AUTO GYRO MTOsport User manual

Manufacturer Maintenance Manual

(Line Maintenance)

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 1 of 12

Manufacturer Maintenance Manual

for Gyroplane MTOsport

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 2 of 12

0 –PREFACE

This document contains proprietary information of AutoGyro GmbH, Germany which is provided in

confidence and solely for the purpose of supporting aircraft certification and providing applicable

information regarding the proper use, maintenance, inspection, repair, servicing and parts application

of AutoGyro GmbH products and services, as directed therein. Neither this manual nor any information

in it may be disclosed to others, or used for any other purpose, including but not limited to, design,

create, develop, reproduce, manufacture or derive any design, part, product, material, process,

modification, configuration change or repair, or to obtain airworthiness authorisation’s approval to do

so.

With the possession and use of this manual the user accepts and agrees to bound by the foregoing

terms.

If a Government agency or Department intends to disclose any information, written notice should be

given to:

AutoGyro GmbH

Dornierstraße 14

31137 Hildesheim

GERMANY

Phone: +49 (0) 51 21 / 8 80 56-00

Fax: +49 (0) 51 21 / 8 80 56-19

E-Mail: info@auto-gyro.com

All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of AutoGyro GmbH. AutoGyro reserves the

right to change or improve its products and to make changes in the content of this manual without obligation to notify any person or organisation of such changes or

improvements. Notifications to the Civil Aviation Authorities or other organisations based on legal regulations are unaffected.

MTOsport, Calidus, Cavalon, the AutoGyro logo and word picture mark are trademarks or registered trademarks of AutoGyro AG, registered in Germany and other

countries.

Other company and product names mentioned herein may be trademarks of their respective companies. Mention of third-party products is for informational purposes only

and constitutes neither an endorsement nor a recommendation. AutoGyro assumes no responsibility with regard to the performance or use of these products. All

understandings, agreements, or warranties, if any, take place directly between the vendors and the prospective users.

U.S. and foreign patents of AutoGyro AG are used in the Calidus and Cavalon gyroplanes - (US.Pat.No. 8,690,100; US.Pat.No. D699,153)

Every effort has been made to ensure that the information in this manual is accurate. AutoGyro GmbH is not responsible for printing or clerical errors.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 3 of 12

1 –INTRODUCTION

This manual provides accepted and recommended maintenance procedures applicable for the

MTOsport gyroplane, designed and manufactured by AutoGyro GmbH, Hildesheim, Germany. The

generic term “maintenance” comprises checks, inspections, replacement, repair and other tasks,

which are defined in “01-11-00 Definitions and Standard Procedures”. The manual also provides a full

description of the aircraft and its systems and troubleshooting (fault isolation) procedures. Where

applicable, the manual refers to related manuals, such as the engine manufacturer’s documentation or

Component Maintenance Manuals, for example battery, avionics, or optional equipment.

All task descriptions follow aerospace, industry and safety standards or special AutoGyro procedures.

The procedures, methods, instructions and parameters specified in this manual must be adhered to by

all means. It is not permitted to change procedures or to alter parameters provided herein. Proposed

deviations from the procedures, methods and instructions contained in this manual should be directed

to:

AutoGyro GmbH

Att.: Technical Publications

Dornierstraße 14

31137 Hildesheim

GERMANY

Fax: +49 (0) 51 21 / 8 80 56-19

E-Mail: info@auto-gyro.com

The manual has been prepared in accordance with ATA Specification No. 100 being a common

standard in aviation and for your convenience. The ATA100 numbering system is described under

“Organization and Handling of the Manual”.

This manual will be revised as necessary to incorporate changes in design, parts, approved

procedures, or parameters. Note that the manual is only valid if available in current version. The use of

an out dated manual may render the aircraft in unsafe or even not airworthy condition. The revision

service is described below.

Manufacturer Information [Letters] (MI) or Airworthiness Directives (AD) will also be covered by the

revision service and incorporated in the maintenance manual.

