day and under Visual Flight Rules only.

Smoking in the aircraft is prohibited

OCCUPANT WARNING

This aircraft has not been certificated to an

International Requirement

L R

Roll Trim

Front seat

back straps

limit stops

must be fitted

if rear stick is

fitted

OPERATING LIMITATIONS

Aerobatic Limitations

Aerobatic manoeuvres are prohibited.

Manoeuvres involving a deliberate reduction in normal ‘g’ shall be avoided.

CG Range Limits (Gyroplane) – refer to Pilots Handbook data.

Airspeed Limitations

Maximum Indicated Airspeed (Vne): 120mph

Other Limitations

This aircraft shall be flown by day and under Visual Flight Rules only.

Smoking in the aircraft is prohibited

Copyright of RotorSport UK Ltd

Document number RSUK0060

Page 20 of 101 Page issue 6, dated 12.04.16

Coolant header tank Engine oil tank

Fuel tank beside the filler neck (shows 39ltrs capacity if only one tank installed).

Low voltage placard mounted on instrument panel.

Warning lamp placards. (where not annotated on panel)

Pressure gauge placard

(unless panel annotated)

Fuel capacity: 75 ltrs

Preferred fuel:

EN228 MOGAS super or super plus

(AVGAS 100LL permissible)

Coolant

Header Tank

.

Filled with 50/50

water/antifreeze

Oil tank

Capacity 3 ltrs.

Use Shell VSX or

equivalent Motorcycle

oil SF or SG

Continuously lit Low Volt lamp

indicates

electrical demand exceeds supply, and

the battery is being drained. If lit in flight,

reduce demand until unlit. If not possible,

expedite landing.

Canopy

unlocked

Table of contents

Other AUTO GYRO Aircraft manuals

AUTO GYRO

AUTO GYRO CAVALON User manual

AUTO GYRO

AUTO GYRO CAVALON Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Pro Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Rotax 915 IS Owner's manual

AUTO GYRO

AUTO GYRO MTOsport User manual

AUTO GYRO

AUTO GYRO MTOsport User manual

AUTO GYRO

AUTO GYRO Cavalon Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Owner's manual