Revision Service

This manual must always be maintained in current, up-to-date status. The latest version status is

available at www.auto-gyro.com. Note that the manual is subdivided into 6 parts which will be revised

individually. As an example, the revision index for the manufacturer maintenance manual (MMM),

MTOsport (MT), Part B could be ‘MMM-MT-B_13-04-20’. Note that the date code is ‘yy-mm-dd’ so files

will sort chronologically.

For the purpose of current status this manual will not be published in paper format. A current

personalized copy will be provided by AutoGyro GmbH for all certified and registered service partners

on the basis of a subscription service. Registered users will be informed about new revisions. We

recommend not to keep printouts or paper copies for reference.

Record of Revisions

The manufacturer will keep this manual current as an entire document. After each revision of a part

the latest revision index (i.e. list of revision indices for each part) will be published on AutoGyro’s web

portal and/or by E-Mail to each subscription customer. The document part’s revision index can be

found in the footer on the left hand side of each page.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 4 of 12

INTENTIONALLY LEFT BLANK

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 5 of 12

Contents

0 –PREFACE...........................................................................................................................................2

1 –INTRODUCTION................................................................................................................................3

Revision Service...................................................................................................................................3

Record of Revisions .............................................................................................................................3

Maintenance Concept and Eligibility ....................................................................................................7

Warnings, Caution and Notes ..............................................................................................................7

Organization and Handling of the Manual............................................................................................8

ATA100 Numbering System.................................................................................................................8

ATA100 –Chapter Code..................................................................................................................8

Nomenclature and Structure of Maintenance Tasks (Job Cards)....................................................9

Page Block Code..............................................................................................................................9

Effectivities......................................................................................................................................10

Parts List Codes –PC / PIT............................................................................................................10

Abbreviations and Acronyms..............................................................................................................11

Service Bulletin (SB) and Airworthiness Directives (AD) ...................................................................12

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 6 of 12

INTENTIONALLY LEFT BLANK

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 7 of 12

Maintenance Concept and Eligibility

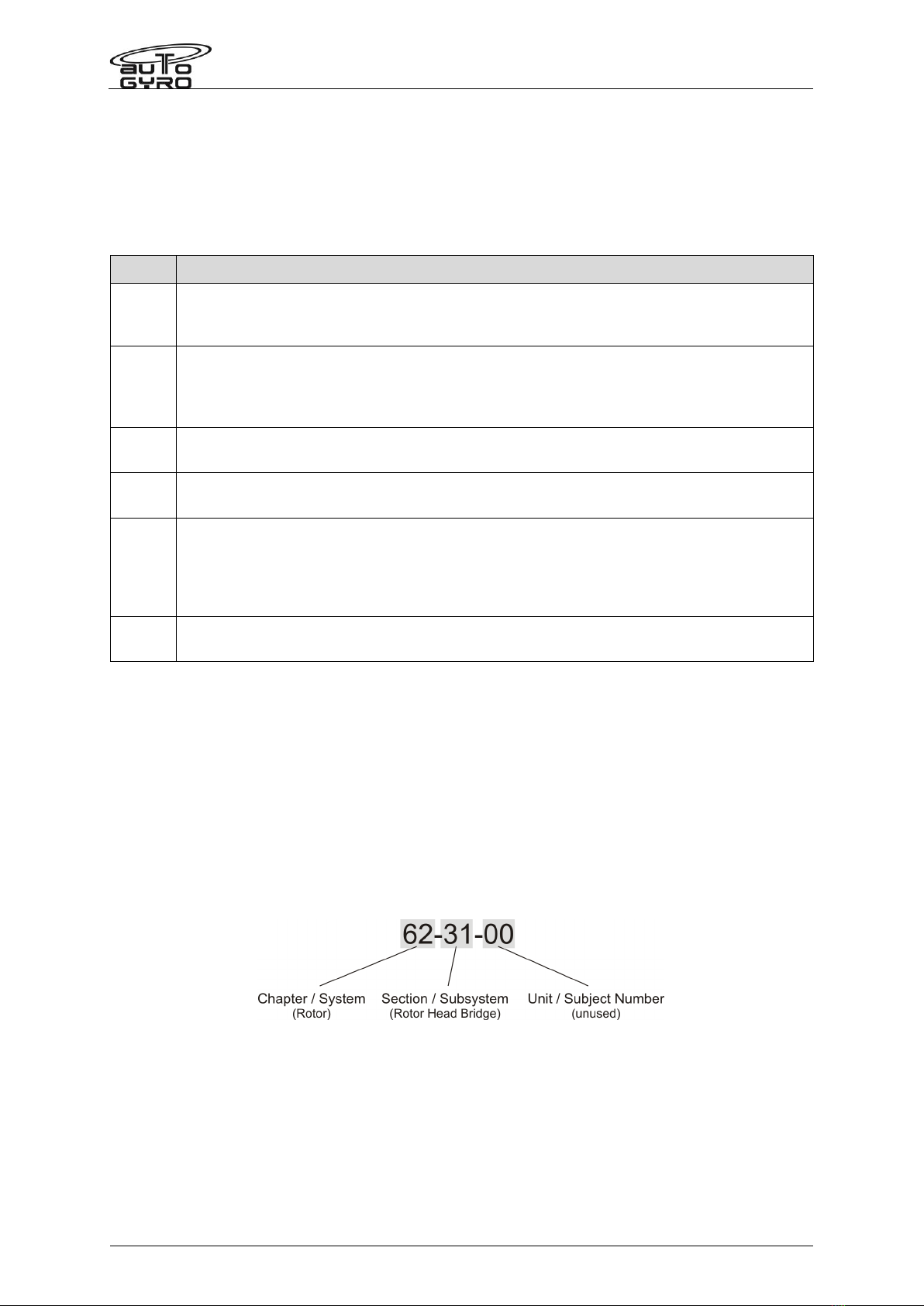

The maintenance concept of the MTOsport gyroplane is structured into 4 qualification levels:

Basic operational (OPR) Maintenance / Pilot Checks and Servicing

Line (LNE) Maintenance (inspection of Critical Parts (CP) included)

Heavy (HVY) Maintenance (Flight Safety Sensitive Maintenance Tasks, handling of CPs)

Specialized (SPC) Level Tasks (Major Modification, Repair & Overhaul, Special Topics)

The respective maintenance level for each maintenance task is printed in right hand position in the

header line on each Job Card as three-letter code for quick reference (see red circle in example

below) and repeated under ‘GENERAL, REFERENCES AND REQUIREMENTS’.

Maintenance tasks may be carried out solely by persons or organizations fulfilling the requirements for

personal qualification, infrastructure and required equipment, and only in strict compliance with the

documentation and manuals listed in below table. Examples are provided for better illustration:

Level

Qualification

Documentation

Example

OPR

Licensed Pilot or

trained/briefed person

Pilot’s Operating Handbook

and Job Cards marked ‘OPR’

Check and replenish

engine coolant.

LNE

AutoGyro maint. course (and

organization approval) ‘Line’

Manufacturer Maint. Manual

(MMM) Job Cards ‘LNE’

All tasks to perform a

100 hrs inspection

HVY

AutoGyro maint. course and

organization approval ‘Heavy’

Manufacturer Maint. Manual

(MMM) Job Cards ‘HVY’

Adj. / replace rotor

head, flight controls

SPC

AutoGyro special courses and

org. approval ‘Specialized’

MMM Job Cards ‘SPC’ and

manufacturer instructions

Main frame overhaul,

major mod., repair

Warnings, Caution and Notes

This manual uses WARNINGs, CAUTIONs and NOTEs in bold italic letters to indicate especially

critical and important instructions. The call-outs appear at the top of the Maintenance Job Card if of

general nature or applicable for the complete task, or will directly precede the individual Work Step.

The meaning of each call-out is defined below:

WARNING: A warning means that the neglect of the appropriate procedure or

condition could result in personal injury or fatal accidents.

CAUTION: A caution means that the neglect of the appropriate procedure or

condition could result in damage to or destruction of equipment.

NOTE: A note stresses the attention for a special circumstance, which is essential

to emphasize.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 8 of 12

Organization and Handling of the Manual

This manual is structured according to ATA100 numbering system. The numbering system will be

explained later in more detail.

On document level, the manual is subdivided into 6 parts, named A to F. The designation and content

of each part is listed below:

Part

Designation / Content

A

Introduction and Declarations

This section. Explains the basic concept, handling of this manual, its structure according to

the ATA100 numbering system, abbreviations and acronyms.

B

Master Servicing Manual (ATA Chapters 00 to 20)

General description of the aircraft, basic definitions and standard procedures, tools,

spares, airworthiness limitations, time limits, inspections and checks.

Briefly, part B describes ‘what is to be done, and when’.

C

System Description Section (ATA Chapters 21 to 90)

Part C describes all aircraft systems, following the ATA100 numbering system.

D

Diagrams and Charts

Part D contains diagrams and charts, if necessary in special sizes or as fold-outs.

E

Maintenance Job Cards

[Maintenance] Job Cards are collected in Part E. Note that the footer of Part E does not

spell out to the part’s designation, but just shows part and the job index of the referred

maintenance task according to the ATA100 numbering system.

Briefly, Part E describes ‘how something has to be done’.

(F)

Protocols and Forms

Protocols and forms, such as maintenance check lists, are available for download.

ATA100 Numbering System

ATA100 –Chapter Code

The Air Transport Association (ATA) Standard 100 numbering system is a widely accepted standard

that provides a 6 digit numbering system to identify aircraft systems, subsystems and individual

components in a structured, hierarchical approach.

The first or leftmost pair of digits defines the Chapter, respectively system. The next pair of digits

refers to the subsystem. The third pair of digits specifies a unit. Only complex systems use unit

numbers. In case of simple systems, all information is contained in the main chapter and there is no

subsystem or unit breakdown.

The ATA100 numbering system and the corresponding system designations were adopted where ever

possible and rational. In some cases the wording and nomenclature was adapted to match the design

specifics of a gyroplane in best possible way. Due to its high degree of system integration, some

systems cannot clearly be assigned to a single function. In this case the system or component was

categorized by its main function. Example: the pneumatic trim cylinder also acts as brake in its

secondary function.

Chapter 02 has been modified to contain “TOOLS, SPARES AND CONSUMABLE MATERIALS”.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 9 of 12

Nomenclature and Structure of Maintenance Tasks (Job Cards)

Part E of this manual describes maintenance tasks to be performed by a qualified person in order to

check, inspect, replenish, adjust, replace, repair, clean, or to identify malfunctions. Each Task is

outlined in detail in a [Maintenance] Job Card.

Each [Maintenance] Job Card (sometimes referred to as Task Card) consists of

Task Description (header, descriptive text) with task level in most right position

a section referring to GENERAL, REFERENCES AND REQUIREMENTS

a section listing SPECIAL TOOLS AND CONSUMABLE MATERIALS

a section pointing out PRECAUTIONS AND SAFETY MEASURES

a section called PROCEDURES, which lists all Work Steps to be performed subsequently

a PARTS LIST listing part numbers and associated information, and

explanatory GRAPHICS, such as explosion drawings or photographs

For ease of navigation each page in Part E shows a unique job index in the page footer consisting of 3

elements:

Chapter Code

(acc. to ATA100, see explanation below)

Page Block Code

(distinct index/number per type of maintenance action, see explanation below)

Sub-Index

Page Block Code

The pages within a chapter are structured and numbered according to the page block numbering

system as specified below:

Subject

Code

Introduction / Description and Operation

0

Fault Isolation / Trouble Shooting

1

Maintenance Procedures

2

Servicing

3

Removal / Installation / Disassembly / Assembly

4

Adjustment / Test

5

Inspection

6

Cleaning / Painting

7

Repair / Replacement / Retrofit / Modification

8

Storage

9

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 10 of 12

Effectivities

A job card may contain information relating to different versions of the referred aircraft. This may be

stipulated by optional equipment installed, by different design states (Serial Number driven), or

modification (MI, AD).

The keyword EFFECTIVITY, followed by a term describing its applicability, marks the start of

instructions that apply exclusively to a specified version. Examples:

EFFECTIVITY: Variable Pitch Propeller

The following instructions must be performed and are applicable only if a Variable Pitch Propeller is

installed

EFFECTIVITY: up to S/N 0123

The following instructions apply to serial numbers 0123 and before

EFFECTIVITY: S/N 0124 to S/N 0248

The following instructions refer only to serial numbers 0124 up to, and including, 0248

EFFECTIVITY: S/N 0124 and subsequent

The following instructions must be performed for serial numbers starting 0124 and subsequent

EFFECTIVITY: before MI 2011-99

Instructions refer to modification state before/without the referenced MI implemented

EFFECTIVITY: MI 2011-99 accomplished

Instructions apply only to those versions where the referenced MI has been accomplished

The end of the range of validity is marked by the term EFFECTIVITY –END

In case the effectivity solely comprises of the subsequent work step, or another effectivity statement is

introduced, the term EFFECTIVITY –END will be omitted.

Instructions outside of EFFECTIVITY statements apply to the standard model, respectively to all

versions.

Parts List Codes –PC / PIT

Parts Lists specify PC (Procurement Code) and PIT (procure item through) for each item (see

example). The procurement code may show L0, L1, L2 or L3 as explained below.

L0

Part/Assembly available for purchase for a registered pilot/operator (OPR)

L1

Part/Assembly orderable for individuals/organizations qualified to perform Line Maint.

L2

Part/Assembly orderable for organizations qualified to perform Heavy Maintenance

L3

Part/Assembly orderable for organizations qualified to perform Specialized Level tasks

‘PIT’ lists the order number of the part, bundle, set, or smallest assembly in which the referred part is

contained.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 11 of 12

Abbreviations and Acronyms

In this manual, a minimum number of abbreviations are used. Where possible the abbreviations and

acronyms used correspond with regulations and common standards.

AD

Airworthiness Directive

ATA

Air Transport Association

CHT

Cylinder Head Temperature

CP

Critical Part

CRP

Carbon Reinforced Plastic

DOM

Date of Manufacture

ELT

Emergency Locator Transmitter

FOD

Foreign Object Damage (Debris)

GRP

Glass Reinforced Plastic

hrs

hours

i.f.d.

in flight direction

JNP

Jahresnachprüfung (annual inspection, annual airworthiness review)

LED

Light Emitting Diode

LH

left hand

LR

Limited reusability

(Parts or components that can be used only once or a limited number of times,

such as self-locking nuts, split pins, …)

LTA

Lufttüchtigkeitsanweisung (AD, issued by the Airworthiness Authority)

MAP

Manifold Absolute Pressure

MI

Manufacturer Information [Letter] (dt. Herstellerinformation)

MLL

Manufacturer Life Limit

MMM

Manufacturer Maintenance Manual

N/A

not applicable

NPI

non procurable item

OAT

Outside Air Temperature

PC

Procurement Code

PIT

procure item through

POH

Pilot’s Operating Handbook

Qty.

Quantity

RBT

Rotor Bearing Temperature

rcv

receive

rec.

recommended

RH

right hand

RPM

Revolutions Per Minute

SB

Service Bulletin

SoC

Statement of Compliance

sqm

square metre(s)

STP

Stückprüfung (C of A, i.e. conformity of airworthiness)

TADS

Type Approval Data Sheet (dt.: Geräte-Kennblatt)

TBO

Time Between Overhaul

VPP

Variable Pitch Propeller

VSI

Vertical Speed Indicator

xmt

transmit

yr

year(s)

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-A_16-02-08

Part A –Introduction and Declarations

Page 12 of 12

Service Bulletin (SB) and Airworthiness Directives (AD)

Service Bulletin (SB), old designation Manufacturer Information [Letters] (MI) (Herstellerinformationen)

or Airworthiness Directives (AD) will be incorporated into the Maintenance Manual with the next

revision

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 1 of 24

Contents

CHAPTER 00 - INTRODUCTION / AIRCRAFT GENERAL.....................................................................3

General.................................................................................................................................................3

CHAPTER 01 - GENERAL.......................................................................................................................4

01-11-00 Definitions, Terms and Standard Procedures ..................................................................4

01-12-00 Standard Bolt Torques......................................................................................................6

01-21-00 Standard Commercial Tools.............................................................................................6

01-91-00 Conversion Tables............................................................................................................7

CHAPTER 02 - TOOLS, SPARES AND CONSUMABLE MATERIALS...................................................9

02-51-00 Consumable Materials......................................................................................................9

CHAPTER 03 - MINIMUM EQUIPMENT REQUIREMENT....................................................................10

CHAPTER 04 –MANUFACTURER LIFE LIMITATIONS.......................................................................11

CHAPTER 05 - TIME LIMITS, INSPECTIONS & CHECKS...................................................................12

05-10-00 Time Limits .....................................................................................................................12

05-20-00 Scheduled Inspections & Checks...................................................................................13

Daily / Pre-Flight Check..................................................................................................................13

Complementary / Servicing Tasks..................................................................................................13

25 hrs Inspection (one-time / non-recurrent)..................................................................................13

100 hrs / Annual Inspection............................................................................................................13

05-21-00 Temporary Scheduled Inspections & Checks ................................................................13

05-30-00 Unscheduled Inspections ...............................................................................................14

05-50-00 Conditional Inspections ..................................................................................................14

05-51-00 Inspections - Special Operational Conditions.................................................................14

Operation in sand or dust...............................................................................................................14

Winter operation .............................................................................................................................14

05-55-00 Inspections - Special Operational Incident.....................................................................15

Suspected hard landing..................................................................................................................15

Rotor contact with obstacle ............................................................................................................15

Propeller contact with obstacle or external impact.........................................................................15

Birdstrike.........................................................................................................................................15

Lightning strike ...............................................................................................................................16

05-60-00 Ground Test Run............................................................................................................16

05-70-00 Functional Test Flight .....................................................................................................16

05-90-00 Maintenance Records & Aircraft Logs............................................................................16

CHAPTER 06 - DIMENSIONS & AREAS...............................................................................................17

CHAPTER 07 - LIFTING / JACKING / SHORING..................................................................................18

CHAPTER 08 - LEVELING & WEIGHING .............................................................................................18

CHAPTER 09 - TOWING & TAXIING ....................................................................................................18

CHAPTER 10 - PARKING, STORAGE & RETURN TO SERVICE........................................................18

CHAPTER 11 - PLACARDS & MARKINGS...........................................................................................19

CHAPTER 12 - SERVICING ..................................................................................................................21

12-10-00 Cleaning..........................................................................................................................21

12-20-00 Lubrication......................................................................................................................21

Lubrication: Teeter hinge................................................................................................................21

Lubrication: Pre-rotator drive coupling sleeve................................................................................21

Lubrication: Pre-rotator belt and pulleys.........................................................................................21

12-30-10 Servicing: Engine Air Filter .............................................................................................21

12-30-20 Servicing: Tire Pressure .................................................................................................22

12-30-30 Servicing: Battery............................................................................................................22

12-30-40 Servicing: Engine Coolant ..............................................................................................22

12-40-00 Replenishing/Replacement of Fluids..............................................................................22

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 2 of 24

CHAPTER 13-17 –UNASSIGNED / N/A...............................................................................................22

CHAPTER 18 –VIBRATION & NOISE ANALYSIS ...............................................................................23

CHAPTER 19–20 –UNASSIGNED / N/A ..............................................................................................24

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 3 of 24

CHAPTER 00 - INTRODUCTION / AIRCRAFT GENERAL

General

The MTOsport is a ‘new generation’ gyroplane with 3-bladed push propeller and a 2-blade aluminium

main rotor system with swivelling rotor head. It features an open-cockpit fuselage with two seats in

tandem configuration. The load carrying frame consists of inert-gas welded stainless steel square

tubing. Fuselage and stabilizer with rudder are made from glass fibre reinforced (GRP) plastic.

The tricycle gear with GRP (glass fibre reinforced plastic) suspension bow features a steerable nose

gear.

Rotor flight control consists of conventional linkage using push-rods while the rudder is controlled by

cables.

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 4 of 24

CHAPTER 01 - GENERAL

01-11-00 Definitions, Terms and Standard Procedures

The following definitions, procedures and words with special meanings are used in this manual:

adjust

To put in specified position or condition, usually using tools or devices

Example: Adjust the clearance to 1 mm

Check (noun)

A set of check items to be performed. Example: pre-flight check

check (verb)

To make sure that the item is present and/or a given requirement is fulfilled. No

tools are required.

Example: Warning Lights…Check NONE

Critical Part (CP)

“Critical Parts” are those parts whose failure during ground or flight operation could

have a disastrous effect on the gyroplane.

dent

Depression in a surface having area and depth with no sharp edges

(see also ‘nick’)

discard

Put away in order to exclude inadvertent or intentional re-use of the item. Comply

with FOD procedures.

dispose of

Discard item or substance while employing strict procedures, such as

environmental or legal requirements.

hand-tighten

Use the bare hand without any tools, gloves or extra efforts

inspect / examine

To look carefully at an item and compare with its standard or specification. Tools or

devices may be needed. The condition may be explicitly specified (example: no

corrosion). Generally, or if not otherwise stated, inspect/examine means:

Make sure that the item

- is complete

- is correctly attached

- has no loose parts

- shows no signs of leaks

- is not cracked or damaged

- is not worn

Make sure that

- the surface protection is not damaged

- all locking devices are installed correctly

Make sure that items such as pipes, hoses and cables

- look serviceable

- do not rub against other items

For log books and other technical records:

- find pending faults

- make sure they are up-to-date and correctly maintained

Inspection

Maintenance procedure to be performed as described in this manual.

Example: 100 hrs / Annual Inspection

maintenance

Any one or combination of overhaul, repair, inspection, replacement, modification

or defect rectification of an aircraft or component, with the exception of pre-flight

inspection

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 5 of 24

measure

To find out dimensions, capacity or quantity of something. Except for counting of

smaller numbers, calibrated measurement devices are needed.

monitor

To watch a parameter or item over a certain period of time in order to read an exact

value, derive a trend or identify a change caused by an event.

Example: monitor rotor speed indication, monitor RPM drop, …

nick

A dent with sharp edges (see also ‘dent)

re-torque

Refer to procedure ‘torque-tighten’. In contrary to procedure ‘torque check’

attachment hardware may rotate during re-torquing.

Record (noun)

Technical name for a documentation that shows the accomplishment of

maintenance tasks or other activities, usually stating the responsible person’s

name and date of compliance.

record (verb)

To make an (official) entry in a maintenance record.

remove securing

hardware

Cut open and remove split pins, lock wire, and such. Wear eye protection. Hold

securing hardware with other hand to prevent particles from darting around. Collect

all splinters and particles of securing hardware and discard.

replace

To remove an unserviceable item and install a serviceable in the same location

servicing

Simple tasks such as lubrication and cleaning, checking and adjusting of air tire

pressure, replenishing of fluids

set

To change (or verify) status of equipment to a given parameter, condition or mode.

Example: set altimeter sub-scale to 1013 hPa

torque-check

Refer to procedure ‘torque-tighten’. Check with the (minimum) torque value

supplied. Attachment hardware must NOT turn! If rotation of attachment hardware

was noticeable the torque check FAILED. Refer to procedure described in Job

Card.

torque-tighten

Use a calibrated tool with the correct range and handle properly and carefully. Set

tool to minimum torque (if min. and max. torque values are provided). Use

stretched fingers at the long end of the tool and counterhold directly at the pivot

point.

Click-Type: Stop upon the first clicking. If multiple clicking is heard or further

rotation is suspected, open/unscrew and repeat. Replace attachment hardware if

appropriate. In order to align attachment hardware (for example in case of a split

pin) adjust tool to the maximum allowed torque and tighten carefully until hardware

aligns. NO clicking must be heard! If clicking was heard, redo the complete

procedure while trying different attachment hardware and/or in different installation

position.

verify

Check that a certain dimension or condition, or set of these, is in-line with given

specifications. In order to do so, a special (measurement) procedure will be

required and the reference to comply with will be specified.

If not otherwise stated the following standards are based on aeronautical regulations and

recommendations (AC43.13-1B), industry and safety standards, and general practices, and shall be

applicable throughout this manual. Examples are:

Torquing

Securing (handling of lockwire and other securing hardware)

Removal of securing hardware

FOD (foreign object damage) protection

Discard and disposal procedures

Handling of hazardous material

Workplace safety

Manufacturer

Maintenance Manual

AutoGyro

MTOsport

MMM-MT-B_14-11-19

Part B –Master Servicing Manual (Ch. 00 –20)

Page 6 of 24

01-12-00 Standard Bolt Torques

Standard torques are M4 2-3 Nm, M5 5-6 Nm, M6 11 +/-1 Nm, M8 25 +/-3Nm, M10 35 +/-4Nm.

Always assess the joint to be tightened and use engineering judgement –do not overtighten plastic or

unsupported tube joints!

01-21-00 Standard Commercial Tools

Most maintenance tasks on the MTOsport can be conducted using standard, commercially available

metric tools. In addition, the following standard commercial tools are required:

Inclinometer (digital) / Digital spirit level with angle gauge

Spring balance / Dynamometer

Tensiometer (to measure cable tension)

1m aluminium ruler

Fuel hose clamp

Torque wrench (in required torque ranges)

Multimeter

3 m-tape measure

Torch light

Tyre pressure gauge / tyre filling device

Other manuals for MTOsport

1

Table of contents

Other AUTO GYRO Aircraft manuals

AUTO GYRO

AUTO GYRO Cavalon Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Rotax 915 IS Owner's manual

AUTO GYRO

AUTO GYRO RotorSport CALIDUS User manual

AUTO GYRO

AUTO GYRO MTOsport User manual

AUTO GYRO

AUTO GYRO CAVALON Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Pro Owner's manual

AUTO GYRO

AUTO GYRO Cavalon Owner's manual

AUTO GYRO

AUTO GYRO CAVALON User manual

Popular Aircraft manuals by other brands

PAPILLON

PAPILLON BODYGUARD 7 manual

BushCaddy

BushCaddy LSA Pilot operating handbook

Bliss

Bliss BH-993CA quick start guide

Piper

Piper Cherokee Archer II Pilot operating handbook

Schempp-Hirth Flugzeugbau

Schempp-Hirth Flugzeugbau DISCUS CS 1990 Flight manual

Bruce Goldsmith Design

Bruce Goldsmith Design Link pilot manual